headlamp LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 32 of 667

GENERAL SPECIFICATION DATA

9

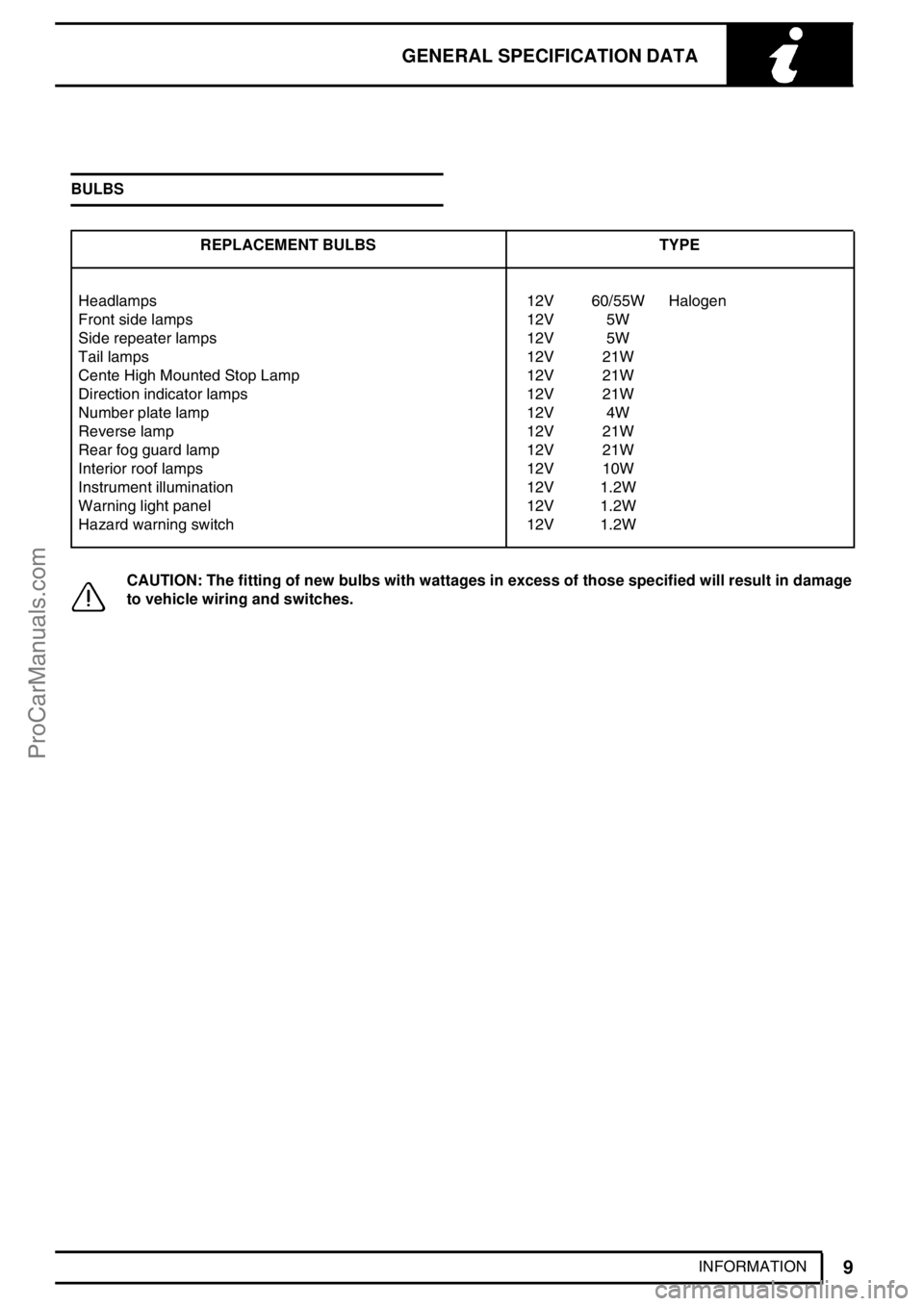

INFORMATION BULBS

REPLACEMENT BULBS TYPE

Headlamps 12V 60/55W Halogen

Front side lamps 12V 5W

Side repeater lamps 12V 5W

Tail lamps 12V 21W

Cente High Mounted Stop Lamp 12V 21W

Direction indicator lamps 12V 21W

Number plate lamp 12V 4W

Reverse lamp 12V 21W

Rear fog guard lamp 12V 21W

Interior roof lamps 12V 10W

Instrument illumination 12V 1.2W

Warning light panel 12V 1.2W

Hazard warning switch 12V 1.2W

CAUTION: The fitting of new bulbs with wattages in excess of those specified will result in damage

to vehicle wiring and switches.

ProCarManuals.com

Page 58 of 667

10 - MAINTENANCE

CONTENTS

Page

MAINTENANCE

UNDERBONNET VIEW - Td5 1..............................................................................

SEATS AND SEAT BELTS 2..................................................................................

LAMPS, HORNS AND WARNING INDICATORS 2................................................

WIPERS AND WASHERS 3...................................................................................

HANDBRAKE 3.......................................................................................................

BATTERY CONDITION - Td5 4..............................................................................

HANDSET BATTERY 5...........................................................................................

HEADLAMP ALIGNMENT 5....................................................................................

ROAD WHEELS 6...................................................................................................

TYRE PRESSURES, CONDITION AND TREAD DEPTH 6....................................

BRAKE PADS, CALIPERS AND DISCS 7..............................................................

ROAD WHEEL SPEED SENSOR HARNESS - Td5 7............................................

FUEL FILTER ELEMENT 8.....................................................................................

FUEL FILTER SEDIMENTER - Td5 8.....................................................................

INTERCOOLER / COOLING SYSTEM 9................................................................

AMBIENT AIR PRESSURE (AAP) SENSOR - Td5 9..............................................

DOOR LOCKS AND HINGES 10............................................................................

ENGINE COOLANT 10...........................................................................................

BRAKE FLUID 11....................................................................................................

AIR FILTER ELEMENT AND DUMP VALVE 11.....................................................

AUXILIARY DRIVE BELT 12...................................................................................

PAS FLUID, CLUTCH FLUID AND SCREEN WASHER LEVELS 12.....................

STEERING BOX 13................................................................................................

ENGINE OIL 14.......................................................................................................

CENTRIFUGE ROTOR - Td5 14.............................................................................

FULL FLOW OIL FILTER 15...................................................................................

GEARBOX OIL 15...................................................................................................

TRANSFER BOX OIL 16.........................................................................................

FRONT AND REAR AXLE OIL 17..........................................................................

PROPELLER SHAFTS 18.......................................................................................

CLUTCH PIPES AND UNIONS 18..........................................................................

PAS PIPES AND UNIONS 19.................................................................................

ENGINE, GEARBOX, TRANSFER BOX AND AXLES 19.......................................

EXHAUST SYSTEM 20...........................................................................................

STEERING BOX AND SUSPENSION 20...............................................................

STEERING BALL JOINTS 21.................................................................................

SHOCK ABSORBERS 22.......................................................................................

TOWING BRACKET 22...........................................................................................

ENGINE AND TRANSMISSION MOUNTINGS 23..................................................

ProCarManuals.com

Page 61 of 667

10MAINTENANCE

2

MAINTENANCE SEATS AND SEAT BELTS

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return under

its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check security of seat belt buckle mountings.

8.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure. Release

seat belt buckle and check for correct operation.

9.Check tightness of accessible seat belt

mountingsLAMPS, HORNS AND WARNING INDICATORS

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of brake

lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

ProCarManuals.com

Page 64 of 667

MAINTENANCE

5

MAINTENANCE HANDSET BATTERY

Remove

NOTE: Do not remove a battery until you

are ready to install the replacement.

Always fit a Land Rover STC4080 or a

Panasonic CR2032 replacement battery.

1.Unlock the vehicle and disarm the alarm system.

2.Turn the ignition switch to position’II’, then turn

to position’0’and remove the key.

3.Carefully prise the handset apart, starting from

the keyring end. Avoid damaging the seal

between the two halves of the case.

CAUTION: Do not allow moisture to get

inside the handset.

4.Slide the battery out of its clip, taking care to

avoid touching the circuit board or the contact

surfaces of the clip.

5.Press and hold one of the buttons for at least 5

seconds to drain any residual power from the

handset.

Refit

6.Fit the new battery, ensuring that correct polarity

is maintained (+ve side facing up). Finger marks

will adversely affect battery life. Avoid touching

the flat surfaces of the battery, and wipe clean

before fitment.

7.Reassemble the two halves of the handset.

Operate the Padlock symbol button at least 4

times within range of the vehicle to

resynchronise the hanset.HEADLAMP ALIGNMENT

1.Check alignment of headlamps.See

ELECTRICAL, Adjustment.

ProCarManuals.com

Page 475 of 667

76CHASSIS AND BODY

6

REPAIR

21.Disconnect headlamp, side lamp, repeater and

indicator multiplugs.

22.With assistance, remove wing.

23.Remove bolt, remove grille support bracket.

24.Remove 4 screws securing side and indicator

lamps.

25.Remove 2 screws securing headlamp finisher to

wing, remove finisher.

26.Remove 4 screws and remove headlamp from

wing, collect sealing ring.

27.Release side repeater lamp from wing.

28.Remove bonnet cable grommet.

ProCarManuals.com

Page 476 of 667

CHASSIS AND BODY

7

REPAIR Refit

29.Fit bonnet cable grommet.

30.Fit side repeater lamp to wing.

31.Fit headlamp sealing ring, fit headlamp and

tighten screws.

32.Fit headlamp finisher, side and indicator lamps

and tighten screws.

33.Fit grille support bracket and tighten bolt.

34.With assistance, position and align wing to body

and locate bonnet cable to wing.

35.Connect headlamp, indicator, side lamp and side

repeater lamp multiplugs.

36.Fit bolt securing wing to bulkhead.

37.Fit bolts securing wing to’A’post.

38.Fit nut and bolt securing support stay to wing.

39.Fit bolt securing inner and outer wing to chassis.

40.Fit bolts securing radiator bracket to wing.

41.Fit bolts securing outer wing to inner wing.

42.Align wing and finally tighten all bolts.

43.Position wheel arch extension to wing, and fit

securing studs.

44.Position PAS reservoir to wing and tighten bolts.

45.Position expansion tank pipe and secure with

studs.

46.Position EGR solenoid and tighten bolts.

47.Position heater air intake seal and fit air intake.

48.Fit heater air intake bracket and tighten bolts.

49.Fit heater air intake grille and tighten screws.

50.Align air cleaner intake elbow, tighten screws

and fit grille.

51.Fit wheel arch liner.See this Section.

52.Position bonnet release cable to lock and tighten

screw.

53.Fit cooling fan cowl.

54.Fit front grille.See this Section.STEP - FOLDING - REAR DOOR

Service repair no - 76.10.41

Remove

1.Remove 2 bolts securing step to chassis

member, remove step and collect spacers.

Refit

2.Position step, fit spacer washers and tighten

bolts.

ProCarManuals.com

Page 487 of 667

76CHASSIS AND BODY

18

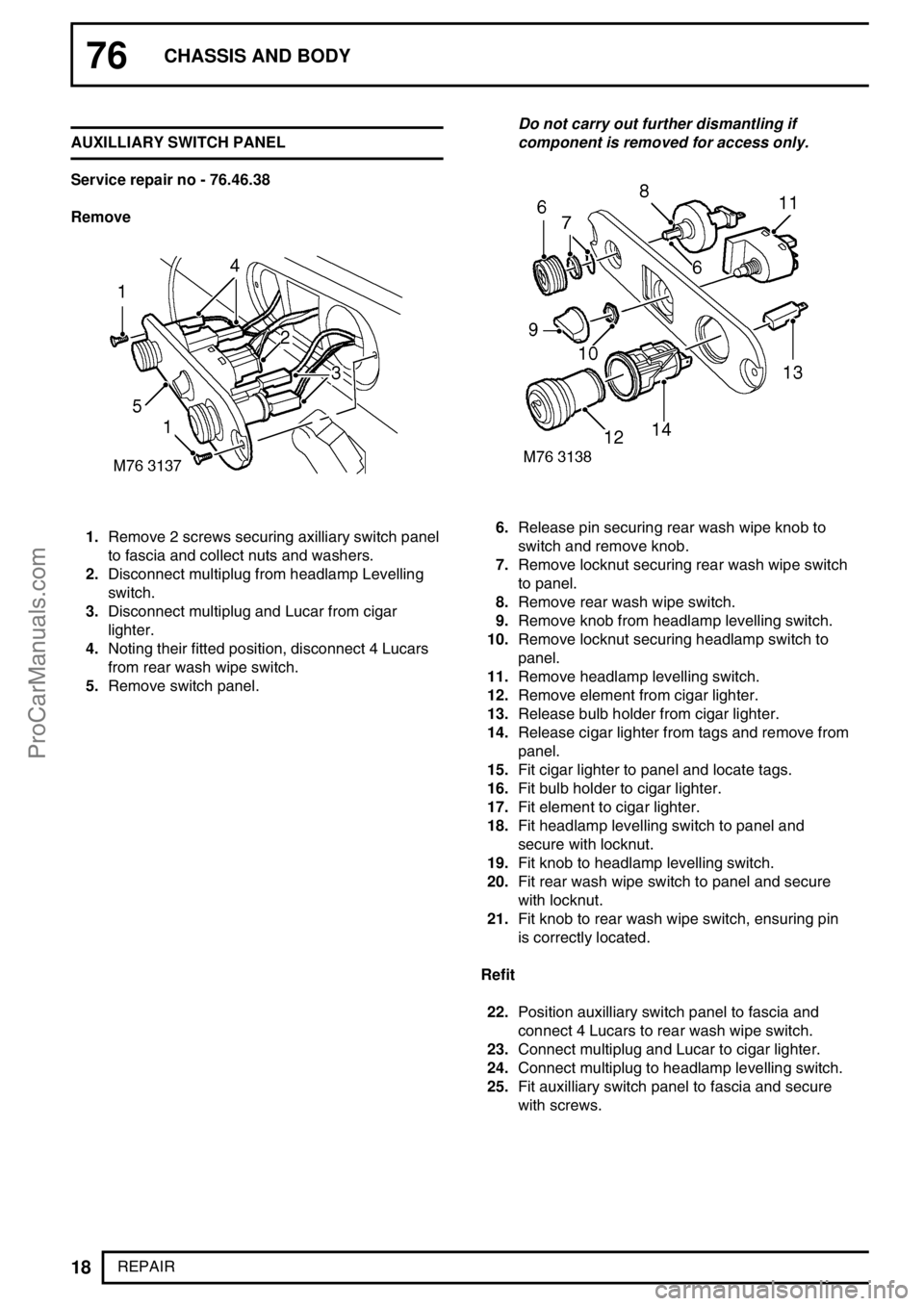

REPAIR AUXILLIARY SWITCH PANEL

Service repair no - 76.46.38

Remove

1.Remove 2 screws securing axilliary switch panel

to fascia and collect nuts and washers.

2.Disconnect multiplug from headlamp Levelling

switch.

3.Disconnect multiplug and Lucar from cigar

lighter.

4.Noting their fitted position, disconnect 4 Lucars

from rear wash wipe switch.

5.Remove switch panel.Do not carry out further dismantling if

component is removed for access only.6.Release pin securing rear wash wipe knob to

switch and remove knob.

7.Remove locknut securing rear wash wipe switch

to panel.

8.Remove rear wash wipe switch.

9.Remove knob from headlamp levelling switch.

10.Remove locknut securing headlamp switch to

panel.

11.Remove headlamp levelling switch.

12.Remove element from cigar lighter.

13.Release bulb holder from cigar lighter.

14.Release cigar lighter from tags and remove from

panel.

15.Fit cigar lighter to panel and locate tags.

16.Fit bulb holder to cigar lighter.

17.Fit element to cigar lighter.

18.Fit headlamp levelling switch to panel and

secure with locknut.

19.Fit knob to headlamp levelling switch.

20.Fit rear wash wipe switch to panel and secure

with locknut.

21.Fit knob to rear wash wipe switch, ensuring pin

is correctly located.

Refit

22.Position auxilliary switch panel to fascia and

connect 4 Lucars to rear wash wipe switch.

23.Connect multiplug and Lucar to cigar lighter.

24.Connect multiplug to headlamp levelling switch.

25.Fit auxilliary switch panel to fascia and secure

with screws.

ProCarManuals.com

Page 508 of 667

77 - PANEL REPAIRS

CONTENTS

Page

INFORMATION

BODY REPAIRS 1..................................................................................................

ELECTRONIC CONTROL UNITS (ECU’s) 3..........................................................

BODY DIMENSIONS

CHASSIS AND BODY 1..........................................................................................

CHASSIS FRAME ALIGNMENT 2..........................................................................

GAP AND PROFILE INFORMATION 9...................................................................

SEALING AND CORROSION PROTECTION

APPROVED MATERIALS 1....................................................................................

APPLICATION EQUIPMENT 4...............................................................................

CORROSION PROTECTION 8...............................................................................

CAVITY WAX 12.....................................................................................................

SEALANTS AND ADHESIVES 17..........................................................................

WATER LEAKS 28..................................................................................................

PANELS

SERVICEABLE PANELS 1.....................................................................................

PROCEDURES

GENERAL WELDING PRECAUTIONS 1...............................................................

PANEL REPLACEMENT PROCEDURE 2..............................................................

REPAIR PROCEDURES 6......................................................................................

REPAIR

WING LOWER FRONT 1........................................................................................

HEADLAMP MOUNTING PANEL 1........................................................................

WING UPPER - LH 2..............................................................................................

WING UPPER - RH 2..............................................................................................

WHEEL ARCH - FRONT 3......................................................................................

BULKHEAD ASSEMBLY 3......................................................................................

SCREEN APERTURE 4..........................................................................................

SILL - FRONT 5......................................................................................................

’B/C’&’D’POST 5..................................................................................................

CORNER CAPPING 6.............................................................................................

BODY SIDE CAPPING 6.........................................................................................

ProCarManuals.com

Page 555 of 667

77PANEL REPAIRS

2

PANELS

4.Headlamp mounting panel - inner

5.Headlamp mounting panel - outer

6.Wing upper

7.Headlamp reinforcement panel

8.Wing lower

ProCarManuals.com

Page 566 of 667

PANEL REPAIRS

1

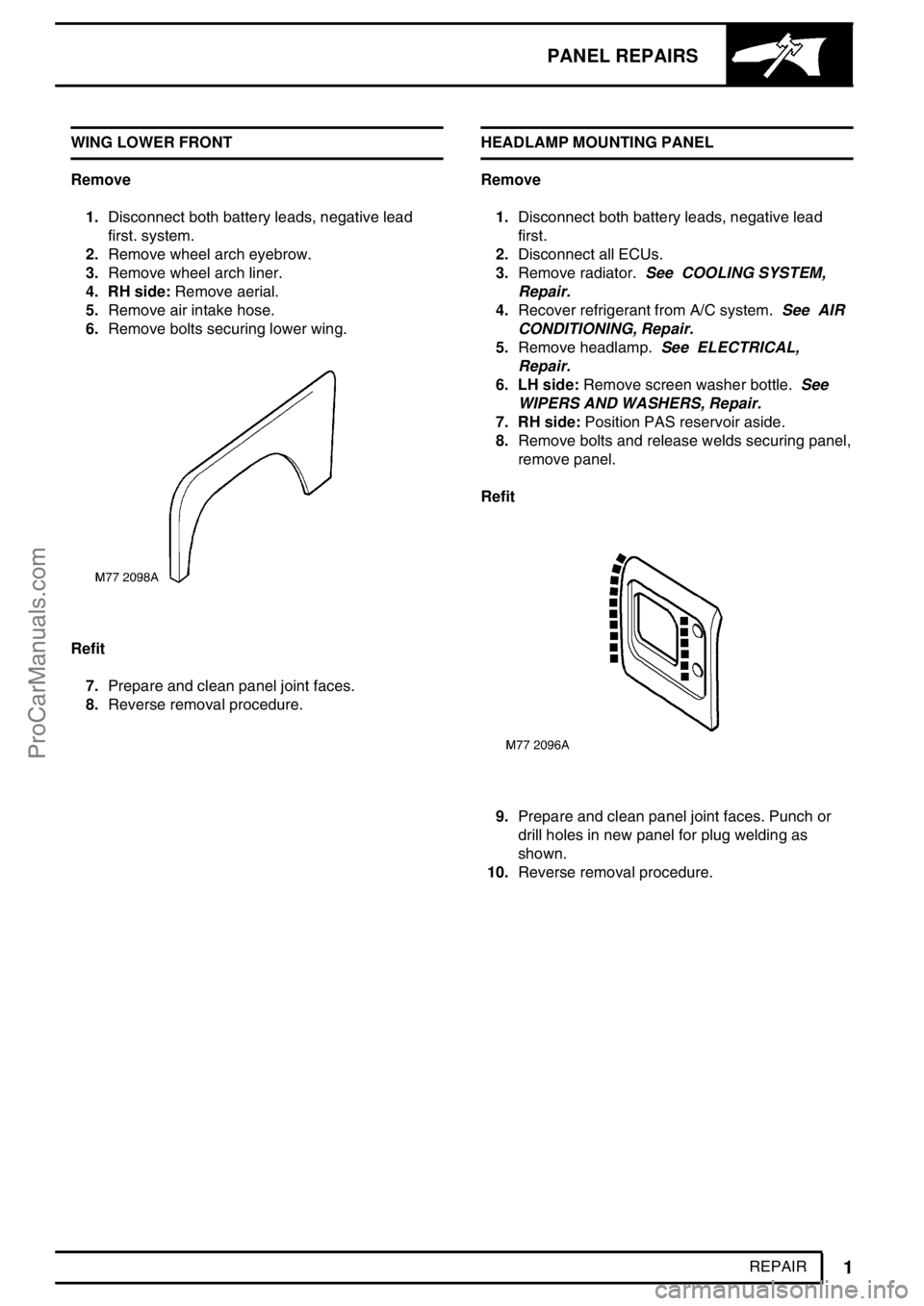

REPAIR WING LOWER FRONT

Remove

1.Disconnect both battery leads, negative lead

first. system.

2.Remove wheel arch eyebrow.

3.Remove wheel arch liner.

4. RH side:Remove aerial.

5.Remove air intake hose.

6.Remove bolts securing lower wing.

Refit

7.Prepare and clean panel joint faces.

8.Reverse removal procedure.HEADLAMP MOUNTING PANEL

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect all ECUs.

3.Remove radiator.See COOLING SYSTEM,

Repair.

4.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

5.Remove headlamp.See ELECTRICAL,

Repair.

6. LH side:Remove screen washer bottle.See

WIPERS AND WASHERS, Repair.

7. RH side:Position PAS reservoir aside.

8.Remove bolts and release welds securing panel,

remove panel.

Refit

9.Prepare and clean panel joint faces. Punch or

drill holes in new panel for plug welding as

shown.

10.Reverse removal procedure.

ProCarManuals.com