engine LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 114 of 667

ENGINE

29

DESCRIPTION AND OPERATION Timing chain guides

1.Hydraulic tensioner

2.Adjustable tensioner arm

3.Duplex timing chain4.Camshaft sprocket

5.Fixed tensioner arm

6.Crankshaft sprocket

The crankshaft sprocket to camshaft sprocket timing chain is held taut by a tensioner arm acting on the slack side

of the chain. The tensioner is automatically adjusted by means of an hydraulically operated tensioner adjuster.

The drive side of the chain has a plastic guide attached to the front face of the cylinder block. The fixed guide is

attached to the front of the engine block by two bolts. The tensioner arm is fixed to the front of the cylinder block

by a single pivot bolt which allows the tensioner arm to pivot about its axis.

NOTE: The adjustable tensioner arm is not interchangeable between pre-EU3 and EU3 vehicles

due to a change in geometry on the EU3 version.

ProCarManuals.com

Page 115 of 667

12ENGINE

30

DESCRIPTION AND OPERATION CAMSHAFT COVER COMPONENTS

The camshaft cover cover components are described below:

Camshaft cover

The camshaft cover is cast from aluminium alloy and is fixed to the camshaft carrier / cylinder head assembly by

thirteen bolts. The cover has spacers and sealing washers inserted into each of the thirteen bolt holes.

A breather hose is connected to a port at the top of the camshaft cover by means of a hose clip which vents

crankcase gases back to the air intake via a breather valve in the air intake tract, located forward of the

turbocharger in the flexible air intake duct.

A rubber seal is fitted between the camshaft cover and camshaft carrier.

An oil filler aperture is included in the top of the camshaft cover, which is sealed with a plastic cap with integral

rubber seal.

CAMSHAFT TIMING CHAIN COMPONENTS

The timing chain cover and timing chain components are described below:

Timing chain cover

The timing chain cover is cast and machined aluminium alloy and is attached to the cylinder head by a bolt at the

RH top of the cover and by a stud and nut at the LH top of the cover. Eight screws are used to attach the timing

chain cover to the front of the engine block. The timing cover is located to the cylinder block front face by two

dowels.

A viscous fan is attached to an idler pulley at the front of the engine block. The fan bearing is located on a shaft

and held in place by a circlip and a bearing flange, the inner race of the fan bearing is an interference fit on the

shaft. The fan idler pulley is attached to the bearing hub by three bolts and the fan itself is secured to the pulley

and bearing shaft by a left-hand threaded nut.

The front of the crankshaft passes through a hole in the lower part of the timing cover. An oil seal is pressed into a

recess in the front of the timing cover to seal the interface between the front of the crankshaft and the timing

cover.

A stub pipe is fitted to the front RH side of the timing cover which is used to attach the oil drain pipe from the

vacuum pump by means of a hose and spring clip.

Timing chains

The timing chain between the camshaft and crankshaft sprockets is a duplex type, each chain having 56 links.

The timing chain is contained between a fixed plastic guide and an hydraulically adjustable plastic tensioner arm

which are attached to the front of the engine block.

To cope with the higher injection loads of the EU3 engine, the timing drive between the camshaft and crankshaft

has been upgraded. This requires thicker chain links to be used, therefore the individual pre EU3 and EU3

components are not interchangeable.

To distinguish between the two timing chains the links are different colours. A pre EU3 chain has blue links. An

EU3 chain has bronze links.

The oil pump timing chain is a single type and traverses the oil pump sprocket and the rear crankshaft sprocket.

The timing chains are oil lubricated, with oil being provided by a chain lubrication jet and from oil flow returning

back to the sump from the cylinder head. An oil hole is included at the front left hand side of the cylinder head

which supplies oil from the cylinder head oil galleries.

ProCarManuals.com

Page 116 of 667

ENGINE

31

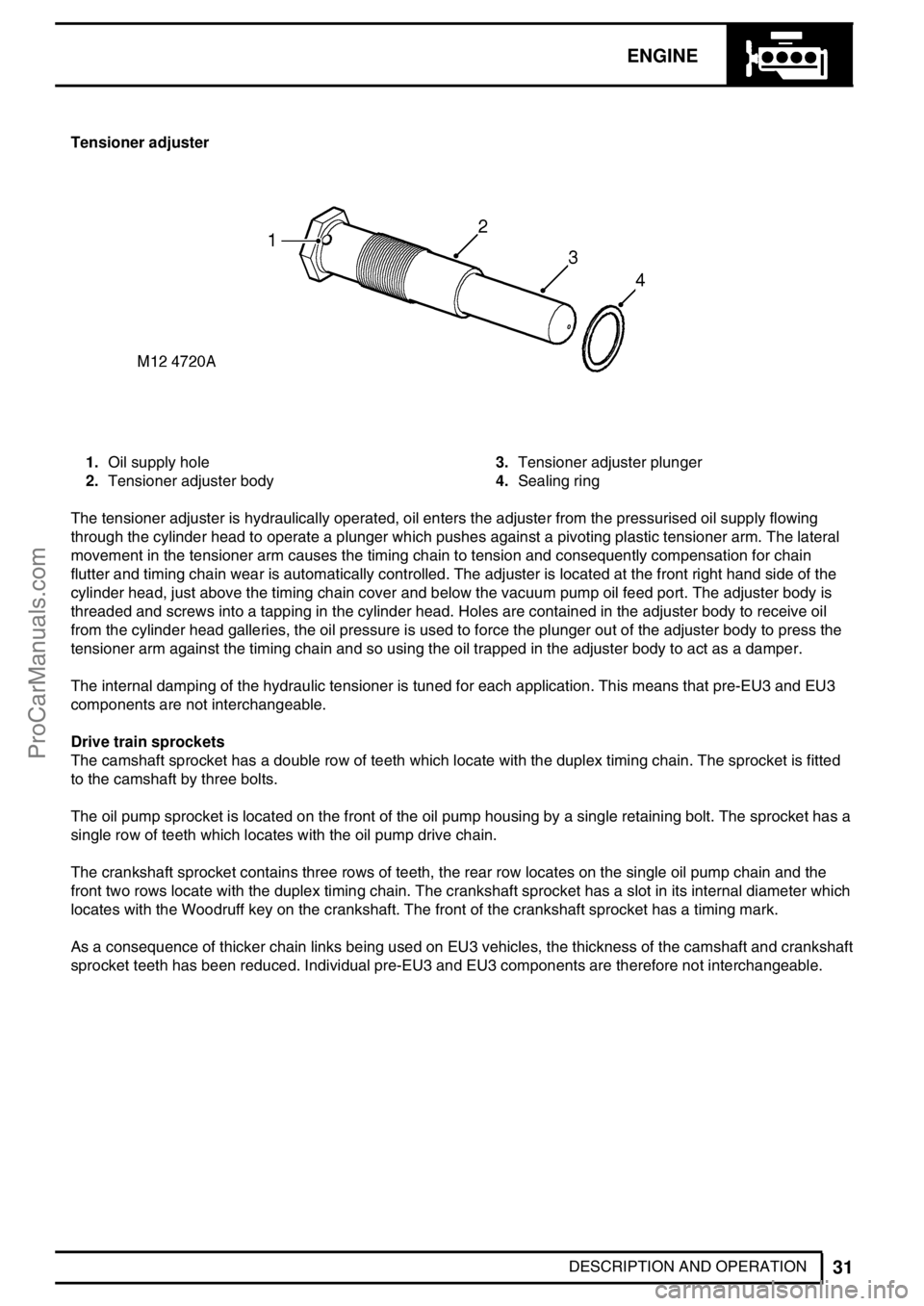

DESCRIPTION AND OPERATION Tensioner adjuster

1.Oil supply hole

2.Tensioner adjuster body3.Tensioner adjuster plunger

4.Sealing ring

The tensioner adjuster is hydraulically operated, oil enters the adjuster from the pressurised oil supply flowing

through the cylinder head to operate a plunger which pushes against a pivoting plastic tensioner arm. The lateral

movement in the tensioner arm causes the timing chain to tension and consequently compensation for chain

flutter and timing chain wear is automatically controlled. The adjuster is located at the front right hand side of the

cylinder head, just above the timing chain cover and below the vacuum pump oil feed port. The adjuster body is

threaded and screws into a tapping in the cylinder head. Holes are contained in the adjuster body to receive oil

from the cylinder head galleries, the oil pressure is used to force the plunger out of the adjuster body to press the

tensioner arm against the timing chain and so using the oil trapped in the adjuster body to act as a damper.

The internal damping of the hydraulic tensioner is tuned for each application. This means that pre-EU3 and EU3

components are not interchangeable.

Drive train sprockets

The camshaft sprocket has a double row of teeth which locate with the duplex timing chain. The sprocket is fitted

to the camshaft by three bolts.

The oil pump sprocket is located on the front of the oil pump housing by a single retaining bolt. The sprocket has a

single row of teeth which locates with the oil pump drive chain.

The crankshaft sprocket contains three rows of teeth, the rear row locates on the single oil pump chain and the

front two rows locate with the duplex timing chain. The crankshaft sprocket has a slot in its internal diameter which

locates with the Woodruff key on the crankshaft. The front of the crankshaft sprocket has a timing mark.

As a consequence of thicker chain links being used on EU3 vehicles, the thickness of the camshaft and crankshaft

sprocket teeth has been reduced. Individual pre-EU3 and EU3 components are therefore not interchangeable.

ProCarManuals.com

Page 117 of 667

12ENGINE

32

DESCRIPTION AND OPERATION CYLINDER BLOCK FLOW

ProCarManuals.com

Page 118 of 667

ENGINE

33

DESCRIPTION AND OPERATION 1.Oil squirt jets (5 off)

2.Main oil delivery gallery

3.Inflow from oil cooler housing

4.Flow to oil cooler / filters (from oil pump via cylinder block)

5.Sump

6.Oil pick-up pipe

7.Flow from oil pump (relief-valve in housing)

8.Oil pump

9.Cross-drilling supply to main and crankshaft bearings

10.To cylinder head

Oil from the sump is drawn up through a two-piece plastic pick-up which contains a mesh to siphon any relatively

large pieces of material which could cause damage to the pump. The head of the pick-up is centrally immersed in

the sump oil and oil is delivered to the inlet side of the eccentric rotor pump through a gallery in the stiffener plate.

Pressurised oil from the pump is passed through to the cylinder block where it is delivered to the centrifuge filter

and full-flow filter via a port in the RH cylinder block which interfaces with a port in the centre gallery of the oil

cooler housing. The oil pump contains an oil pressure relief valve which opens to allow oil to be recirculated back

around the pump if the oil pressure increases to a high enough level.

10% of the oil flow from the pump is diverted through the centrifuge filter and returned to the sump via the

centrifuge filter drain tube. The remaining 90% of the oil passes through the standard full-flow filter to the main oil

gallery in the cylinder block.

ProCarManuals.com

Page 119 of 667

12ENGINE

34

DESCRIPTION AND OPERATION OIL COOLER / FILTER FLOW

(THERMOSTAT OPEN)

ProCarManuals.com

Page 120 of 667

ENGINE

35

DESCRIPTION AND OPERATION 1.To cylinder block main gallery (from rear of oil cooler housing)

2.Oil cooler housing

3.Oil pressure switch

4.Full-flow filter

5.Centrifuge filter

6.Return to sump

7.Flow from oil pump (via cylinder block)

8.Oil cooler matrix

When the engine temperature is below 74°C, the thermostat in the full-flow filter adaptor housing is closed and a

proportion of the oil flow to the main oil gallery is diverted to the oil cooler to supply an oil feed to the turbocharger

bearings. Oil passes through the oil cooler to the front gallery in the oil cooler housing where there is a tapping to

connect the feed pipe to the turbocharger. Oil used by the turbocharger bearings is returned to the sump through

an oil drain pipe which connects to a port in the LH side of the cylinder block.

The remainder of the oil flow leaving the full-flow filter outlet is passed into the cylinder block via a port at the rear

of oil cooler rear gallery.

When the oil temperature rises above 74°C the thermostat in the full-flow filter housing begins to open to allow a

proportion of the oil from the full-flow filter to pass through the oil cooler before it reaches the main oil gallery in the

cylinder block. In this instance, oil supply to the turbocharger bearings is fed directly from the full-flow filter without

first passing through the oil cooler. Between 74°C and 88°C the thermostat valve plunger opens by about 9 mm

(0.3 in) to allow proportionally more oil to flow through the oil cooler before being passed to the cylinder block main

oil delivery gallery. Above 88°C the thermostat valve continues to open by about 1mm (0.03 in) for every 10°C

increase in temperature until the valve is fully open, when all the oil flow to the cylinder block is forced to pass to

the cylinder block via the oil cooler.

An oil pressure switch is located in a port in the rear gallery of the oil cooler housing to sense the oil pressure level

before flow enters the main oil gallery in the engine block. A warning lamp in the instrument cluster is switched on

if the oil pressure is detected as being too low.

Drillings from the cylinder block main oil gallery direct oil to the crankshaft main bearings and cross drillings in the

crankshaft direct oil to the big-end bearings. An additional five drillings in the cylinder block supply oil at reduced

pressure to the oil squirt jets for piston cooling and gudgeon pin lubrication.

Oil supply from the cylinder block is then passed to the cylinder head galleries through a non-return valve which is

included as an integral item in the lower face of the cylinder head.

ProCarManuals.com

Page 121 of 667

12ENGINE

36

DESCRIPTION AND OPERATION CYLINDER HEAD FLOW

1.Cast-in groove between cylinder head and

camshaft carrier

2.Rocker shaft flow

3.Lash adjuster supply channels (10 off)

4.Non-return valve

5.Chain lubrication jet supply6.Oil return from vacuum pump

7.Oil supply to timing chain tensioner adjuster

8.Oil supply to vacuum pump

9.Oil supply hole to camshaft sprocket and timing

chain

Oil passes to the cylinder head from the cylinder block via a non-return valve which is included to prevent oil

draining away from the lash adjusters when the engine is switched off.

Oil is passed to a cast-in groove between the top of the cylinder head and the camshaft carrier. The part of the

channel on the top left hand side of the cylinder head has ten cross-drillings which supply oil to the hydraulic lash

adjusters and finger followers. Lubrication oil fed to the lash adjusters passes up through the lash adjuster body

and into the socket of the finger followers. The oil exits the finger followers through a small hole to lubricate the

surfaces between the camshaft lobes and rollers.

ProCarManuals.com

Page 122 of 667

ENGINE

37

DESCRIPTION AND OPERATION An additional tapping is included at the front left hand side of the cylinder head to supply oil to the chain lubrication

jet and a through hole near the front centre of the cylinder head allows a passage of oil through from the cast-in

groove to lubricate the timing chain and camshaft sprocket.

At the centre front of the cylinder head, the cast-in groove channels oil into the rocker shaft via the front rocker

shaft fixing. Oil flow through the rocker shaft and clearance around the rocker shaft fixings provides oil feed to the

camshaft bearings.

A tapping towards the right hand side of the cylinder head diverts oil supply from the cast-in groove down to a stub

pipe which attaches to a feed line to the vacuum pump. An hydraulic tensioner is located below the vacuum stub

pipe which receives oil through a small hole in the side of the tensioner body to force a plunger against a plastic

faced adjuster shoe for timing chain tensioning. Oil from the vacuum pump is returned to the a port in the timing

chain cover via a short hose which connects to stub pipes at both ends using spring clips.

ProCarManuals.com

Page 123 of 667

12ENGINE

38

DESCRIPTION AND OPERATION

ProCarManuals.com