ignition LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 268 of 667

FUEL SYSTEM

1

ADJUSTMENT HEATER PLUG TEST

Service repair no - 19.90.20.01

Check

1. Test out of engine

2.Remove heater plug.See Repair.

3.UsingLRT-12-511,connect RED lead to battery

’+’positive and the BLACK lead to battery’-’

negative.

4.Position heater plug into tester and retain with

spring loaded bar.

5.Connect YELLOW lead to heater plug terminal.

6.Press red button on tester and note ammeter

reading. Keep button depressed, heater plug tip

should start to glow after 5 seconds

CAUTION: The heater plug tip must glow

first, if it fails to do so, replace heater plug.

7.The ammeter reading should show an initial

current draw of 25 amps, which should fall to 12

amps after 20 seconds.

8.Refit heater plug.See Repair.FUEL SYSTEM - BLEED

Service repair no - 19.50.07

Fuel Purging Procedure

1.If the vehicle runs out of fuel, or the fuel level is

so low that the fuel system draws air into the fuel

rail, the fuel rail will need to be purged before the

engine will start. This can be achieved by

following a set procedure. The process does not

require the use of any specialist equipment and

can be performed by the driver of the vehicle.

The process is as follows:

2.Switch off ignition and wait 15 seconds.

3.Turn ignition key to position 2 and wait 3

minutes, (this ensures that the fuel system

purges all the air from the fuel rail within the

cylinder head).

4.Depress the throttle pedal to more than 90% of

its total travel, (to the throttle stop).

5.Crank the engine keeping the throttle pedal

depressed.

NOTE: This operation is controlled by the

ECM and it is important that the purging

operation is not carried out on a vehicle

that has not run out of fuel. If it is carried out

unnecessarily it can lead to the engine flooding

and failing to start.

This operation will be cancelled:

6.As soon as engine speed exceeds 600 rev/min.

7.The driver allows the throttle pedal to close to a

position less than 90% of its travel.

8.The ignition key is released from the start

position.

NOTE: The engine must not be cranked for

more than 30 seconds in any one period.

9.Repeat the above procedure if the engine fails to

start.

ProCarManuals.com

Page 424 of 667

STEERING

1

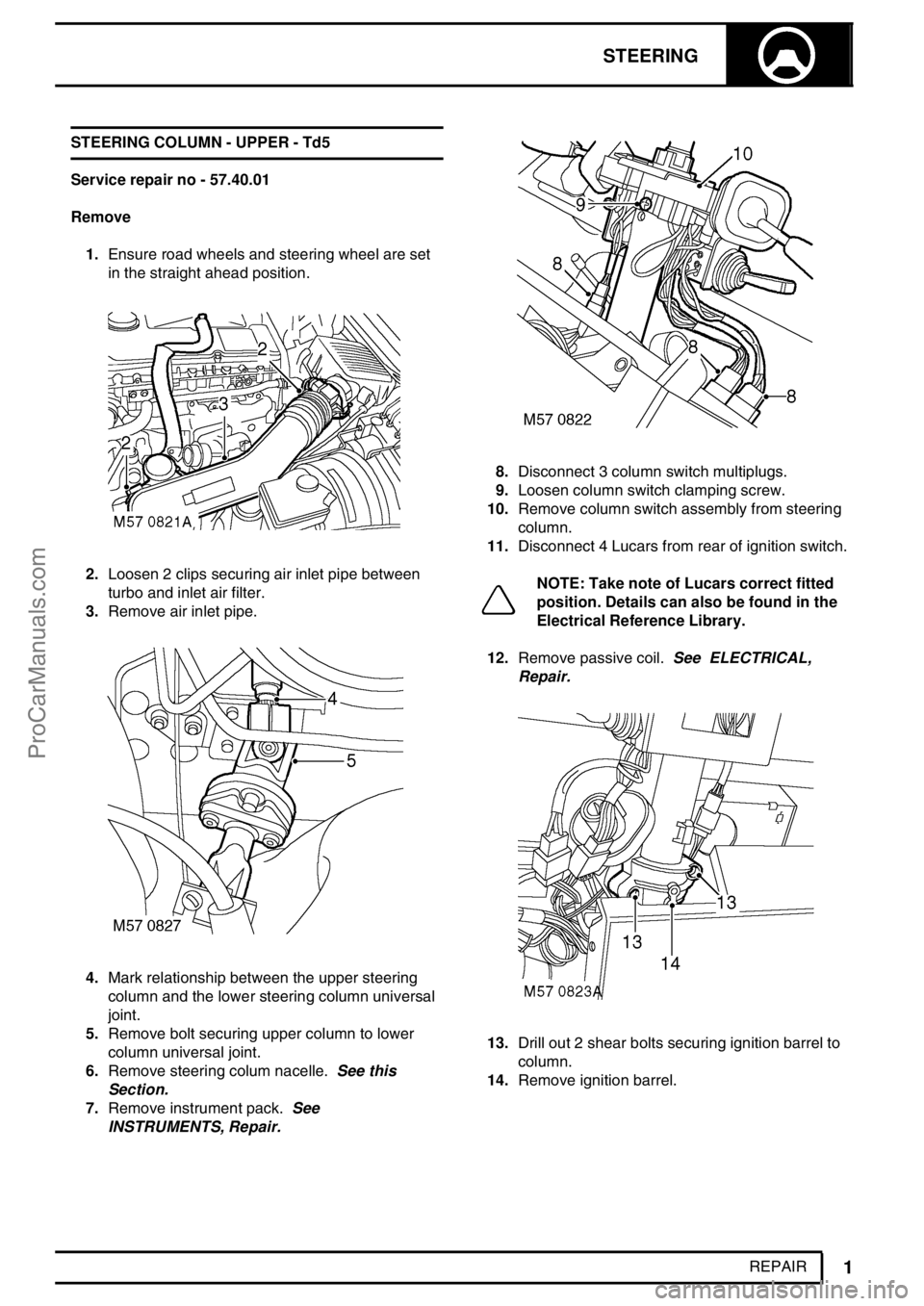

REPAIR STEERING COLUMN - UPPER - Td5

Service repair no - 57.40.01

Remove

1.Ensure road wheels and steering wheel are set

in the straight ahead position.

2.Loosen 2 clips securing air inlet pipe between

turbo and inlet air filter.

3.Remove air inlet pipe.

4.Mark relationship between the upper steering

column and the lower steering column universal

joint.

5.Remove bolt securing upper column to lower

column universal joint.

6.Remove steering colum nacelle.See this

Section.

7.Remove instrument pack.See

INSTRUMENTS, Repair.

8.Disconnect 3 column switch multiplugs.

9.Loosen column switch clamping screw.

10.Remove column switch assembly from steering

column.

11.Disconnect 4 Lucars from rear of ignition switch.

NOTE: Take note of Lucars correct fitted

position. Details can also be found in the

Electrical Reference Library.

12.Remove passive coil.See ELECTRICAL,

Repair.

13.Drill out 2 shear bolts securing ignition barrel to

column.

14.Remove ignition barrel.

ProCarManuals.com

Page 426 of 667

STEERING

3

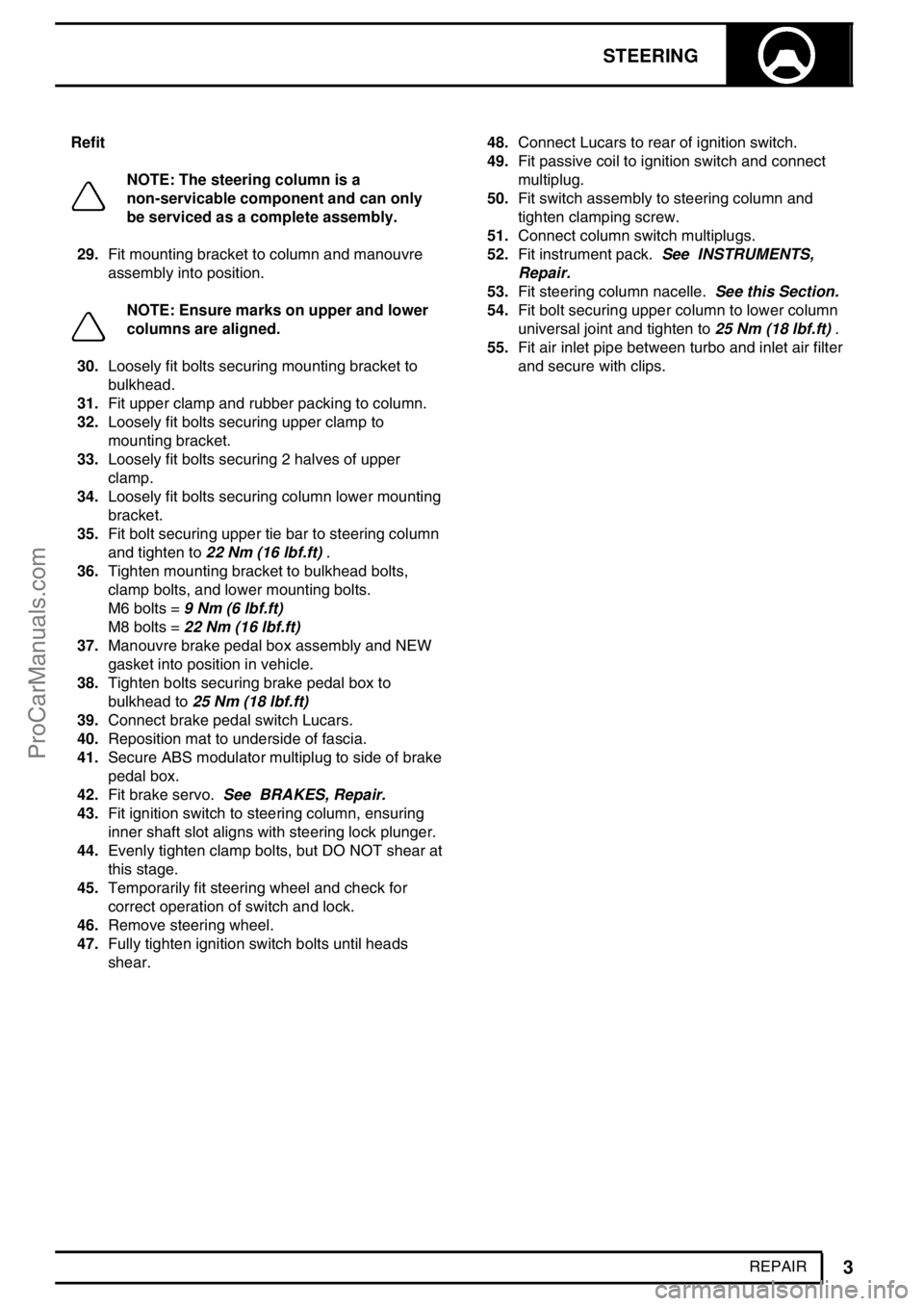

REPAIR Refit

NOTE: The steering column is a

non-servicable component and can only

be serviced as a complete assembly.

29.Fit mounting bracket to column and manouvre

assembly into position.

NOTE: Ensure marks on upper and lower

columns are aligned.

30.Loosely fit bolts securing mounting bracket to

bulkhead.

31.Fit upper clamp and rubber packing to column.

32.Loosely fit bolts securing upper clamp to

mounting bracket.

33.Loosely fit bolts securing 2 halves of upper

clamp.

34.Loosely fit bolts securing column lower mounting

bracket.

35.Fit bolt securing upper tie bar to steering column

and tighten to22 Nm (16 lbf.ft).

36.Tighten mounting bracket to bulkhead bolts,

clamp bolts, and lower mounting bolts.

M6 bolts =9 Nm (6 lbf.ft)

M8 bolts =22 Nm (16 lbf.ft)

37.Manouvre brake pedal box assembly and NEW

gasket into position in vehicle.

38.Tighten bolts securing brake pedal box to

bulkhead to25 Nm (18 lbf.ft)

39.Connect brake pedal switch Lucars.

40.Reposition mat to underside of fascia.

41.Secure ABS modulator multiplug to side of brake

pedal box.

42.Fit brake servo.See BRAKES, Repair.

43.Fit ignition switch to steering column, ensuring

inner shaft slot aligns with steering lock plunger.

44.Evenly tighten clamp bolts, but DO NOT shear at

this stage.

45.Temporarily fit steering wheel and check for

correct operation of switch and lock.

46.Remove steering wheel.

47.Fully tighten ignition switch bolts until heads

shear.48.Connect Lucars to rear of ignition switch.

49.Fit passive coil to ignition switch and connect

multiplug.

50.Fit switch assembly to steering column and

tighten clamping screw.

51.Connect column switch multiplugs.

52.Fit instrument pack.See INSTRUMENTS,

Repair.

53.Fit steering column nacelle.See this Section.

54.Fit bolt securing upper column to lower column

universal joint and tighten to25 Nm (18 lbf.ft).

55.Fit air inlet pipe between turbo and inlet air filter

and secure with clips.

ProCarManuals.com

Page 597 of 667

84WIPERS AND WASHERS

4

DESCRIPTION AND OPERATION REAR WIPER - FROM 02MY

1.Rear wiper relay

The rear wiper system is unchanged except for the addition of a wiper motor relay into the electrical circuit.

The new rear wiper relay is located in the tail door, below the wiper motor. The relay coil is energised by a feed

supplied from the rear wiper switch. When the relay contacts close, a feed is supplied via the ignition switch

(position II) and a fuse in the passenger compartment fuse box, through the relay contacts to the wiper motor.

ProCarManuals.com

Page 610 of 667

ELECTRICAL

1

DESCRIPTION AND OPERATION SECURITY AND CENTRAL DOOR LOCKING

SYSTEM - FROM 02MY

The following description details the functionality and operation of the 10AS Security and Central Door Locking

(CDL) System fitted to 2002MY Defender. The system contains some new features and also retains some

features from previous Defender models. The alarm system and CDL system are controlled by the 10AS anti-theft

alarm ECU.

New door lock barrels are introduced and use the same key as the ignition switch barrel, thereby eliminating the

requirement for a separate key for the doors.

NOTE: Some markets will only have some of the features described and some will have no

security or central door locking functions.

The security system comprises the following components:

10AS anti-theft alarm ECU

Remote handset transmitters

Transponder coil

Volumetric sensor

CDL actuators

Bonnet switch

Driver’s door key barrel switch

Door switches

Bonnet switch

Battery Backed-Up Sounder (BBUS) or alarm sounder

Security LED

Engine immobilised warning lamp

Direction indicators

ProCarManuals.com

Page 612 of 667

ELECTRICAL

3

DESCRIPTION AND OPERATION ANTI-THEFT ALARM - FROM 02MY

The alarm and immobilisation system on 2002MY Defender is similar to that used on Discovery Series I (LJ)

models from 1996MY. The alarm system comprises the anti-theft alarm ECU, bonnet and door switches and a

volumetric sensor.

Anti-Theft Alarm ECU

The anti-theft alarm ECU is located behind the instrument pack and receives a permanent battery supply via fuses

6 and 7 in the under seat fuse box. The ECU also receives a battery supply via the ignition switch position II and

fuse 1 in the passenger compartment fuse box. The ECU is connected to the various supporting components by

two harness connectors.

The ECU controls the alarm system (perimetric and volumetric security), CDL system, engine immobilisation

system (Td5 only) and various other vehicle functions including direction indicators and interior lamps.

The anti-theft alarm ECU incorporates an RF receiver and antenna for reception of RF signals from the remote

handset for locking and alarm arming. The antenna is unterminated at one end, and for optimum performance the

antenna must not be wound around adjoining harnesses.

The anti-theft alarm ECU operates at one of two frequencies which are identified by a label on the unit. The

frequencies are:

433 MHz - Europe, Gulf States, South Africa

315 MHz - North America, South East Asia, Japan, Australia.

The anti-theft alarm ECU also incorporates an integral inertia switch. In the event of an impact of sufficient severity

to trigger the inertia switch when the ignition is on, the ECU will unlock all doors and operate the hazard warning

lamps. The ECU will remain in this condition for a pre-programmed period of 2 minutes. To reinstate CDL

functionality and to deactivate the hazard warning lamps, the ignition should be turned off and then on after the 2

minute timer has expired.

NOTE: There is a separate inertia switch for fuel cut off.

ProCarManuals.com

Page 613 of 667

86ELECTRICAL

4

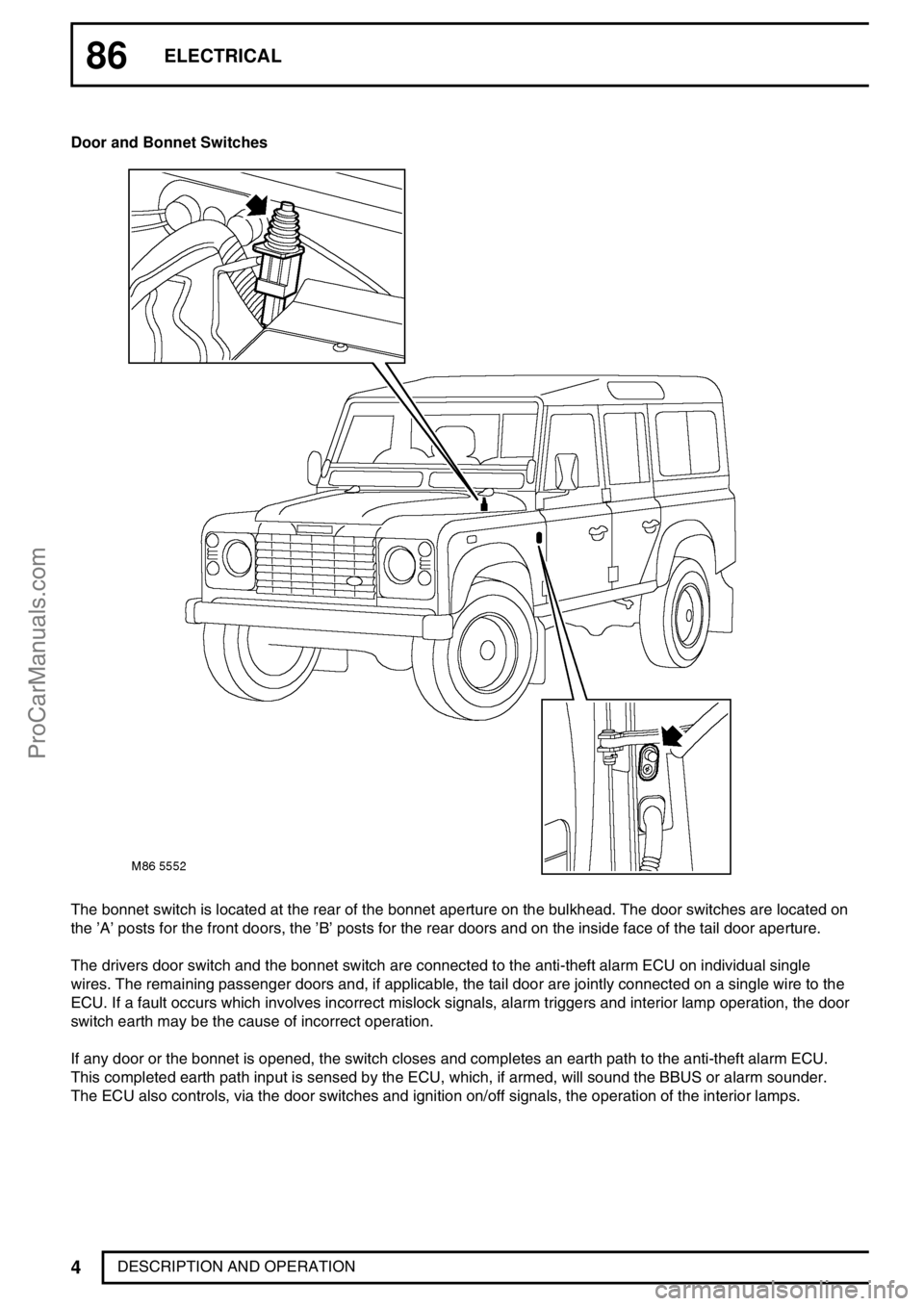

DESCRIPTION AND OPERATION Door and Bonnet Switches

The bonnet switch is located at the rear of the bonnet aperture on the bulkhead. The door switches are located on

the’A’posts for the front doors, the’B’posts for the rear doors and on the inside face of the tail door aperture.

The drivers door switch and the bonnet switch are connected to the anti-theft alarm ECU on individual single

wires. The remaining passenger doors and, if applicable, the tail door are jointly connected on a single wire to the

ECU. If a fault occurs which involves incorrect mislock signals, alarm triggers and interior lamp operation, the door

switch earth may be the cause of incorrect operation.

If any door or the bonnet is opened, the switch closes and completes an earth path to the anti-theft alarm ECU.

This completed earth path input is sensed by the ECU, which, if armed, will sound the BBUS or alarm sounder.

The ECU also controls, via the door switches and ignition on/off signals, the operation of the interior lamps.

ProCarManuals.com

Page 616 of 667

ELECTRICAL

7

DESCRIPTION AND OPERATION Alarm Sounders

1.Battery Backed Up Sounder (BBUS)

2.Alarm sounder

Two types of alarm sounder are available, dependant on the vehicle market configuration.

A Battery Backed-Up Sounder (BBUS) is used in some markets and located in the LH front wing, behind the

headlamp. This is a tamper proof sounder with its own power supply which allows it to continue operating even if

disconnected from the vehicle power supply. The BBUS is connected to a permanent battery supply via fuse 7 in

the under seat fuse box. Two further connections are made to the anti-theft alarm ECU and a fourth connection is

to an earth header. If the BBUS is disconnected without first being disarmed by the anti-theft alarm ECU, it will

operate for 4.5 minutes.

To disarm the BBUS, when the battery is to be disconnected for instance, the ignition must be turned on to

position II and back to the off position , after which a 17 second delay is initiated to allow the battery or BBUS

connector to be disconnected. If the BBUS sounds, it can be disarmed by unlocking the vehicle with the remote

handset.

Where a BBUS is not specified, a standard vehicle horn is used for the alarm sounder and is located in the LH

front wing, behind the headlamp. The sounder is operated by an alarm relay which is controlled by the anti-theft

alarm ECU. The relay receives a permanent battery supply via fusible link 6 in the under seat fuse box. The relay

coil is connected to the anti-theft alarm ECU which provides an earth for the coil when horn operation is required.

This operates the relay contacts and supplies battery voltage to the sounder, causing it to operate.

ProCarManuals.com

Page 619 of 667

86ELECTRICAL

10

DESCRIPTION AND OPERATION Remote Handset

The remote handset is a separate unit from the vehicle key and is used to arm and disarm the alarm system. The

handset comprises two buttons; lock and unlock. The handset contains a battery (CR3032) and a printed circuit

board containing the circuitry to generate the RF signals.

NOTE: In selected markets, the vehicle key, when used in the drivers door key barrel switch, will

not disarm the alarm system.

The remote handset RF code consists of two parts. One part is a fixed code that is unique to the handset and the

second part is a rolling code which changes in accordance with a predetermined pattern. The anti-theft alarm ECU

can store the codes of up to four different remote handsets at any one time.

If the remote handset battery falls below a predetermined level, the handset will transmit an additional RF signal

code to the anti-theft alarm ECU when either button is depressed. The security LED will display this as two rapid

flashes every 0.5 seconds to visually display the low handset battery condition. This will continue for the 10

second confirmation period or until the ignition is switched on.

Resynchronisation of Remote Handset

If either the remote handset battery or the vehicle battery is removed or disconnected, the rolling part the handset

code is lost and the handset(s) need to be resynchronised to the anti-theft alarm ECU. The resynchronisation

procedure is as follows:

Disconnect the vehicle battery.

Wait for 30 seconds for residual current to dissipate.

Reconnect the vehicle battery.

Carefully prise the remote handset apart and remove the battery. Avoid unnecessary handling of the battery.

With the battery removed, press either the lock or unlock button several times to remove residual current from

the circuitry.

Check the handset battery with a voltmeter. If the battery voltage is less than 2.7 volts, replace the battery.

Ensure that the battery contact surfaces are clean and replace the battery in the handset clip with the + symbol

uppermost. Put the two halves of the handset case back together.

DO NOT press any buttons.

With the handset within range of the vehicle, press the lock button four times in quick succession. The

anti-theft alarm ECU will respond by locking the vehicle.

Press the unlock button once to complete the resynchronisation procedure.

ProCarManuals.com

Page 621 of 667

86ELECTRICAL

12

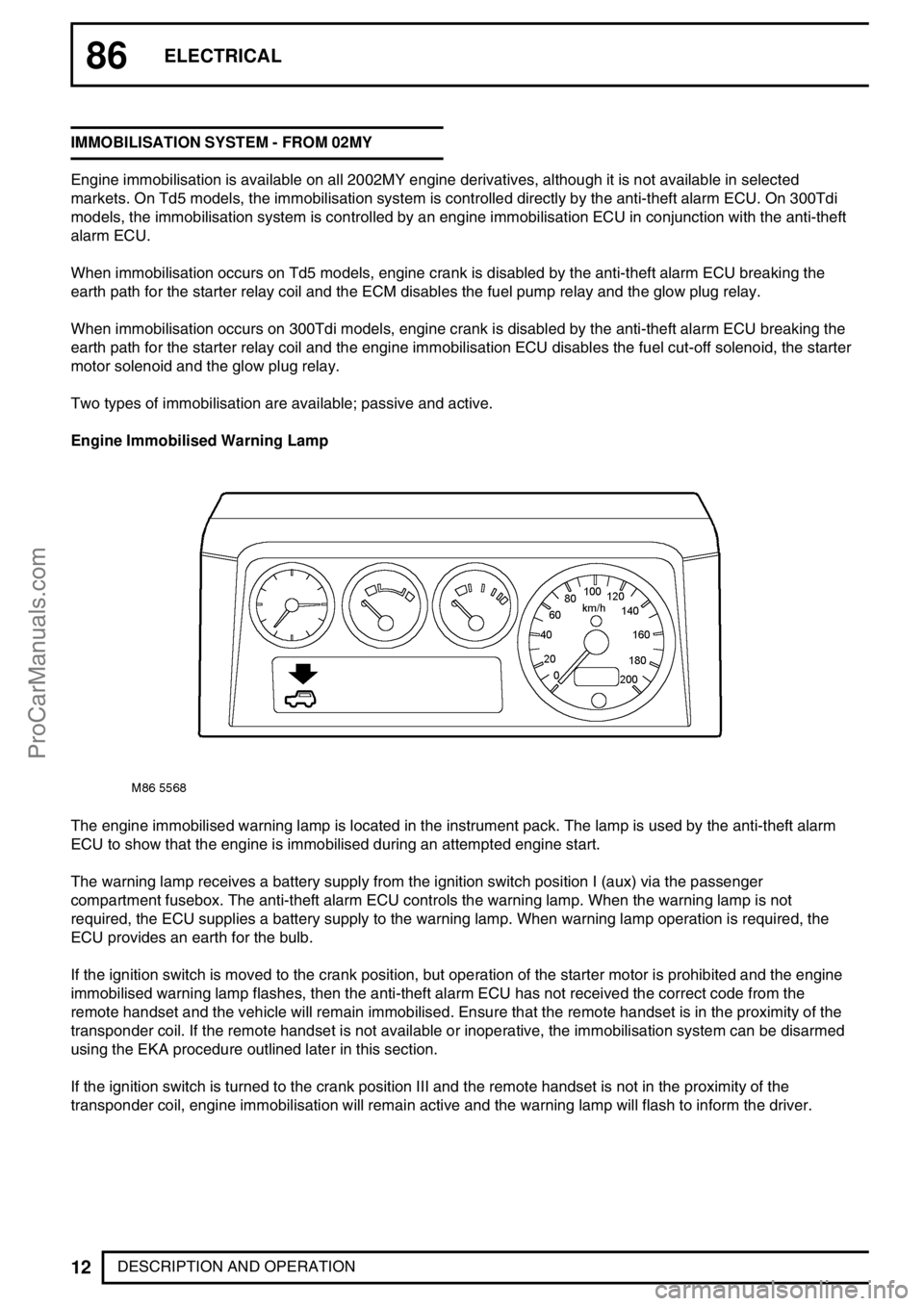

DESCRIPTION AND OPERATION IMMOBILISATION SYSTEM - FROM 02MY

Engine immobilisation is available on all 2002MY engine derivatives, although it is not available in selected

markets. On Td5 models, the immobilisation system is controlled directly by the anti-theft alarm ECU. On 300Tdi

models, the immobilisation system is controlled by an engine immobilisation ECU in conjunction with the anti-theft

alarm ECU.

When immobilisation occurs on Td5 models, engine crank is disabled by the anti-theft alarm ECU breaking the

earth path for the starter relay coil and the ECM disables the fuel pump relay and the glow plug relay.

When immobilisation occurs on 300Tdi models, engine crank is disabled by the anti-theft alarm ECU breaking the

earth path for the starter relay coil and the engine immobilisation ECU disables the fuel cut-off solenoid, the starter

motor solenoid and the glow plug relay.

Two types of immobilisation are available; passive and active.

Engine Immobilised Warning Lamp

The engine immobilised warning lamp is located in the instrument pack. The lamp is used by the anti-theft alarm

ECU to show that the engine is immobilised during an attempted engine start.

The warning lamp receives a battery supply from the ignition switch position I (aux) via the passenger

compartment fusebox. The anti-theft alarm ECU controls the warning lamp. When the warning lamp is not

required, the ECU supplies a battery supply to the warning lamp. When warning lamp operation is required, the

ECU provides an earth for the bulb.

If the ignition switch is moved to the crank position, but operation of the starter motor is prohibited and the engine

immobilised warning lamp flashes, then the anti-theft alarm ECU has not received the correct code from the

remote handset and the vehicle will remain immobilised. Ensure that the remote handset is in the proximity of the

transponder coil. If the remote handset is not available or inoperative, the immobilisation system can be disarmed

using the EKA procedure outlined later in this section.

If the ignition switch is turned to the crank position III and the remote handset is not in the proximity of the

transponder coil, engine immobilisation will remain active and the warning lamp will flash to inform the driver.

ProCarManuals.com