clutch LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 4 of 667

CONTENTS

01 INTRODUCTION

04 GENERAL SPECIFICATION DATA

05 ENGINE TUNING DATA

07 GENERAL FITTING REMINDERS

09 LUBRICANTS, FLUIDS AND CAPACITIES

10 MAINTENANCE

12 ENGINE

17 EMISSION CONTROL

18 ENGINE MANAGEMENT SYSTEM

19 FUEL SYSTEM

26 COOLING SYSTEM

30 MANIFOLD AND EXHAUST SYSTEM

33 CLUTCH

37 MANUAL GEARBOX

41 TRANSFER GEARBOX

47 PROPELLER SHAFTS

57 STEERING

60 FRONT SUSPENSION

64 REAR SUSPENSION

70 BRAKES

76 CHASSIS AND BODY

77 PANEL REPAIRS

82 AIR CONDITIONING

84 WIPERS AND WASHERS

86 ELECTRICAL

88 INSTRUMENTS

01

04

05

07

09

10

12

17

18

19

26

30

33

37

41

47

57

60

64

70

76

77

82

84

86

88

ProCarManuals.com

Page 22 of 667

04 - GENERAL SPECIFICATION DATA

CONTENTS

Page

INFORMATION

ENGINE - Td5 1......................................................................................................

FUEL SYSTEM - Td5 3...........................................................................................

COOLING SYSTEM - Td5 3....................................................................................

CLUTCH - Td5 3.....................................................................................................

TRANSMISSION - Td5 4.........................................................................................

STEERING 5...........................................................................................................

SUSPENSION 6......................................................................................................

ROAD SPRING DATA 6..........................................................................................

SHOCK ABSORBERS 7.........................................................................................

BRAKES 7...............................................................................................................

AIR CONDITIONING 8............................................................................................

WIPER MOTORS 8.................................................................................................

ELECTRICAL 8.......................................................................................................

BULBS9 .................................................................................................................

VEHICLE WEIGHTS AND PAYLOAD 10................................................................

TOWING WEIGHTS 11...........................................................................................

OFF-ROAD PERFORMANCE 11............................................................................

TYRE SIZE AND PRESSURES 12.........................................................................

WHEELS 12............................................................................................................

VEHICLE DIMENSIONS 13....................................................................................

ProCarManuals.com

Page 26 of 667

GENERAL SPECIFICATION DATA

3

INFORMATION FUEL SYSTEM - Td5

Type Direct injection from pressure regulated supply with.................................................................................

cooled return flow

Pressure regulator setting 4 bar (58 lbf.in

2) ................................................

Pump Electric two stage submersible................................................................................

Pump output

Low pressure 30 l/h (6.6 gal/h) at 0.5 bar (7.25 lbf.in

2) ..........................................................

High pressure 180 l/h (39.6 gal/h) at 4 bar (58 lbf.in2) ..........................................................

Max consumption 30 l/h (6.6 gal/h).............................................................

Injectors Electronic unit injectors...........................................................................

Injector normal operating pressure 1500 bar (21750 lbf.in

2) ..................................

Filter In-line canister filter/water separator with water.................................................................................

detection

COOLING SYSTEM - Td5

Type Pressurised spill return partial flow, thermostatically.................................................................................

controlled

Cooling fans 11 blade axial flow on viscous coupling and 11 blade.....................................................................

axial flow electric

Electric cooling fan switching points

On Vehicle speeds of 50 mph (80 km/h) and below while...........................................................................

ambient temperature is 28°C (82°F) or above

Off Vehicle speeds of 62.5 mph (100 km/h) and above or...........................................................................

ambient temperatures of 25°C (77°F) and below

Coolant pump Centrifugal impeller, belt driven from crankshaft...................................................................

Thermostat Waxstat with pressure relief valve.......................................................................

Thermostat opening temperature

Initial opening 82°C (179°F) ..........................................................

Fully open 96°C (204°F) ...............................................................

Expansion tank cap relief valve operating pressure 1.4 bar (20.3 lbf.in

2) .........

CLUTCH - Td5

Type Diaphragm spring, hydraulically operated with.................................................................................

self-centering pre-loaded release bearing

Drive plate diameter 267 mm.........................................................

Pressure plate diameter 270 mm...................................................

ProCarManuals.com

Page 55 of 667

09LUBRICANTS, FLUIDS AND CAPACITIES

2

INFORMATION Propeller shaft Front

and RearNLGI - 2 Multi-purpose Lithium based GREASE

Lubrication nipples

(hubs, ball joints

etc.)

Seat slides

Door lock striker

Brake and clutch

reservoirsBrake fluids having a minimum boiling point of 260°C (500°F) and complying with

FMVSS 116 DOT4

Engine coolant Use Texaco XLC long life coolant. Use one part anti-freeze to one part water for

protection down to -36°C (-33°F).

IMPORTANT: Coolant solution must not fall below 50% anti-freeze otherwise

damage to engine is liable to occur. Maximun concentration is 60%.

Battery lugs, Petroleum jelly.

Earthing surfacesNOTE: Do not use Silicone Grease

where paint has

been removed

Air Conditioning

System Refrigerant Use only refrigerant R134a

Compressor Oil ND-OIL 8

LUBRICATION PRACTICE

Use a high quality oil of the correct viscosity range and service classification in the engine during maintenance and

when topping up. The use of oil not to the correct specification can lead to high oil and fuel consumption and

ultimately to damaged components.

Oil to the correct specification contains additives which disperse the corrosive acids formed by combustion and

prevent the formation of sludge which can block the oilways. Additional oil additives should not be used. Always

adhere to the recommended servicing intervals.

WARNING: Many liquids and other substances used in motor vehicles are poisonous. They must

not be consumed and must be kept away from open wounds. These substances, among others,

include anti-freeze, windscreen washer additives, lubricants and various adhesives.

ProCarManuals.com

Page 58 of 667

10 - MAINTENANCE

CONTENTS

Page

MAINTENANCE

UNDERBONNET VIEW - Td5 1..............................................................................

SEATS AND SEAT BELTS 2..................................................................................

LAMPS, HORNS AND WARNING INDICATORS 2................................................

WIPERS AND WASHERS 3...................................................................................

HANDBRAKE 3.......................................................................................................

BATTERY CONDITION - Td5 4..............................................................................

HANDSET BATTERY 5...........................................................................................

HEADLAMP ALIGNMENT 5....................................................................................

ROAD WHEELS 6...................................................................................................

TYRE PRESSURES, CONDITION AND TREAD DEPTH 6....................................

BRAKE PADS, CALIPERS AND DISCS 7..............................................................

ROAD WHEEL SPEED SENSOR HARNESS - Td5 7............................................

FUEL FILTER ELEMENT 8.....................................................................................

FUEL FILTER SEDIMENTER - Td5 8.....................................................................

INTERCOOLER / COOLING SYSTEM 9................................................................

AMBIENT AIR PRESSURE (AAP) SENSOR - Td5 9..............................................

DOOR LOCKS AND HINGES 10............................................................................

ENGINE COOLANT 10...........................................................................................

BRAKE FLUID 11....................................................................................................

AIR FILTER ELEMENT AND DUMP VALVE 11.....................................................

AUXILIARY DRIVE BELT 12...................................................................................

PAS FLUID, CLUTCH FLUID AND SCREEN WASHER LEVELS 12.....................

STEERING BOX 13................................................................................................

ENGINE OIL 14.......................................................................................................

CENTRIFUGE ROTOR - Td5 14.............................................................................

FULL FLOW OIL FILTER 15...................................................................................

GEARBOX OIL 15...................................................................................................

TRANSFER BOX OIL 16.........................................................................................

FRONT AND REAR AXLE OIL 17..........................................................................

PROPELLER SHAFTS 18.......................................................................................

CLUTCH PIPES AND UNIONS 18..........................................................................

PAS PIPES AND UNIONS 19.................................................................................

ENGINE, GEARBOX, TRANSFER BOX AND AXLES 19.......................................

EXHAUST SYSTEM 20...........................................................................................

STEERING BOX AND SUSPENSION 20...............................................................

STEERING BALL JOINTS 21.................................................................................

SHOCK ABSORBERS 22.......................................................................................

TOWING BRACKET 22...........................................................................................

ENGINE AND TRANSMISSION MOUNTINGS 23..................................................

ProCarManuals.com

Page 60 of 667

MAINTENANCE

1

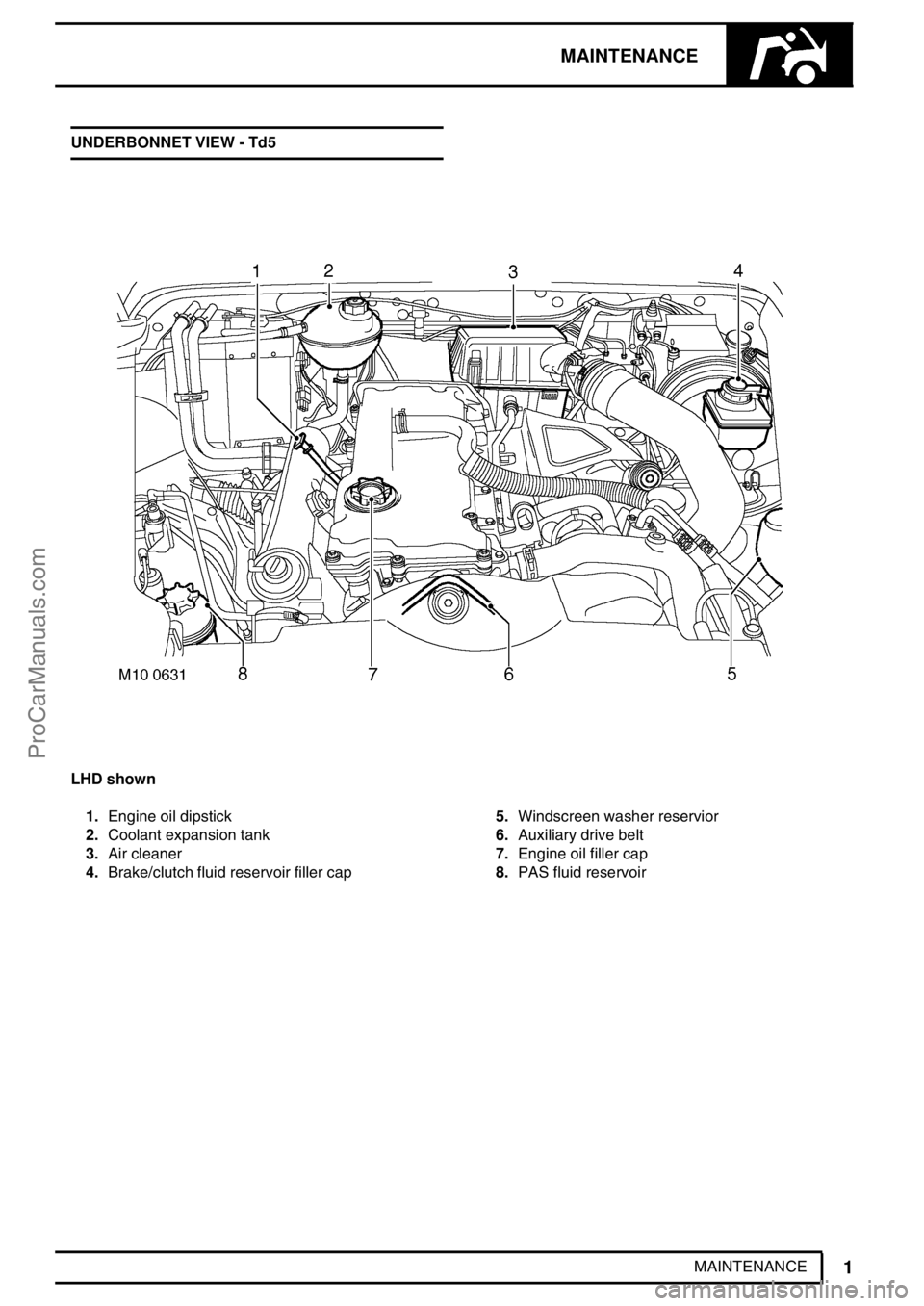

MAINTENANCE UNDERBONNET VIEW - Td5

LHD shown

1.Engine oil dipstick

2.Coolant expansion tank

3.Air cleaner

4.Brake/clutch fluid reservoir filler cap5.Windscreen washer reservior

6.Auxiliary drive belt

7.Engine oil filler cap

8.PAS fluid reservoir

ProCarManuals.com

Page 71 of 667

10MAINTENANCE

12

MAINTENANCE AUXILIARY DRIVE BELT

Check

1.Check auxiliary drive belt for signs of splits,

fraying, oil contamination and wear.

NOTE: Any requirement to replace the

auxiliary drive belt should be advised to

the customer as this will incur additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

Renew

1.Renew auxiliary drive belt.See ELECTRICAL,

Repair.

NOTE: Additional time is built into the

96,000/8 year service time to allow for

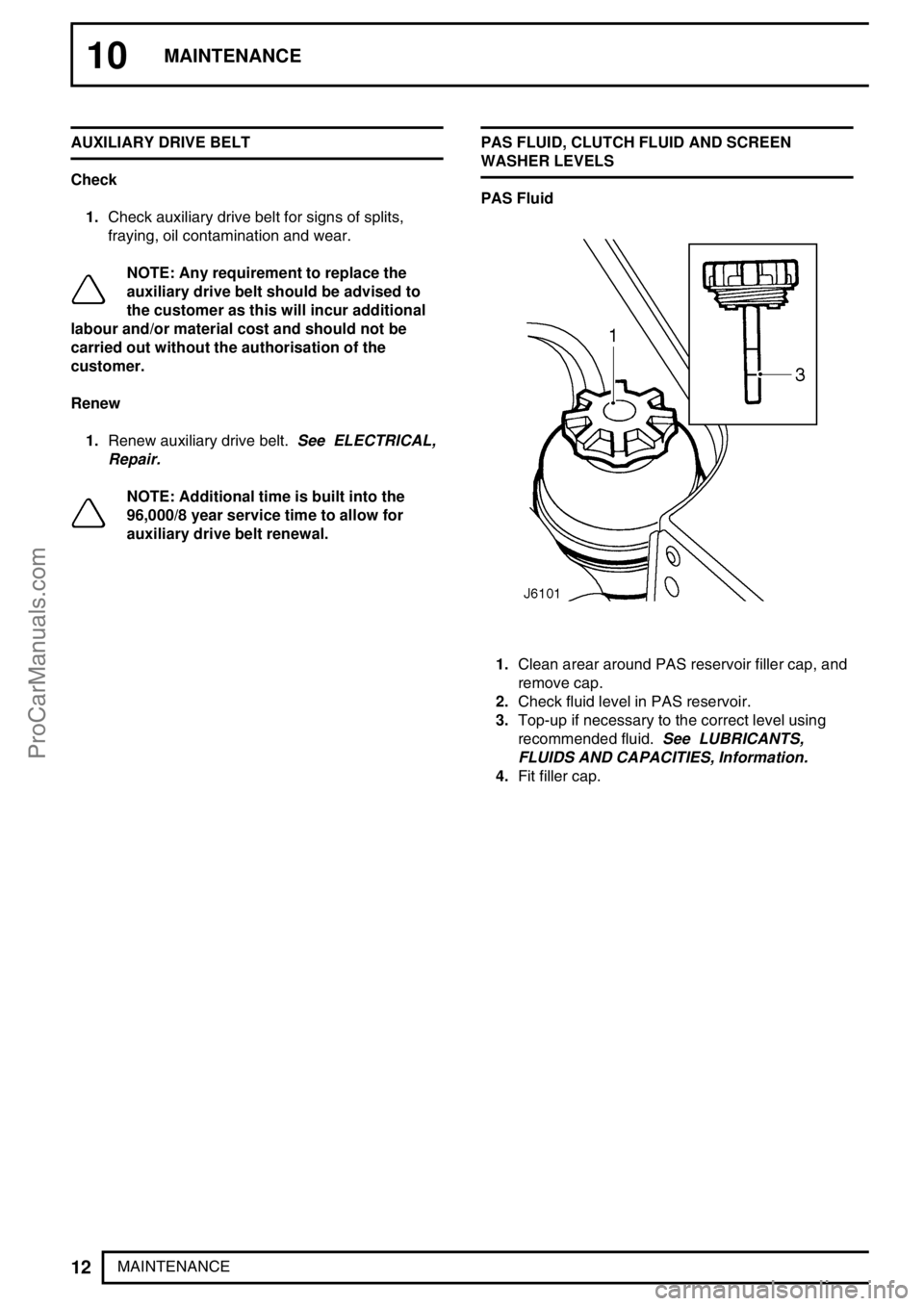

auxiliary drive belt renewal.PAS FLUID, CLUTCH FLUID AND SCREEN

WASHER LEVELS

PAS Fluid

1.Clean arear around PAS reservoir filler cap, and

remove cap.

2.Check fluid level in PAS reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.

ProCarManuals.com

Page 72 of 667

MAINTENANCE

13

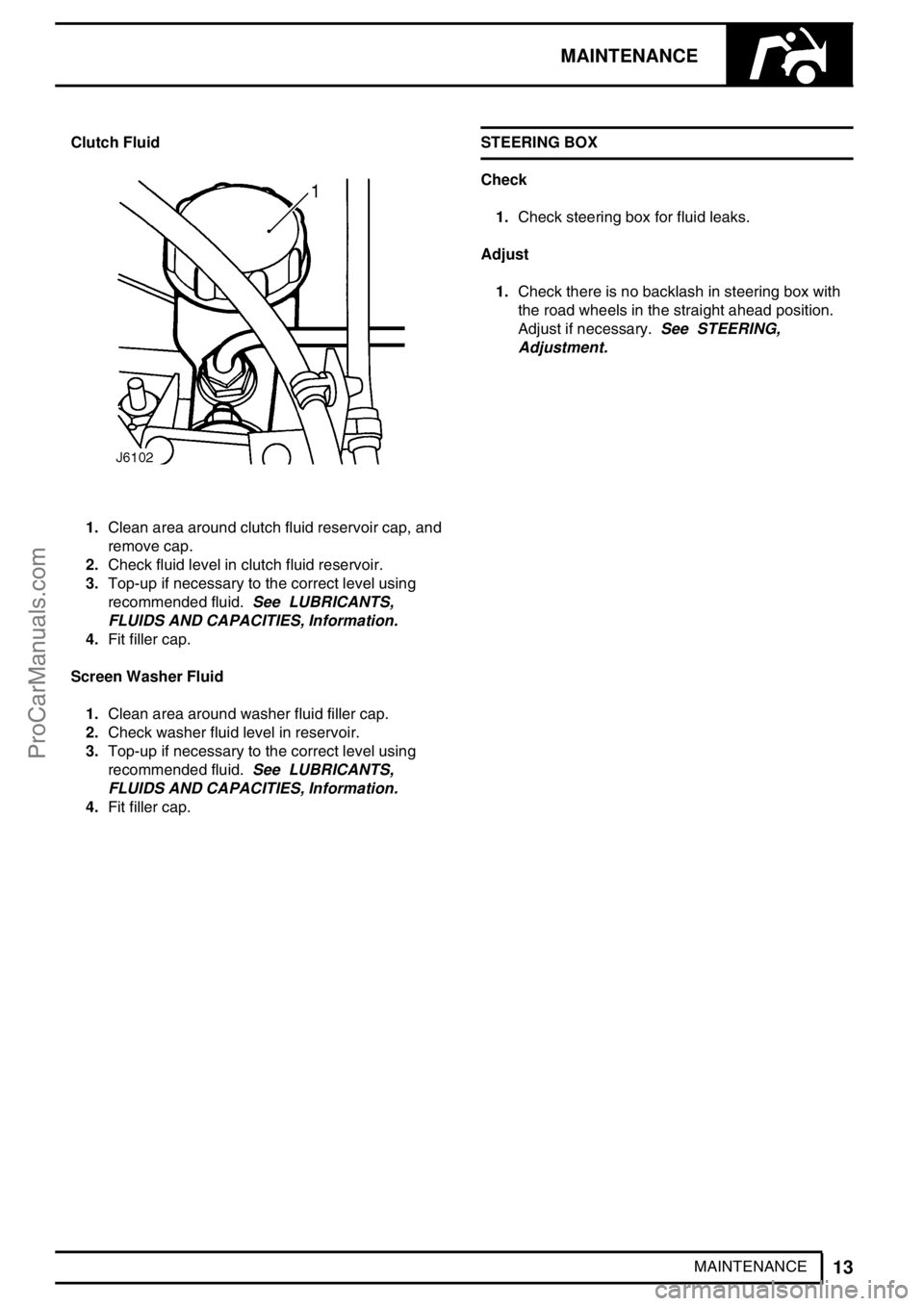

MAINTENANCE Clutch Fluid

1.Clean area around clutch fluid reservoir cap, and

remove cap.

2.Check fluid level in clutch fluid reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.

Screen Washer Fluid

1.Clean area around washer fluid filler cap.

2.Check washer fluid level in reservoir.

3.Top-up if necessary to the correct level using

recommended fluid.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information.

4.Fit filler cap.STEERING BOX

Check

1.Check steering box for fluid leaks.

Adjust

1.Check there is no backlash in steering box with

the road wheels in the straight ahead position.

Adjust if necessary.See STEERING,

Adjustment.

ProCarManuals.com

Page 77 of 667

10MAINTENANCE

18

MAINTENANCE PROPELLER SHAFTS

1.Clean area around front universal joint grease

nipple.

2.Apply recommended grease to the grease

nipple.See LUBRICANTS, FLUIDS AND

CAPACITIES, Information.CLUTCH PIPES AND UNIONS

Check

1.Check route of clutch pipe from master cylinder

to slave cylinder. Ensure that pipe is correctly

retained and shows no signs of fluid leakage or

chafing.

2.Check unions for signs of fluid leakage.

ProCarManuals.com

Page 82 of 667

MAINTENANCE

23

MAINTENANCE ENGINE AND TRANSMISSION MOUNTINGS

1.Check condition of front LH engine mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

2.Check condition of front RH engine mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

3.Check condition of rear LH gearbox mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.

4.Check condition of rear RH gearbox mounting.

Tighten fixings if necessary.See ENGINE ,

Repair.ROAD TEST

There are two purposes for conducting a road test.

Firstly, to ensure the work completed within the

dealership meets the standards required as layed

down by dealership processes. Secondly, for a skilled

technician to assess the general condition of the

vehicle and report any conditions that the customer

should be made aware of.

CAUTION: Two wheel roller tests must not

be carried out. Four wheel roller tests

must be restricted to 3 mph (5 kph).

1.Check for correct operation of starter switch.

Ensure the engine starts in a correct manner.

Leave the engine running.

2.With vehicle stationary, turn steering from lock to

lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

3.Depress clutch and select all gears in turn.

Check for smooth notch free engagement.

4.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

Engine noise

Gearbox noise

Suspension noise

Body noise

Braking system operation

Gear selection

Engine performance

5.Check for correct operation of all instruments

and warning devices where practical.

6.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

7.Check all underbonnet fluid levels and top-up if

necessary.

ProCarManuals.com