fuse box LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 244 of 667

ENGINE MANAGEMENT SYSTEM

21

DESCRIPTION AND OPERATION RELAY - FUEL PUMP

The fuel pump relay is located in the engine compartment fuse box. It switches on the fuel pump to draw fuel from

the tank to the electronic unit injectors (EUI).

Input / Output

The fuel pump relay is a 4 pin normally open relay. The fuel pump relay (C0730-4) is provided with a feed by the

main relay (C0063-78) via header 291 on a brown/orange wire. An earth path is provided for the fuel pump relay

(C0730-6) via the ECM (C658-5) on a blue/purple wire. This energises the fuel pump relay and allows a feed to be

provided to the fuel pump. When the ECM interrupts the earth, the relay is de-energised and the fuel pump stops

operating.

The fuel pump relay can fail in one or more of the following ways:

Relay open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Broken relay return spring.

In the event of a fuel pump relay failure any of the following symptoms may be observed:

Engine will crank but not start.

If the engine is running, it will stop.

RELAY - MAIN

The main relay is located in the engine compartment fuse box and supplies battery voltage to the following:

The ECM.

The MAF sensor.

Fuel pump relay.

Input / Output

The main relay is a 4 pin normally open relay, which must be energised to provide a voltage to the ECM. The main

relay (C0063-86) is provided with an earth path via a transistor within the ECM (C0658-21) on a blue/red wire.

When the earth path is completed, the relay is energised and supplies the ECM (C0658-3, C0658-22 & C0658-27)

with a feed on brown/orange wires via header 291.

The main relay can fail in the following ways:

Relay open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Broken relay return spring.

In the event of a main relay failure any of the following symptoms may be observed:

Engine will crank but not start.

If the engine is running, it will stop.

For the ECM start up to take place the ignition feed when the switch is in position’II’must be greater than 6.0

volts.

ProCarManuals.com

Page 349 of 667

37MANUAL GEARBOX

4

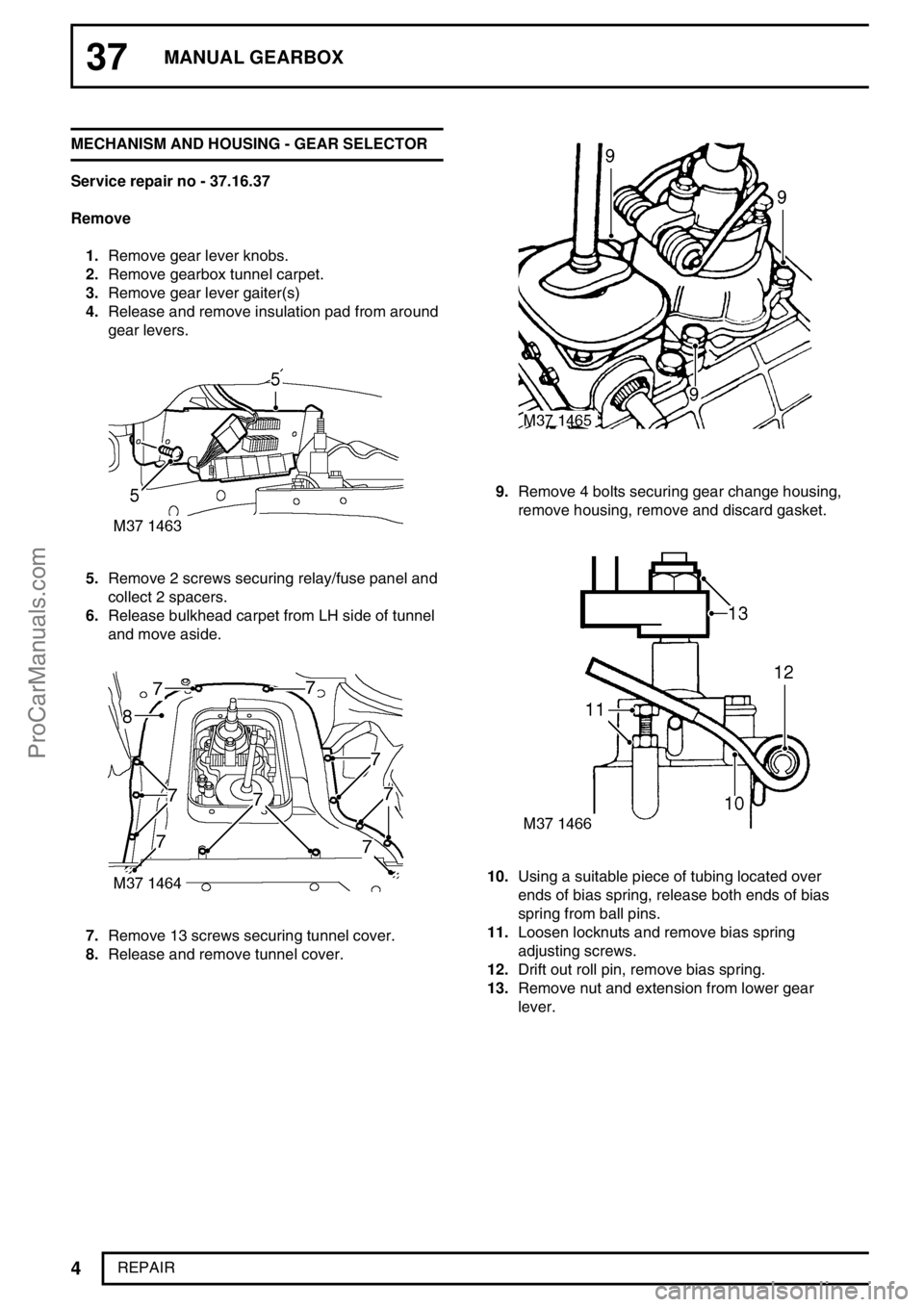

REPAIR MECHANISM AND HOUSING - GEAR SELECTOR

Service repair no - 37.16.37

Remove

1.Remove gear lever knobs.

2.Remove gearbox tunnel carpet.

3.Remove gear lever gaiter(s)

4.Release and remove insulation pad from around

gear levers.

5.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

6.Release bulkhead carpet from LH side of tunnel

and move aside.

7.Remove 13 screws securing tunnel cover.

8.Release and remove tunnel cover.

9.Remove 4 bolts securing gear change housing,

remove housing, remove and discard gasket.

10.Using a suitable piece of tubing located over

ends of bias spring, release both ends of bias

spring from ball pins.

11.Loosen locknuts and remove bias spring

adjusting screws.

12.Drift out roll pin, remove bias spring.

13.Remove nut and extension from lower gear

lever.

ProCarManuals.com

Page 350 of 667

MANUAL GEARBOX

5

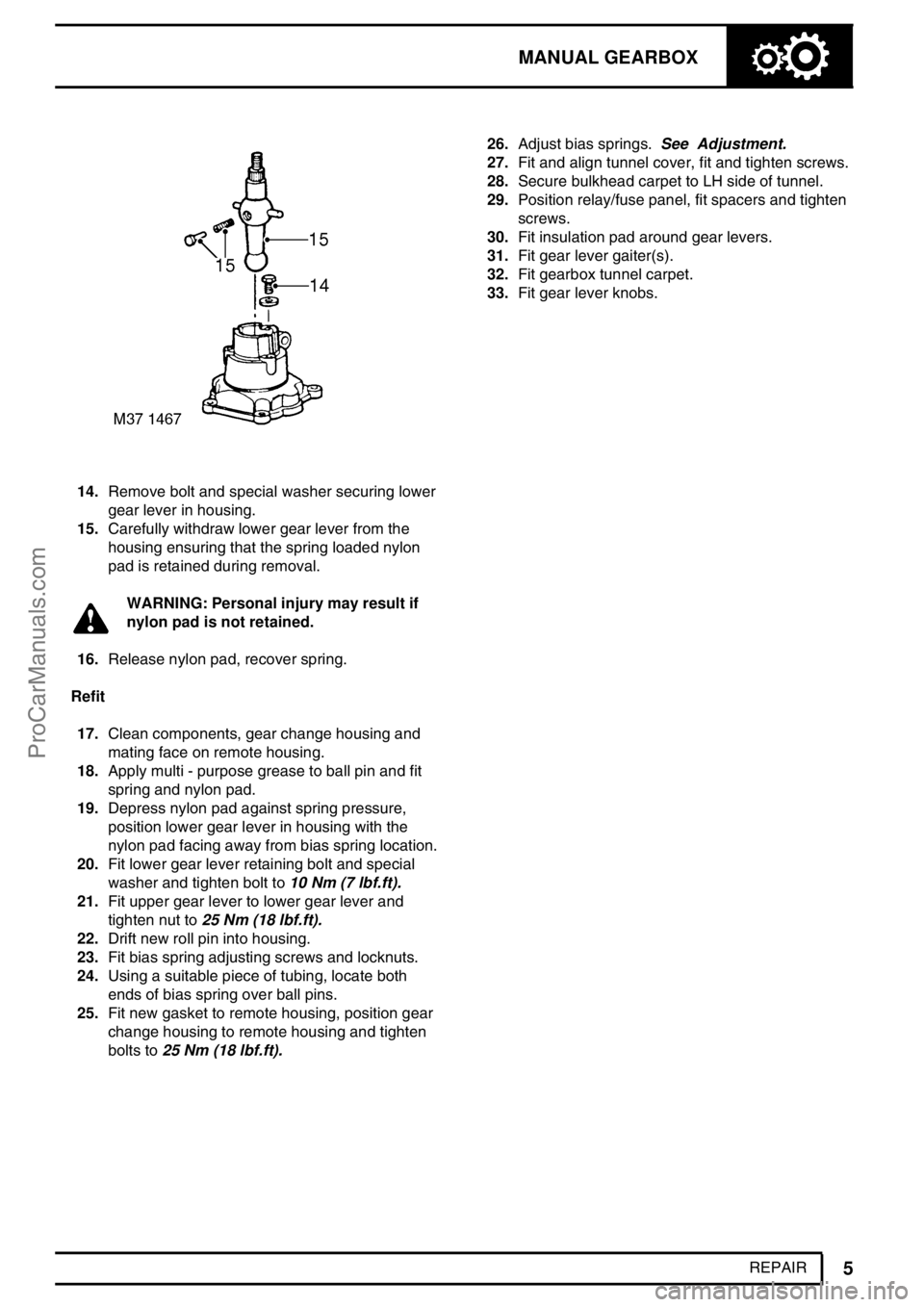

REPAIR

14.Remove bolt and special washer securing lower

gear lever in housing.

15.Carefully withdraw lower gear lever from the

housing ensuring that the spring loaded nylon

pad is retained during removal.

WARNING: Personal injury may result if

nylon pad is not retained.

16.Release nylon pad, recover spring.

Refit

17.Clean components, gear change housing and

mating face on remote housing.

18.Apply multi - purpose grease to ball pin and fit

spring and nylon pad.

19.Depress nylon pad against spring pressure,

position lower gear lever in housing with the

nylon pad facing away from bias spring location.

20.Fit lower gear lever retaining bolt and special

washer and tighten bolt to10 Nm (7 lbf.ft).

21.Fit upper gear lever to lower gear lever and

tighten nut to25 Nm (18 lbf.ft).

22.Drift new roll pin into housing.

23.Fit bias spring adjusting screws and locknuts.

24.Using a suitable piece of tubing, locate both

ends of bias spring over ball pins.

25.Fit new gasket to remote housing, position gear

change housing to remote housing and tighten

bolts to25 Nm (18 lbf.ft).26.Adjust bias springs.See Adjustment.

27.Fit and align tunnel cover, fit and tighten screws.

28.Secure bulkhead carpet to LH side of tunnel.

29.Position relay/fuse panel, fit spacers and tighten

screws.

30.Fit insulation pad around gear levers.

31.Fit gear lever gaiter(s).

32.Fit gearbox tunnel carpet.

33.Fit gear lever knobs.

ProCarManuals.com

Page 351 of 667

37MANUAL GEARBOX

6

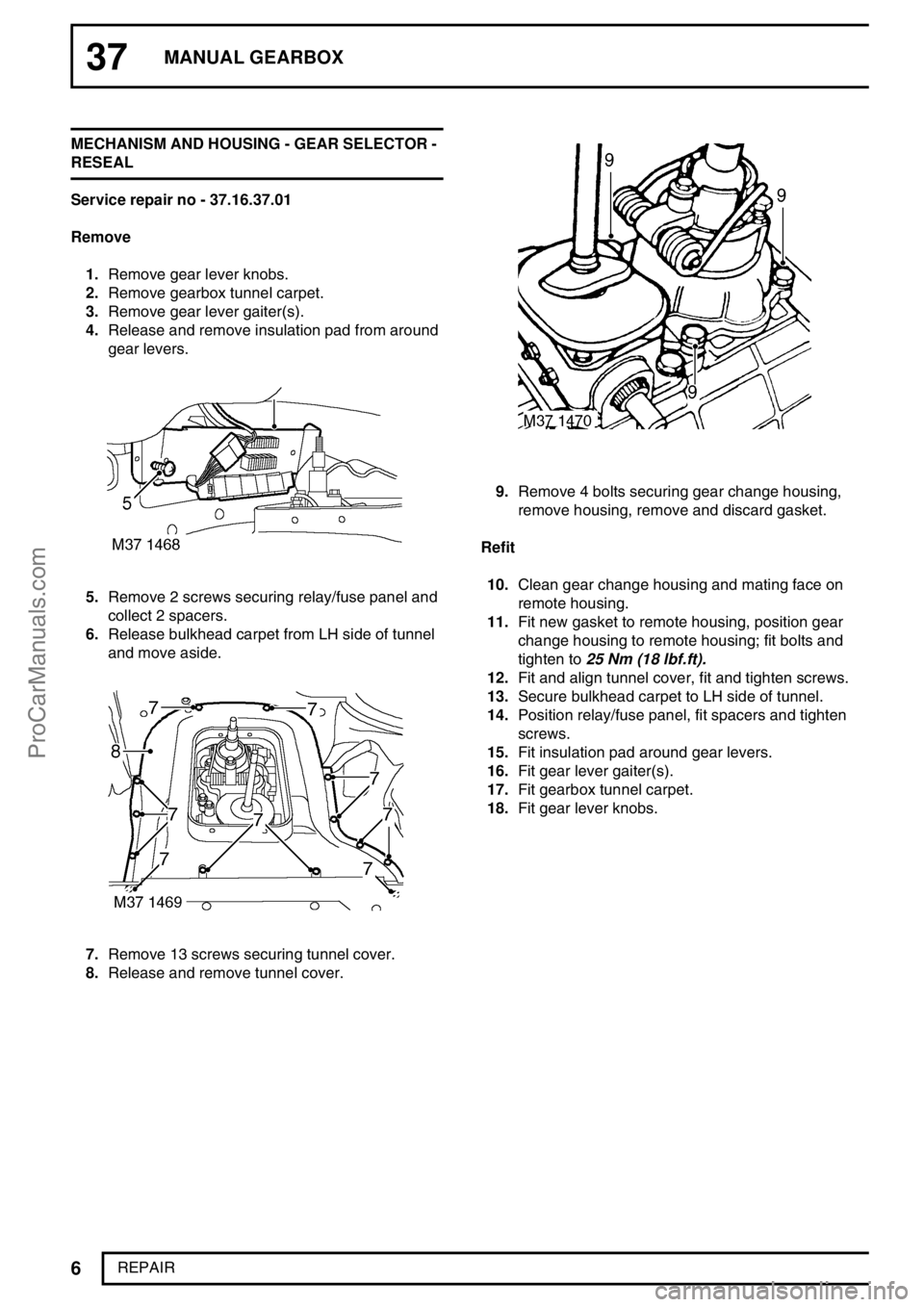

REPAIR MECHANISM AND HOUSING - GEAR SELECTOR -

RESEAL

Service repair no - 37.16.37.01

Remove

1.Remove gear lever knobs.

2.Remove gearbox tunnel carpet.

3.Remove gear lever gaiter(s).

4.Release and remove insulation pad from around

gear levers.

5.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

6.Release bulkhead carpet from LH side of tunnel

and move aside.

7.Remove 13 screws securing tunnel cover.

8.Release and remove tunnel cover.

9.Remove 4 bolts securing gear change housing,

remove housing, remove and discard gasket.

Refit

10.Clean gear change housing and mating face on

remote housing.

11.Fit new gasket to remote housing, position gear

change housing to remote housing; fit bolts and

tighten to25 Nm (18 lbf.ft).

12.Fit and align tunnel cover, fit and tighten screws.

13.Secure bulkhead carpet to LH side of tunnel.

14.Position relay/fuse panel, fit spacers and tighten

screws.

15.Fit insulation pad around gear levers.

16.Fit gear lever gaiter(s).

17.Fit gearbox tunnel carpet.

18.Fit gear lever knobs.

ProCarManuals.com

Page 357 of 667

37MANUAL GEARBOX

12

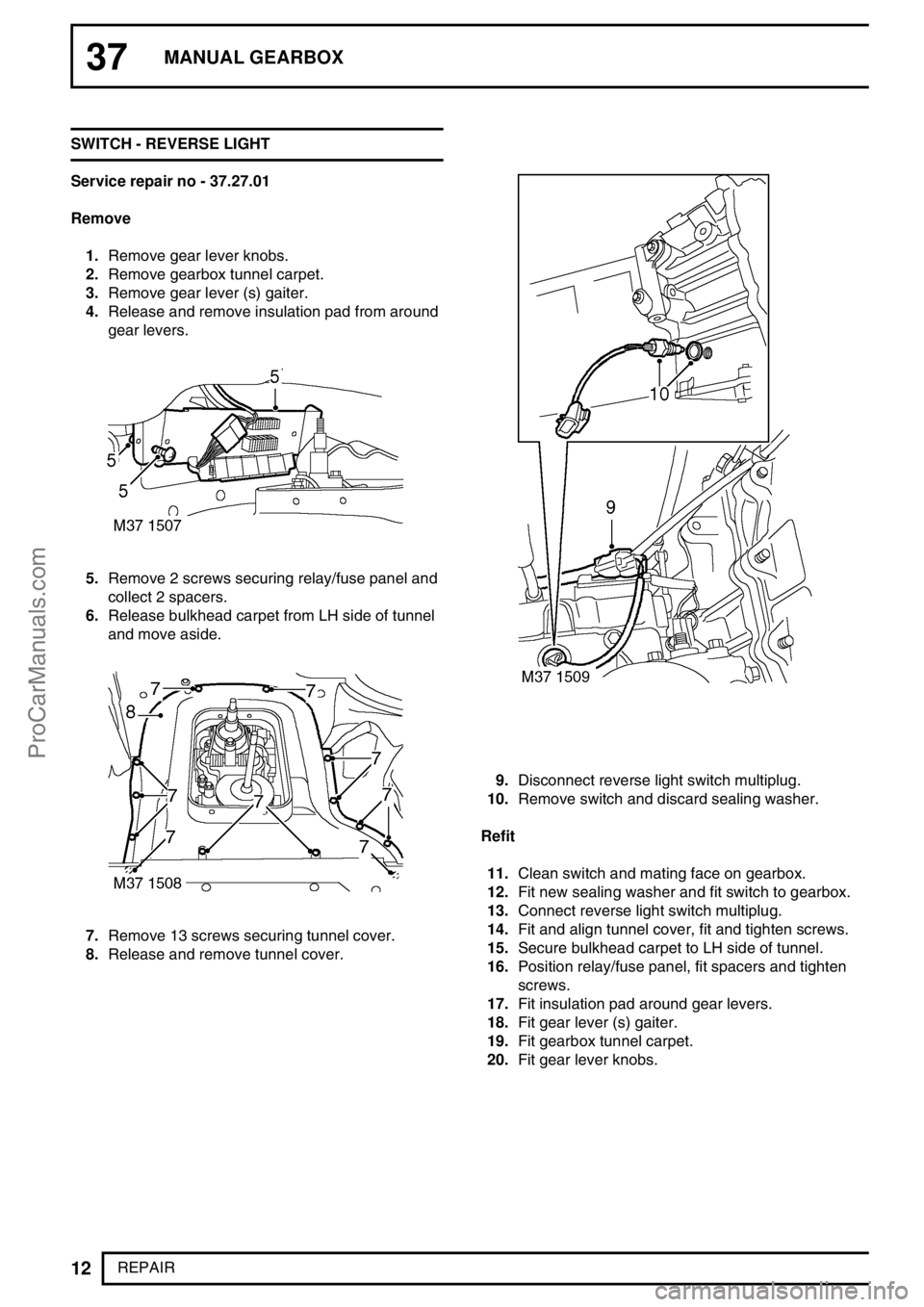

REPAIR SWITCH - REVERSE LIGHT

Service repair no - 37.27.01

Remove

1.Remove gear lever knobs.

2.Remove gearbox tunnel carpet.

3.Remove gear lever (s) gaiter.

4.Release and remove insulation pad from around

gear levers.

5.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

6.Release bulkhead carpet from LH side of tunnel

and move aside.

7.Remove 13 screws securing tunnel cover.

8.Release and remove tunnel cover.

9.Disconnect reverse light switch multiplug.

10.Remove switch and discard sealing washer.

Refit

11.Clean switch and mating face on gearbox.

12.Fit new sealing washer and fit switch to gearbox.

13.Connect reverse light switch multiplug.

14.Fit and align tunnel cover, fit and tighten screws.

15.Secure bulkhead carpet to LH side of tunnel.

16.Position relay/fuse panel, fit spacers and tighten

screws.

17.Fit insulation pad around gear levers.

18.Fit gear lever (s) gaiter.

19.Fit gearbox tunnel carpet.

20.Fit gear lever knobs.

ProCarManuals.com

Page 360 of 667

TRANSFER GEARBOX

1

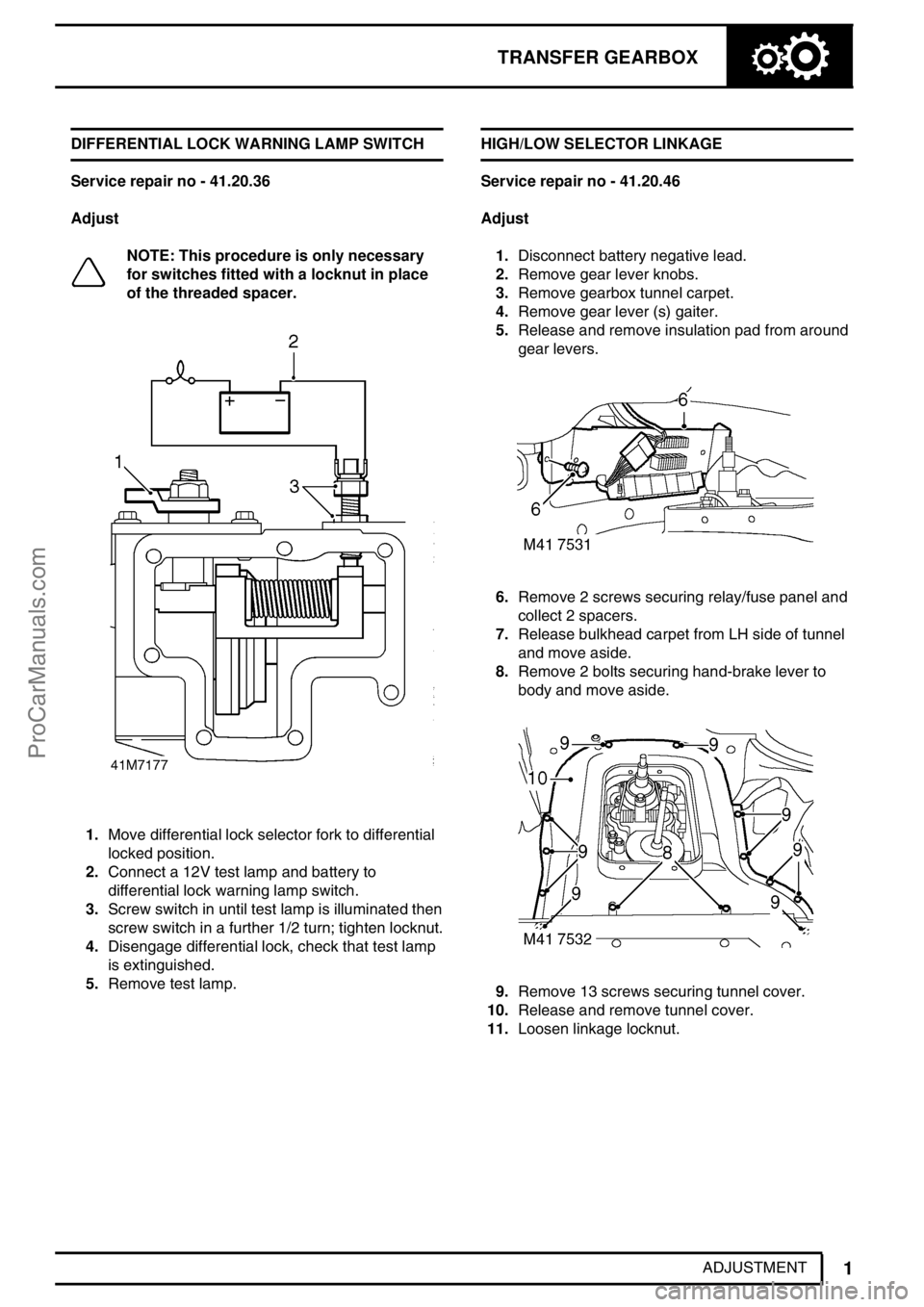

ADJUSTMENT DIFFERENTIAL LOCK WARNING LAMP SWITCH

Service repair no - 41.20.36

Adjust

NOTE: This procedure is only necessary

for switches fitted with a locknut in place

of the threaded spacer.

1.Move differential lock selector fork to differential

locked position.

2.Connect a 12V test lamp and battery to

differential lock warning lamp switch.

3.Screw switch in until test lamp is illuminated then

screw switch in a further 1/2 turn; tighten locknut.

4.Disengage differential lock, check that test lamp

is extinguished.

5.Remove test lamp.HIGH/LOW SELECTOR LINKAGE

Service repair no - 41.20.46

Adjust

1.Disconnect battery negative lead.

2.Remove gear lever knobs.

3.Remove gearbox tunnel carpet.

4.Remove gear lever (s) gaiter.

5.Release and remove insulation pad from around

gear levers.

6.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

7.Release bulkhead carpet from LH side of tunnel

and move aside.

8.Remove 2 bolts securing hand-brake lever to

body and move aside.

9.Remove 13 screws securing tunnel cover.

10.Release and remove tunnel cover.

11.Loosen linkage locknut.

ProCarManuals.com

Page 361 of 667

41TRANSFER GEARBOX

2

ADJUSTMENT

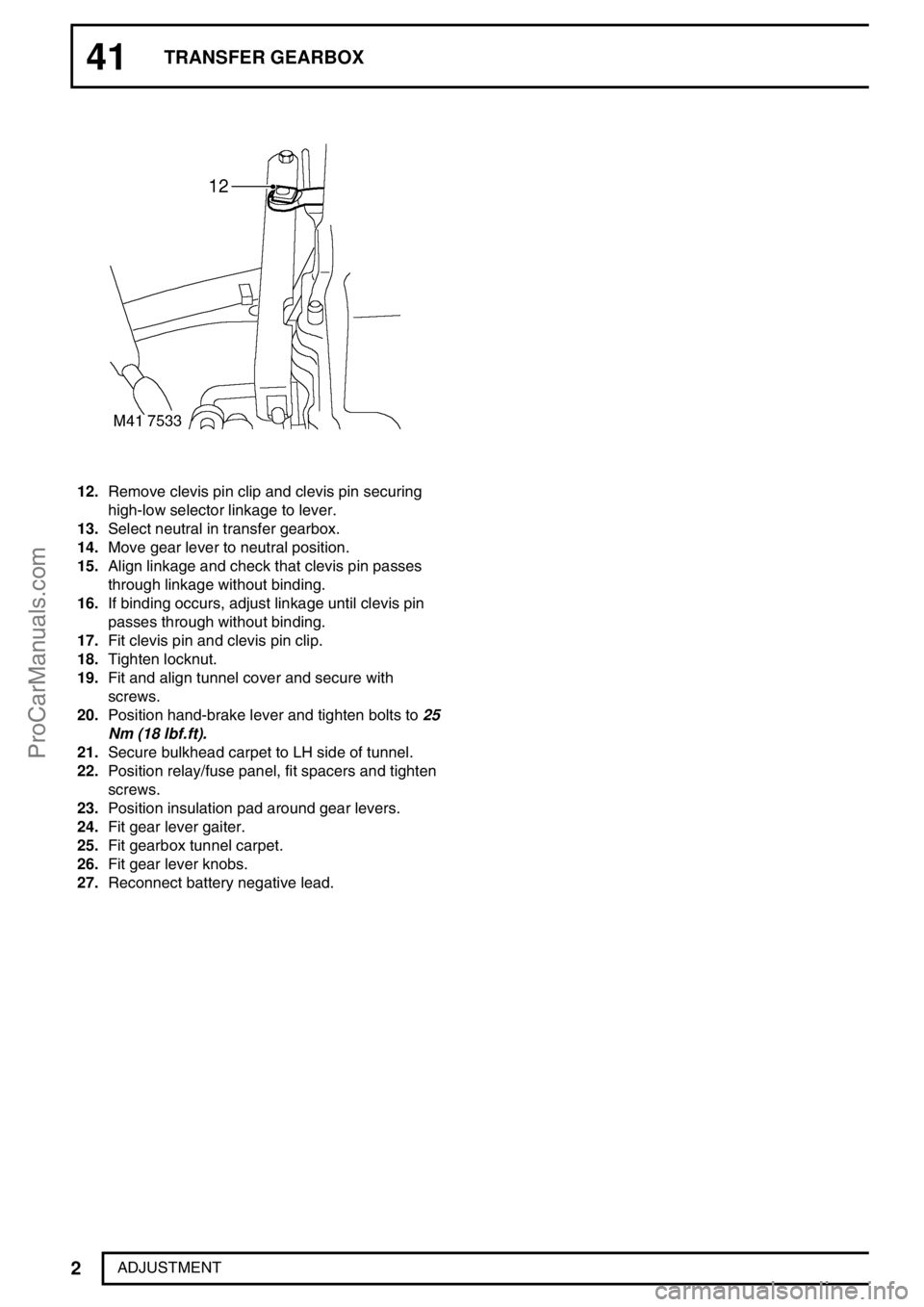

12.Remove clevis pin clip and clevis pin securing

high-low selector linkage to lever.

13.Select neutral in transfer gearbox.

14.Move gear lever to neutral position.

15.Align linkage and check that clevis pin passes

through linkage without binding.

16.If binding occurs, adjust linkage until clevis pin

passes through without binding.

17.Fit clevis pin and clevis pin clip.

18.Tighten locknut.

19.Fit and align tunnel cover and secure with

screws.

20.Position hand-brake lever and tighten bolts to25

Nm (18 lbf.ft).

21.Secure bulkhead carpet to LH side of tunnel.

22.Position relay/fuse panel, fit spacers and tighten

screws.

23.Position insulation pad around gear levers.

24.Fit gear lever gaiter.

25.Fit gearbox tunnel carpet.

26.Fit gear lever knobs.

27.Reconnect battery negative lead.

ProCarManuals.com

Page 368 of 667

TRANSFER GEARBOX

7

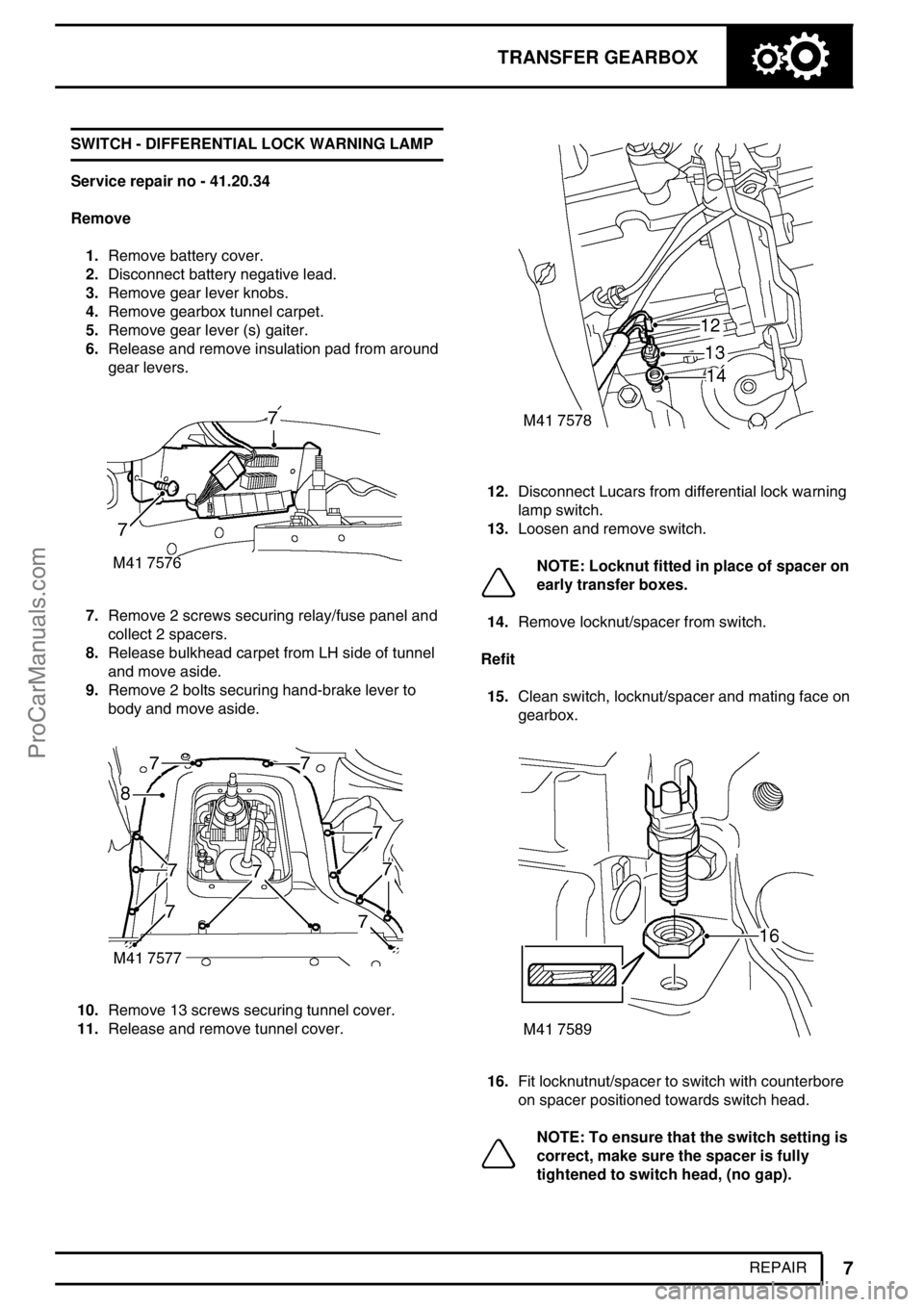

REPAIR SWITCH - DIFFERENTIAL LOCK WARNING LAMP

Service repair no - 41.20.34

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever (s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.

12.Disconnect Lucars from differential lock warning

lamp switch.

13.Loosen and remove switch.

NOTE: Locknut fitted in place of spacer on

early transfer boxes.

14.Remove locknut/spacer from switch.

Refit

15.Clean switch, locknut/spacer and mating face on

gearbox.

16.Fit locknutnut/spacer to switch with counterbore

on spacer positioned towards switch head.

NOTE: To ensure that the switch setting is

correct, make sure the spacer is fully

tightened to switch head, (no gap).

ProCarManuals.com

Page 369 of 667

41TRANSFER GEARBOX

8

REPAIR 17.Apply Hylomar PL32 sealant to switch threads.

18.Position switch into gearbox housing until

locknut/spacer bottoms out on housing.

19. Switches fitted with spacer:Tighten spacer

securing differential lock switch to11 Nm (8

lbf.ft).

20.Connect Lucars to switch.

21. Switches fitted with locknut:Adjust switch.

See Adjustment.

22.Fit and align tunnel cover, fit and tighten screws.

23.Fit hand-brake lever and tighten bolts to25 Nm

(18 lbf.ft).

24.Secure bulkhead carpet to LH side of tunnel.

25.Position relay/fuse panel, fit spacers and tighten

screws.

26.Fit insulation pad around gear levers.

27.Fit gear lever (s) gaiter.

28.Fit gearbox tunnel carpet.

29.Fit gear lever knobs.

30.Reconnect battery negative lead.

31.Fit battery cover.SEAL - INPUT SHAFT

Service repair no - 41.20.50

Remove

1.Remove transfer gearbox.See this Section.

2.Remove and discard input shaft oil seal from

transfer gearbox.

Refit

3.Clean oil seal recess in transfer gearbox.

4.Lubricate new oil seal with transfer gearbox oil.

5.UsingLRT-37-014, fit input shaft seal to transfer

gearbox.

6.Fit transfer gearbox.See this Section.

ProCarManuals.com

Page 374 of 667

TRANSFER GEARBOX

13

REPAIR SWITCH - LOW DETECT

Service repair no - 41.30.05

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever(s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move lever aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.12.Release switch multiplug from bracket on

transfer gearbox, disconnect from harness.

13.Remove switch.

Refit

14.Clean switch and mating face on transfer

gearbox.

15.Fit nut/spacer to switch with counterbore

positioned towards switch head.

16.Apply Hylomar PL32 sealant to switch threads.

17.Fit switch and tighten to24 Nm (19 lbf.ft).

18.Connect multiplug to harness.

19.Fit and align tunnel cover, fit and tighten screws.

20.Position hand-brake lever and tighten bolts to25

Nm (18 lbf.ft).

21.Secure bulkhead carpet to LH side of tunnel.

22.Position relay/fuse panel, fit spacers and tighten

screws.

23.Fit insulation pad around gear levers.

24.Fit gear lever (s) gaiter.

25.Fit gearbox tunnel carpet.

26.Fit gear lever knobs.

27.Reconnect battery negative lead.

28.Fit battery cover.

ProCarManuals.com