fuel LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 245 of 667

18ENGINE MANAGEMENT SYSTEM

22

DESCRIPTION AND OPERATION SWITCH - BRAKE PEDAL

The brake pedal switch is located at the rear of the brake pedal box, and activates when the brake pedal is

operated. The ECM uses the signal from the brake pedal to activate the brake lamps and to limit fuelling under

braking.

The brake pedal switch can fail in any of the following ways:

Switch open circuit.

Short circuit to vehicle supply.

Short circuit to earth.

SWITCH - CLUTCH PEDAL

The clutch pedal switch is located on the clutch master cylinder and is activated when the clutch pedal is operated.

The ECM uses the signal from the clutch pedal switch to provide surge damping during gear change. Surge

damping stops engine speed rising dramatically (engine flaring) during gear change. Surge damping assists

driveability as follows:

Smoother gear change.

Greater exhaust gas emission control.

Improved fuel consumption.

Input / Output

When the clutch pedal is in the rest position, the clutch switch is closed. This allows a feed to flow from the switch

(C0667-1) to the ECM (C0658-35) on a black/white wire. When the clutch pedal is pressed the switch contacts

open, cutting the feed to the ECM.

The clutch pedal switch can fail in any one of the following ways:

Switch open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

In the event of a clutch pedal switch failure surge damping will be inactive.

ProCarManuals.com

Page 249 of 667

18ENGINE MANAGEMENT SYSTEM

26

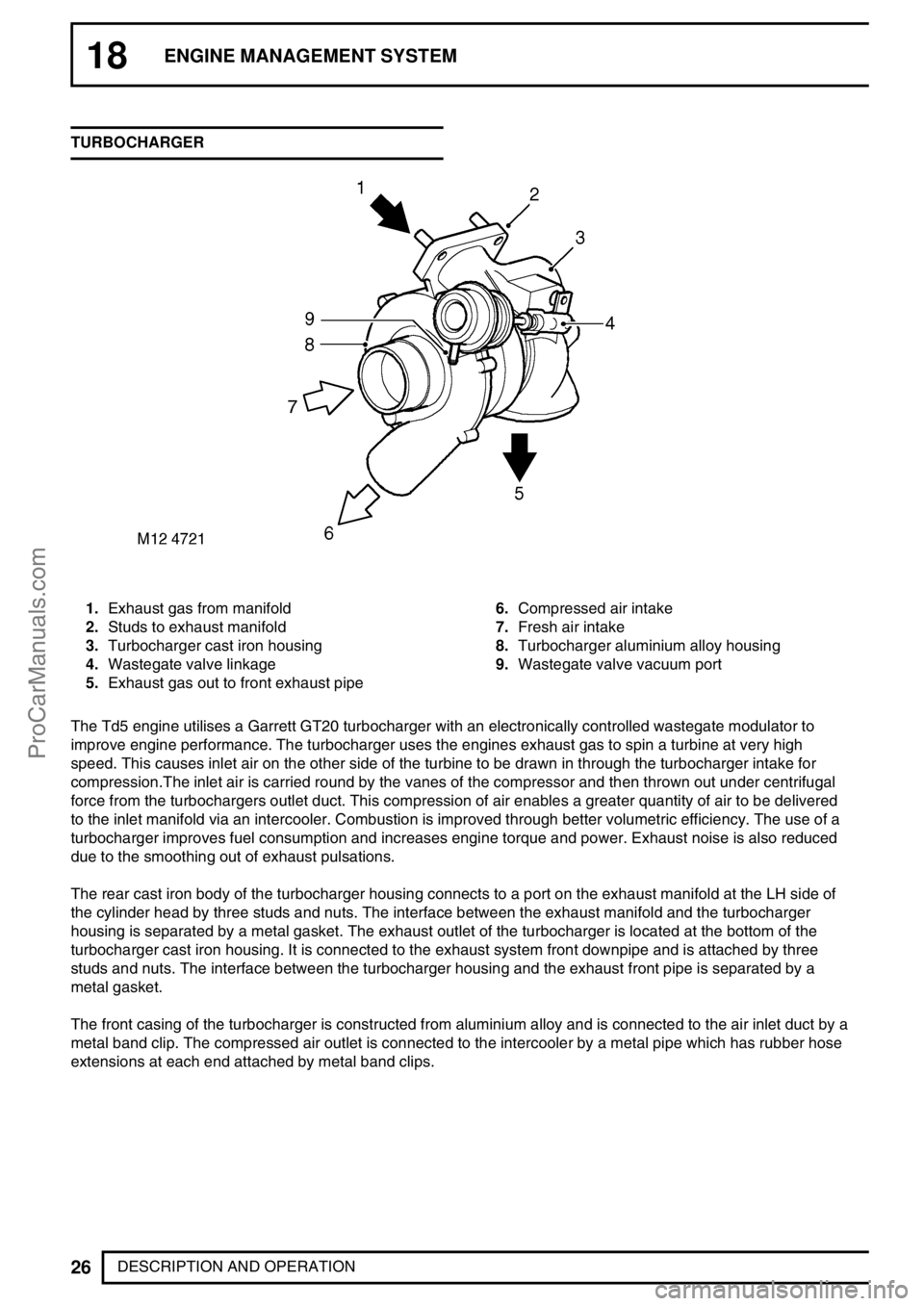

DESCRIPTION AND OPERATION TURBOCHARGER

1.Exhaust gas from manifold

2.Studs to exhaust manifold

3.Turbocharger cast iron housing

4.Wastegate valve linkage

5.Exhaust gas out to front exhaust pipe6.Compressed air intake

7.Fresh air intake

8.Turbocharger aluminium alloy housing

9.Wastegate valve vacuum port

The Td5 engine utilises a Garrett GT20 turbocharger with an electronically controlled wastegate modulator to

improve engine performance. The turbocharger uses the engines exhaust gas to spin a turbine at very high

speed. This causes inlet air on the other side of the turbine to be drawn in through the turbocharger intake for

compression.The inlet air is carried round by the vanes of the compressor and then thrown out under centrifugal

force from the turbochargers outlet duct. This compression of air enables a greater quantity of air to be delivered

to the inlet manifold via an intercooler. Combustion is improved through better volumetric efficiency. The use of a

turbocharger improves fuel consumption and increases engine torque and power. Exhaust noise is also reduced

due to the smoothing out of exhaust pulsations.

The rear cast iron body of the turbocharger housing connects to a port on the exhaust manifold at the LH side of

the cylinder head by three studs and nuts. The interface between the exhaust manifold and the turbocharger

housing is separated by a metal gasket. The exhaust outlet of the turbocharger is located at the bottom of the

turbocharger cast iron housing. It is connected to the exhaust system front downpipe and is attached by three

studs and nuts. The interface between the turbocharger housing and the exhaust front pipe is separated by a

metal gasket.

The front casing of the turbocharger is constructed from aluminium alloy and is connected to the air inlet duct by a

metal band clip. The compressed air outlet is connected to the intercooler by a metal pipe which has rubber hose

extensions at each end attached by metal band clips.

ProCarManuals.com

Page 251 of 667

18ENGINE MANAGEMENT SYSTEM

28

DESCRIPTION AND OPERATION OPERATION

Engine Management

The ECM controls the operation of the engine using stored information within its memory. This guarantees

optimum performance from the engine in terms of torque delivery, fuel consumption and exhaust emissions in all

operating conditions, while still giving optimum driveability.

The ECM will receive information from its sensors under all operating conditions, especially during:

Cold starting.

Hot starting.

Idle.

Wide open throttle.

Acceleration.

Adaptive strategy.

Backup strategy for sensor failures.

The ECM receives information from various sensors to determine the current operating state of the engine. The

ECM then refers this information to stored values in its memory and makes any necessary changes to optimise

air/fuel mixture and fuel injection timing. The ECM controls the air/fuel mixture and fuel injection timing via the

Electronic Unit Injectors (EUI), by the length of time the EUI’s are to inject fuel into the cylinder. This is a rolling

process and is called adaptive strategy. By using this adaptive strategy the ECM is able to control the engine to

give optimum driveability under all operating conditions.

During cold start conditions the ECM uses ECT information to allow more fuel to be injected into the cylinders.

This, combined with the glow plug timing strategy supplied by the ECM, facilitates good cold starting.

During hot start conditions, the ECM uses ECT and FT information to implement the optimum fuelling strategy to

facilitate good hot starting.

During idle and wide open throttle conditions, the ECM uses mapped information within its memory to respond to

input information from the TP sensor to implement the optimum fuelling strategy to facilitate idle and wide open

throttle.

To achieve an adaptive strategy for acceleration, the ECM uses input information from the CKP sensor, the TP

sensor, the ECT sensor, the MAP/IAT sensor, and the FT sensor. This is compared to mapped information within

its memory to implement the optimum fuelling strategy to facilitate acceleration.

Fuel Delivery / Injection Control

The fuel delivery/injection control delivers a precise amount of finely atomised fuel to mix with the air in the

combustion chamber to create a controlled explosion. To precisely control fuel delivery and control fuel injection,

the following input conditions must be met:

CKP information.

Injection timing map information.

FT information.

ECT information.

The ECM monitors the conditions required for optimum combustion of fuel in the cylinder from the various sensors

around the engine and then compares it against stored information. From this calculation, the ECM can adjust the

quantity and timing of the fuel being delivered into the cylinder. The ECM uses CKP information as follows:

To calculate engine speed.

To determine engine crankshaft position.

Engine speed and crankshaft position allows the ECM to determine fuel injection timing.

The ECM also uses ECT and FT information to allow optimum fuel delivery and injection control for all engine

coolant and fuel temperatures.

ProCarManuals.com

Page 254 of 667

19 - FUEL SYSTEM

CONTENTS

Page

DESCRIPTION AND OPERATION

COMPONENT LOCATION 1...................................................................................

DESCRIPTION 2.....................................................................................................

FUEL PUMP AND FUEL GAUGE SENDER 3........................................................

FUEL PRESSURE REGULATOR 5........................................................................

INJECTORS 7.........................................................................................................

FUEL FILTER 9.......................................................................................................

WATER SENSOR 10..............................................................................................

OPERATION 11......................................................................................................

ADJUSTMENT

HEATER PLUG TEST 1..........................................................................................

FUEL SYSTEM - BLEED 1.....................................................................................

FUEL TANK - DRAIN 2...........................................................................................

REPAIR

ELEMENT - AIR FILTER 1......................................................................................

SENSOR - FUEL TEMPERATURE 1......................................................................

SWITCH - INERTIA - FUEL CUT OFF 2.................................................................

SENSOR - MASS AIR FLOW (MAF) 2....................................................................

SENSOR - COMBINED MAP AND IAT 3................................................................

SENSOR - AMBIENT AIR PRESSURE (AAP) 3.....................................................

ELEMENT - FUEL FILTER 4...................................................................................

COOLER - FUEL 4..................................................................................................

TURBOCHARGER 5...............................................................................................

FILTER ASSEMBLY - AIR 6...................................................................................

INJECTOR - SET 7.................................................................................................

HEATER PLUGS - SET 9.......................................................................................

INTERCOOLER 9...................................................................................................

POTENTIOMETER - THROTTLE 10......................................................................

PUMP - FUEL 10.....................................................................................................

REGULATOR - FUEL PRESSURE 11....................................................................

FUEL TANK 12.......................................................................................................

NECK - FUEL TANK FILLER 14.............................................................................

ProCarManuals.com

Page 256 of 667

FUEL SYSTEM

1

DESCRIPTION AND OPERATION COMPONENT LOCATION

1.HP stage

2.LP stage

3.Filters

4.Jet pump

5.Fuel pump and fuel gauge sender unit

6.LP return connection

7.LP feed connection8.HP feed connection

9.Air bleed connection

10.Fuel filter

11.Water sensor

12.Fuel cooler

13.Fuel pressure regulator

14.Electronic Unit Injectors

ProCarManuals.com

Page 257 of 667

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION DESCRIPTION

General

The fuel delivery system comprises a fuel tank, fuel pump, fuel pressure regulator, five injectors and a fuel filter.

The system is controlled by the ECM, which energises the fuel pump relay and controls the operation and timing

of each injector solenoid.

Unlike other Diesel engines, the Td5 has no injection pump. The diesel direct injection system receives fuel at

pressure from a two stage fuel pump located in the fuel tank. The system incorporates a fuel return to the fuel

pump, via a fuel cooler attached to the inlet manifold, and a fuel filter. A fuel pressure regulator is located in a

housing on the rear of the cylinder head. The regulator maintains the fuel delivered to the injectors at a constant

pressure and returns excess fuel back to the fuel filter and pump via the fuel cooler.

A fuel filter is positioned on the chassis longitudinal, below the RH rear wheel arch. The fuel feed and return to and

from the engine passes through the filter. The filter also incorporates a water sensor, which illuminates a warning

lamp in the instrument pack.

A moulded fuel tank is located at the rear underside of the vehicle between the chassis longitudinals. The tank

provides the attachment for the fuel pump and the fuel gauge sender unit, which is located inside the tank.

Fuel Tank and Breather

The fuel tank and breather system is a major part of the fuel delivery system. The fuel tank and breathers are

located at the rear of the vehicle between the chassis longitudinals.

Fuel Tank

The moulded fuel tank is made from High Molecular Weight (HMW) High Density Polyethylene (HDPE), and is

manufactured using a proportion of recycled plastic.

The tank is held in position by a metal cradle which is secured to the chassis cross members by four bolts, two

holding the front of the cradle in position, two holding the rear. The fuel tank has a useable capacity of 75 litres

(16.5 gallons).

An aperture in the top surface of the tank allows for the fitment of the fuel pump and fuel gauge sender unit, which

is retained with a locking ring. A reflective metallic covering is attached to the tank with three scrivets to shield the

tank from heat generated by the exhaust system.

Fuel Tank Breather System

The fuel tank filler tube incorporates a tank vent which allows air and fuel vapour displaced from the tank when

filling to vent to atmosphere via the filler neck.

A breather spout within the tank controls the tank’Full’height. When fuel covers the spout it prevents fuel vapour

and air from escaping from the tank. This causes the fuel to’back-up’in the filler tube and shuts off the filler gun.

The position of the spout ensures that when the filler gun shuts off, a vapour space of approximately 10% of the

tanks total capacity remains. The vapour space ensures that the Roll Over Value (ROV) is always above the fuel

level and vapour can escape and allow the tank to breathe.

The ROV is welded to the top surface of the tank. It is connected by a tube to the filler tube, which in turn is

connected to the atmospheric vent pipe. The ROV allows fuel vapour to pass through it during normal vehicle

operation. In the event of the vehicle being overturned the valve shuts off, sealing the tank and preventing fuel

from spilling from the atmospheric vent pipe.

ProCarManuals.com

Page 258 of 667

FUEL SYSTEM

3

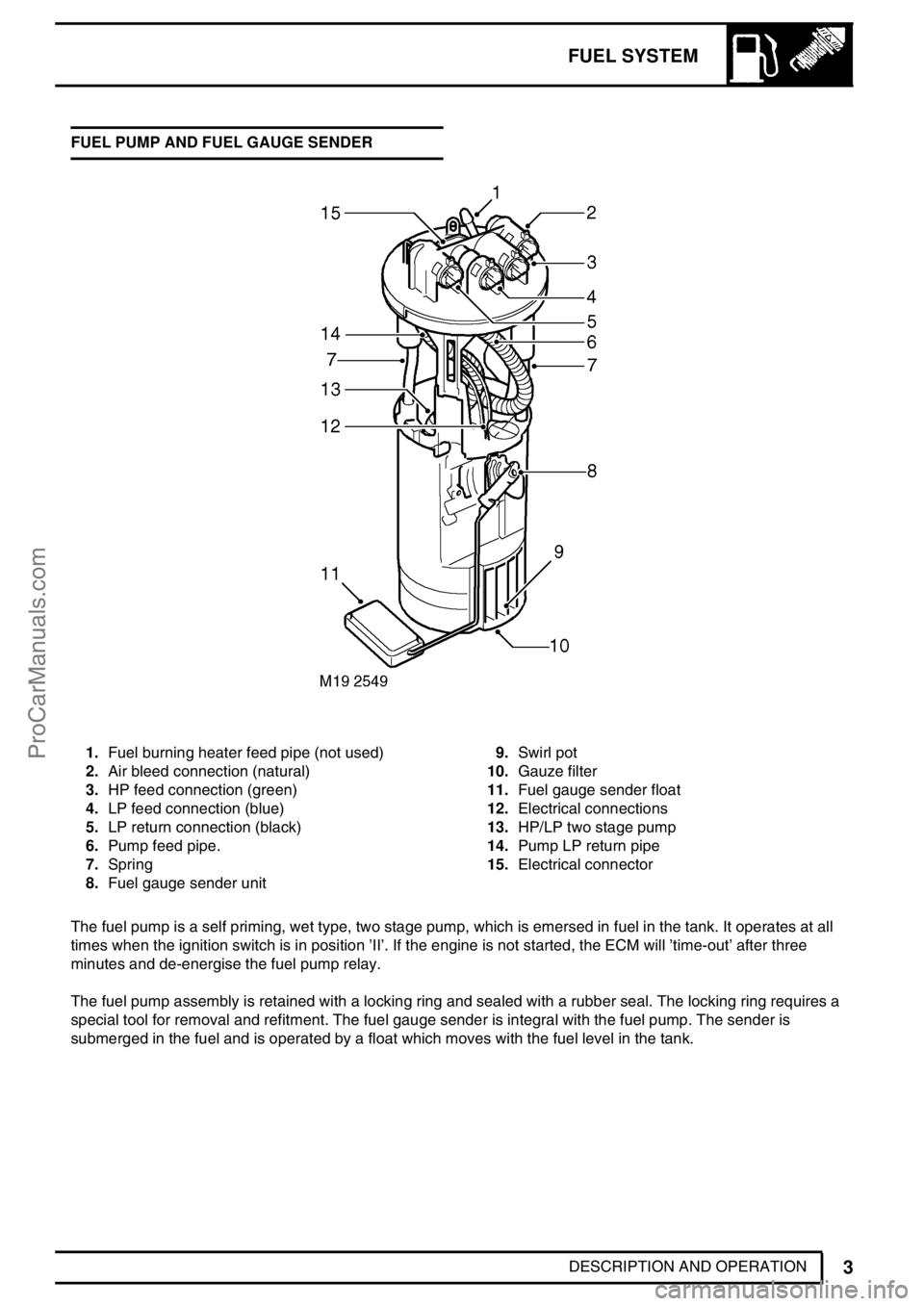

DESCRIPTION AND OPERATION FUEL PUMP AND FUEL GAUGE SENDER

1.Fuel burning heater feed pipe (not used)

2.Air bleed connection (natural)

3.HP feed connection (green)

4.LP feed connection (blue)

5.LP return connection (black)

6.Pump feed pipe.

7.Spring

8.Fuel gauge sender unit9.Swirl pot

10.Gauze filter

11.Fuel gauge sender float

12.Electrical connections

13.HP/LP two stage pump

14.Pump LP return pipe

15.Electrical connector

The fuel pump is a self priming, wet type, two stage pump, which is emersed in fuel in the tank. It operates at all

times when the ignition switch is in position’II’. If the engine is not started, the ECM will’time-out’after three

minutes and de-energise the fuel pump relay.

The fuel pump assembly is retained with a locking ring and sealed with a rubber seal. The locking ring requires a

special tool for removal and refitment. The fuel gauge sender is integral with the fuel pump. The sender is

submerged in the fuel and is operated by a float which moves with the fuel level in the tank.

ProCarManuals.com

Page 259 of 667

19FUEL SYSTEM

4

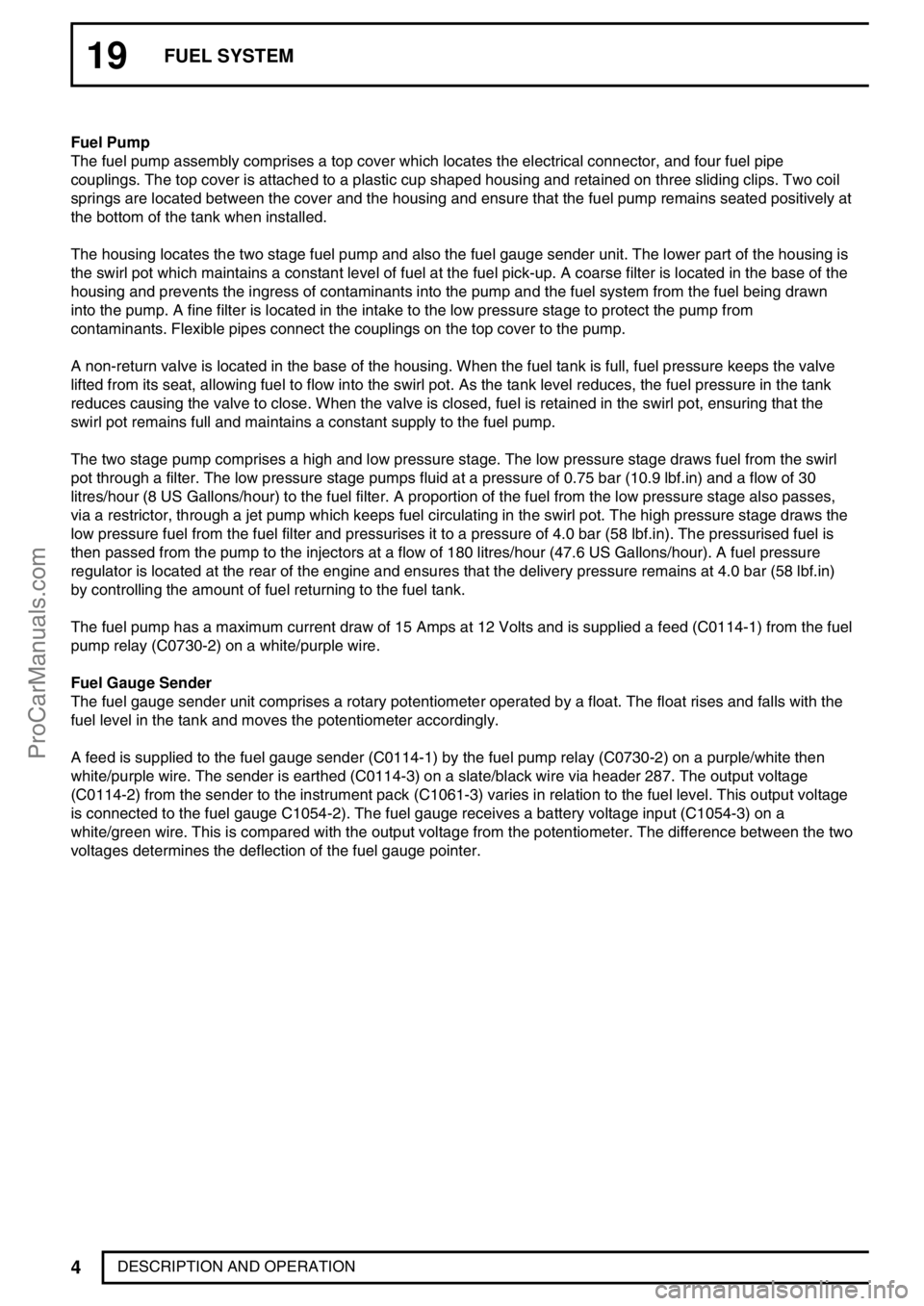

DESCRIPTION AND OPERATION Fuel Pump

The fuel pump assembly comprises a top cover which locates the electrical connector, and four fuel pipe

couplings. The top cover is attached to a plastic cup shaped housing and retained on three sliding clips. Two coil

springs are located between the cover and the housing and ensure that the fuel pump remains seated positively at

the bottom of the tank when installed.

The housing locates the two stage fuel pump and also the fuel gauge sender unit. The lower part of the housing is

the swirl pot which maintains a constant level of fuel at the fuel pick-up. A coarse filter is located in the base of the

housing and prevents the ingress of contaminants into the pump and the fuel system from the fuel being drawn

into the pump. A fine filter is located in the intake to the low pressure stage to protect the pump from

contaminants. Flexible pipes connect the couplings on the top cover to the pump.

A non-return valve is located in the base of the housing. When the fuel tank is full, fuel pressure keeps the valve

lifted from its seat, allowing fuel to flow into the swirl pot. As the tank level reduces, the fuel pressure in the tank

reduces causing the valve to close. When the valve is closed, fuel is retained in the swirl pot, ensuring that the

swirl pot remains full and maintains a constant supply to the fuel pump.

The two stage pump comprises a high and low pressure stage. The low pressure stage draws fuel from the swirl

pot through a filter. The low pressure stage pumps fluid at a pressure of 0.75 bar (10.9 lbf.in) and a flow of 30

litres/hour (8 US Gallons/hour) to the fuel filter. A proportion of the fuel from the low pressure stage also passes,

via a restrictor, through a jet pump which keeps fuel circulating in the swirl pot. The high pressure stage draws the

low pressure fuel from the fuel filter and pressurises it to a pressure of 4.0 bar (58 lbf.in). The pressurised fuel is

then passed from the pump to the injectors at a flow of 180 litres/hour (47.6 US Gallons/hour). A fuel pressure

regulator is located at the rear of the engine and ensures that the delivery pressure remains at 4.0 bar (58 lbf.in)

by controlling the amount of fuel returning to the fuel tank.

The fuel pump has a maximum current draw of 15 Amps at 12 Volts and is supplied a feed (C0114-1) from the fuel

pump relay (C0730-2) on a white/purple wire.

Fuel Gauge Sender

The fuel gauge sender unit comprises a rotary potentiometer operated by a float. The float rises and falls with the

fuel level in the tank and moves the potentiometer accordingly.

A feed is supplied to the fuel gauge sender (C0114-1) by the fuel pump relay (C0730-2) on a purple/white then

white/purple wire. The sender is earthed (C0114-3) on a slate/black wire via header 287. The output voltage

(C0114-2) from the sender to the instrument pack (C1061-3) varies in relation to the fuel level. This output voltage

is connected to the fuel gauge C1054-2). The fuel gauge receives a battery voltage input (C1054-3) on a

white/green wire. This is compared with the output voltage from the potentiometer. The difference between the two

voltages determines the deflection of the fuel gauge pointer.

ProCarManuals.com

Page 260 of 667

FUEL SYSTEM

5

DESCRIPTION AND OPERATION FUEL PRESSURE REGULATOR

NOTE: Non EU3 Model illustrated.

1.Gasket

2.Housing

3.Bolt

4.Fuel feed union and pipe

5.Fuel return union and hose

6.Fuel temperature sensor

7.Bonded seal8.’O’ring

9.Circlip

10.Fuel pressure regulator

11.’O’ring

12.’O’ring

13.Gauze filter

The fuel pressure regulator is located in a cast alloy housing which is attached to the rear right hand corner of the

cylinder head with three flanged bolts and sealed with a metal gasket. Two ports in the housing connect with ports

in the cylinder head for fuel pressure feed and return. A gauze filter is located in the pressure feed port in the

cylinder head, and filters the fuel before it reaches the injectors. The filter is a fit for life item but can be changed if

required. An’O’ring is located in a recess in the cylinder head and provides additional sealing for the pressure

feed port between the gauze filter, the cylinder head, and the housing.

A union and pipe is attached to the feed port in the housing and connects with a quick release coupling to the fuel

pressure feed pipe from the fuel pump. A second union and hose is located in the return port and provides the fuel

return connection to the fuel cooler. A third port provides location for the fuel temperature sensor, which is sealed

to the housing with a bonded seal. The fuel temperature sensor is used by the ECM for engine management.

ProCarManuals.com

Page 261 of 667

19FUEL SYSTEM

6

DESCRIPTION AND OPERATION The fuel pressure regulator is located in a machined port in the lower part of the housing. The regulator is sealed

in the housing with two’O’rings and secured with an internal clip.

The regulator maintains the fuel pump delivery pressure at 4 bar (58 lbf.in

2). When the fuel pressure exceeds 4

bar (58 lbf.in2), the regulator opens and allows fuel to return to the fuel tank via the fuel cooler. The fuel returned

from the regulator is directed back into the fuel filter before being drawn by the high pressure stage of the fuel

pump and directed back to the injectors. A special tool can be attached to the regulator housing fuel feed port and

allows for the fitment of a suitable gauge to measure fuel pump delivery pressure.

ProCarManuals.com