service LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 393 of 873

33CLUTCH

2

REPAIR BLEED HYDRAULIC SYSTEM

Service repair no - 33.15.01

Procedure

NOTE: During bleed procedure, keep fluid

reservoir topped up to avoid introducing

air to system. For hydraulic fluid

recommendations.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information, Recommended

Lubricants and Fluids

1.Attach suitable tubing to slave cylinder bleed

screw.

2.Place free end of tube in a glass jar containing

clutch fluid.

3.Loosen bleed screw.

4.Pump clutch pedal, pausing at end of each

stroke, until fluid from tubing is free of air.

Keeping free end of tube below surface of fluid.

5.Hold clutch pedal down, tighten bleed screw.

6.Top up fluid reservoir.MASTER CYLINDER

Service repair no - 33.20.01/03

NOTE: All flexible and pipe connections

and joints should be tightened to

15 Nm.

Remove

1.Evacuate hydraulic fluid from system.

2.Disconnect fluid pipe at master cylinder. Plug

master cylinder fluid port and seal end of

hydraulic pipe to prevent ingress of foreign

matter.

3.Lower fascia fuse box panel.

4.Remove master cylinder fixings.

5.Remove retaining washer and clevis pin from

push rod and clutch pedal.

6.Remove master cylinder.

Page 394 of 873

CLUTCH

3

REPAIR Refit

7.Fit the master cylinder and fixings.

8.Fit push-rod to pedal and retain with clevis pin

and washer.

9.Raise fasica fuse box panel.

10.Fit fluid pipe to master cylinder.

11.Bleed system.

See Bleed Hydraulic System

RELEASE BEARING ASSEMBLY

Service repair no - 33.10.07

Remove

1.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

2.Remove clutch slave cylinder.See Slave

Cylinder

3.Withdraw retainer staple.

4.Withdraw bearing and sleeve. If required, press

bearing off sleeve. Fit replacement bearing with

domed face outwards from sleeve.

5.Remove spring clip and fixings.

6.Withdraw release lever assembly.

Refit

7.Smear pivot with grease and fit release lever and

retain with spring clip and bolt.

8.Smear release bearing sleeve inner diameter

with molybdenum disulphide base grease.

9.Reverse removal procedure. 1 to 4.

Page 395 of 873

33CLUTCH

4

REPAIR SLAVE CYLINDER

Service repair no - 33.35.01

NOTE: All flexible and pipe connections

and joints should be tightened to

15 Nm.

Remove

1.Evacuate clutch system fluid at slave cylinder

bleed valve.

2.Disconnect fluid pipe.

3.Remove two securing bolts and withdraw slave

cylinder and backing plate.

4.If dust cover is not withdrawn with slave cylinder,

withdraw it from bell housing.

Refit

5.Withdraw dust cover and backing plate from

slave cylinder.

6.Coat both sides of backing plate with Hylomar

P232M waterproof jointing compound.

7.Locate backing plate and dust cover in position

on slave cylinder.

8.Fit slave cylinder, engaging push-rod through

centre of dust cover and with bleed screw

uppermost.

9.Reconnect fluid pipe.

10.Replenish and bleed clutch hydraulic system.

11.Check for fluid leaks with pedal depressed and

also with system at rest.

Page 396 of 873

CLUTCH

5

REPAIR RENEWING HYDRAULIC DAMPER - Tdi

Service repair no - 33.15.05

NOTE: All flexible and pipe connections

and joints should be tightened to

15 Nm.

Remove

1.Remove the pipe between the slave cylinder and

damper.

2.Disconnect the hydraulic hose from the damper.

3.Remove the two bolts securing the damper to

the bracket and remove the damper.

Refit

4.Fit the damper to the bracket and tighten the two

bolts.

5.Connect the flexible hose to the damper.

6.Fit the pipe to the slave cylinder and to the

damper and tighten the unions.

7.Bleed the hydraulic system.

Page 397 of 873

CLUTCH

1

OVERHAUL MASTER CYLINDER

Service repair no - 30.20.07

1.Remove master cylinder.

See Repair, Master

Cylinder

Disassemble

2.Pull back and remove rubber sealing boot from

pushrod.

3.Depress push-rod and extract circlip.

4.Withdraw push-rod assembly.

5.Withdraw piston assembly.

6.Withdraw retainer and spring.

7.Remove two piston seals and piston washer.

Inspecting

8.Clean all components thoroughly using new

hydraulic fluid. Dry, using a lint-free cloth.

9.Examine cylinder bore and piston, ensure they

are smooth to touch with no corrosion, score

marks or ridges. If in doubt, fit new components.

10.Fit new seals and rubber boot. These items are

all included in master cylinder overhaul kit.

11.Ensure that feed and by-pass ports are not

obstructed.

12.Ensure reservoir cap vent is clear.

Assemble

NOTE: Cleanliness is essential, ensure

hands are free of grease or dirt. Lubricate

cylinder bore and rubber seals with new

hydraulic fluid before assembly.

13.Fit a new piston washer and thinner of two piston

seals, lip last, over piston nose, up against

drilled piston head. Fit thicker seal into piston

groove with lip facing towards seal at opposite

end.

14.Insert spring and retainer into master cylinder

bore.

15.Insert piston and seal assembly, ensuring that

seal lips do not bend back.

16.Reverse 3 and 4, correctly locating circlip.

17.Stretch new rubber boot over push-rod, pack

with rubber grease. Fit securely into locating

groove.

18.Operate push-rod several times to ensure free

movement of internal components.

19.Fit master cylinder.

Page 398 of 873

33CLUTCH

2

OVERHAUL SLAVE CYLINDER

Service repair no - 33.35.07

Overhaul

1.Remove slave cylinder.

See Repair, Slave

Cylinder

Disassemble

2.Withdraw rubber boot.

3.Withdraw push-rod.

4.Remove circlip.

5.Extract piston and seal assembly, applying low

pressure air to fluid inlet if necessary.

6.Withdraw spring.

7.Remove bleed valve.

Inspecting

8.Clean all components thoroughly using new

hydraulic fluid, and dry using lint-free cloth.

9.Examine cylinder bore and piston which must be

free from corrosion, scores and ridges.

10.Replace seal and rubber boot using appropriate

repair kit.

Assemble

NOTE: Cleanliness is essential, ensure

hands are free of grease or dirt.

11.Fit bleed valve. Do not overtighten.

12.Lubricate seals, piston and bore using new

hydraulic fluid.

13.Fit seal into piston groove, lip of seal towards

fluid inlet end of cylinder.

14.Enter piston assembly, spring first, into cylinder

bore. Ensure that seal lip does not fold back.

15.Secure with circlip.

16.Fill rubber boot with rubber grease.

17.Reverse removal procedure. 1 to 3.

Page 403 of 873

R380

1

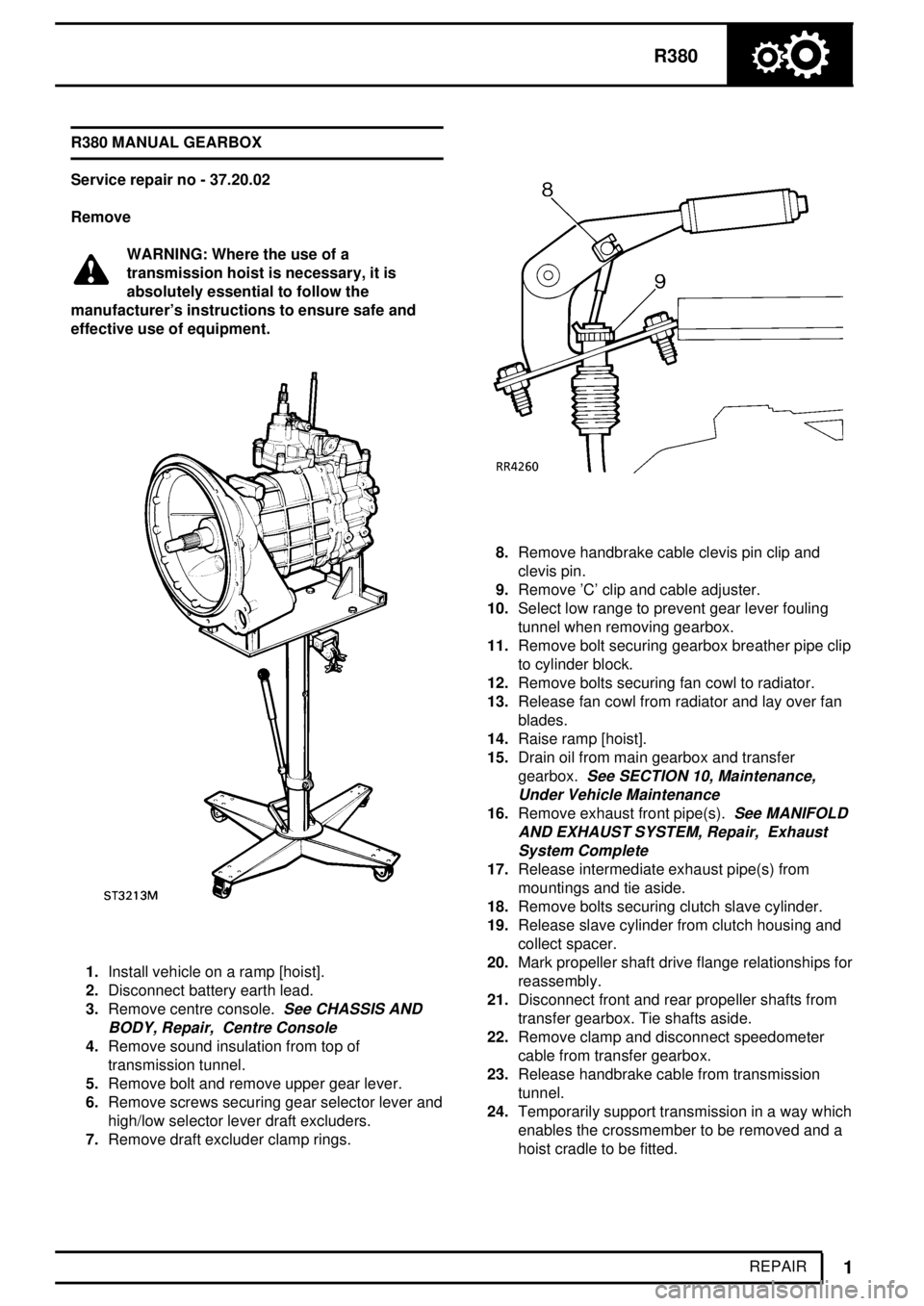

REPAIR R380 MANUAL GEARBOX

Service repair no - 37.20.02

Remove

WARNING: Where the use of a

transmission hoist is necessary, it is

absolutely essential to follow the

manufacturer's instructions to ensure safe and

effective use of equipment.

1.Install vehicle on a ramp [hoist].

2.Disconnect battery earth lead.

3.Remove centre console.

See CHASSIS AND

BODY, Repair, Centre Console

4.Remove sound insulation from top of

transmission tunnel.

5.Remove bolt and remove upper gear lever.

6.Remove screws securing gear selector lever and

high/low selector lever draft excluders.

7.Remove draft excluder clamp rings.

8.Remove handbrake cable clevis pin clip and

clevis pin.

9.Remove 'C' clip and cable adjuster.

10.Select low range to prevent gear lever fouling

tunnel when removing gearbox.

11.Remove bolt securing gearbox breather pipe clip

to cylinder block.

12.Remove bolts securing fan cowl to radiator.

13.Release fan cowl from radiator and lay over fan

blades.

14.Raise ramp [hoist].

15.Drain oil from main gearbox and transfer

gearbox.

See SECTION 10, Maintenance,

Under Vehicle Maintenance

16.Remove exhaust front pipe(s).See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

System Complete

17.Release intermediate exhaust pipe(s) from

mountings and tie aside.

18.Remove bolts securing clutch slave cylinder.

19.Release slave cylinder from clutch housing and

collect spacer.

20.Mark propeller shaft drive flange relationships for

reassembly.

21.Disconnect front and rear propeller shafts from

transfer gearbox. Tie shafts aside.

22.Remove clamp and disconnect speedometer

cable from transfer gearbox.

23.Release handbrake cable from transmission

tunnel.

24.Temporarily support transmission in a way which

enables the crossmember to be removed and a

hoist cradle to be fitted.

Page 404 of 873

37MANUAL GEARBOX

2

REPAIR 25.Remove nuts and bolts securing transmission

cross-member to chassis.

26.Remove nuts and bolts securing cross-member

mountings to transmission.

27.Remove cross-member.

28.Manufacture an adapter plate to dimensions

given in service tool section and attach it to a

transmission hoist. To achieve balance of the

transmission unit when mounted to hoist, it is

essential that pointA,is situated over lifting hoist

ram. Drill holesBto suit hoist table. Secure the

transmission unit cradle at pointCusing the

lower bolts retaining transfer gearbox rear cover.

Raise hoist just enough to take weight of

transmission.

29.Lower hoist sufficiently to allow transfer gearbox

selector lever to clear transmission tunnel

aperture.

30.Disconnect differential lock switch connectors.

31.Disconnect reverse lamp switch connectors.

32.Remove clips securing gearbox breather pipes

to harness.

33.Support engine under sump with a jack.

CAUTION: Use a wooden block to protect

sump.

34.Remove bell housing nuts.

35.Withdraw transmission whilst ensuring all

connections to engine and chassis are released.36.Remove transmission assembly from hoist

cradle and position safely on a bench.

37.Remove breather pipes. Discard pipe union

sealing washers.

38.Remove 'Nyloc' nut, and remove bolt, securing

lever to high/low shaft.

39.Collect spacer washer.

40.Remove 2 clips and remove differential lock

lever link.

41.Remove lower locknut from high/low operating

rod.

42.Place a sling round transfer box and attach to

hoist.

43.Remove nut and 5 bolts securing transfer

gearbox to extension housing.

44.Withdraw transfer gearbox.

Page 407 of 873

R380

1

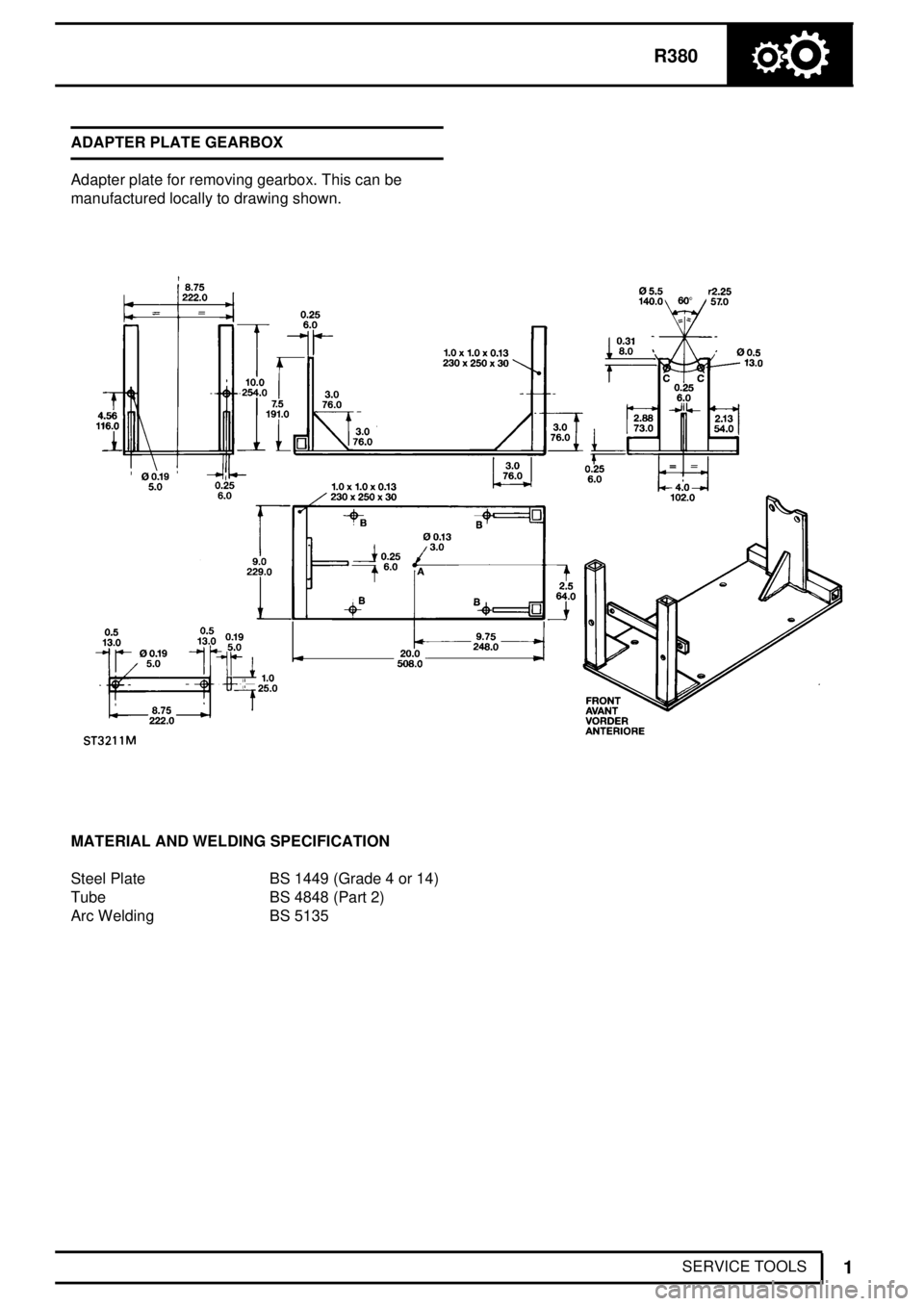

SERVICE TOOLS ADAPTER PLATE GEARBOX

Adapter plate for removing gearbox. This can be

manufactured locally to drawing shown.

MATERIAL AND WELDING SPECIFICATION

Steel Plate BS 1449 (Grade 4 or 14)

Tube BS 4848 (Part 2)

Arc Welding BS 5135

Page 415 of 873

TRANSFER GEARBOX

1

REPAIR LT230T TRANSFER GEARBOX

Service repair no - 41.10.25

Remove

Adaptor plate for removing transfer gearbox

The transfer gearbox is removed from underneath the

vehicle. Using a transmission hoist with an adaptor

plate for securing the transfer gearbox to the hoist.

The adaptor can be manufactured locally to the

drawing below.

WARNING: When using a transmission

hoist it is essential to follow the hoist

manufacturer's instructions.