engine LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 155 of 667

12ENGINE

30

REPAIR Refit

10.Clean oil cooler and mating faces.

11.Fit oil pressure switch and tighten to9Nm(7

lbf.ft).

12.Position oil cooler using a new gasket and

tighten bolts to25 Nm (18 lbf.ft).

13.Position oil filter adaptor, fit new gasket and

tighten bolts to25 Nm (18 lbf.ft).

14.Position oil filter element hand tight then a

further half turn.

15.Position coolant hose to oil cooler and secure

clip.

16.Position coolant pipe and tighten clutch housing

bolt to50 Nm (37 lbf.ft).

17.Connect oil pressure switch multiplug.

18.Fit centrifuge assembly.See this Section.

19.Refill cooling system.See COOLING SYSTEM,

Adjustment.

20.Top up engine oil.CENTRIFUGE ASSEMBLY

Service repair no - 12.60.90

Remove

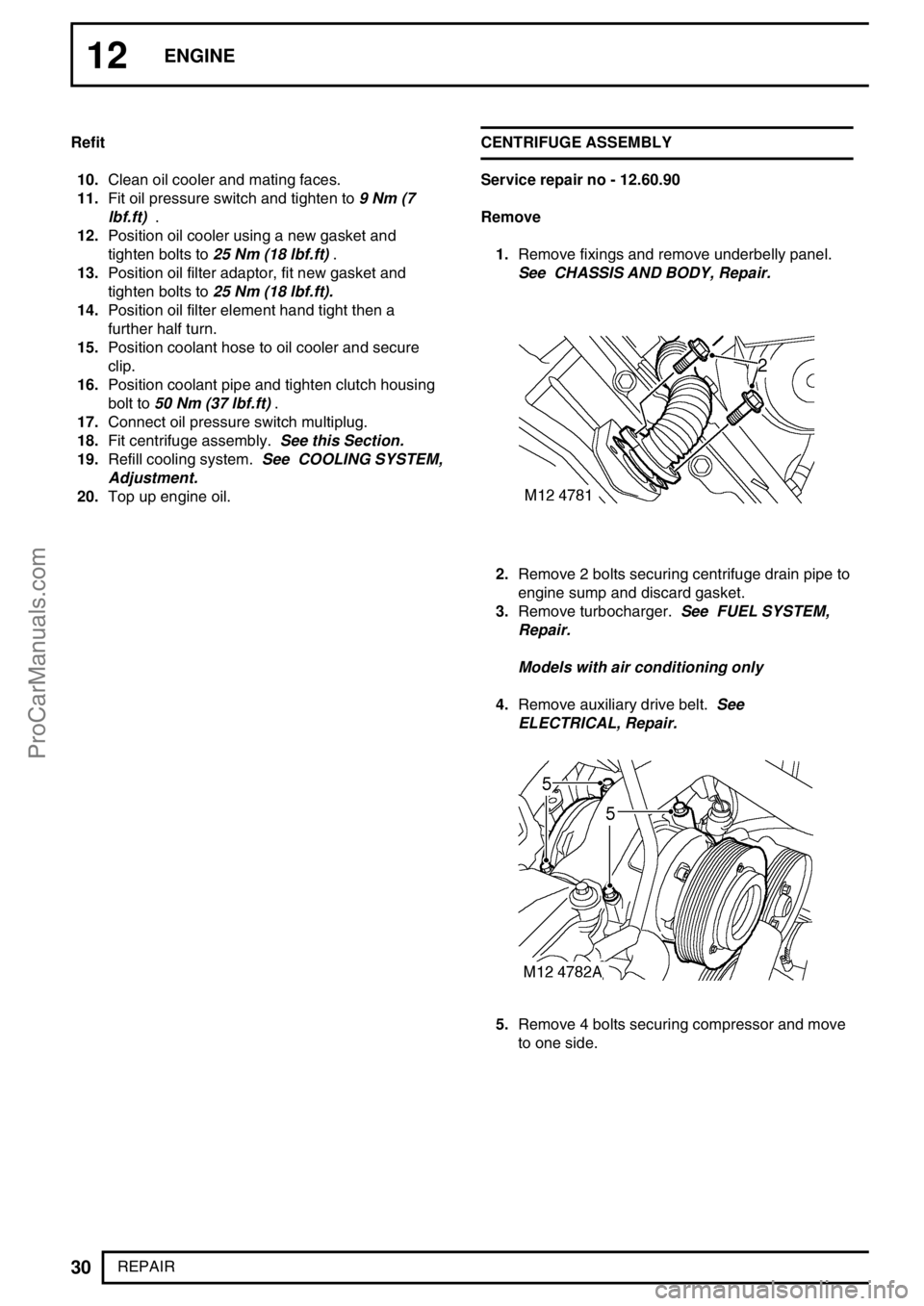

1.Remove fixings and remove underbelly panel.

See CHASSIS AND BODY, Repair.

2.Remove 2 bolts securing centrifuge drain pipe to

engine sump and discard gasket.

3.Remove turbocharger.See FUEL SYSTEM,

Repair.

Models with air conditioning only

4.Remove auxiliary drive belt.See

ELECTRICAL, Repair.

5.Remove 4 bolts securing compressor and move

to one side.

ProCarManuals.com

Page 156 of 667

ENGINE

31

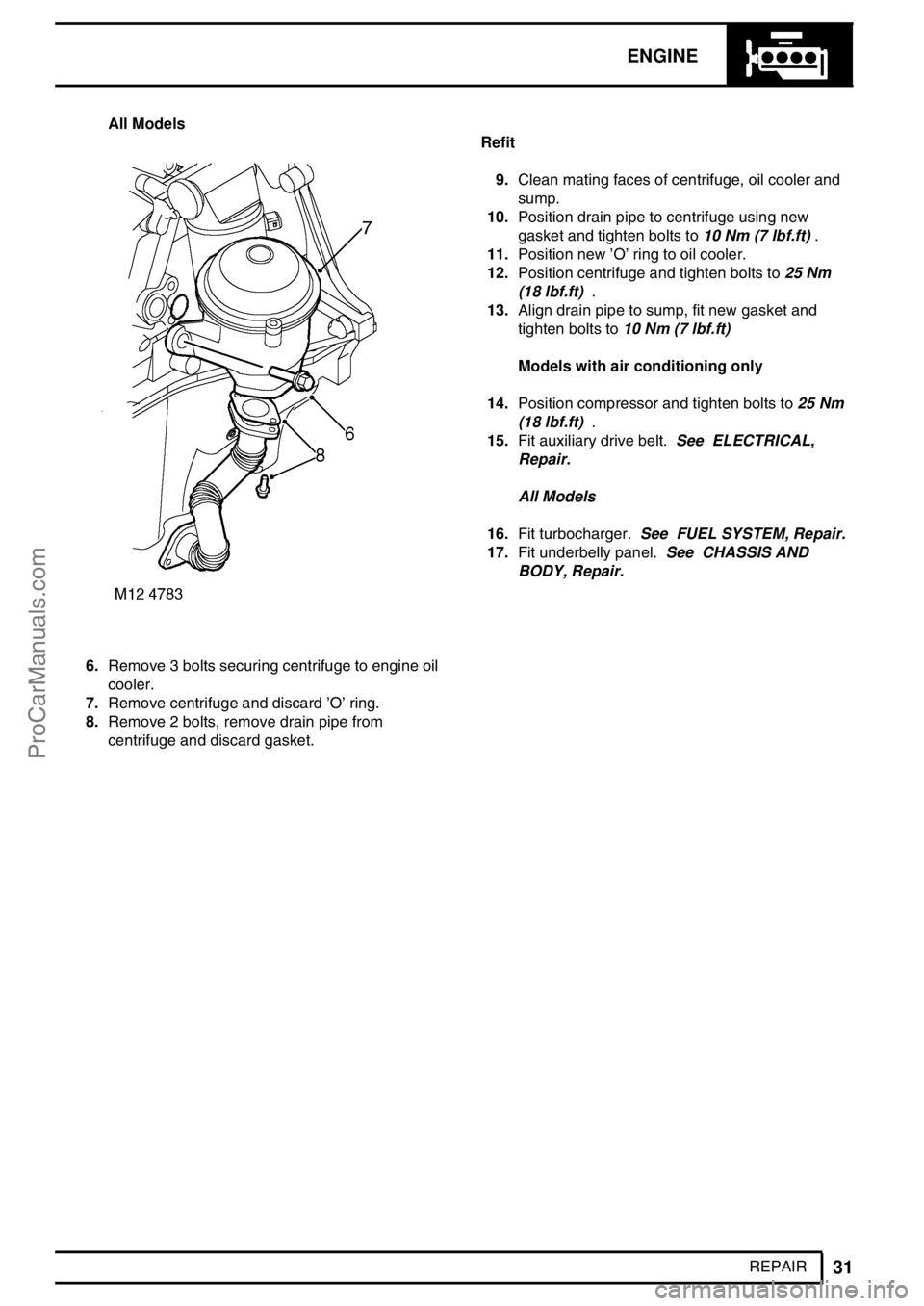

REPAIR All Models

6.Remove 3 bolts securing centrifuge to engine oil

cooler.

7.Remove centrifuge and discard’O’ring.

8.Remove 2 bolts, remove drain pipe from

centrifuge and discard gasket.Refit

9.Clean mating faces of centrifuge, oil cooler and

sump.

10.Position drain pipe to centrifuge using new

gasket and tighten bolts to10 Nm (7 lbf.ft).

11.Position new’O’ring to oil cooler.

12.Position centrifuge and tighten bolts to25 Nm

(18 lbf.ft).

13.Align drain pipe to sump, fit new gasket and

tighten bolts to10 Nm (7 lbf.ft)

Models with air conditioning only

14.Position compressor and tighten bolts to25 Nm

(18 lbf.ft).

15.Fit auxiliary drive belt.See ELECTRICAL,

Repair.

All Models

16.Fit turbocharger.See FUEL SYSTEM, Repair.

17.Fit underbelly panel.See CHASSIS AND

BODY, Repair.

ProCarManuals.com

Page 157 of 667

12ENGINE

32

REPAIR ROTOR - CENTRIFUGE

Service repair no - 12.60.91

Remove

1.Remove 2 bolts and remove centrifuge cover.

2.Remove and discard’O’ring and rotor

Refit

3.Clean centrifuge body and cover.

4.Fit new rotor.

5.Fit centrifuge cover using new’O’ring and

tighten bolts to9 Nm (7 lbf.ft).OIL SEAL - TIMING COVER

Service repair no - 12.65.05

Remove

1.Remove crankshaft pulley.See this Section.

2.PositionLRT-12-092into crankshaft front oil seal

and discard seal.

Refit

3.Using a lint free cloth, thoroughly clean oil seal

recess and the running surface on crankshaft

pulley.

4.Position new seal into timing chain housing. Drift

seal into place usingLRT-12-156.

5.RemoveLRT-12-156.

6.Fit crankshaft pulley.See this Section.

ProCarManuals.com

Page 158 of 667

ENGINE

33

REPAIR TIMING CHAIN AND SPROCKETS

Service repair no - 12.65.13

Remove

1.Remove crankshaft front oil seal.See this

Section.

2.Remove cylinder head gasket.See this

Section.

3.Remove sump gasket.See this Section.

4.Release clip securing vacuum pump drain hose

to timing chain cover.

5.Remove 8 bolts securing timing chain cover.

6.Remove cover.

7.Remove timing chain and camshaft sprocket.

8.Remove 2 bolts and remove timing chain fixed

guide.

9.Remove bolt and remove timing chain adjustable

guide.

10.Remove bolt securing oil pump drive sprocket.

11.Remove crankshaft sprocket, oil pump drive

chain and sprocket.

12.Remove bolt and remove timing chain lubrication

jet.

Refit

13.Clean timing chain lubrication jet.

14.Fit lubrication jet and tighten bolt to10 Nm (7

lbf.ft).

15.Clean oil pump drive sprocket bolt threads.

16.Clean timing sprockets and chain guides.

17.Ensure that crankshaft is set to TDC firing No. 1

cylinder.

18.Fit oil pump drive chain to crankshaft sprocket

and fit sprocket to crankshaft.

19.Fit sprocket to oil pump.

20.Apply Loctite 242 to oil pump sprocket bolt

threads and tighten bolt to25 Nm (18 lbf.ft).

21.Fit timing chain fixed guide and tighten M10 bolt

to45 Nm (34 lbf.ft)and M6 bolt to10 Nm (7

lbf.ft).

22.Fit timing chain adjustable guide and tighten bolt

to25 Nm (18 lbf.ft).

ProCarManuals.com

Page 159 of 667

12ENGINE

34

REPAIR

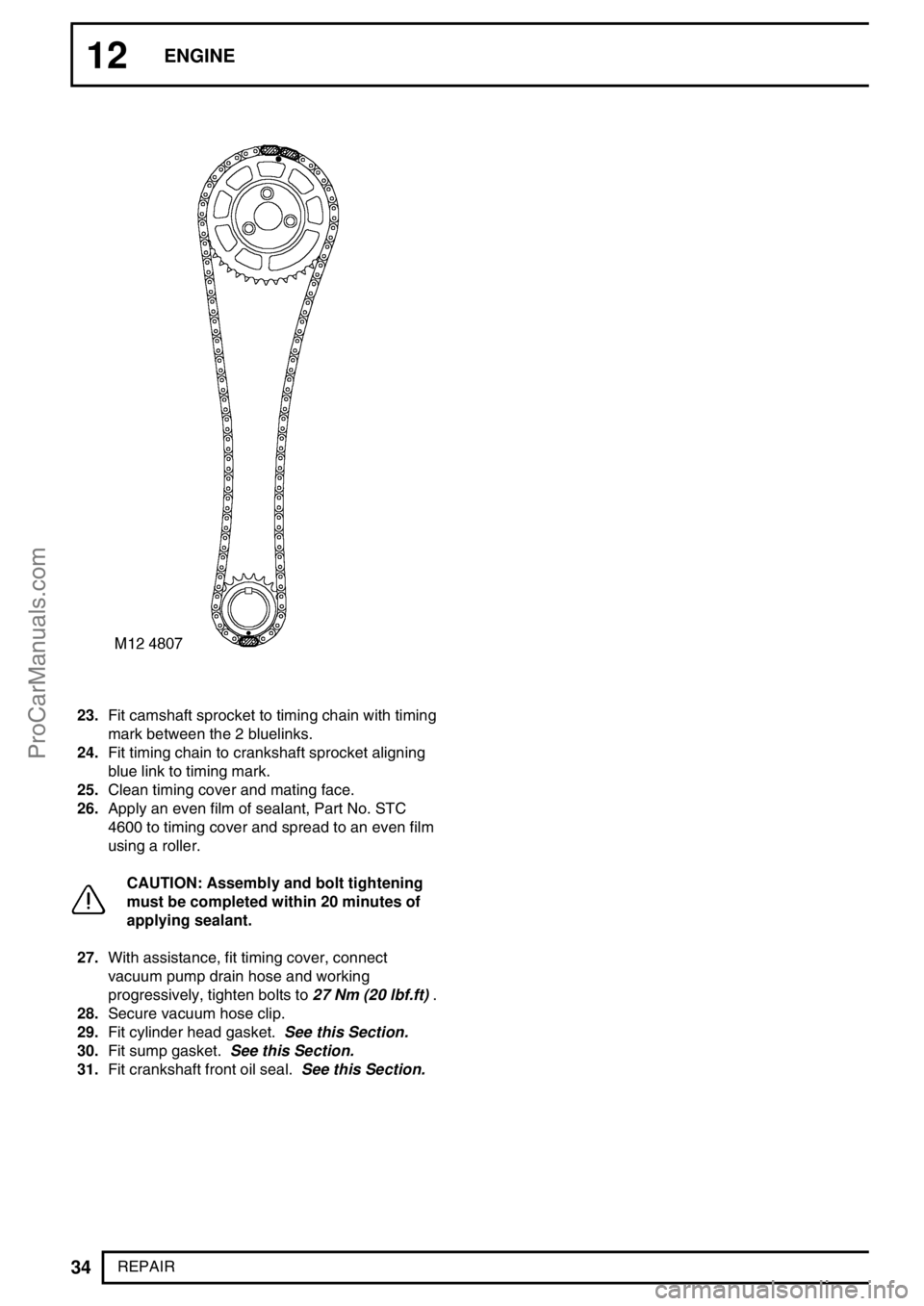

23.Fit camshaft sprocket to timing chain with timing

mark between the 2 bluelinks.

24.Fit timing chain to crankshaft sprocket aligning

blue link to timing mark.

25.Clean timing cover and mating face.

26.Apply an even film of sealant, Part No. STC

4600 to timing cover and spread to an even film

using a roller.

CAUTION: Assembly and bolt tightening

must be completed within 20 minutes of

applying sealant.

27.With assistance, fit timing cover, connect

vacuum pump drain hose and working

progressively, tighten bolts to27 Nm (20 lbf.ft).

28.Secure vacuum hose clip.

29.Fit cylinder head gasket.See this Section.

30.Fit sump gasket.See this Section.

31.Fit crankshaft front oil seal.See this Section.

ProCarManuals.com

Page 160 of 667

ENGINE

1

OVERHAUL GASKET - INLET MANIFOLD

Service repair no - 30.15.08.01

Remove

NOTE: The following procedure covers

both EU3 and non EU3 engines

NOTE: EU3 Engine in main illustration, Pre

EU3 condition shown in inset.

1.Remove and discard 2 Allen screws securing

EGR pipe or EGR cooler to exhaust manifold.

2.Remove bolt securing EGR pipe to cylinder

head, (if fitted)

3.Disconnect multiplug from IAT and MAP sensor.

4.Remove 4 bolts securing fuel cooler to inlet

manifold. and remove cooler.

5.Remove bolt securing engine dipstick tube to

camshaft carrier.

6.Release and remove engine dipstick tube.

7.Remove’O’ring from dip stick tube.

8.Disconnect 4 leads from glow plugs.

9.Remove 2 nuts and 8 bolts and remove inlet

manifold.

10.Remove manifold gasket.Refit

1.Clean inlet manifold and mating face, clean

mating faces of EGR pipe, exhaust manifold and

EGR cooler (if fitted).

2.Fit new gasket.

3.Position inlet manifold and working from the

centre outwards, fit inlet manifold nuts and bolts

and tighten to25 Nm (18 lbf.ft).

4.Connect glow plug leads.

5.Clean engine dipstick tube.

6.Fit new’O’ring to dipstick tube.

7.Fit engine dipstick tube to camshaft carrier and

tighten bolt to10 Nm (7 lbf.ft).

8.Position fuel cooler and tighten bolts to25 Nm

(18 lbf.ft).

9.Connect multiplug to IAT and MAP sensor.

10.Position EGR pipe or EGR cooler to exhaust

manifold and using new Allen screws tighten to

10 Nm (7 lbf.ft).

11.Fit EGR pipe clamp to cylinder head, (if fitted)

and tighten bolt to10 Nm (7 lbf.ft).

ProCarManuals.com

Page 161 of 667

12ENGINE

2

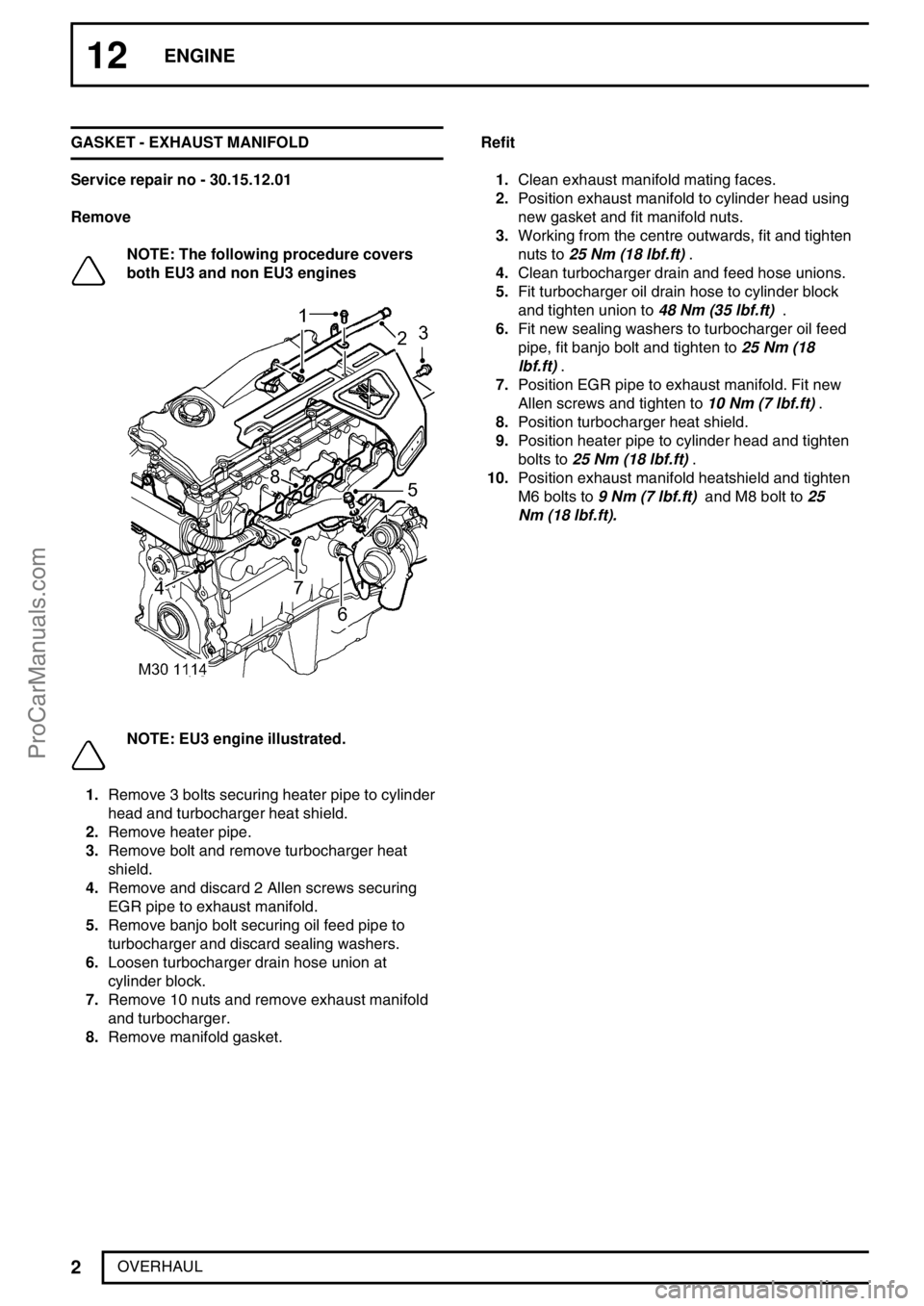

OVERHAUL GASKET - EXHAUST MANIFOLD

Service repair no - 30.15.12.01

Remove

NOTE: The following procedure covers

both EU3 and non EU3 engines

NOTE: EU3 engine illustrated.

1.Remove 3 bolts securing heater pipe to cylinder

head and turbocharger heat shield.

2.Remove heater pipe.

3.Remove bolt and remove turbocharger heat

shield.

4.Remove and discard 2 Allen screws securing

EGR pipe to exhaust manifold.

5.Remove banjo bolt securing oil feed pipe to

turbocharger and discard sealing washers.

6.Loosen turbocharger drain hose union at

cylinder block.

7.Remove 10 nuts and remove exhaust manifold

and turbocharger.

8.Remove manifold gasket.Refit

1.Clean exhaust manifold mating faces.

2.Position exhaust manifold to cylinder head using

new gasket and fit manifold nuts.

3.Working from the centre outwards, fit and tighten

nuts to25 Nm (18 lbf.ft).

4.Clean turbocharger drain and feed hose unions.

5.Fit turbocharger oil drain hose to cylinder block

and tighten union to48 Nm (35 lbf.ft).

6.Fit new sealing washers to turbocharger oil feed

pipe, fit banjo bolt and tighten to25 Nm (18

lbf.ft).

7.Position EGR pipe to exhaust manifold. Fit new

Allen screws and tighten to10 Nm (7 lbf.ft).

8.Position turbocharger heat shield.

9.Position heater pipe to cylinder head and tighten

bolts to25 Nm (18 lbf.ft).

10.Position exhaust manifold heatshield and tighten

M6 bolts to9 Nm (7 lbf.ft)and M8 bolt to25

Nm (18 lbf.ft).

ProCarManuals.com

Page 162 of 667

ENGINE

3

OVERHAUL GASKET - CYLINDER HEAD

Service repair no - 12.29.02.01

Remove

CAUTION: The following procedures

should only be carried out when cylinder

head is to be overhauled; for replacement

of cylinder head gasket only, see Repairs section -

Gasket - Cylinder head.

NOTE: The following procedure covers

both EU3 and non EU3 engines

1.Remove exhaust manifold gasket.See

MANIFOLD AND EXHAUST SYSTEM, Repair.

2.Remove inlet manifold gasket.See MANIFOLD

AND EXHAUST SYSTEM, Repair.

3. Models with EGR cooler:Remove and discard

2 Allen screws securing EGR pipe to cooler.

4.Progressively loosen then remove 13 bolts

securing camshaft cover, remove cover; remove

and discard gasket.

5.Remove isolators and sealing washers from

cover.

6.Disconnect injector multiplug from camshaft

carrier.

7.Disconnect multiplug from ECT sensor.

8.Remove bolt securing alternator strap bracket to

cylinder head.

9.Set engine to TDC firing - No. 1 cylinder -

coloured links on timing chain are aligned with

timing mark on camshaft sprocket.

10.Fit timing pinLRT-12-058into slot in camshaft.

ProCarManuals.com

Page 163 of 667

12ENGINE

4

OVERHAUL

11.Disconnect alternator/vacuum pump oil feed pipe

union from cylinder head, remove and discard

’O’ring.

12.Remove camshaft sprocket access plug from

front of cylinder head, remove and discard’O’

ring.

13.Remove timing chain fixed guide Allen screw.

14.Remove timing chain tensioner, remove and

discard sealing washer.

15.Remove and discard 3 bolts securing camshaft

sprocket to camshaft; release sprocket from

camshaft.

16.Remove bolt and nut securing front of cylinder

head to timing chain cover.

17.Using sequence shown, progressively loosen

then remove 12 cylinder head bolts; discard

bolts together with their captive washers.

18.Using assistance, remove cylinder head and

place on 2 wooden blocks.

CAUTION: Cylinder head is dowel located,

do not tap it sideways to free it from

cylinder block. Support both ends of

cylinder head on blocks of wood. With the

camshaft carrier bolted down, the injector nozzles

and some of the valves will protrude from the face

of the cylinder head.

19.Remove the cylinder head gasket.

20.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of the cylinder head.

CAUTION: If new pistons, connecting rods

or crankshaft are fitted, it will be

necessary to measure piston stand proud

in order to determine thickness of gasket

required.See this Section.

21.Remove and discard 2 plastic locating dowels

from cylinder block.

22.Carry out cylinder head overhaul procedures.

See this Section.

ProCarManuals.com

Page 164 of 667

ENGINE

5

OVERHAUL Refit

1.Thoroughly clean cylinder block and cylinder

head mating faces.

2.Ensure coolant and oil passageways are clear

and bolt holes are clean and dry.

3.Ensure locating dowel holes in cylinder block are

clean and dry.

4.Fit new plastic locating dowels in cylinder block.

5.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

CAUTION: Gasket must be fitted dry.

6.Ensure that camshaft timing pinLRT-12-158is

still in position and using assistance, fit cylinder

head.

7.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

CAUTION: Cylinder head bolts are

pre-lubricated and do not require

additional lubrication.

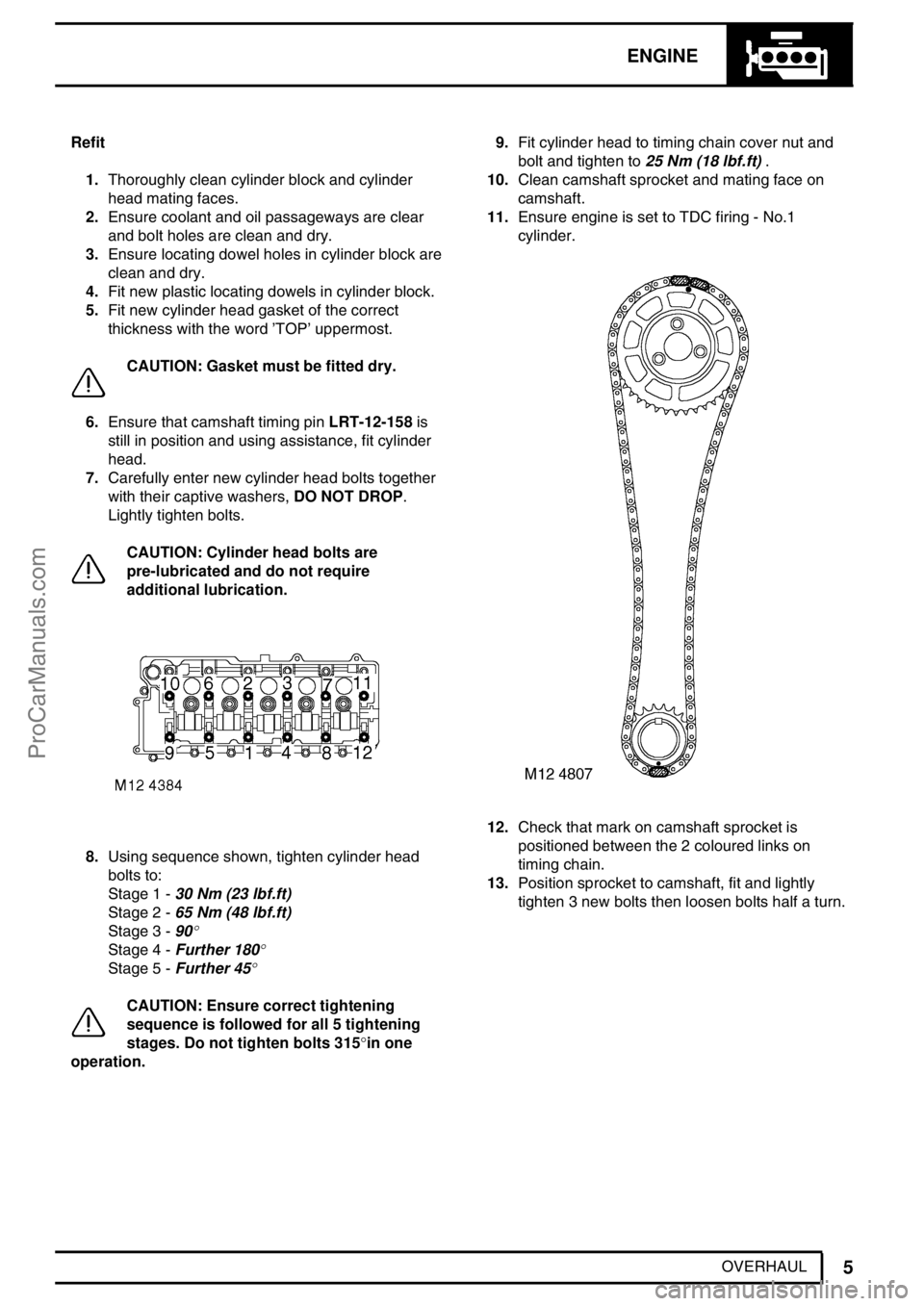

8.Using sequence shown, tighten cylinder head

bolts to:

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90

°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.9.Fit cylinder head to timing chain cover nut and

bolt and tighten to25 Nm (18 lbf.ft).

10.Clean camshaft sprocket and mating face on

camshaft.

11.Ensure engine is set to TDC firing - No.1

cylinder.

12.Check that mark on camshaft sprocket is

positioned between the 2 coloured links on

timing chain.

13.Position sprocket to camshaft, fit and lightly

tighten 3 new bolts then loosen bolts half a turn.

ProCarManuals.com