torque LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 750 of 873

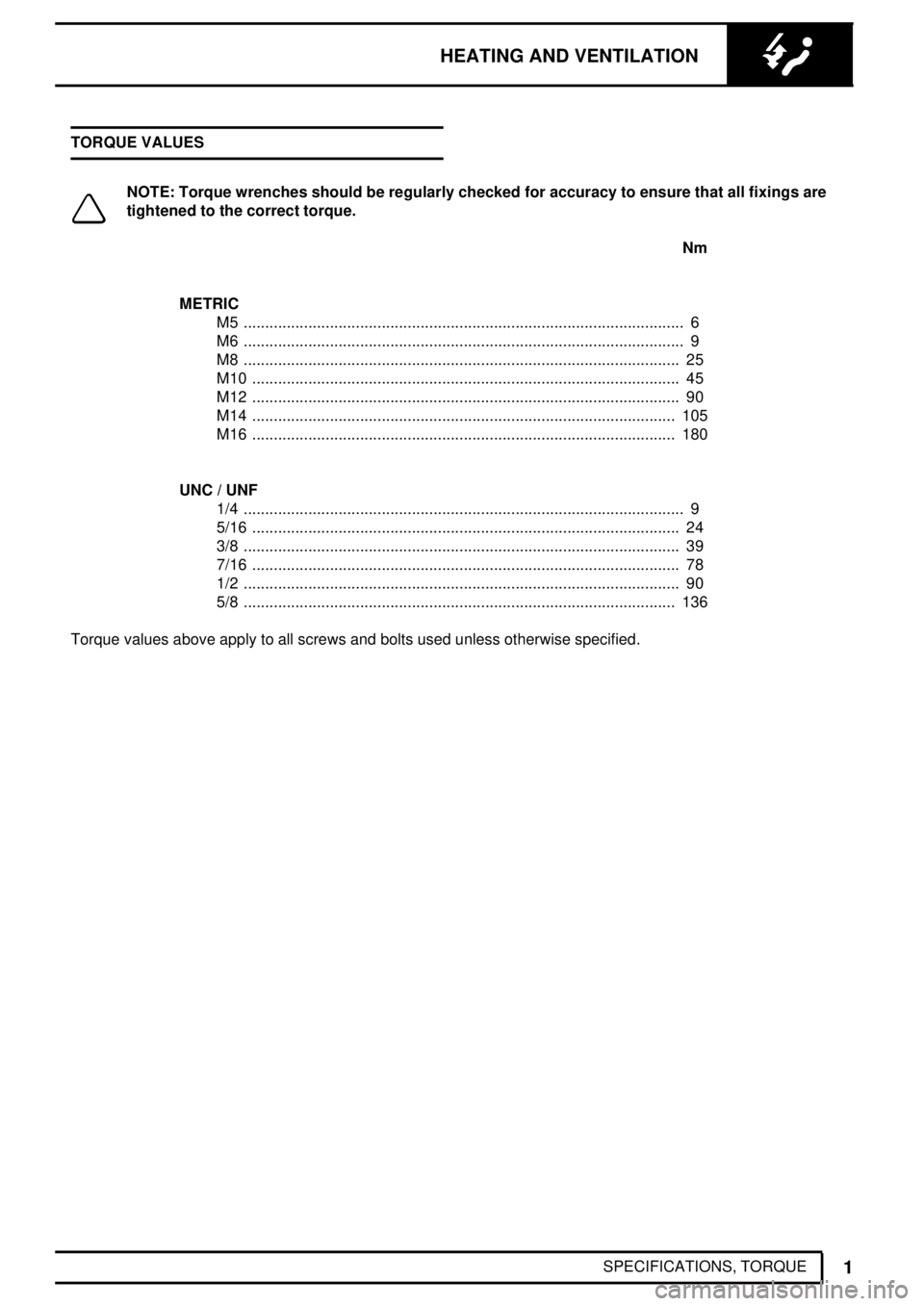

HEATING AND VENTILATION

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

METRIC

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................

Torque values above apply to all screws and bolts used unless otherwise specified.

Page 756 of 873

AIR CONDITIONING

1

FAULT DIAGNOSIS AIR CONDITIONING FAULTS

FAULT CAUSE REMEDY

1. Incorrect voltage. 1. Check voltage.

A.2. Open or defective fuse or relay. 2. Check and replace as necessary.

BLOWER3. Loose wire connection including 3. Check system wires; tighten

MOTORground. all connections.

INOPERATIVE4. Switch open or defective. 4. Replace switch.

OR SLOW5. Tight, worn, or burnt motor 5. Replace motor.

RUNNINGbearings.

6. Open rotor windings. 6. Replace motor.

7. Worn motor brushes. 7. Replace motor.

8. Shaft binding-blade misaligned. 8. Check alignment. Repair or replace

as necessary.

9. Defective resistors 9. Rectify or replace.

1. Incorrect voltage. 1. Check voltage.

2. Open or defective fuse or relay. 2. Check and replace as necessary.

B.3. Defective thermostat control or 3. Replace thermostat or

COMPRESSORpressure switch. pressure switch.

CLUTCH4. Shorted or open field coil. 4. Replace coil.

INOPERATIVE5. Bearing seized (clutch will not 5. Replace clutch pulley assembly.

disengage).

6. Refrigeration circuit problem causing

heavy load and excessive drive

torque.6. Check and rectify.

1. Incorrect alignment. 1. Check alignment; repair as

necessary.

2. Loose belt. 2. Adjust to proper tension.

C.3. Compressor not mounted securely. 3. Repair as necessary.

COMPRESSOR4. Bearing in clutch-pulley 4. Remove clutch and replace

CLUTCHassembly not pressed in. clutch pulley assembly.

NOISY5. Low voltage to clutch. 5. Check connections and voltage.

6. Clutch will not spin freely. 6. Refer to B5 above.

7. Oil on clutch face. 7. Check compressor seals for leaks.

8. Slipping clutch. 8. Refer to C5 above. Then check air

gap.

9. Overloaded or locked compressor. 9. Repair or replace compressor.

10. Icing. 10. Check for suction line frosting.

Replace expansion valve if

necessary.

Replace receiver/drier if necessary.

D.1. Motor and/or blades improperly 1. Check mountings, adjust as

CONDENSERmounted. necessary.

VIBRATION2. Foreign matter build-up on 2. Clean blades with a suitable

blades. non-inflammable cleaner.

3. Excessive wear of motor bearings. 3. Replace motor.

Page 761 of 873

82AIR CONDITIONING

2

ADJUSTMENT SERVICING PRECAUTIONS

Care must be taken when handling refrigeration

system components. Units must not be lifted by their

hoses, pipes or capillary lines. Hoses and lines must

not be subjected to any twist or stress. Ensure that

hoses are positioned in their correct run before fully

tightening the couplings, and ensure that all clips and

supports are used. Torque wrenches of the correct

type must be used when tightening refrigerant

connections to the stated value. An additional wrench

must be used to hold the union to prevent twisting of

the pipe.

Before connecting any hose or pipe ensure that

refrigerant oil is applied to the seat of the new '0' ring

but not to the threads.

Check the oil trap for the amount of oil lost.

All protective plugs on components must be left in

place until immediately prior to connection.

The receiver/drier contains desiccant which absorbs

moisture. It must be positively sealed at all times.

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

Use alcohol and a clean cloth to clean dirty

connections.

Ensure that all new parts fitted are marked for use

withR134a.

Refrigerant oil

Use the approved refrigerant lubricating oil:

Nippon Denso ND-OIL 8

Unipart R134a ND-OIL8

CAUTION: Do not use any other type of

refrigerant oil.

Refrigerant oil easily absorbs water and must not be

stored for long periods. Do not pour unused oil back

into the container.

When renewing system components, add the

following quantities of refrigerant oil:

Condenser 40ml..........................................................

Evaporator 80ml..........................................................

Pipe or hose 20ml........................................................

Receiver/drier 20ml......................................................

Total of refrigerant oil in system = 180ml = 6.3 Fl

ozA new compressor is sealed and pressurised with

Nitrogen gas, slowly release the sealing cap, gas

pressure should be heard to release as the seal is

broken.

NOTE: A new compressor should always

have its sealing caps in place and must

not be removed until immediately prior to

fitting

Fitting a new compressor

A new compressor is supplied with an oil fill (X) of:

180ml

A calculated quantity of oil must be drained from a

new compressor before fitting.

To calculate the quantity of oil to be drained:

1.Remove sealing plugs from the OLD compressor

2.Invert compressor and gravity drain oil into

measuring cylinder. Rotating the compressor

clutch plate will assist complete draining.

3.Note the quantity of oil drained (Y).

4.Calculate the quantity (Q) of oil to be drained

from the NEW compressor using the following

formula:

X - (Y + 20ml) = Q

Rapid refrigerant discharge

When the air conditioning system is involved in

accident damage and the circuit is punctured, the

refrigerant is discharged rapidly. The rapid discharged

of refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled as follows:

1.Gravity drain all the oil, assist by rotating the

clutch plate (not the pulley).

2.Refill the compressor with the following amount

of new refrigerant oil:

130ml

3.Plug the inlet and outlet ports.

Page 775 of 873

82AIR CONDITIONING

10

REPAIR 2.Disconnect 2 Lucar connectors from thermostat.

3.Position wiring aside.

4.Remove 2 screws securing heater pipe bracket

and position pipes aside.

5.Remove 10 clips retaining upper and lower

casings.

6.Remove 5 screws retaining upper casing.

7.Remove lower casing and evaporator.

8.Remove 4 clips securing evaporator top cover.

9.Remove evaporator top cover.

10.Remove thermostat sensor from evaporator

matrix.

11.Remove evaporator assembly from lower casing.

12.Remove bulkhead seal from case.

Expansion valve

13.Remove insulation from evaporator and

expansion valve connections.

14.Remove expansion valve sensor retaining clip.

15.Unscrew 2 pipe unions. Discard 'O' ring seals.

CAUTION: Use a second wrench to

support pipe adapters and plug

connections.

16.Remove expansion valve.

17.Unscrew pipe union. Discard 'O' ring seal.

18.Remove evaporator pipe.

Refit

19.Reverse removal procedure. Use new 'O' rings,

insulation and bulkhead seal.

NOTE: Use refrigerant oil on all 'O' rings

and mating surfaces. Tighten connection

See Specifications, torque, Torque Values

20.Wrap all exposed metal at hose connections with

prestite tape.

21.Evacuate and recharge system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

22.Leak test any disturbed joints.See Adjustment,

Leak Test System

23.Perform a functional check.

24.Disconnect service unit.

Page 793 of 873

AIR CONDITIONING

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Air conditioning

Compressor flange bolts 10............................................................................

Receiver drier union bolts 6...........................................................................

Dual pressure switch 11..................................................................................

Pressure pipe union nuts - M16 14.................................................................

Discharge pipe union nuts - M22 22...............................................................

Suction pipe union nuts - M24 33...................................................................

AIR CONDITIONING CHARGE DATA

Total oil in system 180ml - 6.3Fl oz...........................................................................

Total refrigerant in system 0,90kg - 32Fl oz..............................................................

Total refrigerant in system with rear air conditioning 1,15kg - 40Fl oz.......................

Page 845 of 873

ELECTRICAL

25

REPAIR STARTER MOTOR - Mpi

Service repair no - 86.60.01

Remove

1.Disconnect battery negative lead.

2.Remove 2 nuts securing cables to starter

solenoid; release cables.

3.Remove 3 bolts securing starter motor.

4.Manoeuvre starter motor clear of bell housing.

5.Remove starter motor.Refit

6.Clean mating faces of starter motor and

differential housing.

7.Manoeuvre starter motor into position.

8.Fit mounting bolts and Tighten to

45 Nm.

9.Connect battery cables to starter solenoid; fit

nuts and tighten to the correct torque.

10.Reconnect battery negative lead.

Page 873 of 873

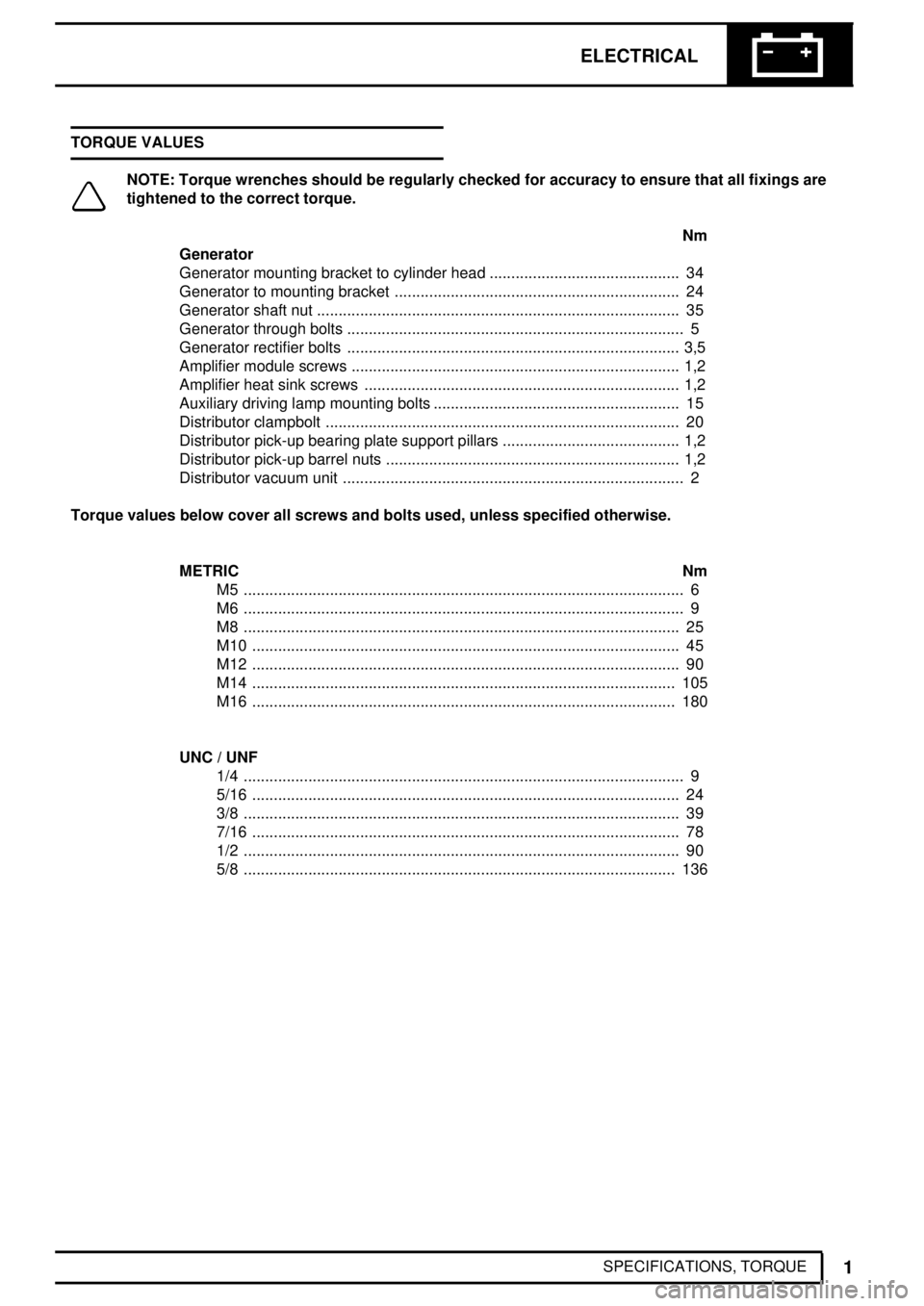

ELECTRICAL

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Generator

Generator mounting bracket to cylinder head 34............................................

Generator to mounting bracket 24..................................................................

Generator shaft nut 35....................................................................................

Generator through bolts 5..............................................................................

Generator rectifier bolts 3,5.............................................................................

Amplifier module screws 1,2............................................................................

Amplifier heat sink screws 1,2.........................................................................

Auxiliary driving lamp mounting bolts 15.........................................................

Distributor clampbolt 20..................................................................................

Distributor pick-up bearing plate support pillars 1,2.........................................

Distributor pick-up barrel nuts 1,2....................................................................

Distributor vacuum unit 2...............................................................................

Torque values below cover all screws and bolts used, unless specified otherwise.

METRIC Nm

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................