engine LAND ROVER DEFENDER 1999 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 124 of 667

ENGINE

1

ADJUSTMENT ENGINE OIL PRESSURE CHECK

Service repair no - 12.90.09.01

Check

1.Remove oil pressure switch.See Repair.

2.Connect pressure check kitLRT-12-052C

adaptor and gauge to oil pressure switch

position on oil cooler.

3.Check and if necessary, top-up engine oil.

4.Run engine at idle speed and check that oil

pressure is within limits given.

5.Switch off ignition.

6.Remove oil pressure check kitLRT-12-052C.

7.Clean oil spillage.

8.Fit oil pressure switch.See Repair.

Adjust

1.If engine oil pressure is not within specified

limits, check condition of oil pump and/or main

and connecting rod bearings.

ProCarManuals.com

Page 126 of 667

ENGINE

1

REPAIR CAMSHAFT

Service repair no - 12.13.02

Remove

1.Remove cylinder head gasket.See this

Section.

2.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of cylinder head.

3.Disconnect multiplug from injector units and

remove harness from camshaft carrier.

4.Remove and discard multiplug’O’ring.

5.Loosen lock nuts and fully retract rocker

adjusting screws.

6.Progressively loosen then remove and discard 6

bolts securing rocker shaft, remove shaft.

7.Using sequence shown, progressively loosen

then remove 13 bolts securing camshaft carrier

to cylinder head.

8.Gently tap the camshaft carrier upwards to break

the sealant bond and remove carrier noting it is

located by 2 dowels.

9.Remove camshaft.

10.Remove and discard camshaft rear oil seal.

11.Remove and discard lock nuts and rocker

adjusting screws.

12.Check bearing surfaces in cylinder head and

camshaft carrier for signs of scoring and wear.

ProCarManuals.com

Page 127 of 667

12ENGINE

2

REPAIR

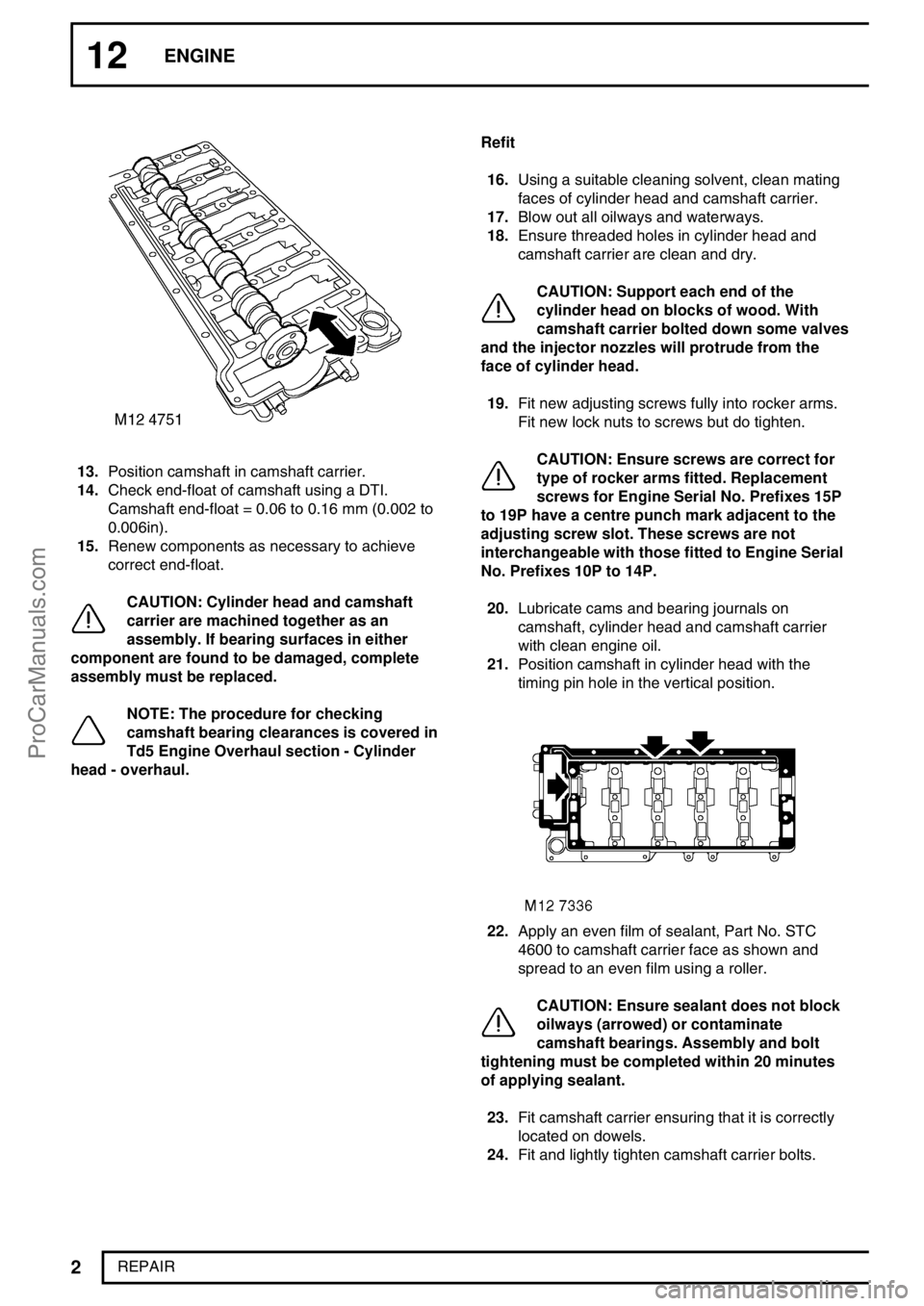

13.Position camshaft in camshaft carrier.

14.Check end-float of camshaft using a DTI.

Camshaft end-float = 0.06 to 0.16 mm (0.002 to

0.006in).

15.Renew components as necessary to achieve

correct end-float.

CAUTION: Cylinder head and camshaft

carrier are machined together as an

assembly. If bearing surfaces in either

component are found to be damaged, complete

assembly must be replaced.

NOTE: The procedure for checking

camshaft bearing clearances is covered in

Td5 Engine Overhaul section - Cylinder

head - overhaul.Refit

16.Using a suitable cleaning solvent, clean mating

faces of cylinder head and camshaft carrier.

17.Blow out all oilways and waterways.

18.Ensure threaded holes in cylinder head and

camshaft carrier are clean and dry.

CAUTION: Support each end of the

cylinder head on blocks of wood. With

camshaft carrier bolted down some valves

and the injector nozzles will protrude from the

face of cylinder head.

19.Fit new adjusting screws fully into rocker arms.

Fit new lock nuts to screws but do tighten.

CAUTION: Ensure screws are correct for

type of rocker arms fitted. Replacement

screws for Engine Serial No. Prefixes 15P

to 19P have a centre punch mark adjacent to the

adjusting screw slot. These screws are not

interchangeable with those fitted to Engine Serial

No. Prefixes 10P to 14P.

20.Lubricate cams and bearing journals on

camshaft, cylinder head and camshaft carrier

with clean engine oil.

21.Position camshaft in cylinder head with the

timing pin hole in the vertical position.

22.Apply an even film of sealant, Part No. STC

4600 to camshaft carrier face as shown and

spread to an even film using a roller.

CAUTION: Ensure sealant does not block

oilways (arrowed) or contaminate

camshaft bearings. Assembly and bolt

tightening must be completed within 20 minutes

of applying sealant.

23.Fit camshaft carrier ensuring that it is correctly

located on dowels.

24.Fit and lightly tighten camshaft carrier bolts.

ProCarManuals.com

Page 128 of 667

ENGINE

3

REPAIR

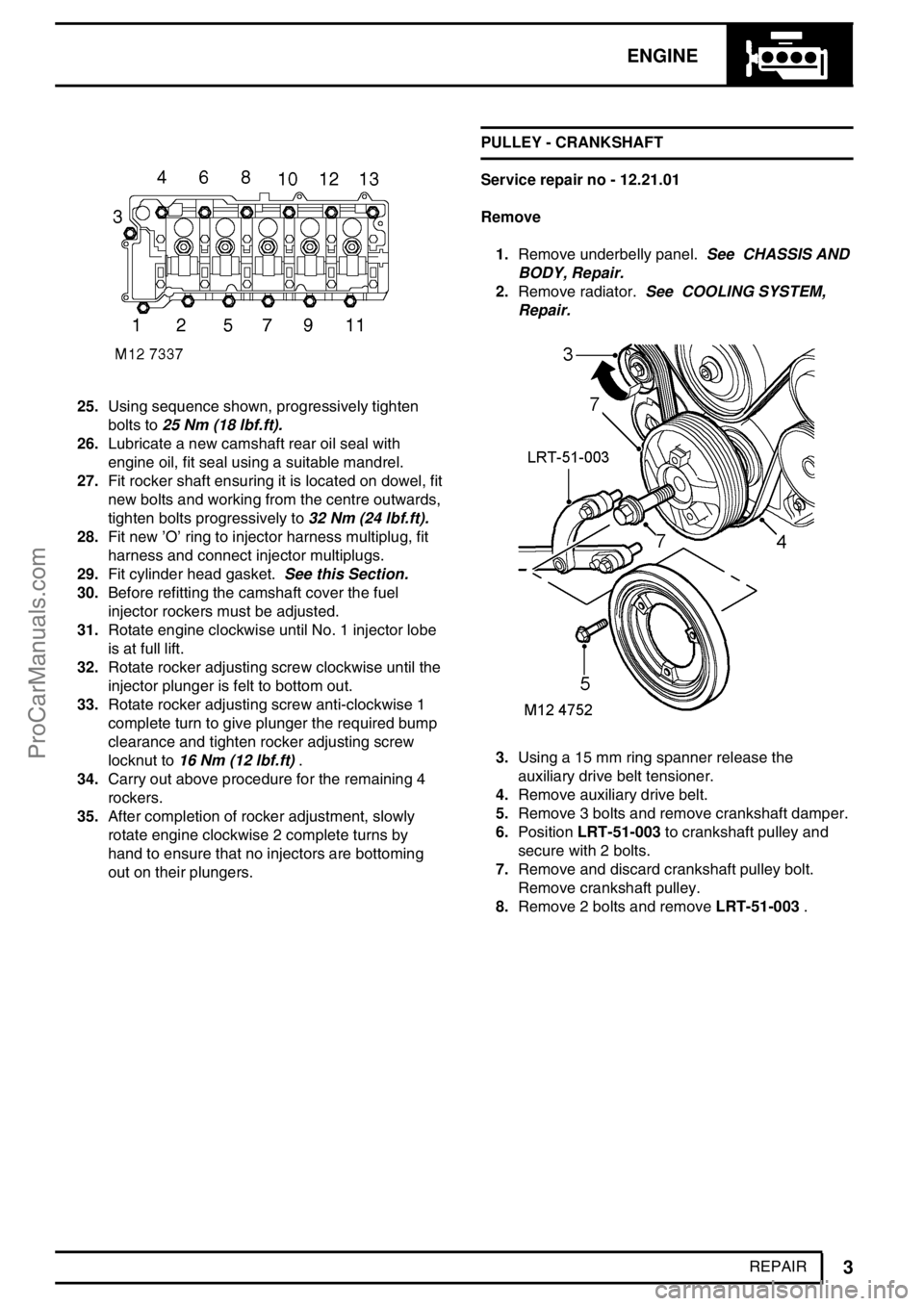

25.Using sequence shown, progressively tighten

bolts to25 Nm (18 lbf.ft).

26.Lubricate a new camshaft rear oil seal with

engine oil, fit seal using a suitable mandrel.

27.Fit rocker shaft ensuring it is located on dowel, fit

new bolts and working from the centre outwards,

tighten bolts progressively to32 Nm (24 lbf.ft).

28.Fit new’O’ring to injector harness multiplug, fit

harness and connect injector multiplugs.

29.Fit cylinder head gasket.See this Section.

30.Before refitting the camshaft cover the fuel

injector rockers must be adjusted.

31.Rotate engine clockwise until No. 1 injector lobe

is at full lift.

32.Rotate rocker adjusting screw clockwise until the

injector plunger is felt to bottom out.

33.Rotate rocker adjusting screw anti-clockwise 1

complete turn to give plunger the required bump

clearance and tighten rocker adjusting screw

locknut to16 Nm (12 lbf.ft).

34.Carry out above procedure for the remaining 4

rockers.

35.After completion of rocker adjustment, slowly

rotate engine clockwise 2 complete turns by

hand to ensure that no injectors are bottoming

out on their plungers.PULLEY - CRANKSHAFT

Service repair no - 12.21.01

Remove

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Remove radiator.See COOLING SYSTEM,

Repair.

3.Using a 15 mm ring spanner release the

auxiliary drive belt tensioner.

4.Remove auxiliary drive belt.

5.Remove 3 bolts and remove crankshaft damper.

6.PositionLRT-51-003to crankshaft pulley and

secure with 2 bolts.

7.Remove and discard crankshaft pulley bolt.

Remove crankshaft pulley.

8.Remove 2 bolts and removeLRT-51-003.

ProCarManuals.com

Page 129 of 667

12ENGINE

4

REPAIR Refit

9.Position new crankshaft pulley to vice.

10.Remove 3 bolts and remove damper from

crankshaft pulley.

11.Using a lint free cloth, thoroughly clean oil seal

recess and the running surface on crankshaft

pulley.

12.Fit crankshaft pulley.

13.FitLRT-51-003to crankshaft pulley and secure

with 2 bolts.

14.Fit new crankshaft pulley bolt and tighten to460

Nm (340 lbf.ft).

NOTE: It is recommended that a torque

multiplier is used to tighten crankshaft

pulley bolt.

15.Remove 2 bolts and removeLRT-51-003from

crankshaft pulley.

16.Fit damper to crankshaft pulley, fit bolts and

tighten to80 Nm (60 lbf.ft).

17.Fit auxiliary drive belt.

18.Fit radiator.See COOLING SYSTEM, Repair.

19.Fit underbelly panel.See CHASSIS AND

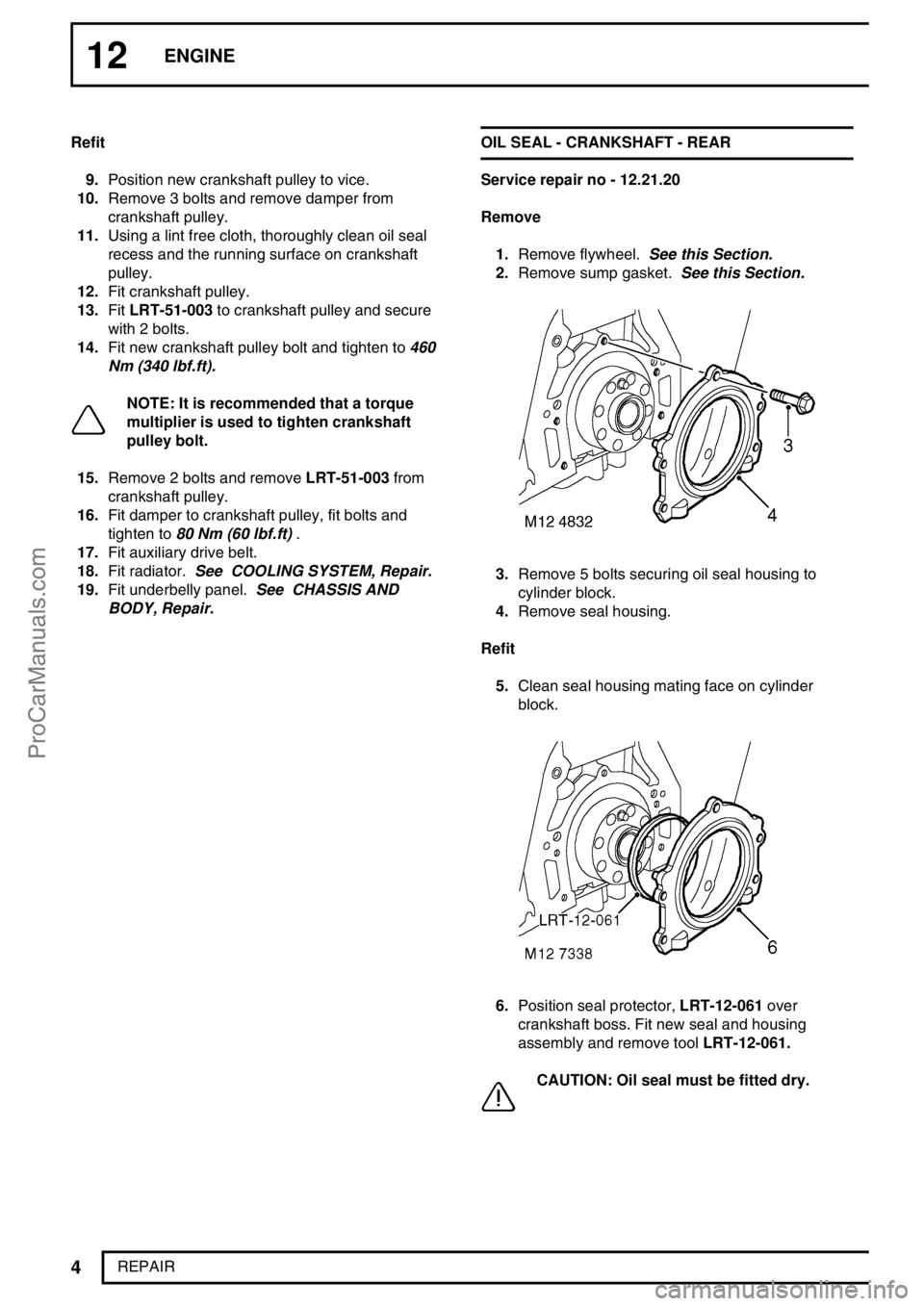

BODY, Repair.OIL SEAL - CRANKSHAFT - REAR

Service repair no - 12.21.20

Remove

1.Remove flywheel.See this Section.

2.Remove sump gasket.See this Section.

3.Remove 5 bolts securing oil seal housing to

cylinder block.

4.Remove seal housing.

Refit

5.Clean seal housing mating face on cylinder

block.

6.Position seal protector,LRT-12-061over

crankshaft boss. Fit new seal and housing

assembly and remove toolLRT-12-061.

CAUTION: Oil seal must be fitted dry.

ProCarManuals.com

Page 130 of 667

ENGINE

5

REPAIR

7.Fit oil seal housing bolts and using sequence

shown, tighten to9 Nm (7 lbf.ft).

8.Fit sump gasket.See this Section.

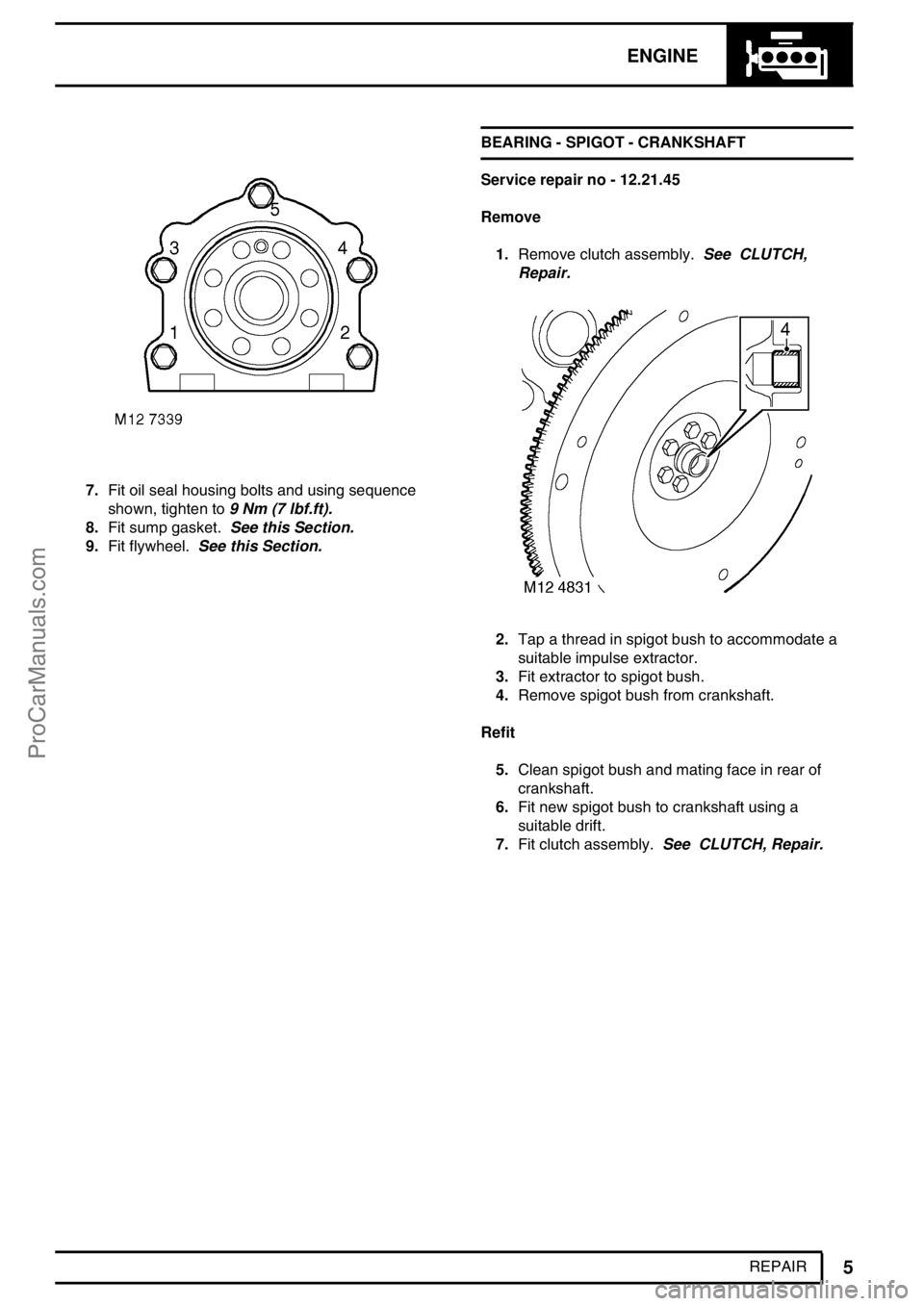

9.Fit flywheel.See this Section.BEARING - SPIGOT - CRANKSHAFT

Service repair no - 12.21.45

Remove

1.Remove clutch assembly.See CLUTCH,

Repair.

2.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

3.Fit extractor to spigot bush.

4.Remove spigot bush from crankshaft.

Refit

5.Clean spigot bush and mating face in rear of

crankshaft.

6.Fit new spigot bush to crankshaft using a

suitable drift.

7.Fit clutch assembly.See CLUTCH, Repair.

ProCarManuals.com

Page 131 of 667

12ENGINE

6

REPAIR GASKET - CYLINDER HEAD

Service repair no - 12.29.02

Remove

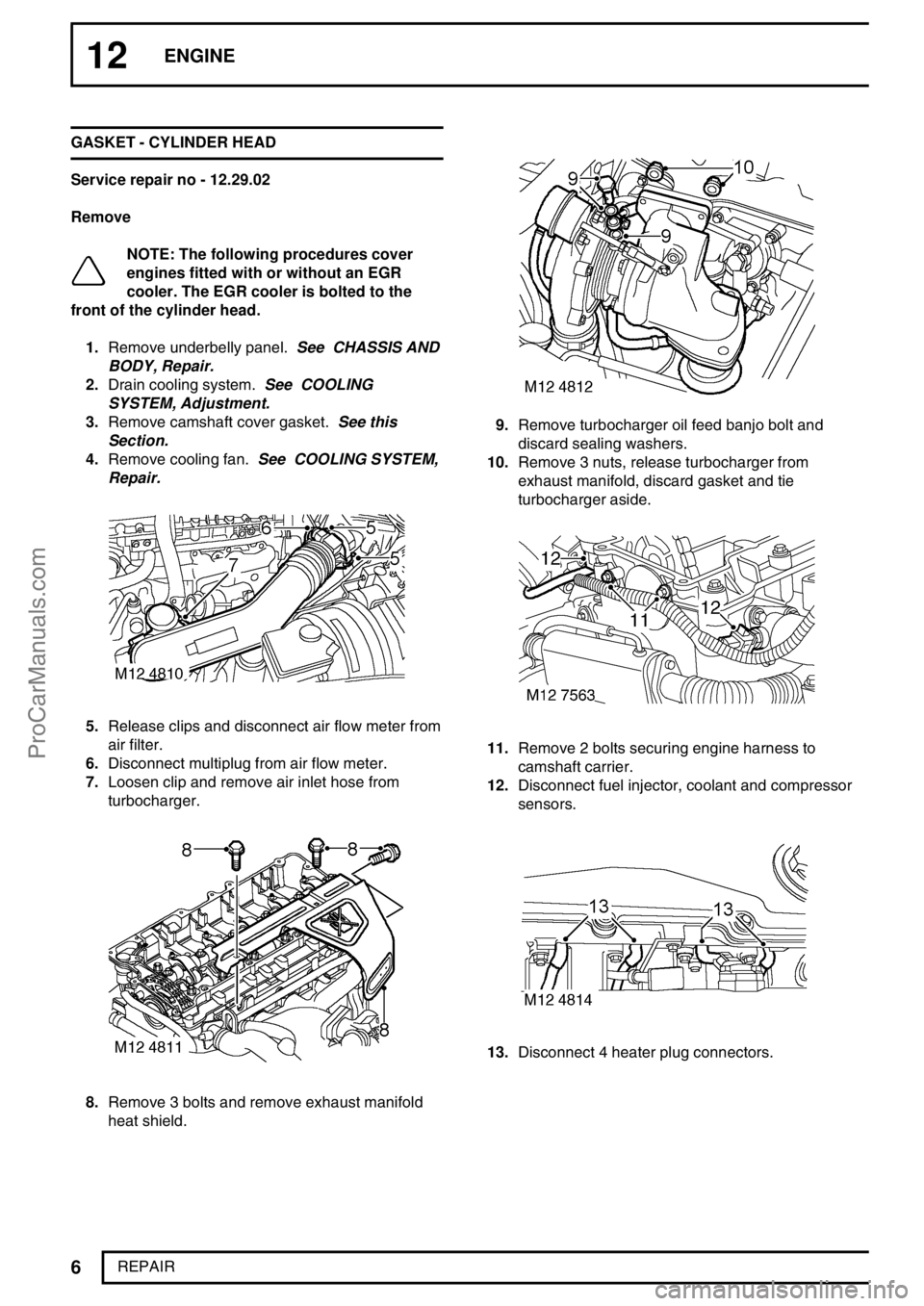

NOTE: The following procedures cover

engines fitted with or without an EGR

cooler. The EGR cooler is bolted to the

front of the cylinder head.

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Drain cooling system.See COOLING

SYSTEM, Adjustment.

3.Remove camshaft cover gasket.See this

Section.

4.Remove cooling fan.See COOLING SYSTEM,

Repair.

5.Release clips and disconnect air flow meter from

air filter.

6.Disconnect multiplug from air flow meter.

7.Loosen clip and remove air inlet hose from

turbocharger.

8.Remove 3 bolts and remove exhaust manifold

heat shield.

9.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

10.Remove 3 nuts, release turbocharger from

exhaust manifold, discard gasket and tie

turbocharger aside.

11.Remove 2 bolts securing engine harness to

camshaft carrier.

12.Disconnect fuel injector, coolant and compressor

sensors.

13.Disconnect 4 heater plug connectors.

ProCarManuals.com

Page 132 of 667

ENGINE

7

REPAIR

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Loosen clip screw and disconnect air intake

hose from EGR valve.

18.Release 3 clips and disconnect coolant hoses

from fuel cooler.

19.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Plug the connections.

20.Disconnect fuel hose from fuel cooler and secure

to connector block on cylinder head. This is to

prevent contamination of the fuel injection

system.

ProCarManuals.com

Page 133 of 667

12ENGINE

8

REPAIR

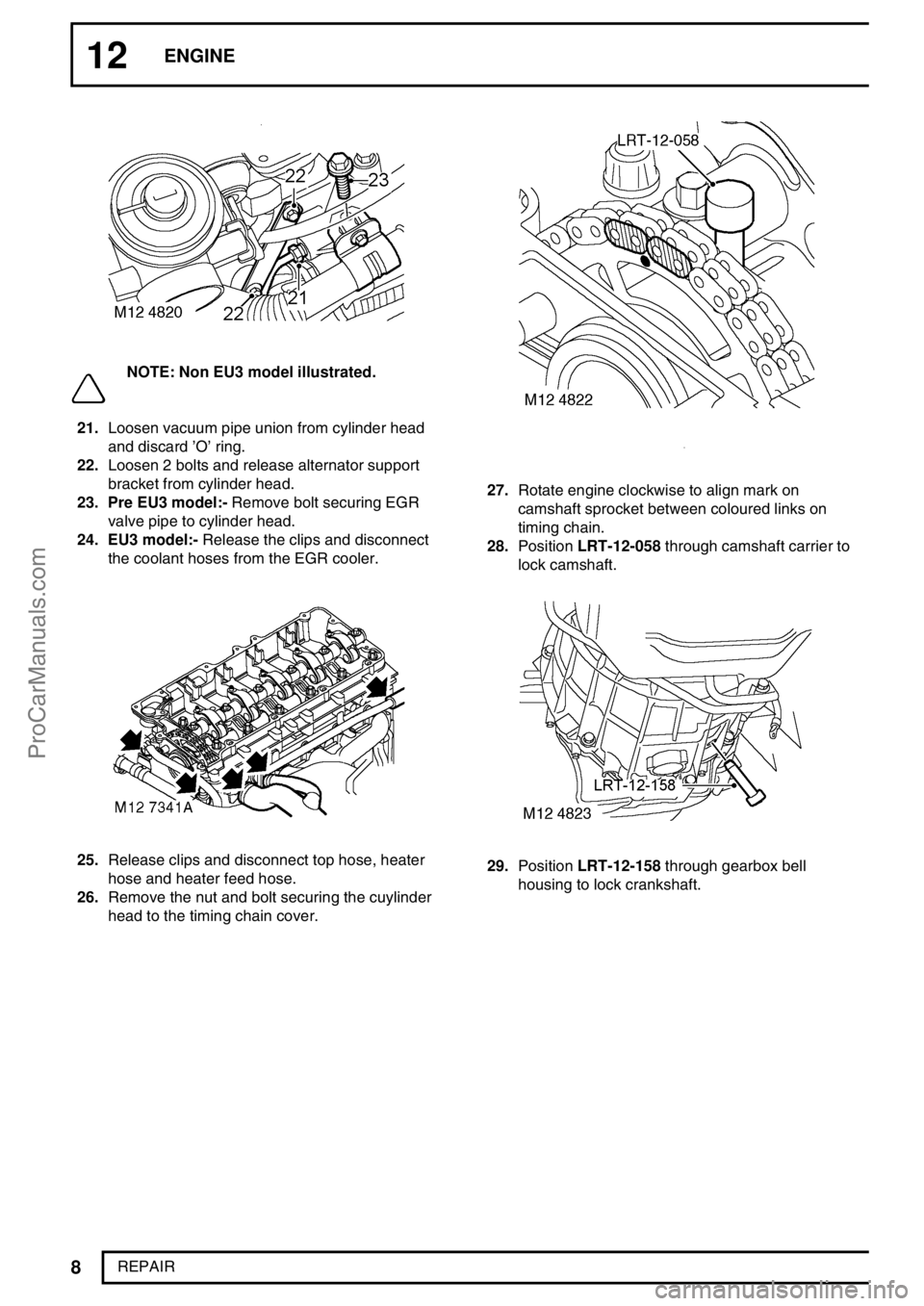

NOTE: Non EU3 model illustrated.

21.Loosen vacuum pipe union from cylinder head

and discard’O’ring.

22.Loosen 2 bolts and release alternator support

bracket from cylinder head.

23. Pre EU3 model:-Remove bolt securing EGR

valve pipe to cylinder head.

24. EU3 model:-Release the clips and disconnect

the coolant hoses from the EGR cooler.

25.Release clips and disconnect top hose, heater

hose and heater feed hose.

26.Remove the nut and bolt securing the cuylinder

head to the timing chain cover.

27.Rotate engine clockwise to align mark on

camshaft sprocket between coloured links on

timing chain.

28.PositionLRT-12-058through camshaft carrier to

lock camshaft.

29.PositionLRT-12-158through gearbox bell

housing to lock crankshaft.

ProCarManuals.com

Page 134 of 667

ENGINE

9

REPAIR

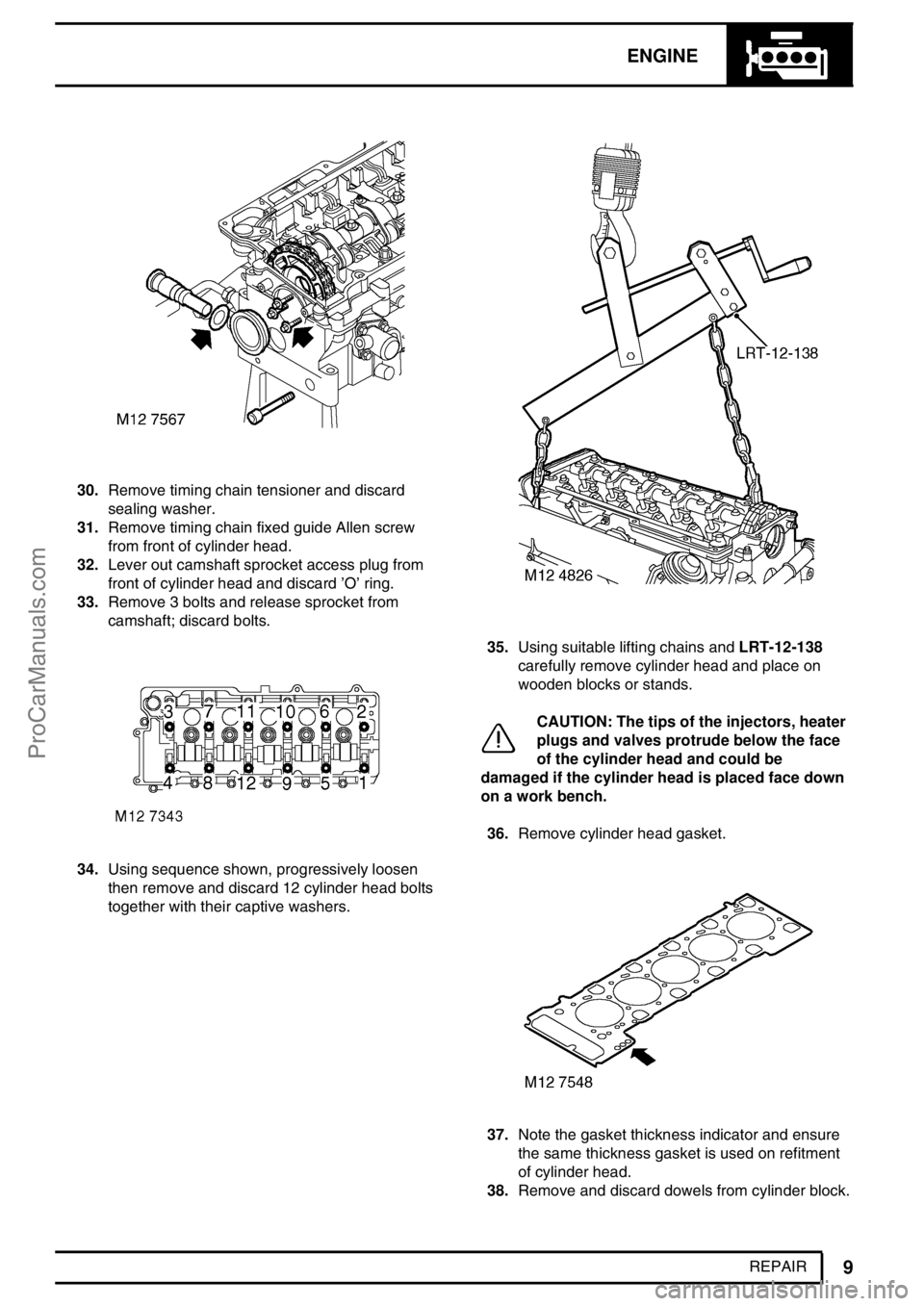

30.Remove timing chain tensioner and discard

sealing washer.

31.Remove timing chain fixed guide Allen screw

from front of cylinder head.

32.Lever out camshaft sprocket access plug from

front of cylinder head and discard’O’ring.

33.Remove 3 bolts and release sprocket from

camshaft; discard bolts.

34.Using sequence shown, progressively loosen

then remove and discard 12 cylinder head bolts

together with their captive washers.

35.Using suitable lifting chains andLRT-12-138

carefully remove cylinder head and place on

wooden blocks or stands.

CAUTION: The tips of the injectors, heater

plugs and valves protrude below the face

of the cylinder head and could be

damaged if the cylinder head is placed face down

on a work bench.

36.Remove cylinder head gasket.

37.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of cylinder head.

38.Remove and discard dowels from cylinder block.

ProCarManuals.com