ECU LAND ROVER DISCOVERY 1995 Service User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 67 of 976

MAINTENANCE

5

MAINTENANCE 2.Clean or replace spark plugs as applicable.

3.It is essential that correct type of spark plugs are

fitted.

4.Incorrect grade of plugs may lead to piston

overheating and engine failure.

Remove

5.Disconnect battery negative lead. Remove H.T.

leads from spark plugs.

6.Remove plugs and washers.

7.When pushing leads onto plugs, ensure that

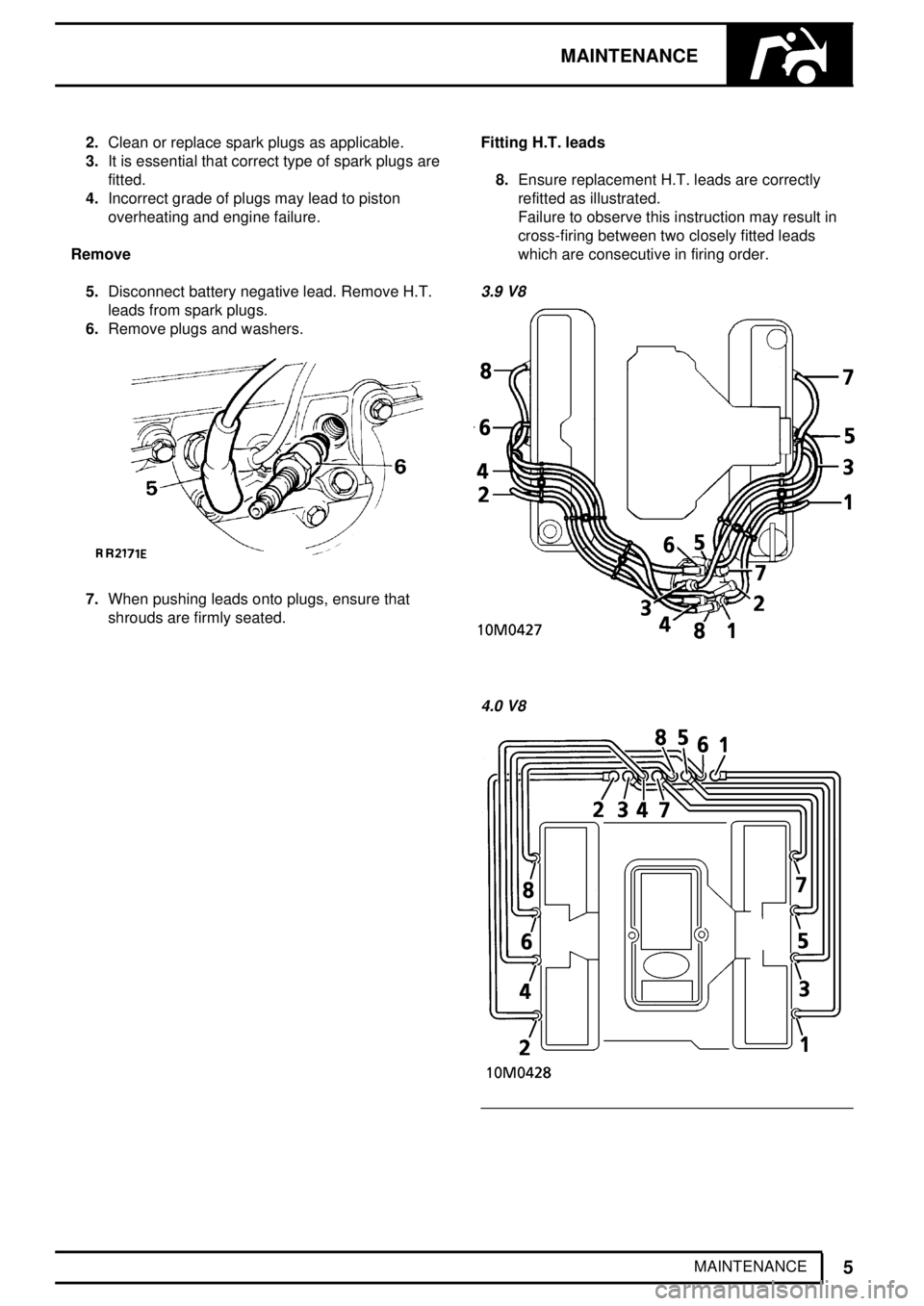

shrouds are firmly seated.Fitting H.T. leads

8.Ensure replacement H.T. leads are correctly

refitted as illustrated.

Failure to observe this instruction may result in

cross-firing between two closely fitted leads

which are consecutive in firing order.

3.9 V8

4.0 V8

Page 68 of 976

10MAINTENANCE

6

MAINTENANCE

RENEW SPARK PLUGS - Mpi

Spark plugs - Mpi

Remove

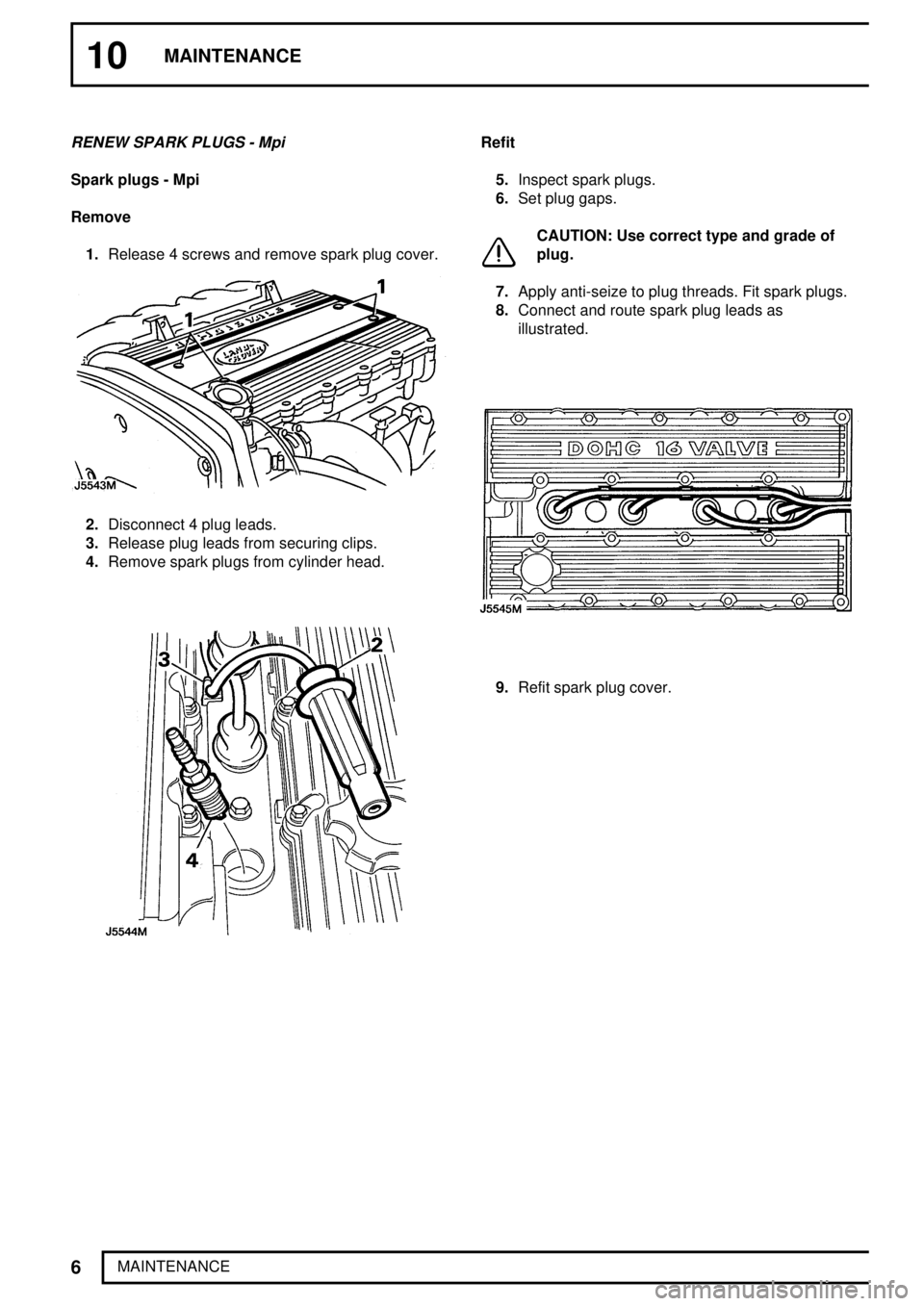

1.Release 4 screws and remove spark plug cover.

2.Disconnect 4 plug leads.

3.Release plug leads from securing clips.

4.Remove spark plugs from cylinder head.

Refit

5.Inspect spark plugs.

6.Set plug gaps.

CAUTION: Use correct type and grade of

plug.

7.Apply anti-seize to plug threads. Fit spark plugs.

8.Connect and route spark plug leads as

illustrated.

9.Refit spark plug cover.

Page 69 of 976

MAINTENANCE

7

MAINTENANCE

CHECK/ADJUST VALVE CLEARANCES. - Tdi

Valve adjustment.See GENERAL SPECIFICATION

DATA, Information, 300 Tdi Engine

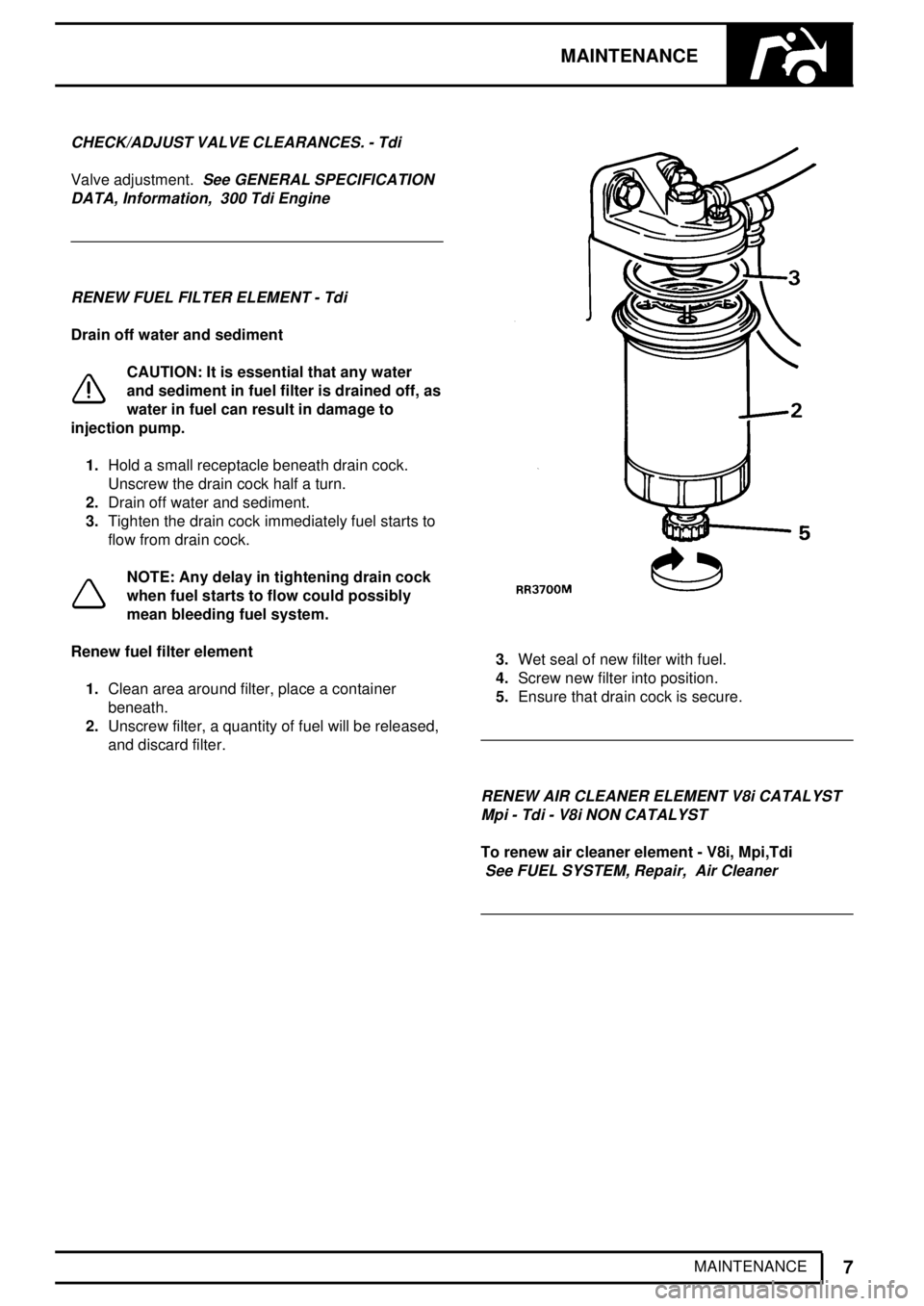

RENEW FUEL FILTER ELEMENT - Tdi

Drain off water and sediment

CAUTION: It is essential that any water

and sediment in fuel filter is drained off, as

water in fuel can result in damage to

injection pump.

1.Hold a small receptacle beneath drain cock.

Unscrew the drain cock half a turn.

2.Drain off water and sediment.

3.Tighten the drain cock immediately fuel starts to

flow from drain cock.

NOTE: Any delay in tightening drain cock

when fuel starts to flow could possibly

mean bleeding fuel system.

Renew fuel filter element

1.Clean area around filter, place a container

beneath.

2.Unscrew filter, a quantity of fuel will be released,

and discard filter.

3.Wet seal of new filter with fuel.

4.Screw new filter into position.

5.Ensure that drain cock is secure.

RENEW AIR CLEANER ELEMENT V8i CATALYST

Mpi - Tdi - V8i NON CATALYST

To renew air cleaner element - V8i, Mpi,Tdi

See FUEL SYSTEM, Repair, Air Cleaner

Page 70 of 976

10MAINTENANCE

8

MAINTENANCE

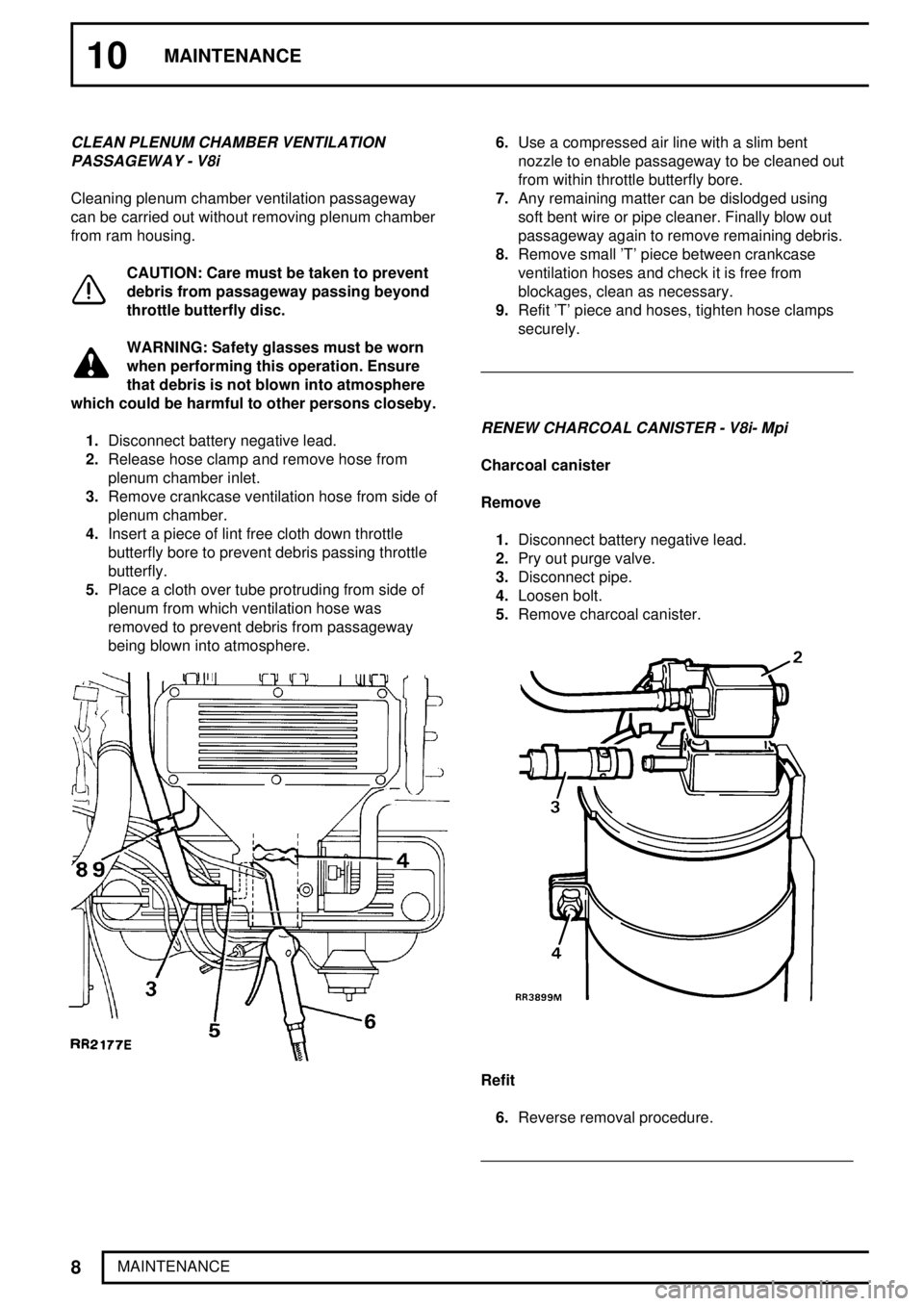

CLEAN PLENUM CHAMBER VENTILATION

PASSAGEWAY - V8i

Cleaning plenum chamber ventilation passageway

can be carried out without removing plenum chamber

from ram housing.

CAUTION: Care must be taken to prevent

debris from passageway passing beyond

throttle butterfly disc.

WARNING: Safety glasses must be worn

when performing this operation. Ensure

that debris is not blown into atmosphere

which could be harmful to other persons closeby.

1.Disconnect battery negative lead.

2.Release hose clamp and remove hose from

plenum chamber inlet.

3.Remove crankcase ventilation hose from side of

plenum chamber.

4.Insert a piece of lint free cloth down throttle

butterfly bore to prevent debris passing throttle

butterfly.

5.Place a cloth over tube protruding from side of

plenum from which ventilation hose was

removed to prevent debris from passageway

being blown into atmosphere.

6.Use a compressed air line with a slim bent

nozzle to enable passageway to be cleaned out

from within throttle butterfly bore.

7.Any remaining matter can be dislodged using

soft bent wire or pipe cleaner. Finally blow out

passageway again to remove remaining debris.

8.Remove small 'T' piece between crankcase

ventilation hoses and check it is free from

blockages, clean as necessary.

9.Refit 'T' piece and hoses, tighten hose clamps

securely.

RENEW CHARCOAL CANISTER - V8i- Mpi

Charcoal canister

Remove

1.Disconnect battery negative lead.

2.Pry out purge valve.

3.Disconnect pipe.

4.Loosen bolt.

5.Remove charcoal canister.

Refit

6.Reverse removal procedure.

Page 78 of 976

10MAINTENANCE

16

MAINTENANCE

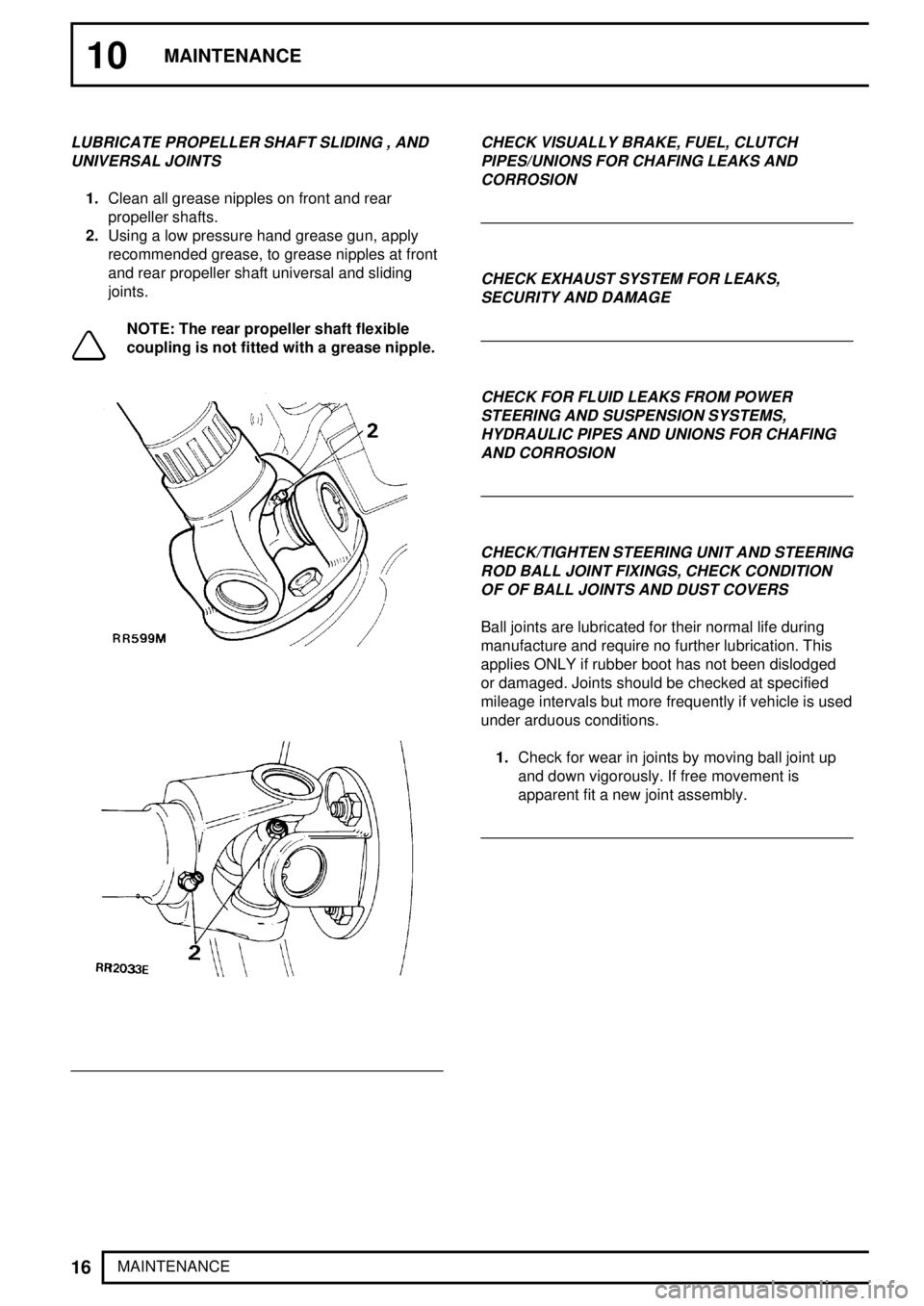

LUBRICATE PROPELLER SHAFT SLIDING , AND

UNIVERSAL JOINTS

1.Clean all grease nipples on front and rear

propeller shafts.

2.Using a low pressure hand grease gun, apply

recommended grease, to grease nipples at front

and rear propeller shaft universal and sliding

joints.

NOTE: The rear propeller shaft flexible

coupling is not fitted with a grease nipple.

CHECK VISUALLY BRAKE, FUEL, CLUTCH

PIPES/UNIONS FOR CHAFING LEAKS AND

CORROSION

CHECK EXHAUST SYSTEM FOR LEAKS,

SECURITY AND DAMAGE

CHECK FOR FLUID LEAKS FROM POWER

STEERING AND SUSPENSION SYSTEMS,

HYDRAULIC PIPES AND UNIONS FOR CHAFING

AND CORROSION

CHECK/TIGHTEN STEERING UNIT AND STEERING

ROD BALL JOINT FIXINGS, CHECK CONDITION

OF OF BALL JOINTS AND DUST COVERS

Ball joints are lubricated for their normal life during

manufacture and require no further lubrication. This

applies ONLY if rubber boot has not been dislodged

or damaged. Joints should be checked at specified

mileage intervals but more frequently if vehicle is used

under arduous conditions.

1.Check for wear in joints by moving ball joint up

and down vigorously. If free movement is

apparent fit a new joint assembly.

Page 79 of 976

MAINTENANCE

17

MAINTENANCE

CHECK/TIGHTEN FRONT AND REAR AXLE

SUSPENSION LINK FIXINGS, CHECK CONDITION

OF MOUNTING RUBBERS

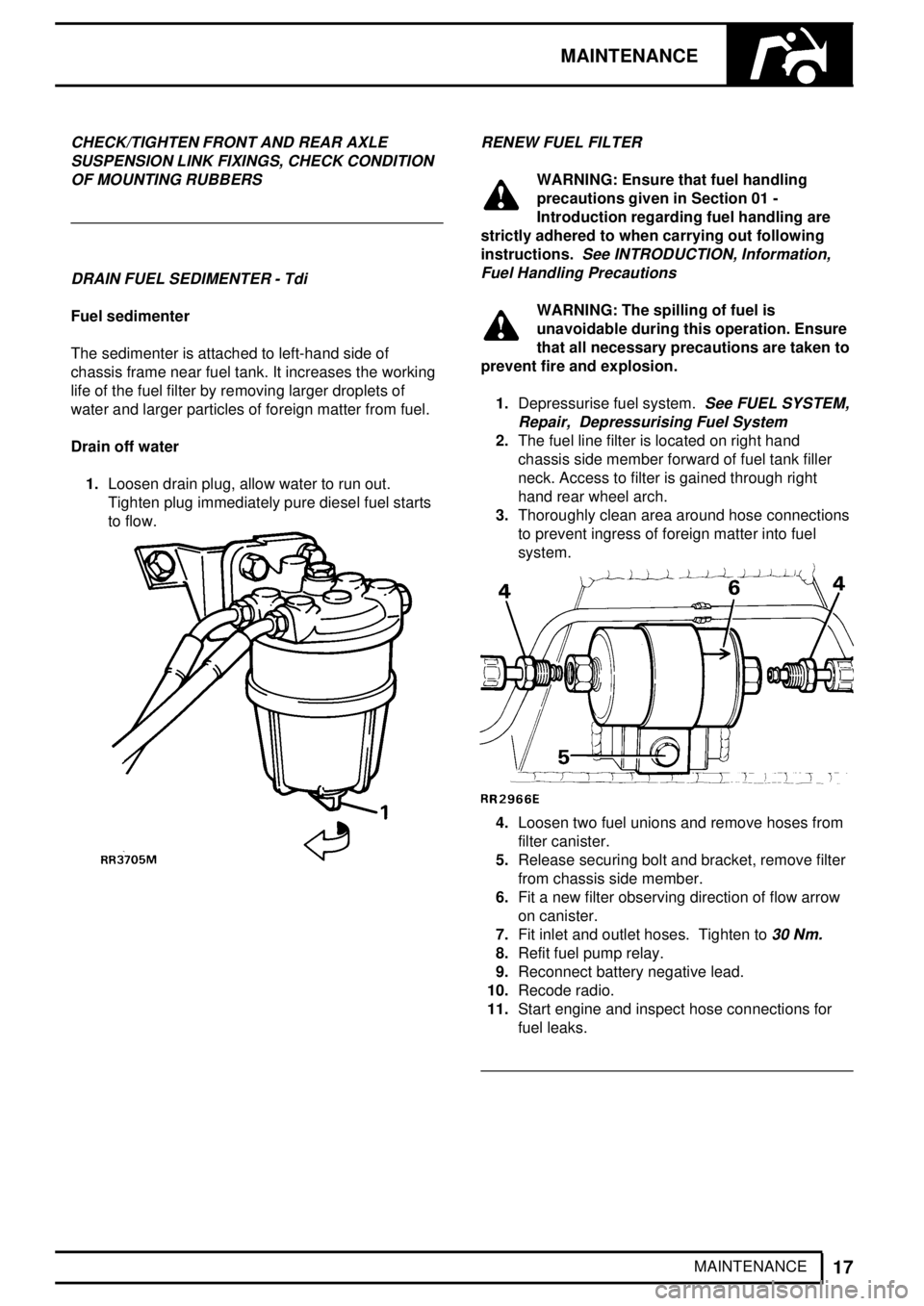

DRAIN FUEL SEDIMENTER - Tdi

Fuel sedimenter

The sedimenter is attached to left-hand side of

chassis frame near fuel tank. It increases the working

life of the fuel filter by removing larger droplets of

water and larger particles of foreign matter from fuel.

Drain off water

1.Loosen drain plug, allow water to run out.

Tighten plug immediately pure diesel fuel starts

to flow.

RENEW FUEL FILTER

WARNING: Ensure that fuel handling

precautions given in Section 01 -

Introduction regarding fuel handling are

strictly adhered to when carrying out following

instructions.

See INTRODUCTION, Information,

Fuel Handling Precautions

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

1.Depressurise fuel system.

See FUEL SYSTEM,

Repair, Depressurising Fuel System

2.The fuel line filter is located on right hand

chassis side member forward of fuel tank filler

neck. Access to filter is gained through right

hand rear wheel arch.

3.Thoroughly clean area around hose connections

to prevent ingress of foreign matter into fuel

system.

4.Loosen two fuel unions and remove hoses from

filter canister.

5.Release securing bolt and bracket, remove filter

from chassis side member.

6.Fit a new filter observing direction of flow arrow

on canister.

7.Fit inlet and outlet hoses. Tighten to

30 Nm.

8.Refit fuel pump relay.

9.Reconnect battery negative lead.

10.Recode radio.

11.Start engine and inspect hose connections for

fuel leaks.

Page 84 of 976

Tdi

3

REPAIR ENGINE

Service repair no - 12.41.01

Remove

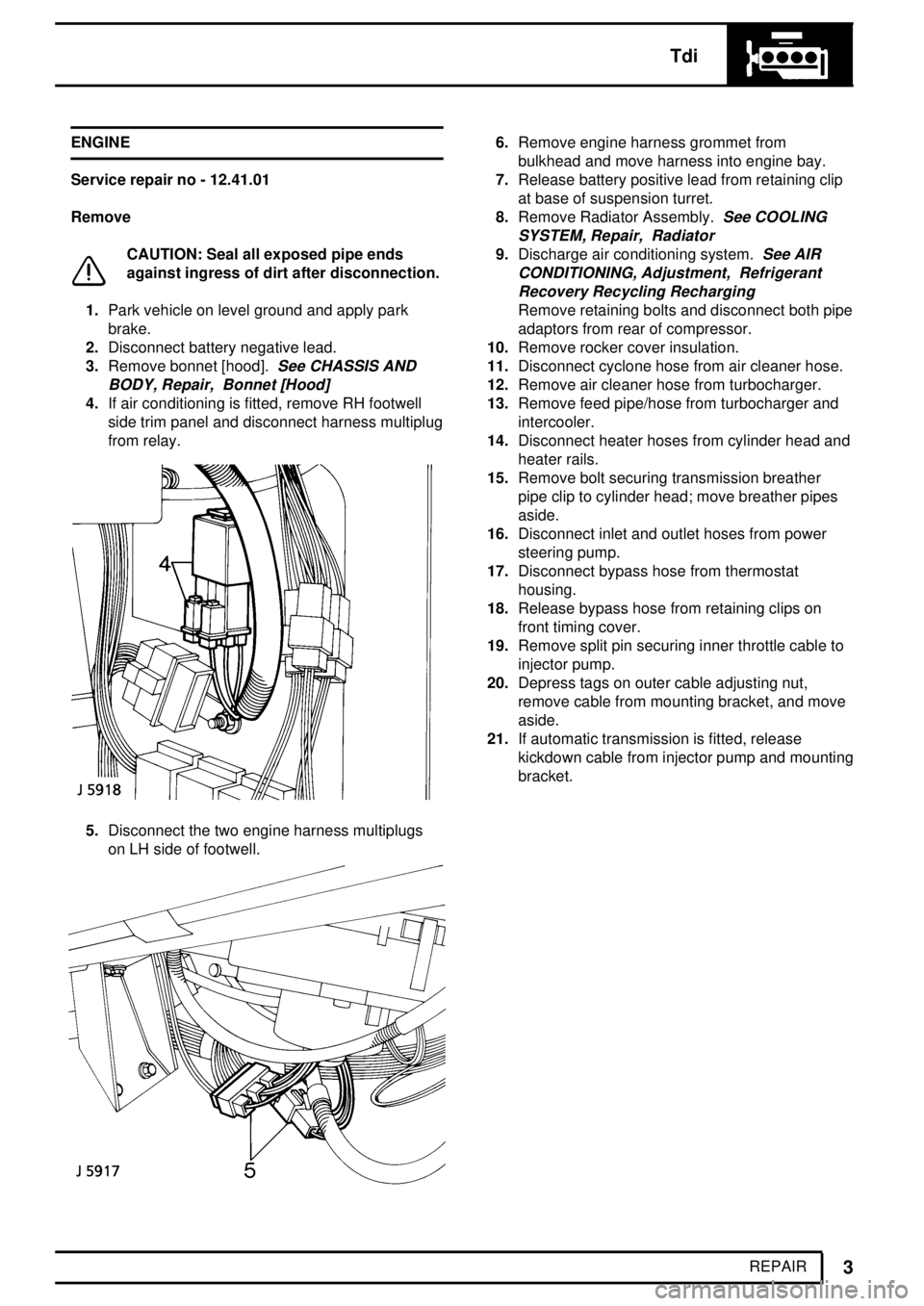

CAUTION: Seal all exposed pipe ends

against ingress of dirt after disconnection.

1.Park vehicle on level ground and apply park

brake.

2.Disconnect battery negative lead.

3.Remove bonnet [hood].

See CHASSIS AND

BODY, Repair, Bonnet [Hood]

4.If air conditioning is fitted, remove RH footwell

side trim panel and disconnect harness multiplug

from relay.

5.Disconnect the two engine harness multiplugs

on LH side of footwell.

6.Remove engine harness grommet from

bulkhead and move harness into engine bay.

7.Release battery positive lead from retaining clip

at base of suspension turret.

8.Remove Radiator Assembly.

See COOLING

SYSTEM, Repair, Radiator

9.Discharge air conditioning system.See AIR

CONDITIONING, Adjustment, Refrigerant

Recovery Recycling Recharging

Remove retaining bolts and disconnect both pipe

adaptors from rear of compressor.

10.Remove rocker cover insulation.

11.Disconnect cyclone hose from air cleaner hose.

12.Remove air cleaner hose from turbocharger.

13.Remove feed pipe/hose from turbocharger and

intercooler.

14.Disconnect heater hoses from cylinder head and

heater rails.

15.Remove bolt securing transmission breather

pipe clip to cylinder head; move breather pipes

aside.

16.Disconnect inlet and outlet hoses from power

steering pump.

17.Disconnect bypass hose from thermostat

housing.

18.Release bypass hose from retaining clips on

front timing cover.

19.Remove split pin securing inner throttle cable to

injector pump.

20.Depress tags on outer cable adjusting nut,

remove cable from mounting bracket, and move

aside.

21.If automatic transmission is fitted, release

kickdown cable from injector pump and mounting

bracket.

Page 85 of 976

12ENGINE

4

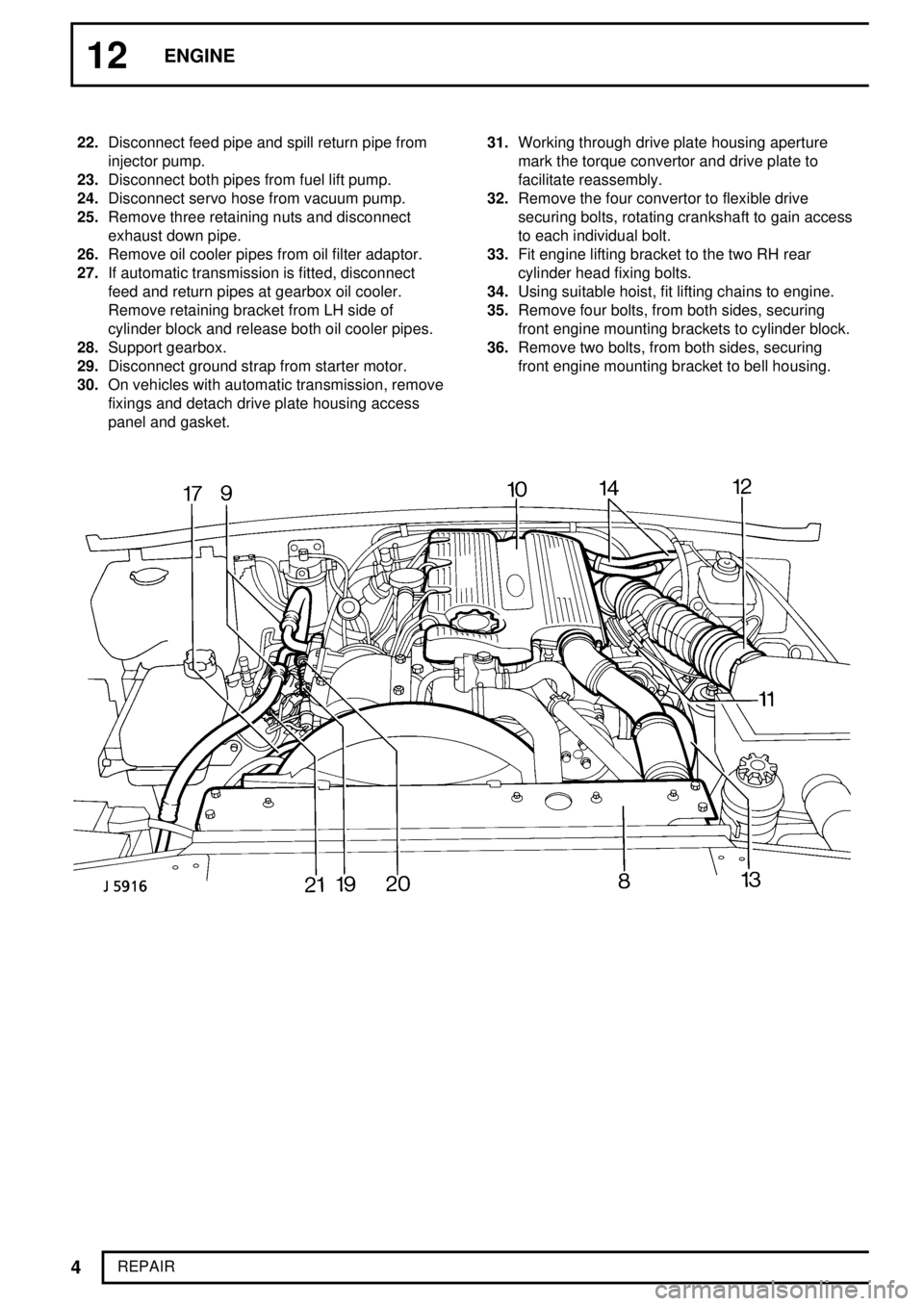

REPAIR 22.Disconnect feed pipe and spill return pipe from

injector pump.

23.Disconnect both pipes from fuel lift pump.

24.Disconnect servo hose from vacuum pump.

25.Remove three retaining nuts and disconnect

exhaust down pipe.

26.Remove oil cooler pipes from oil filter adaptor.

27.If automatic transmission is fitted, disconnect

feed and return pipes at gearbox oil cooler.

Remove retaining bracket from LH side of

cylinder block and release both oil cooler pipes.

28.Support gearbox.

29.Disconnect ground strap from starter motor.

30.On vehicles with automatic transmission, remove

fixings and detach drive plate housing access

panel and gasket.31.Working through drive plate housing aperture

mark the torque convertor and drive plate to

facilitate reassembly.

32.Remove the four convertor to flexible drive

securing bolts, rotating crankshaft to gain access

to each individual bolt.

33.Fit engine lifting bracket to the two RH rear

cylinder head fixing bolts.

34.Using suitable hoist, fit lifting chains to engine.

35.Remove four bolts, from both sides, securing

front engine mounting brackets to cylinder block.

36.Remove two bolts, from both sides, securing

front engine mounting bracket to bell housing.

Page 86 of 976

Tdi

5

REPAIR

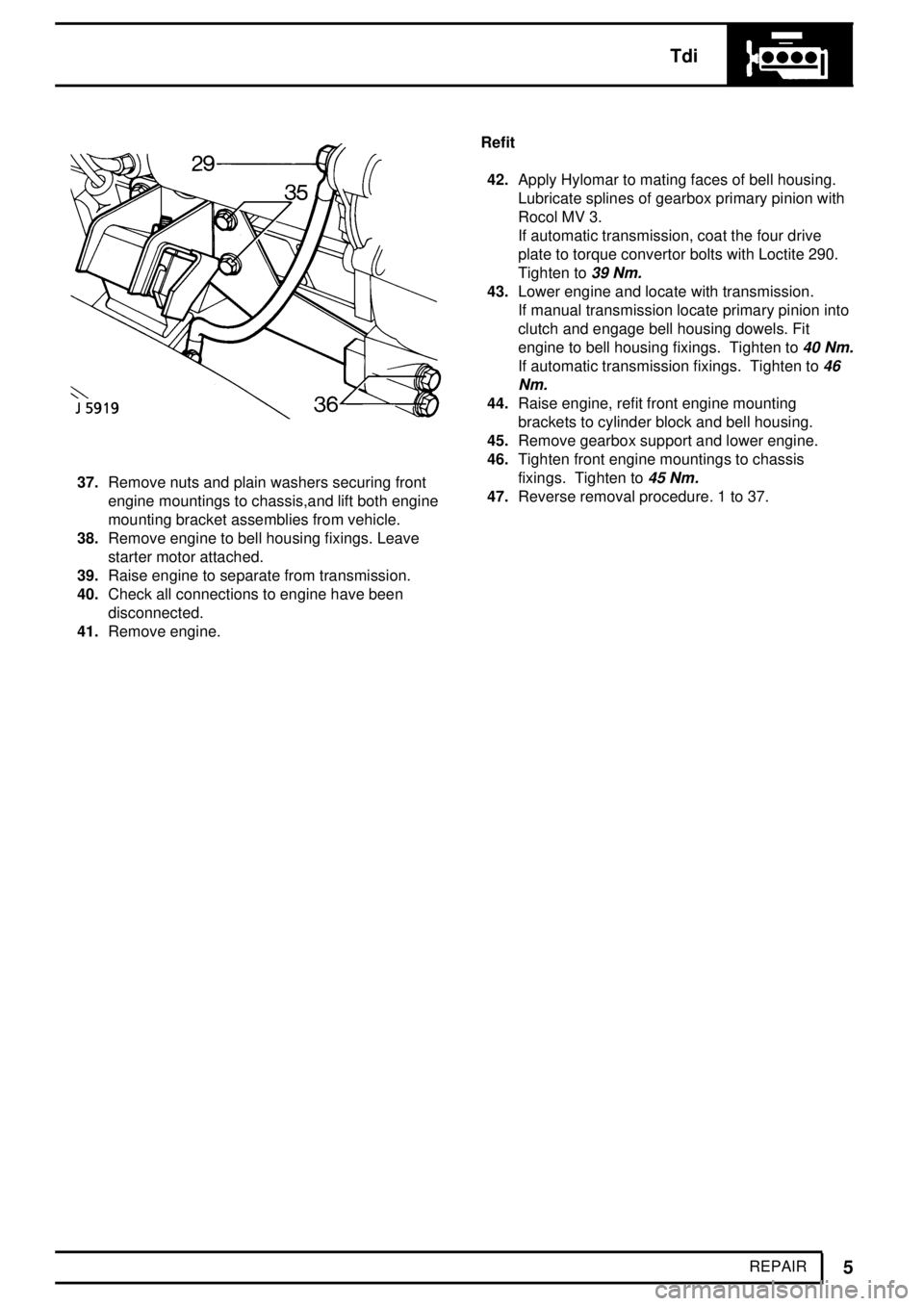

37.Remove nuts and plain washers securing front

engine mountings to chassis,and lift both engine

mounting bracket assemblies from vehicle.

38.Remove engine to bell housing fixings. Leave

starter motor attached.

39.Raise engine to separate from transmission.

40.Check all connections to engine have been

disconnected.

41.Remove engine.Refit

42.Apply Hylomar to mating faces of bell housing.

Lubricate splines of gearbox primary pinion with

Rocol MV 3.

If automatic transmission, coat the four drive

plate to torque convertor bolts with Loctite 290.

Tighten to

39 Nm.

43.Lower engine and locate with transmission.

If manual transmission locate primary pinion into

clutch and engage bell housing dowels. Fit

engine to bell housing fixings. Tighten to

40 Nm.

If automatic transmission fixings. Tighten to46

Nm.

44.Raise engine, refit front engine mounting

brackets to cylinder block and bell housing.

45.Remove gearbox support and lower engine.

46.Tighten front engine mountings to chassis

fixings. Tighten to

45 Nm.

47.Reverse removal procedure. 1 to 37.

Page 87 of 976

12ENGINE

6

REPAIR CRANKSHAFT PULLEY

Service repair no - 12.21.01

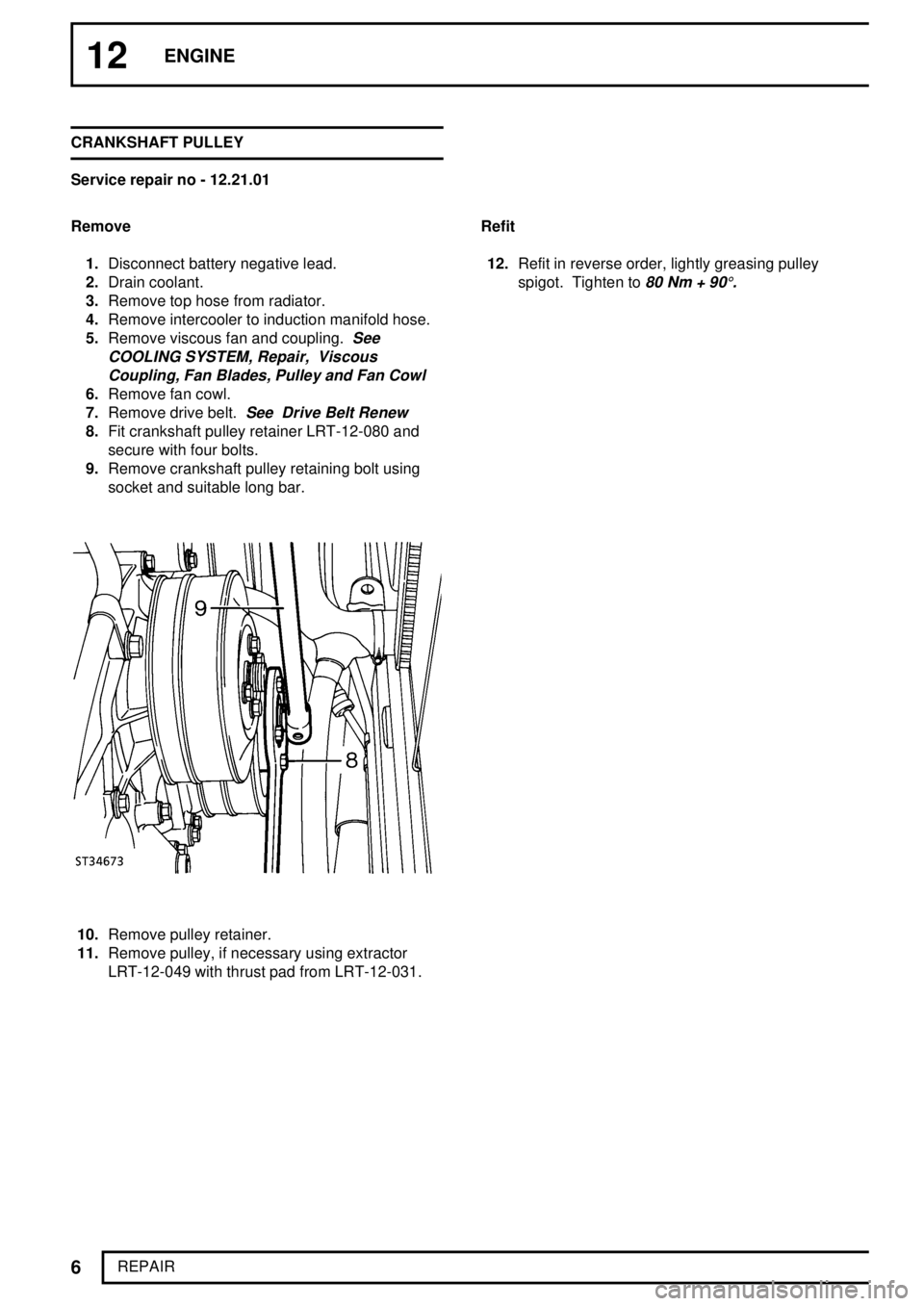

Remove

1.Disconnect battery negative lead.

2.Drain coolant.

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous fan and coupling.

See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

6.Remove fan cowl.

7.Remove drive belt.

See Drive Belt Renew

8.Fit crankshaft pulley retainer LRT-12-080 and

secure with four bolts.

9.Remove crankshaft pulley retaining bolt using

socket and suitable long bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049 with thrust pad from LRT-12-031.Refit

12.Refit in reverse order, lightly greasing pulley

spigot. Tighten to

80 Nm + 90°.