check engine LAND ROVER DEFENDER 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 195 of 667

12ENGINE

36

OVERHAUL 9.Check that the cut-out in piston skirt is

positioned above the oil squirt jet.

10.Repeat for other pistons in turn ensuring that

pistons and connecting rods are fitted in cylinder

bores from which they were removed.

11.Fit connecting rod bearings.See this Section.

CAUTION: If new pistons, connecting rods

or crankshaft have been fitted, it will be

necessary to select correct thickness of

cylinder head gasket.See this Section.CRANKSHAFT

Service repair no - 12.21.33.01

Remove

1.Remove timing chain and sprockets.See this

Section.

2.Remove crankshaft rear oil seal.See this

Section.

3.Remove connecting rod bearings.See this

Section.

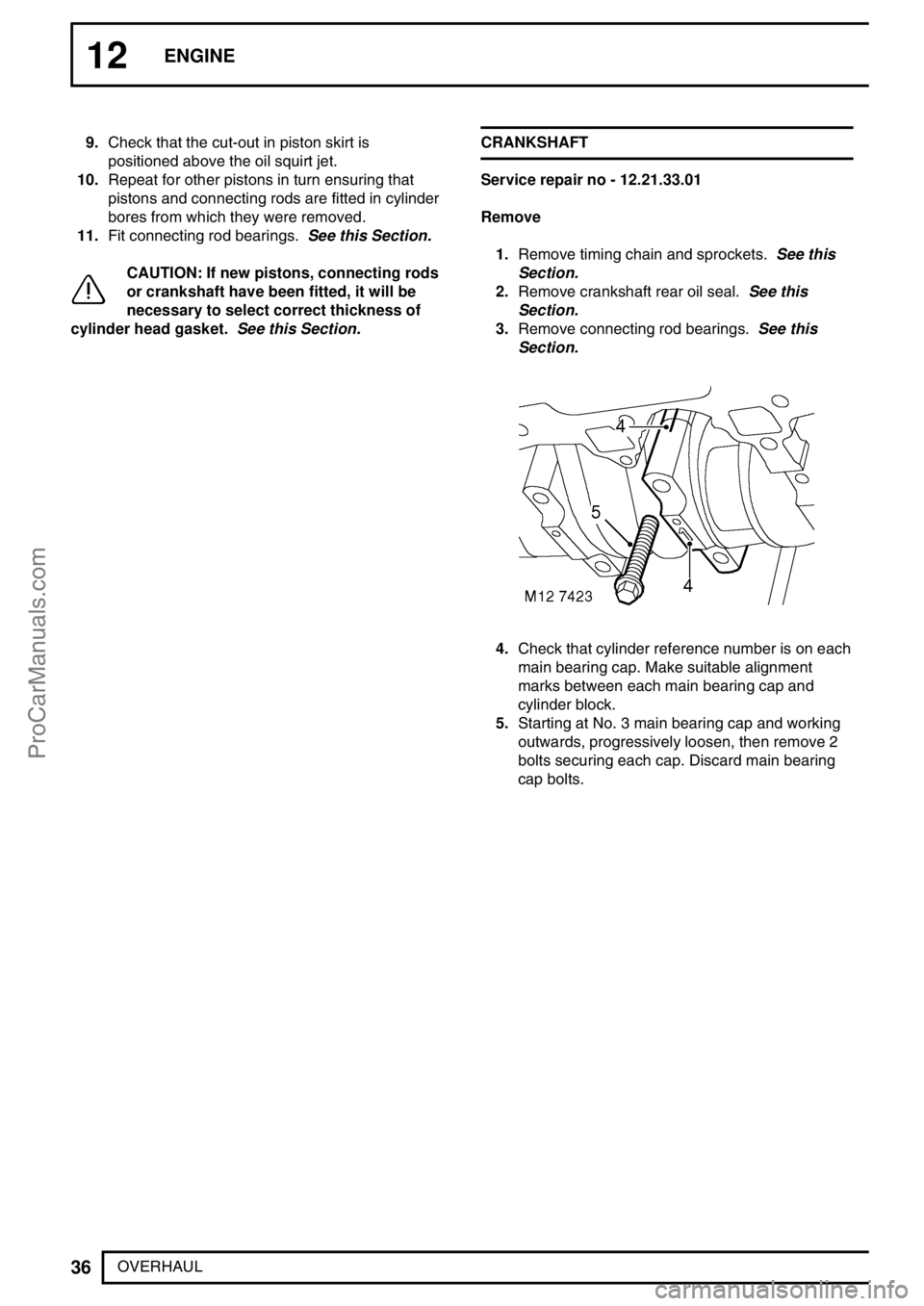

4.Check that cylinder reference number is on each

main bearing cap. Make suitable alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No. 3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts.

ProCarManuals.com

Page 196 of 667

ENGINE

37

OVERHAUL

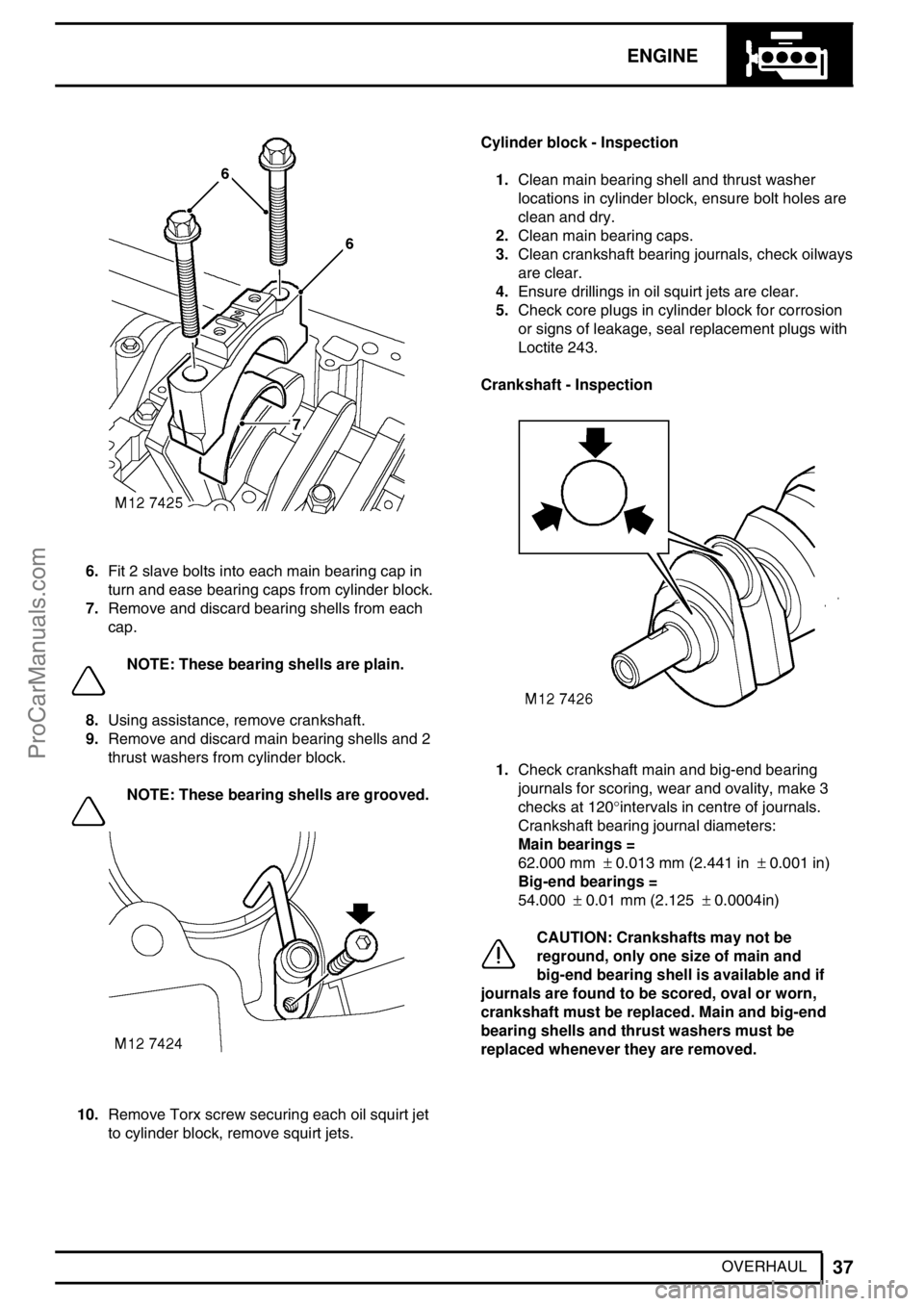

6.Fit 2 slave bolts into each main bearing cap in

turn and ease bearing caps from cylinder block.

7.Remove and discard bearing shells from each

cap.

NOTE: These bearing shells are plain.

8.Using assistance, remove crankshaft.

9.Remove and discard main bearing shells and 2

thrust washers from cylinder block.

NOTE: These bearing shells are grooved.

10.Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.Cylinder block - Inspection

1.Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes are

clean and dry.

2.Clean main bearing caps.

3.Clean crankshaft bearing journals, check oilways

are clear.

4.Ensure drillings in oil squirt jets are clear.

5.Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs with

Loctite 243.

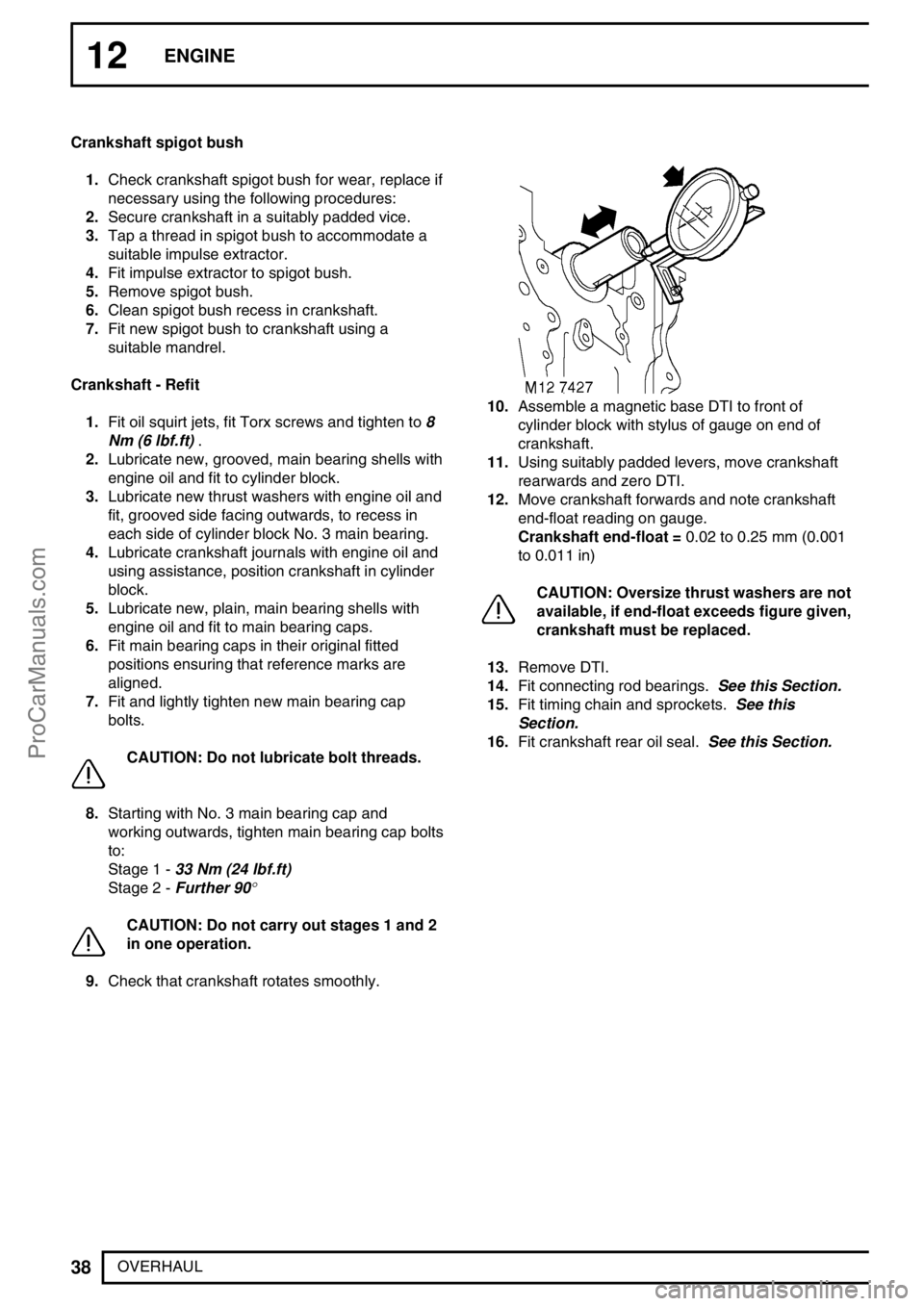

Crankshaft - Inspection

1.Check crankshaft main and big-end bearing

journals for scoring, wear and ovality, make 3

checks at 120°intervals in centre of journals.

Crankshaft bearing journal diameters:

Main bearings =

62.000 mm±0.013 mm (2.441 in±0.001 in)

Big-end bearings =

54.000±0.01 mm (2.125±0.0004in)

CAUTION: Crankshafts may not be

reground, only one size of main and

big-end bearing shell is available and if

journals are found to be scored, oval or worn,

crankshaft must be replaced. Main and big-end

bearing shells and thrust washers must be

replaced whenever they are removed.

ProCarManuals.com

Page 197 of 667

12ENGINE

38

OVERHAUL Crankshaft spigot bush

1.Check crankshaft spigot bush for wear, replace if

necessary using the following procedures:

2.Secure crankshaft in a suitably padded vice.

3.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4.Fit impulse extractor to spigot bush.

5.Remove spigot bush.

6.Clean spigot bush recess in crankshaft.

7.Fit new spigot bush to crankshaft using a

suitable mandrel.

Crankshaft - Refit

1.Fit oil squirt jets, fit Torx screws and tighten to8

Nm (6 lbf.ft).

2.Lubricate new, grooved, main bearing shells with

engine oil and fit to cylinder block.

3.Lubricate new thrust washers with engine oil and

fit, grooved side facing outwards, to recess in

each side of cylinder block No. 3 main bearing.

4.Lubricate crankshaft journals with engine oil and

using assistance, position crankshaft in cylinder

block.

5.Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6.Fit main bearing caps in their original fitted

positions ensuring that reference marks are

aligned.

7.Fit and lightly tighten new main bearing cap

bolts.

CAUTION: Do not lubricate bolt threads.

8.Starting with No. 3 main bearing cap and

working outwards, tighten main bearing cap bolts

to:

Stage 1 -33 Nm (24 lbf.ft)

Stage 2 -Further 90

°

CAUTION: Do not carry out stages 1 and 2

in one operation.

9.Check that crankshaft rotates smoothly.

10.Assemble a magnetic base DTI to front of

cylinder block with stylus of gauge on end of

crankshaft.

11.Using suitably padded levers, move crankshaft

rearwards and zero DTI.

12.Move crankshaft forwards and note crankshaft

end-float reading on gauge.

Crankshaft end-float =0.02 to 0.25 mm (0.001

to 0.011 in)

CAUTION: Oversize thrust washers are not

available, if end-float exceeds figure given,

crankshaft must be replaced.

13.Remove DTI.

14.Fit connecting rod bearings.See this Section.

15.Fit timing chain and sprockets.See this

Section.

16.Fit crankshaft rear oil seal.See this Section.

ProCarManuals.com

Page 208 of 667

EMISSION CONTROL

7

DESCRIPTION AND OPERATION CRANKCASE EMISSION CONTROL

All internal combustion engines generate oil vapour and smoke in the crankcase as a result of high crankcase

temperatures and piston ring and valve stem blow-by. A closed crankcase ventilation system is used to vent

crankcase gases back to the air induction system and so reduce the emission of hydrocarbons.

Gases from the crankcase are drawn into the inlet manifold to be burnt in the combustion chambers with the fresh

air/fuel mixture. The system provides effective emission control under all engine operating conditions.

Crankcase gases are drawn through the breather port in the top of the camshaft cover and routed through the

breather hose and breather valve on the flexible air intake duct to be drawn into the turbocharger intake for

delivery to the air inlet manifold via the intercooler.

An oil separator plate is included in the camshaft cover which removes the heavy particles of oil before the

crankcase gas leaves via the camshaft cover port. The rocker cover features circular chambers which promote

swirl in the oil mist emanating from the cylinder head and camshaft carrier. As the mist passes through the series

of chambers between the rocker cover and oil separator plate, oil particles are thrown against the separator walls

where they condense and fall back into the cylinder head via two air inlet holes located at each end of the rocker

cover.

The breather valve is a pressure depression limiting valve which progressively closes as engine speed increases,

thereby limiting the depression in the crankcase. The valve is of moulded plastic construction and has a port on

the underside which plugs into a port in the flexible air duct. A port on the side of the breather valve connects to

the camshaft cover port by means of a breather hose which is constructed from a heavy duty braided rubber hose

which is held in place by hose clips. A corrugated plastic sleeve is used to give further protection to the breather

hose. The breather valve is orientation sensitive, and’TOP’is marked on the upper surface to ensure it is

mounted correctly.

It is important that the system is air tight. Hose connections to ports should be checked and the condition of the

breather hose should be periodically inspected to ensure it is in good condition.

ProCarManuals.com

Page 239 of 667

18ENGINE MANAGEMENT SYSTEM

16

DESCRIPTION AND OPERATION On Defender models, at wide open throttle, track 2 returns a signal of 0.28V and track 1 returns a signal of 4.7V to

the ECM. The ECM calculates the sum of these two figures which totals 5.0V.

The ECM uses this strategy to error check the TP sensor signal and ensure that the requested throttle position is

applied. The third potentiometer track measures the tolerance of tracks 1 and 2 and provides an improved

functionality check of the pedal angle.

NOTE: Three track TP sensors cannot be fitted as replacements on vehicles previously fitted with

two track TP sensors. Replacement ECM’s are configured for two track TP sensors and can be

fitted to all Td5 models. When replacement ECM’s are fitted to vehicles using three track TP

sensors, TestBook must be used to configure the ECM for three track TP sensor use.

If the TP sensor fails, the ECM will illuminate the MIL and the engine will operate at normal idle speed only.

ProCarManuals.com

Page 252 of 667

ENGINE MANAGEMENT SYSTEM

1

REPAIR ENGINE CONTROL MODULE (ECM)

Service repair no - 18.30.03

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery negative lead.

3.Remove RH seat cushion, release clip and

remove ECM access panel.

4.Remove 3 bolts, release ECM and disconnect 2

multiplugs. Remove ECM.

Refit

5.Position new ECM and connect multiplugs.

6.Fit ECM and tighten bolts.

7.Fit access panel and RH seat cushion.

8.Reconnect battery negative lead.

9.Fit battery cover and secure with fixings.SENSOR - ENGINE COOLANT TEMPERATURE

(ECT)

Service repair no - 18.30.10

Remove

1.Disconnect battery negative lead.

2.Remove spring clip and disconnect ECT sensor

multiplug.

3.Position cloth around ECT sensor to absorb

coolant spillage.

4.Remove ECT sensor.

5.Remove sealing washer and discard.

Refit

6.Clean sealing washer, sensor threads and

sensor location.

7.Coat sensor threads with Loctite 577 and fit new

sealing washer.

8.Fit ECT sensor and tighten to20 Nm (14 lbf.ft).

9.Fit spring clip to multiplug and connect multiplug

to ECT sensor.

10.Top up cooling system.

11.Run engine to normal operating temperature.

Check for leaks around ECT sensor.

12.Reconnect battery negative lead.

ProCarManuals.com

Page 268 of 667

FUEL SYSTEM

1

ADJUSTMENT HEATER PLUG TEST

Service repair no - 19.90.20.01

Check

1. Test out of engine

2.Remove heater plug.See Repair.

3.UsingLRT-12-511,connect RED lead to battery

’+’positive and the BLACK lead to battery’-’

negative.

4.Position heater plug into tester and retain with

spring loaded bar.

5.Connect YELLOW lead to heater plug terminal.

6.Press red button on tester and note ammeter

reading. Keep button depressed, heater plug tip

should start to glow after 5 seconds

CAUTION: The heater plug tip must glow

first, if it fails to do so, replace heater plug.

7.The ammeter reading should show an initial

current draw of 25 amps, which should fall to 12

amps after 20 seconds.

8.Refit heater plug.See Repair.FUEL SYSTEM - BLEED

Service repair no - 19.50.07

Fuel Purging Procedure

1.If the vehicle runs out of fuel, or the fuel level is

so low that the fuel system draws air into the fuel

rail, the fuel rail will need to be purged before the

engine will start. This can be achieved by

following a set procedure. The process does not

require the use of any specialist equipment and

can be performed by the driver of the vehicle.

The process is as follows:

2.Switch off ignition and wait 15 seconds.

3.Turn ignition key to position 2 and wait 3

minutes, (this ensures that the fuel system

purges all the air from the fuel rail within the

cylinder head).

4.Depress the throttle pedal to more than 90% of

its total travel, (to the throttle stop).

5.Crank the engine keeping the throttle pedal

depressed.

NOTE: This operation is controlled by the

ECM and it is important that the purging

operation is not carried out on a vehicle

that has not run out of fuel. If it is carried out

unnecessarily it can lead to the engine flooding

and failing to start.

This operation will be cancelled:

6.As soon as engine speed exceeds 600 rev/min.

7.The driver allows the throttle pedal to close to a

position less than 90% of its travel.

8.The ignition key is released from the start

position.

NOTE: The engine must not be cranked for

more than 30 seconds in any one period.

9.Repeat the above procedure if the engine fails to

start.

ProCarManuals.com

Page 302 of 667

COOLING SYSTEM

1

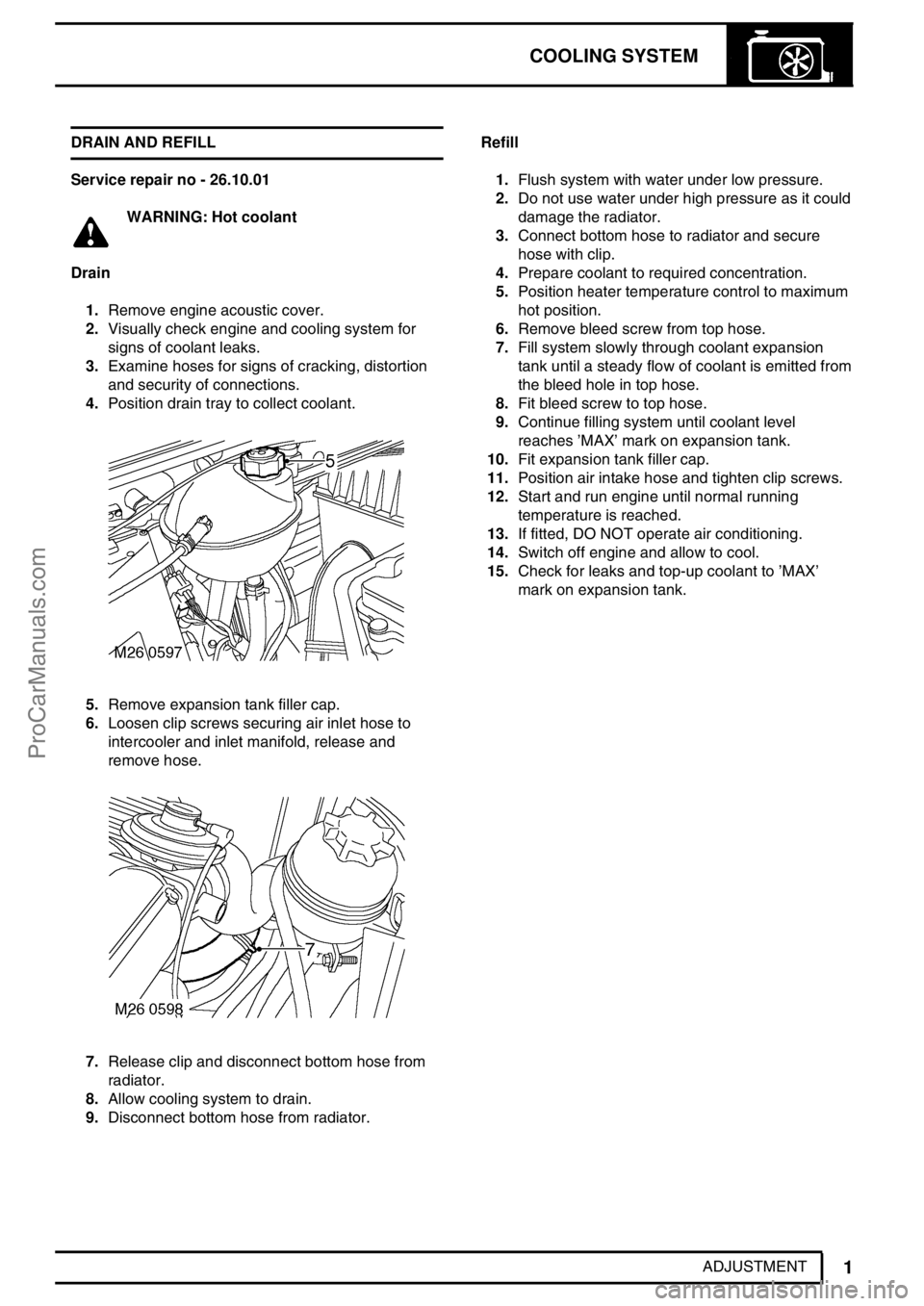

ADJUSTMENT DRAIN AND REFILL

Service repair no - 26.10.01

WARNING: Hot coolant

Drain

1.Remove engine acoustic cover.

2.Visually check engine and cooling system for

signs of coolant leaks.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Position drain tray to collect coolant.

5.Remove expansion tank filler cap.

6.Loosen clip screws securing air inlet hose to

intercooler and inlet manifold, release and

remove hose.

7.Release clip and disconnect bottom hose from

radiator.

8.Allow cooling system to drain.

9.Disconnect bottom hose from radiator.Refill

1.Flush system with water under low pressure.

2.Do not use water under high pressure as it could

damage the radiator.

3.Connect bottom hose to radiator and secure

hose with clip.

4.Prepare coolant to required concentration.

5.Position heater temperature control to maximum

hot position.

6.Remove bleed screw from top hose.

7.Fill system slowly through coolant expansion

tank until a steady flow of coolant is emitted from

the bleed hole in top hose.

8.Fit bleed screw to top hose.

9.Continue filling system until coolant level

reaches’MAX’mark on expansion tank.

10.Fit expansion tank filler cap.

11.Position air intake hose and tighten clip screws.

12.Start and run engine until normal running

temperature is reached.

13.If fitted, DO NOT operate air conditioning.

14.Switch off engine and allow to cool.

15.Check for leaks and top-up coolant to’MAX’

mark on expansion tank.

ProCarManuals.com

Page 510 of 667

PANEL REPAIRS

1

INFORMATION BODY REPAIRS

Body shells are of riveted, bolted and welded

construction and are bolted to the chassis frame.

It is essential that design dimensions and strength are

restored in accident rectification. It is important that

neither structural weakness nor excessive local

stiffness are introduced into the vehicle during body or

chassis repair.

Repairs usually involve a combination of operations

ranging from straightening procedures to renewal of

either individual panels or panel assemblies. The

repairer will determine the repair method and this

decision will take into account a balance of economics

between labour and material costs and the availability

of repair facilities in both equipment and skills. It may

also involve considerations of vehicles down-time,

replacement vehicle availability and repair turn-around

time.

It is expected that a repairer will select the best and

most economic repair method possible, making use of

the facilities available. The instructions given are

intended to assist a skilled body repairer by expanding

approved procedures for panel replacement with the

objective of restoring the vehicle to a safe running

condition and effecting a repair which is visually

acceptable and which, even to the experienced eye,

does not advertise the fact that it has been damaged.

This does not necessarily mean that the repaired

vehicle will be identical in all respects with original

factory build. Repair facilities cannot always duplicate

methods of construction used during production.

The panel repairs shown in this section are all based

on a 110 Station Wagon. Therefore all illustrations

and text relate only to this model. Although certain

areas of the vehicle, such as the front end, are

relevant to all models.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and suspension

geometry checked after completion and if necessary a

road test of the vehicle is carried out, particularly

where safety related items are concerned.Where major units have been disconnected or

removed, it is necessary to ensure that fluid levels are

checked and topped up when necessary. It is also

necessary to ensure that the repaired vehicle is in a

roadworthy condition in respect of tyre pressures,

lights, washer fluid etc.

Body repairs often involve the removal of mechanical

and electrical units as well as associated wiring.

Where this is necessary use the relevant section in

this manual.

Taking into consideration the differences in body

styles, steering and suspension systems as well as

engine and suspension layouts, the location of the

following components as applicable to a particular

vehicle is critical:

Front suspension upper damper

mountings.

Front suspension or sub frame mountings.

Engine mountings on RH and LH chassis

longitudinals.

Rear suspension upper damper mountings.

Rear suspension mountings or lower

pivots.

Steering rack mountings.

Additional points which can be used to check

alignment and assembly are:

Inner holes in crossmember - side - main

floor.

Holes in valance front assembly.

Body to chassis mounting holes.

Holes in rear floor.

Holes in rear lower panels or extension

rear floor.

Fuel tank mountings.

Apertures for windscreen, backlight, bonnet and doors

can be checked by offering up an undamaged

component as a gauge and also by measuring known

dimensions.See BODY DIMENSIONS section.

ProCarManuals.com

Page 534 of 667

PANEL REPAIRS

9

SEALING AND CORROSION PROTECTION Stone Chip Resistant Paint/Primer

Re-treat all areas protected with factory-applied

anti-chip primer with suitable approved material in

repair.

Inspections during Maintenance Servicing

It is a requirement of the Land Rover Corrosion

Warranty that the vehicle body is checked for

corrosion by an authorised Land Rover dealer at least

once a year, to ensure that the factory-applied

protection remains effective.

Service Job Sheets include the following operations to

check bodywork for corrosion:

With the vehicle on a lift, carry out visual

check of underbody sealer for damage.

With the vehicle lowered, inspect exterior

paintwork for damage and body panels for

corrosion.

NOTE: Wash the vehicle and ensure that it

is free from deposits prior to inspection. It

is part of the owner’s responsibility to

ensure that the vehicle is kept free of

accumulations of mud which could accelerate the

onset of corrosion. The Dealer MUST wash the

vehicle prior to inspection of bodywork if the

customer has offered it in a dirty condition, and

pay special attention to areas where access is

difficult.

NOTE: The checks described above are

intended to be visual only. It is not

intended that the operator should remove

trim panels, finishers, rubbing strips or sound

deadening materials when checking the vehicle

for corrosion and paint damage.

With the vehicle on a lift, and using an inspection or

spot lamp, visually check for the following:

Corrosion damage and damaged

paintwork, condition of underbody sealer

on front and rear lower panels, sills and

wheel arches.

Damage to underbody sealer on main floor

and chassis members. Corrosion in areas

adjacent to suspension mountings and fuel

tank fixings.

NOTE: The presence of small blisters in

PVC underbody sealer is acceptable,

providing they do not expose bare metal.

Special attention must be paid to signs of damage

caused to panels or corrosion material by incorrect

jack positioning.

It is essential to follow the correct jacking and lifting

procedures.See GENERAL INFORMATION DATA,

Information section.

With the vehicle lowered, visually check for evidence

of damage and corrosion on all painted areas, in

particular the following:

Front edge of bonnet.

Visible flanges in engine compartment and

boot.

Lower body and door panels.

Where bodywork damage or evidence of corrosion is

found during inspection, rectify this as soon as is

practicable, both to minimise the extent of the damage

and to ensure the long term effectiveness of the

factory-applied corrosion protection treatment. Where

the cost of rectification work is the owner’s

responsibility, the Dealer must advise the owner and

endorse the relevant documentation accordingly.

Where corrosion has become evident and is

emanating from beneath a removable component

(e.g. trim panel, window glass, seat etc.), remove the

component as required to permit effective rectification.

ProCarManuals.com