service LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 371 of 873

Mpi

1

REPAIR COOLANT PUMP

Service repair no - 26.50.01

Remove

1.Position drain tin below coolant pump hose.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

2.Release clip and disconnect hose from coolant

pump housing cover.

3.Remove 5 bolts securing housing cover.

4.Remove housing cover.

5.Remove coolant pump from housing.

6.Discard 3 sealing rings.

Refit

7.Clean coolant pump housing and mating faces.

8.Lubricate new sealing rings with Loctite 405 and

fit to coolant pump.

9.Fit coolant pump to housing.

10.Position housing cover, fit 5 bolts. Tighten to

25Nm

11.Connect hose to housing cover and tighten clip.

12.Refill cooling system.

Page 372 of 873

26COOLING SYSTEM

2

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Disconnect battery negative lead.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

2.Slacken clip and release bottom hose from

radiator, allow coolant to drain into a suitable

container

3.Slacken clip and release bottom hose from

radiator rail.

4.Slacken clip and release top hose from radiator.

5.Release air cleaner to throttle housing hose from

securing brackets.

6.Slacken clip and release bypass hose from

radiator.

7.Slacken clip and release top expansion hose

from radiator.

8.Remove 2 bolts securing radiator side support

brackets.

9.Collect L.H. support bracket and position R.H.

support bracket aside.

10.Slacken clip and release heater hose from

radiator rail.

11.Disconnect 2 multiplugs from cooling fan

assemblies.

Page 374 of 873

26COOLING SYSTEM

4

REPAIR THERMOSTATIC SENSOR

Service repair no - 19.22.18

Remove

1.Disconnect Lucar connector from sensor.

2.Remove sensor.

Refit

3.Clean sensor.

4.Apply Loctite 405 to threads of sensor.

5.Fit sensor and tighten to

15Nm

6.Connect Lucar to sensor.

7.Top-up cooling system.THERMOSTAT

Service repair no - 26.45.01

Remove

1.Position suitable container to collect coolant.

2.Slacken 2 clips and release radiator top hose.

3.Release bypass hose from securing bracket.

4.Release top hose from securing bracket.

5.Remove top hose.

Page 377 of 873

MANIFOLD AND EXHAUST SYSTEM

1

REPAIR EXHAUST SYSTEM COMPLETE

Service repair no - 30.11.01

To improve sealing and accuracy of assembly, a two

piece exhaust system is fitted.

NOTE: Ensure no exhaust leaks are

evident in either a new or old exhaust

system, as this will affect vehicle

performance.

WARNING: To prevent personal injury

occurring from a hot exhaust system, DO

NOT attempt to disconnect any

components until exhaust system has cooled

down.

Page 378 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NO LAND ROVER DISCOVERY 1995 Workshop Manual 30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NO](/img/64/57248/w960_57248-377.png)

30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NOTE: NAS models have four heated

oxygen sensors fitted.

3.Remove two nuts securing rear exhaust

assembly to front exhaust assembly.

4.Remove nuts and release front downpipes from

manifolds. Discard gaskets.

5.Lower front exhaust assembly with catalysts (if

fitted), retain olive.

NOTE: Assistance is required for removing

and refitting rear exhaust assembly.

6.Remove bolts securing three hanger brackets to

chassis. Lower exhaust assembly onto rear axle.

Detach rubbers from hanging brackets.

7.Place extended axle stands underneath chassis,

in front of chassis mounted rear towing brackets.

8.Lower ramp[hoist] until vehicle weight is

supported securely on stands.

9.Lower ramp [hoist] until rear shock absorbers

are ALMOST fully extended.

10.Move rear exhaust to a diagonal position, centre

silencer to right of vehicle.

11.Facing rear of vehicle, twist assembly

anti-clockwise clear of rear axle.

12.Remove rear exhaust assembly from vehicle.

Refit

13.Position rear exhaust assembly over rear axle in

a diagonal position, as for removing.

14.Twist assembly clockwise until it is in mounting

position.

15.Reverse removal procedure. 1. to 9. using new

manifold gaskets and applying exhaust sealer to

system joint.

16.Examine system for leaks, ensuring that system

does not foul underbody components. Rectify if

necessary.EXHAUST MANIFOLD - V8i

Service repair no - Left hand - 30.15.10

Service repair no - Right hand - 30.15.11

Remove

1.Disconnect front exhaust pipe(s) from

manifold(s).

2.Tap back bolt locking tabs and remove eight

bolts, lock tabs and washers.

3.Remove manifold(s) and old gaskets.

Refit

4.Ensure that mating surfaces of cylinder head

and exhaust manifold are clean and smooth.

5.Coat threads of each bolt with anti-seize

compound.

6.Place manifold and new gaskets in position on

cylinder head and fit securing bolts, new

lockplates and plain washers. Plain washers are

fitted between manifold and lockplates.

7.Evenly tighten manifold bolts to

20Nmbend

over lockplate tabs.

8.Reconnect front exhaust pipe, using new

exhaust flange gaskets.

Page 380 of 873

30MANIFOLD AND EXHAUST SYSTEM

4

REPAIR EXHAUST MANIFOLD - Tdi

Service repair no - 30.15.10

Remove

1.Disconnect battery negative lead.

2.Remove heat shield from rear of air intake

manifold.

3.Release dip stick tube from cylinder block.

4.Disconnect the intake hose from the manifold.

5.Remove the two bolts and two nuts securing the

intake manifold to the cylinder head and

withdraw the inlet manifold.

6.Remove air filter inlet pipe to turbo unit.

7.Remove intercooler pipe from turbo to

intercooler.

8.Disconnect the EGR pipe from the inlet manifold

hose.

9.Remove the three fixings at the exhaust pipe

flange.

10.Release the turbo charger oil pipes from the

cylinder block.

11.Remove the turbo boost pipes.

12.Remove seven bolts securing the exhaust

manifold, release the heater rail and remove the

manifold gasket, complete with turbo unit.

13.Remove four bolts and disconnect diaphragm

rod from manifold, and remove turbo charger if

necessary.

Refit

14.Reverse removal procedure. 1 to 12. Use a new

manifold and exhaust flange gaskets.

15.Reconnect battery negative lead. Start engine

and check for leaks.

Page 381 of 873

MANIFOLD AND EXHAUST SYSTEM

5

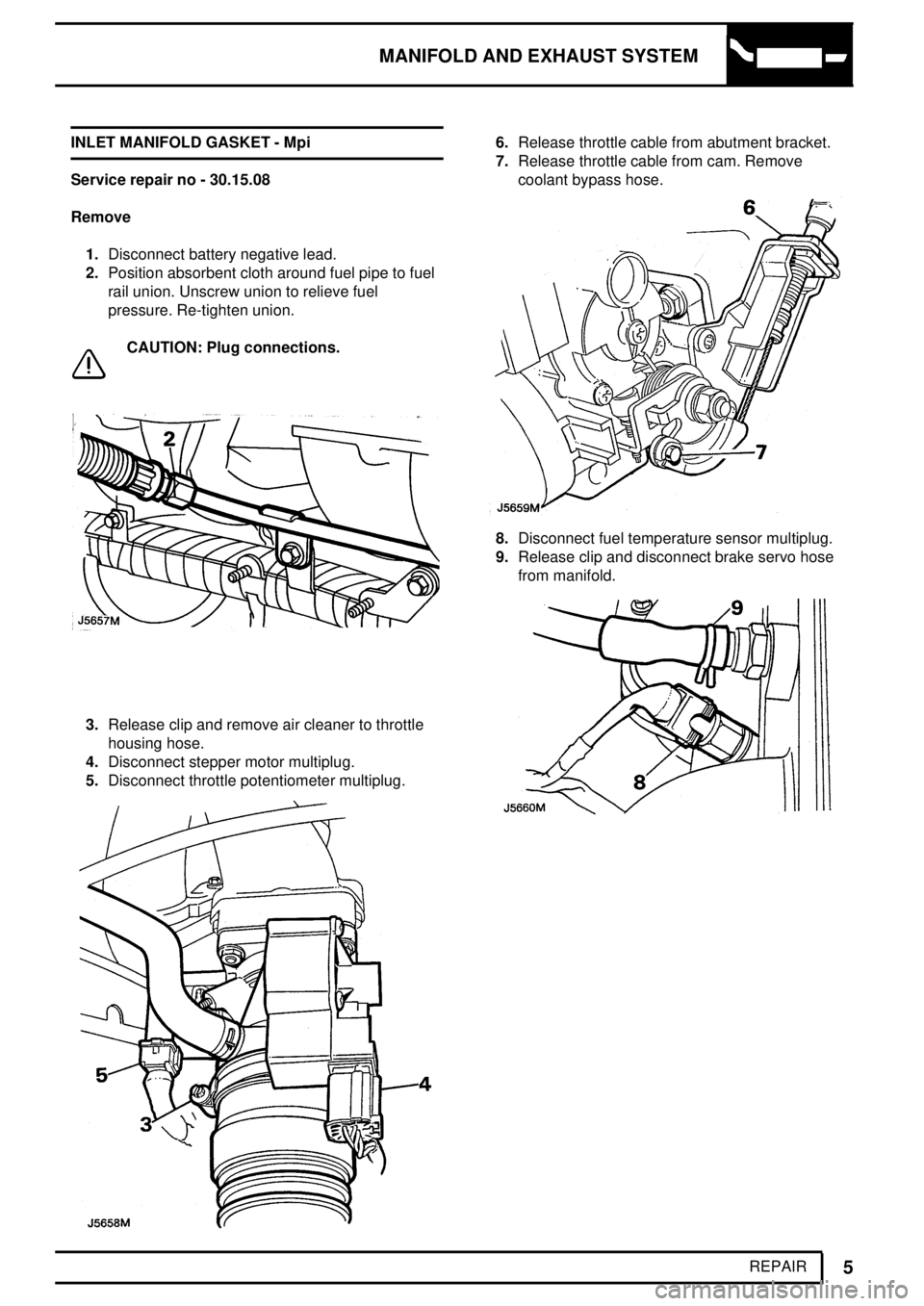

REPAIR INLET MANIFOLD GASKET - Mpi

Service repair no - 30.15.08

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve fuel

pressure. Re-tighten union.

CAUTION: Plug connections.

3.Release clip and remove air cleaner to throttle

housing hose.

4.Disconnect stepper motor multiplug.

5.Disconnect throttle potentiometer multiplug.

6.Release throttle cable from abutment bracket.

7.Release throttle cable from cam. Remove

coolant bypass hose.

8.Disconnect fuel temperature sensor multiplug.

9.Release clip and disconnect brake servo hose

from manifold.

Page 383 of 873

MANIFOLD AND EXHAUST SYSTEM

7

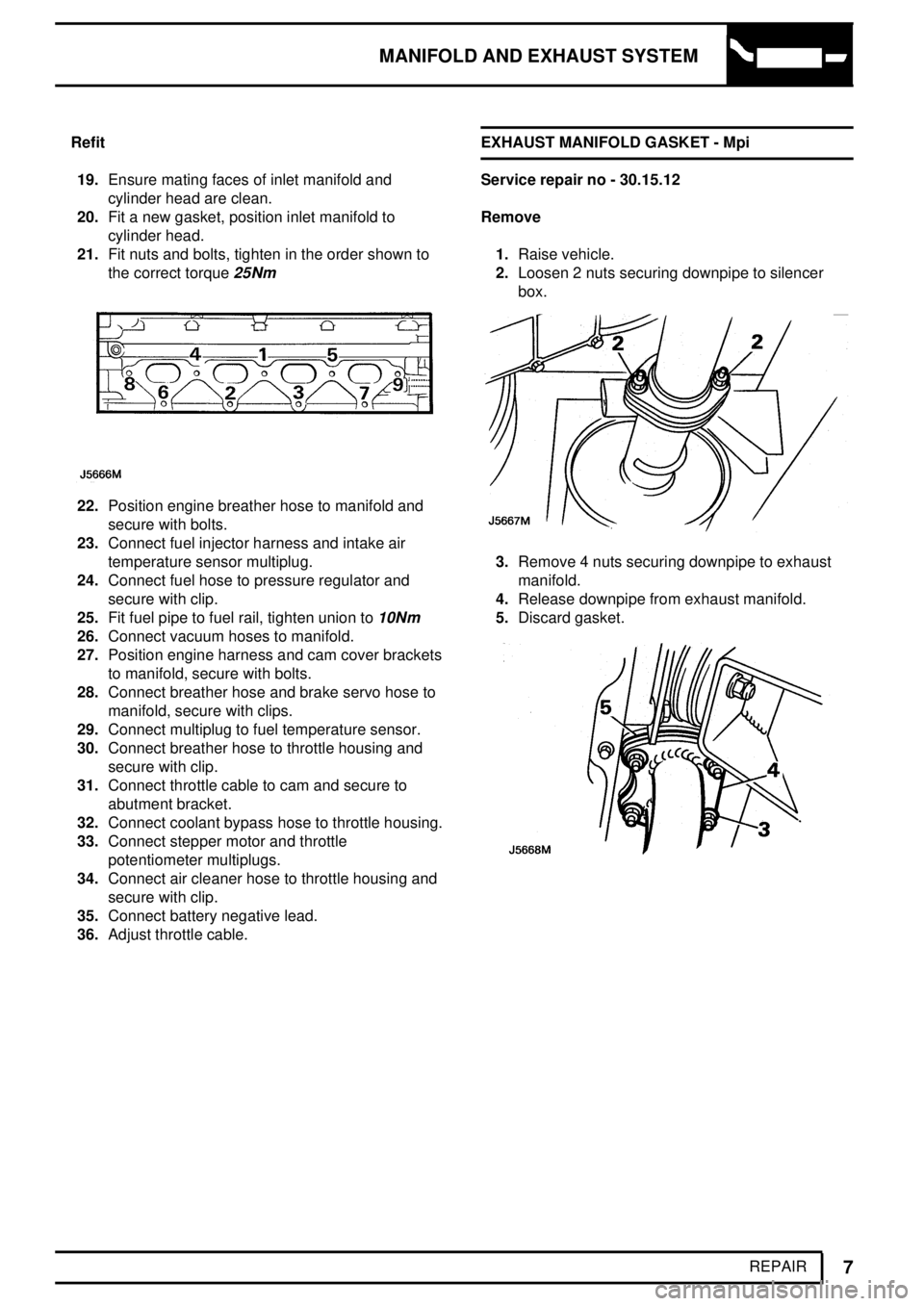

REPAIR Refit

19.Ensure mating faces of inlet manifold and

cylinder head are clean.

20.Fit a new gasket, position inlet manifold to

cylinder head.

21.Fit nuts and bolts, tighten in the order shown to

the correct torque

25Nm

22.Position engine breather hose to manifold and

secure with bolts.

23.Connect fuel injector harness and intake air

temperature sensor multiplug.

24.Connect fuel hose to pressure regulator and

secure with clip.

25.Fit fuel pipe to fuel rail, tighten union to

10Nm

26.Connect vacuum hoses to manifold.

27.Position engine harness and cam cover brackets

to manifold, secure with bolts.

28.Connect breather hose and brake servo hose to

manifold, secure with clips.

29.Connect multiplug to fuel temperature sensor.

30.Connect breather hose to throttle housing and

secure with clip.

31.Connect throttle cable to cam and secure to

abutment bracket.

32.Connect coolant bypass hose to throttle housing.

33.Connect stepper motor and throttle

potentiometer multiplugs.

34.Connect air cleaner hose to throttle housing and

secure with clip.

35.Connect battery negative lead.

36.Adjust throttle cable.EXHAUST MANIFOLD GASKET - Mpi

Service repair no - 30.15.12

Remove

1.Raise vehicle.

2.Loosen 2 nuts securing downpipe to silencer

box.

3.Remove 4 nuts securing downpipe to exhaust

manifold.

4.Release downpipe from exhaust manifold.

5.Discard gasket.

Page 385 of 873

MANIFOLD AND EXHAUST SYSTEM

9

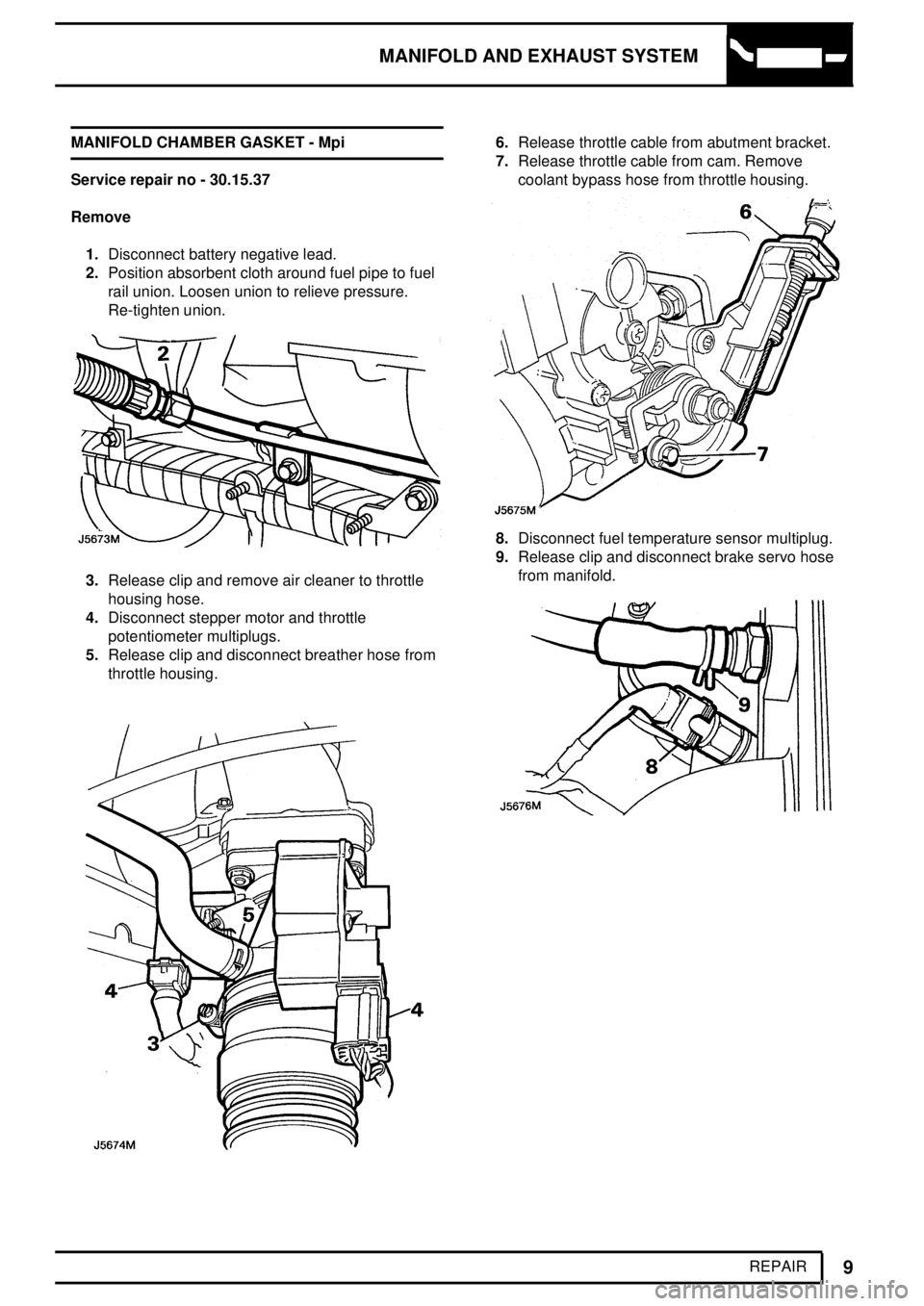

REPAIR MANIFOLD CHAMBER GASKET - Mpi

Service repair no - 30.15.37

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Loosen union to relieve pressure.

Re-tighten union.

3.Release clip and remove air cleaner to throttle

housing hose.

4.Disconnect stepper motor and throttle

potentiometer multiplugs.

5.Release clip and disconnect breather hose from

throttle housing.

6.Release throttle cable from abutment bracket.

7.Release throttle cable from cam. Remove

coolant bypass hose from throttle housing.

8.Disconnect fuel temperature sensor multiplug.

9.Release clip and disconnect brake servo hose

from manifold.

Page 392 of 873

CLUTCH

1

REPAIR CLUTCH ASSEMBLY

Service repair no - 33.10.01

Clutch pressure plate

Renew pressure plate if diaphragm spring fingers are

worn or if pressure plate shows signs of wear, cracks

or burning.

Clutch driven plate

Renew driven plate if centre hub splines are worn or if

lining is contaminated, burned or unevenly worn.

Service tools:

Clutch centralising tool

LRT-12-001 - V8

LRT-12-040 - Tdi

LRT-12-057 - Mpi

Remove

1.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

2.Mark position of clutch cover to flywheel for

reassembly.

3.Remove clutch cover securing bolts, working

evenly and diagonally.

4.Do not disturb three bolts in clutch cover.

5.Remove clutch assembly.

6.Withdraw clutch driven plate.

Refit

NOTE: To prevent clutch plate sticking,

lubricate splines using Rocol MV 3 or

Rocol MTS 1000 grease.

7.Renew/refit clutch driver plate and clutch

assembly using centralising tool, where

applicable, align assembly marks.

8.Secure clutch assembly cover fixings evenly,

working in a diagonal sequence. Tighten to

28

Nm.

9.Fit gearbox to engine.