ABS LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 164 of 873

![LAND ROVER DISCOVERY 1995 User Guide 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S LAND ROVER DISCOVERY 1995 User Guide 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S](/img/64/57248/w960_57248-163.png)

12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.See COOLING SYSTEM,

Repair, Radiator - Mpi

4.Remove bonnet [hood].See CHASSIS AND

BODY, Repair, Bonnet [Hood]

5.Drain engine oil.

6.Position absorbent cloth around fuel pipe to fuel

rail union.

Unscrew union to relieve pressure.

CAUTION: Plug the connections

7.Release clip and disconnect hose from coolant

pump.

8.Release clip and disconnect hose from heater

rail.

Page 172 of 873

12ENGINE

14

REPAIR Refit

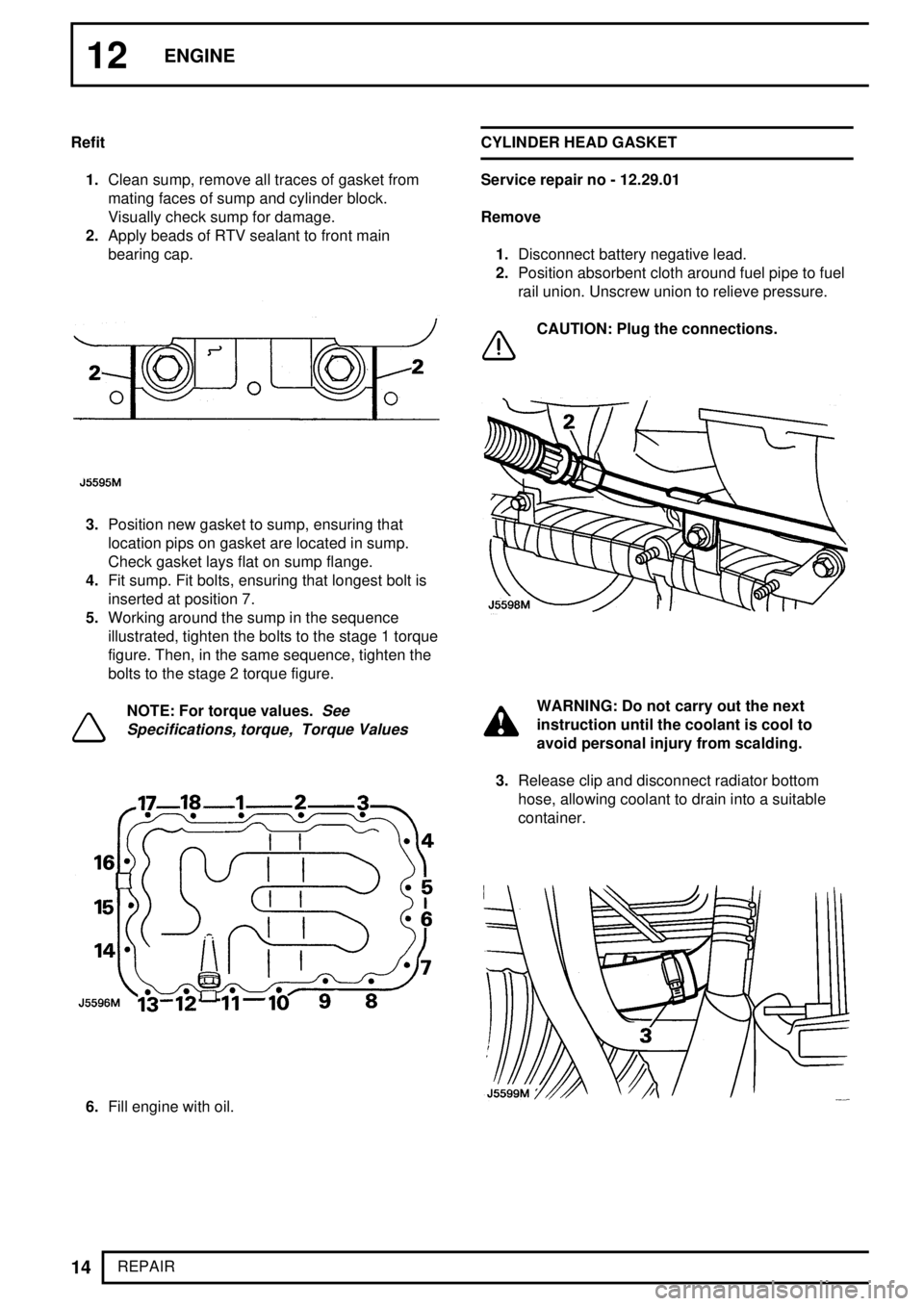

1.Clean sump, remove all traces of gasket from

mating faces of sump and cylinder block.

Visually check sump for damage.

2.Apply beads of RTV sealant to front main

bearing cap.

3.Position new gasket to sump, ensuring that

location pips on gasket are located in sump.

Check gasket lays flat on sump flange.

4.Fit sump. Fit bolts, ensuring that longest bolt is

inserted at position 7.

5.Working around the sump in the sequence

illustrated, tighten the bolts to the stage 1 torque

figure. Then, in the same sequence, tighten the

bolts to the stage 2 torque figure.

NOTE: For torque values.See

Specifications, torque, Torque Values

6.Fill engine with oil.CYLINDER HEAD GASKET

Service repair no - 12.29.01

Remove

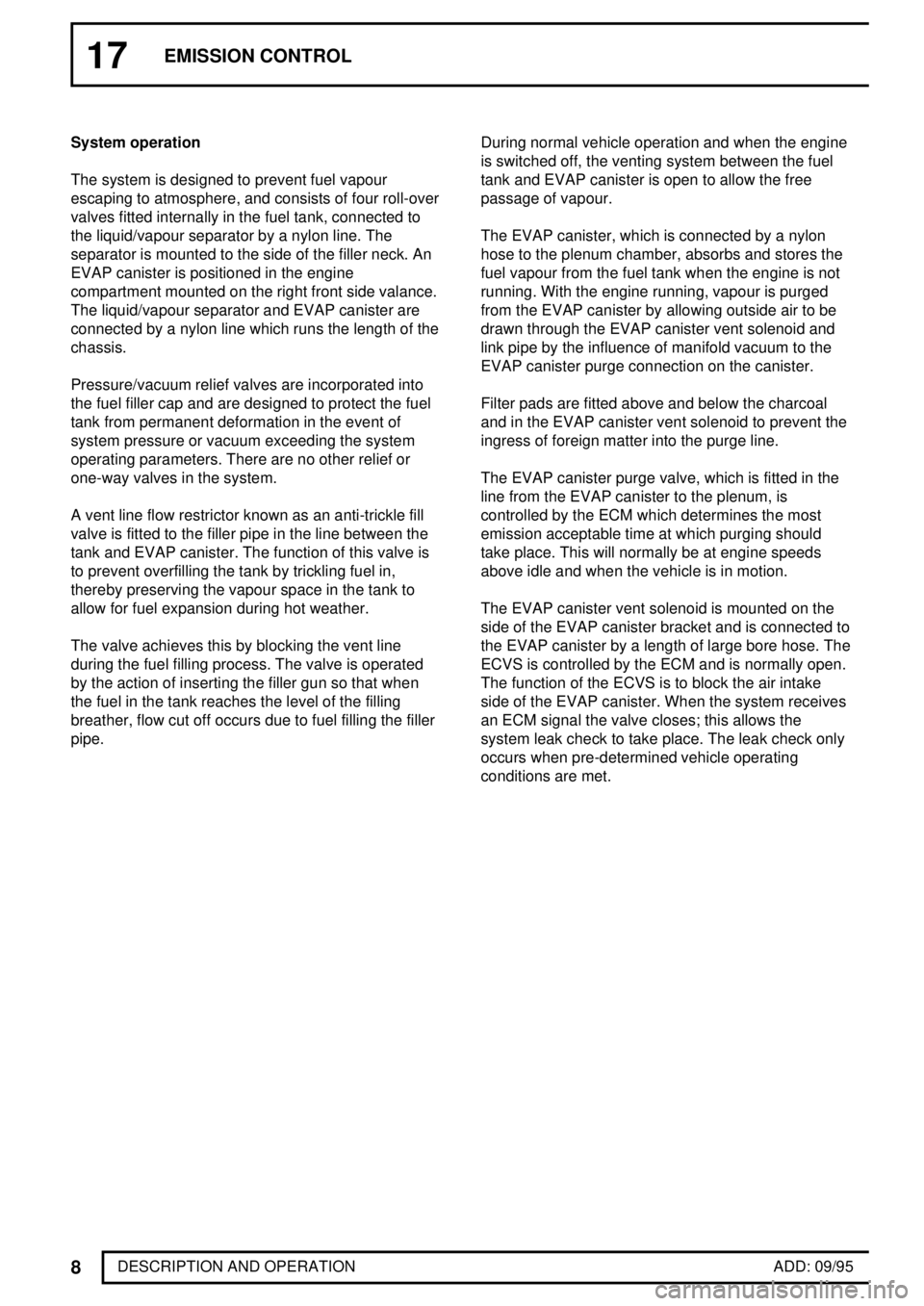

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve pressure.

CAUTION: Plug the connections.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

3.Release clip and disconnect radiator bottom

hose, allowing coolant to drain into a suitable

container.

Page 190 of 873

17EMISSION CONTROL

4

DESCRIPTION AND OPERATION REV: 09/95 Evaporative emission control system - pre

advanced EVAPS.

The system is designed to prevent harmful fuel vapour

from escaping to the atmosphere. The system

consists of a vapour separator tank, connected to the

fuel tank and located between the body inner and

outer panels on the right hand side of the vehicle near

the rear wheel arch. An adsorbtion canister,

containing activated charcoal, is positioned in the

engine compartment attached to the front right

valance. The two components are connected by a

pipe running the length of the chassis.

A Pressure relief to atmosphere.

B From fuel tank to separator.

C To adsorbtion canister.

D Pressure relief valve.

E Pressure relief valve.

F Shut-off valve.

G "Speed Fit" connectors.A pressure relief valve is fitted in the hose which is

open to atmosphere. This valve acts as a safety valve

should a build-up of pressure occur in the system, for

example if a hose became blocked or kinked. The

volume of vapour emitted, in such an instance, would

be acceptable.

A pressure relief valve is also fitted in the hose

connected to the adsorbtion canister and releases

vapor to the canister when the pressure in the

separator reaches between 5 and 7 Kpa.

In the top of the separator a shut-off valve is

incorporated in the vapor exit port to prevent the

possible presence of any liquid fuel being transmitted

to the adsorbtion canister should the vehicle roll over.

The adsorbtion canister, which is connected by a hose

to the plenum chamber, absorbs and stores the fuel

vapour from the fuel tank while the engine is not

running. When the engine is started, the vapour is

purged from the canister by air drawn through an

orifice in the base of the canister and by the influence

of vacuum at the top. The vapour drawn into the

plenum chamber through a solenoid operated purge

valve is finally burnt in the combustion chambers.

The purge valve, which is attached to the adsorbtion

canister support bracket, is controlled by the Engine

Control Module ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion. A signal

from the ECM to the purge valve operates the

solenoid and opens the valve to purge the canister of

fuel vapour.

Page 194 of 873

17EMISSION CONTROL

8

DESCRIPTION AND OPERATION ADD: 09/95 System operation

The system is designed to prevent fuel vapour

escaping to atmosphere, and consists of four roll-over

valves fitted internally in the fuel tank, connected to

the liquid/vapour separator by a nylon line. The

separator is mounted to the side of the filler neck. An

EVAP canister is positioned in the engine

compartment mounted on the right front side valance.

The liquid/vapour separator and EVAP canister are

connected by a nylon line which runs the length of the

chassis.

Pressure/vacuum relief valves are incorporated into

the fuel filler cap and are designed to protect the fuel

tank from permanent deformation in the event of

system pressure or vacuum exceeding the system

operating parameters. There are no other relief or

one-way valves in the system.

A vent line flow restrictor known as an anti-trickle fill

valve is fitted to the filler pipe in the line between the

tank and EVAP canister. The function of this valve is

to prevent overfilling the tank by trickling fuel in,

thereby preserving the vapour space in the tank to

allow for fuel expansion during hot weather.

The valve achieves this by blocking the vent line

during the fuel filling process. The valve is operated

by the action of inserting the filler gun so that when

the fuel in the tank reaches the level of the filling

breather, flow cut off occurs due to fuel filling the filler

pipe.During normal vehicle operation and when the engine

is switched off, the venting system between the fuel

tank and EVAP canister is open to allow the free

passage of vapour.

The EVAP canister, which is connected by a nylon

hose to the plenum chamber, absorbs and stores the

fuel vapour from the fuel tank when the engine is not

running. With the engine running, vapour is purged

from the EVAP canister by allowing outside air to be

drawn through the EVAP canister vent solenoid and

link pipe by the influence of manifold vacuum to the

EVAP canister purge connection on the canister.

Filter pads are fitted above and below the charcoal

and in the EVAP canister vent solenoid to prevent the

ingress of foreign matter into the purge line.

The EVAP canister purge valve, which is fitted in the

line from the EVAP canister to the plenum, is

controlled by the ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion.

The EVAP canister vent solenoid is mounted on the

side of the EVAP canister bracket and is connected to

the EVAP canister by a length of large bore hose. The

ECVS is controlled by the ECM and is normally open.

The function of the ECVS is to block the air intake

side of the EVAP canister. When the system receives

an ECM signal the valve closes; this allows the

system leak check to take place. The leak check only

occurs when pre-determined vehicle operating

conditions are met.

Page 246 of 873

MFI

3

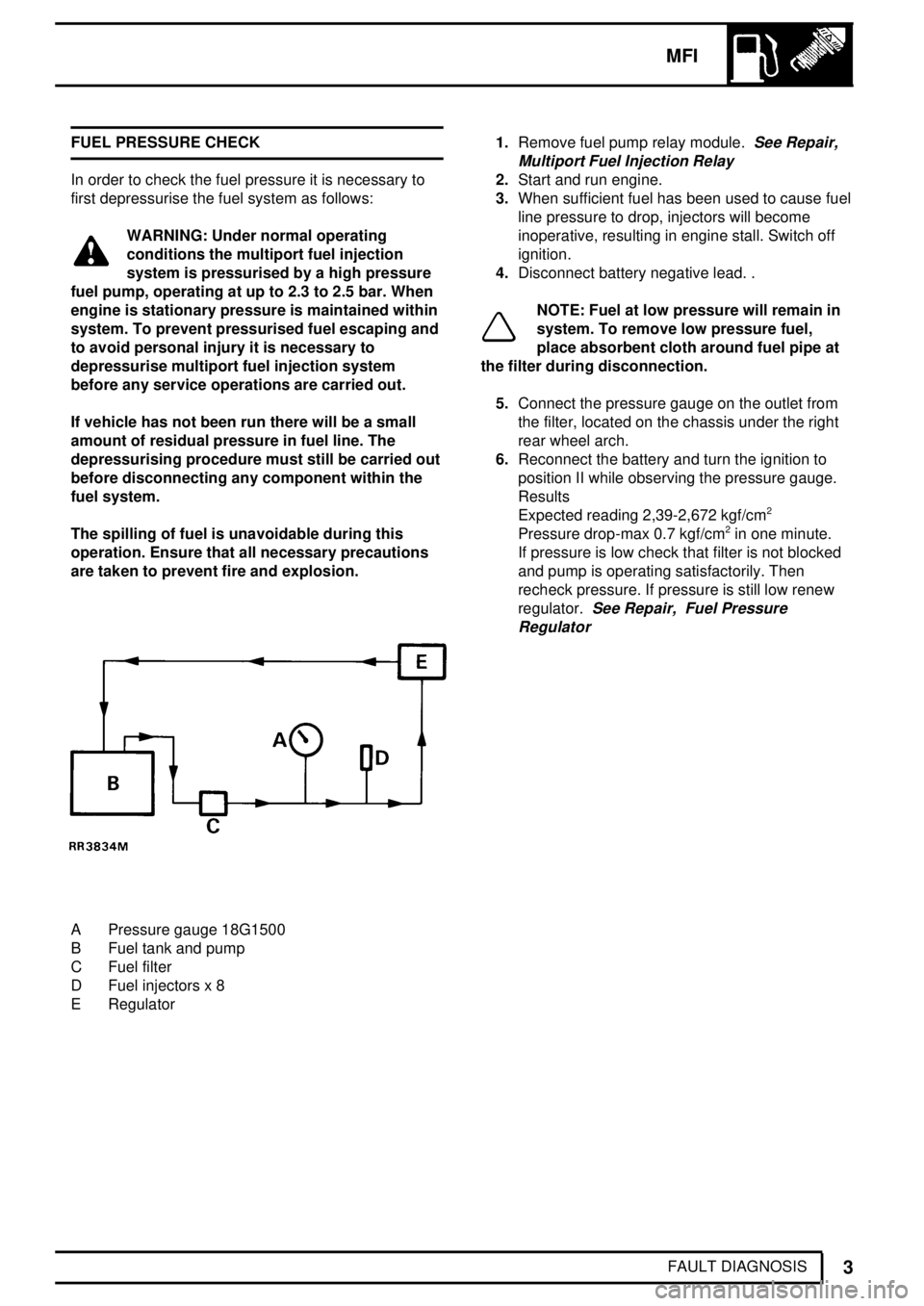

FAULT DIAGNOSIS FUEL PRESSURE CHECK

In order to check the fuel pressure it is necessary to

first depressurise the fuel system as follows:

WARNING: Under normal operating

conditions the multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar. When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

A Pressure gauge 18G1500

B Fuel tank and pump

C Fuel filter

D Fuel injectors x 8

E Regulator1.Remove fuel pump relay module.

See Repair,

Multiport Fuel Injection Relay

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead. .

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel pipe at

the filter during disconnection.

5.Connect the pressure gauge on the outlet from

the filter, located on the chassis under the right

rear wheel arch.

6.Reconnect the battery and turn the ignition to

position II while observing the pressure gauge.

Results

Expected reading 2,39-2,672 kgf/cm

2

Pressure drop-max 0.7 kgf/cm2in one minute.

If pressure is low check that filter is not blocked

and pump is operating satisfactorily. Then

recheck pressure. If pressure is still low renew

regulator.

See Repair, Fuel Pressure

Regulator

Page 252 of 873

19FUEL SYSTEM

6

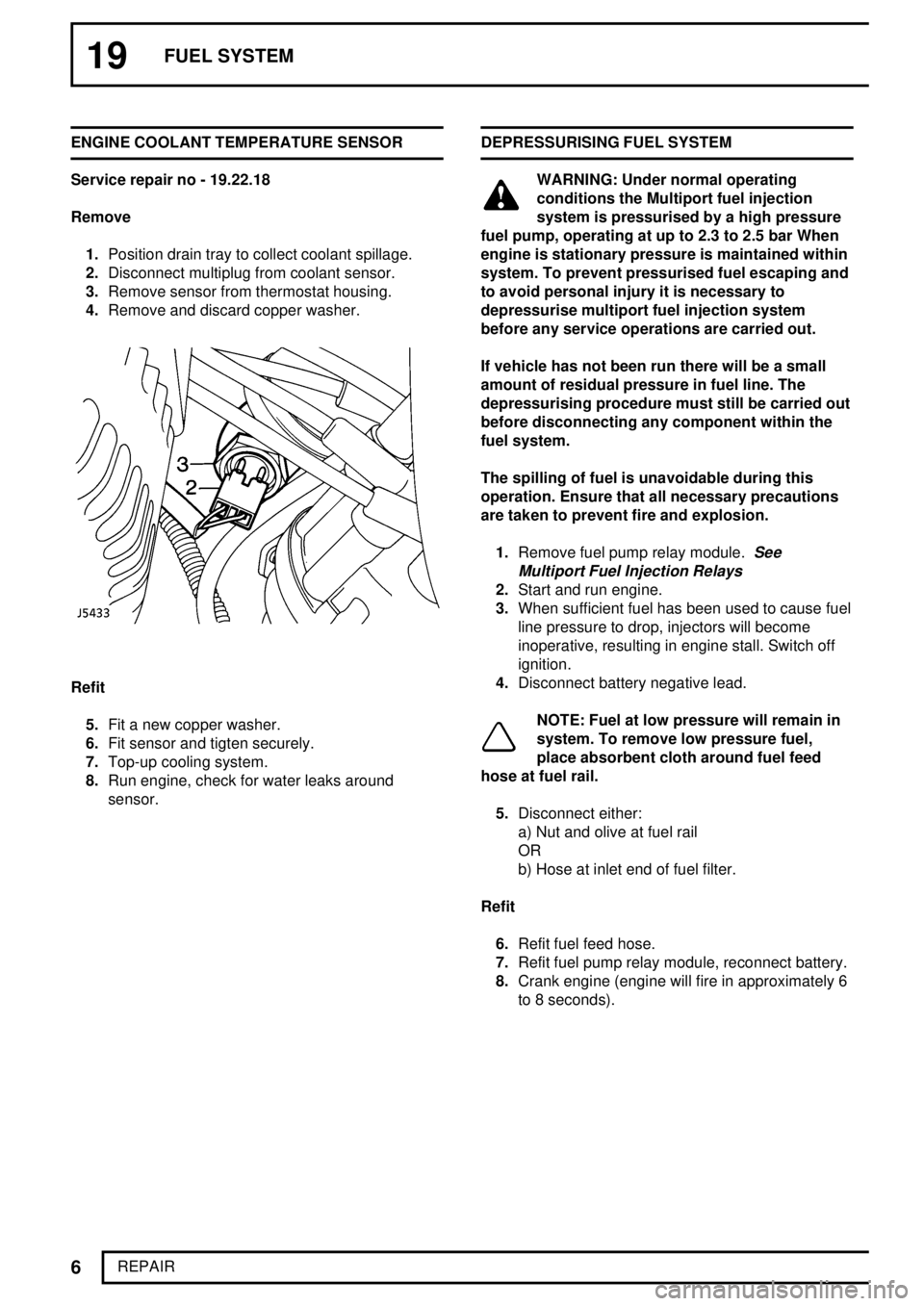

REPAIR ENGINE COOLANT TEMPERATURE SENSOR

Service repair no - 19.22.18

Remove

1.Position drain tray to collect coolant spillage.

2.Disconnect multiplug from coolant sensor.

3.Remove sensor from thermostat housing.

4.Remove and discard copper washer.

Refit

5.Fit a new copper washer.

6.Fit sensor and tigten securely.

7.Top-up cooling system.

8.Run engine, check for water leaks around

sensor.DEPRESSURISING FUEL SYSTEM

WARNING: Under normal operating

conditions the Multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

1.Remove fuel pump relay module.

See

Multiport Fuel Injection Relays

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead.

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel feed

hose at fuel rail.

5.Disconnect either:

a) Nut and olive at fuel rail

OR

b) Hose at inlet end of fuel filter.

Refit

6.Refit fuel feed hose.

7.Refit fuel pump relay module, reconnect battery.

8.Crank engine (engine will fire in approximately 6

to 8 seconds).

Page 255 of 873

MFI

9

REPAIR

15.Remove distributor vacuum hose.

16.Release two screws and remove throttle position

sensor.

17.Remove six screws securing plenum chamber.

Remove plenum chamber.

18.Remove air idle air control valve hose.Throttle lever assembly - remove

19.If fitted - unclip cruise control actuator link. Hold

throttle fully open, release link from countershaft

assembly. Carefully return lever assembly to

close throttle.

20.Release tension on inboard throttle spring.

21.Bend back lock washer tabs.

22.Hold throttle stop lever in closed position,

release nut from throttle shaft.

23.Release tension on outboard throttle spring.

24.Remove overtravel spring.

Page 259 of 873

MFI

13

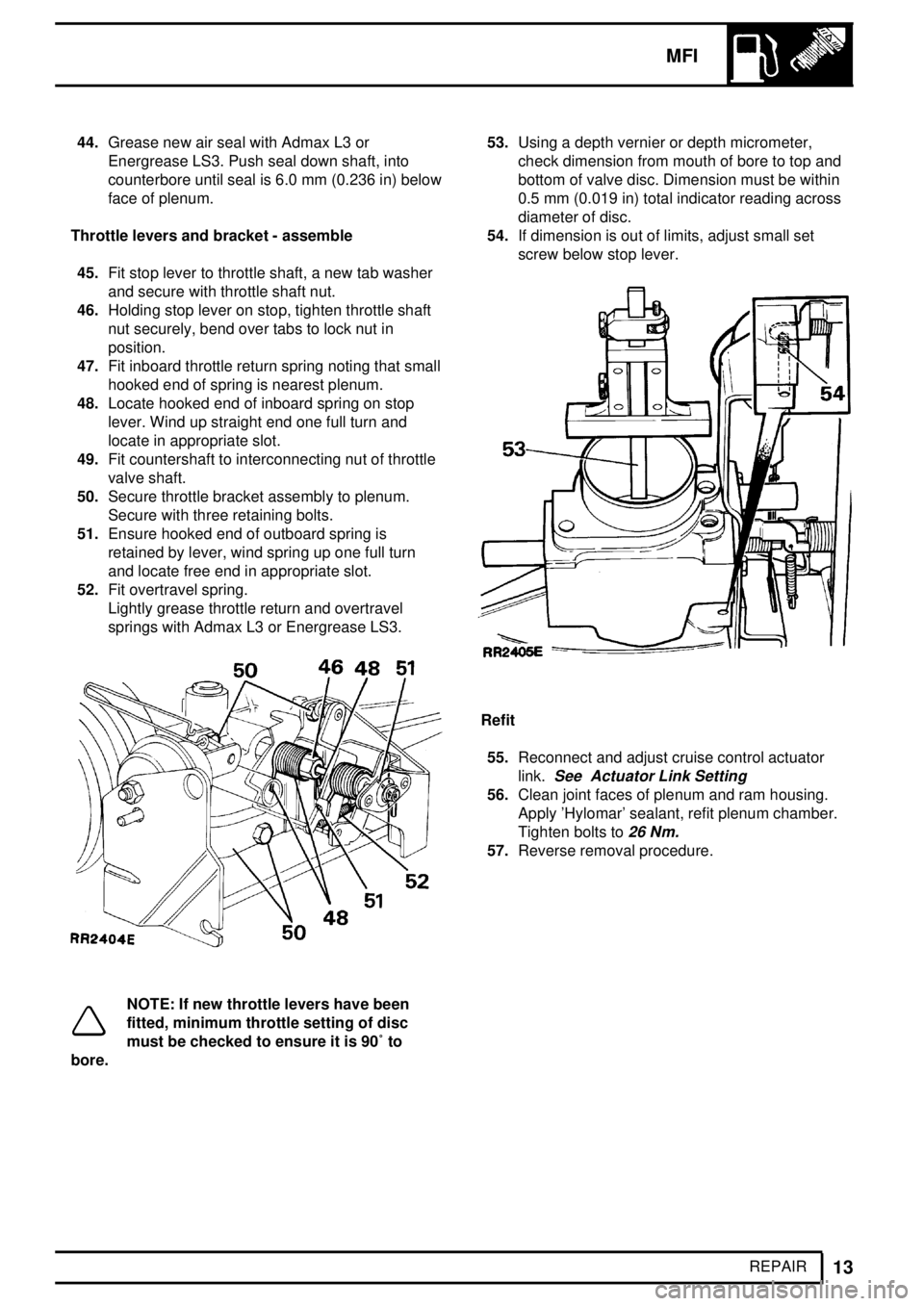

REPAIR 44.Grease new air seal with Admax L3 or

Energrease LS3. Push seal down shaft, into

counterbore until seal is 6.0 mm (0.236 in) below

face of plenum.

Throttle levers and bracket - assemble

45.Fit stop lever to throttle shaft, a new tab washer

and secure with throttle shaft nut.

46.Holding stop lever on stop, tighten throttle shaft

nut securely, bend over tabs to lock nut in

position.

47.Fit inboard throttle return spring noting that small

hooked end of spring is nearest plenum.

48.Locate hooked end of inboard spring on stop

lever. Wind up straight end one full turn and

locate in appropriate slot.

49.Fit countershaft to interconnecting nut of throttle

valve shaft.

50.Secure throttle bracket assembly to plenum.

Secure with three retaining bolts.

51.Ensure hooked end of outboard spring is

retained by lever, wind spring up one full turn

and locate free end in appropriate slot.

52.Fit overtravel spring.

Lightly grease throttle return and overtravel

springs with Admax L3 or Energrease LS3.

NOTE: If new throttle levers have been

fitted, minimum throttle setting of disc

must be checked to ensure it is 90Ê to

bore.53.Using a depth vernier or depth micrometer,

check dimension from mouth of bore to top and

bottom of valve disc. Dimension must be within

0.5 mm (0.019 in) total indicator reading across

diameter of disc.

54.If dimension is out of limits, adjust small set

screw below stop lever.

Refit

55.Reconnect and adjust cruise control actuator

link.

See Actuator Link Setting

56.Clean joint faces of plenum and ram housing.

Apply 'Hylomar' sealant, refit plenum chamber.

Tighten bolts to

26 Nm.

57.Reverse removal procedure.

Page 278 of 873

SFI

7

DESCRIPTION AND OPERATION REV: 09/95 Fuel pressure regulator

The fuel pressure regulator is located at the rear of

the engine in the fuel rail. It consists of a fuel inlet,

outlet, vacuum port and internal diaphragm.

When the engine is under high manifold depression,

the applied vacuum sucks the diaphragm of its seat,

allowing fuel to return to the tank, resulting in a lower

fuel pressure. This is necessary because the high

depression will try to suck the fuel from the injector,

resulting in overfuelling if the pressure remained

constant. Failure will result in a rich mixture at idle but

normal at full load, or a rich mixture resulting in engine

flooding, or a weak mixture. Although the fault will not

illuminate the MIL, faults caused by the failure may be

indicated.Relay module

The engine management system employs a relay

module, which houses the main relay and the fuel

pump relay.

Main relay

The main relay supplies the power feed to the ECM

with a tap off to feed the fuel injectors (8 amps) and

air flow sensor (4 amps). This relay is controlled by

the engine management ECM. This enables the ECM

to remain powered up after ignition is switched off.

During this 'ECM power down routine' the ECM

records all temperature readings and powers the

stepper motor to the fully open position. Failure of this

relay will result in the engine management ECM not

being switched on resulting in engine not starting due

to absence of fuel and ignition.

Fuel pump relay

The fuel pump relay is fed from the ignition relay and

controlled by the engine management ECM. The relay

is activated in ignition key position 2 to prime the fuel

system for a period of time controlled by the ECM.

Failure of this relay will result in no fuel pressure.

Inertia switch

The inertia switch isolates the power supply to the fuel

pump in the event of sudden deceleration. The inertia

switch is located in the engine compartment. It is reset

by depressing the central plunger at the top of the

switch.

Page 285 of 873

19FUEL SYSTEM

2

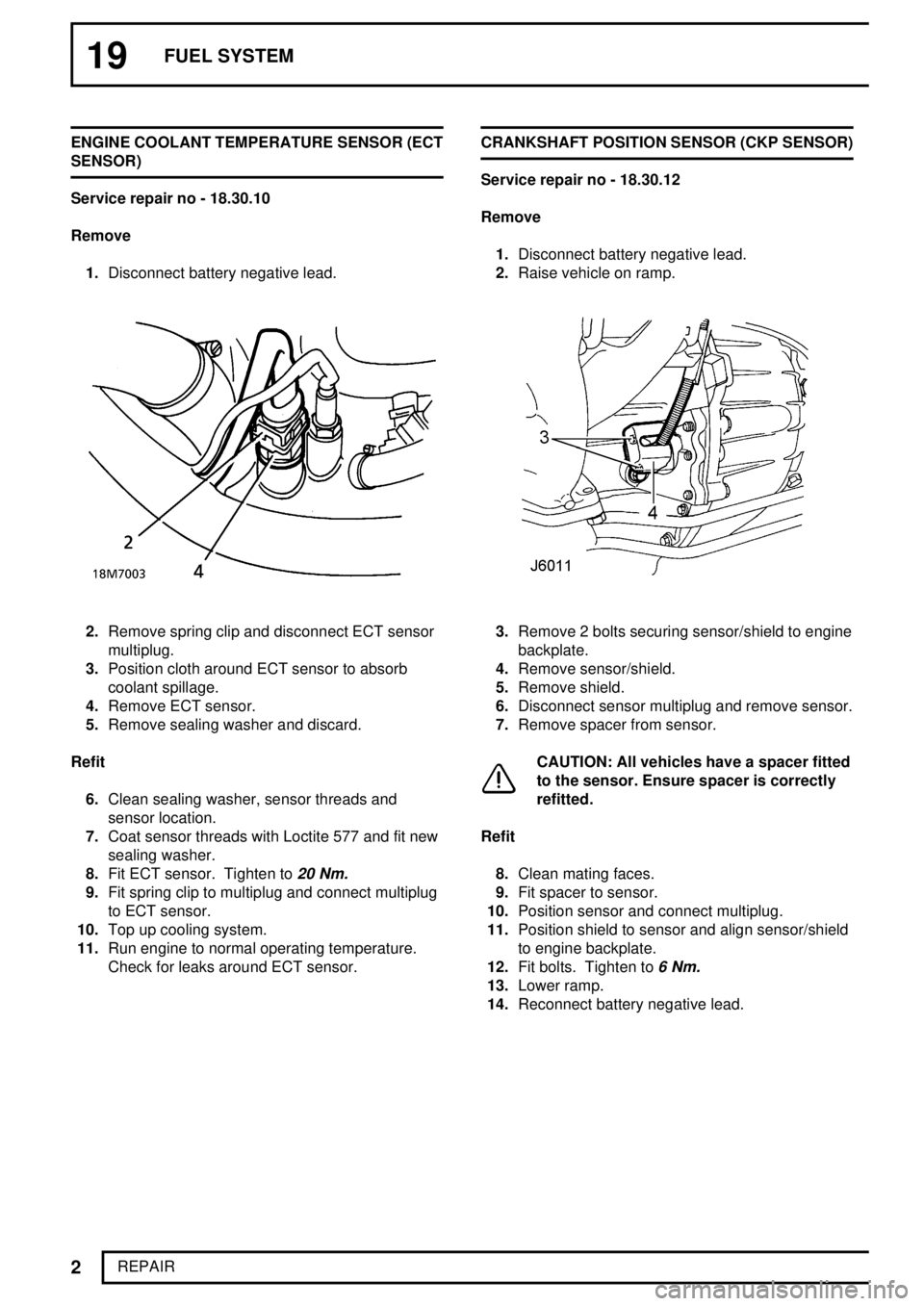

REPAIR ENGINE COOLANT TEMPERATURE SENSOR (ECT

SENSOR)

Service repair no - 18.30.10

Remove

1.Disconnect battery negative lead.

2.Remove spring clip and disconnect ECT sensor

multiplug.

3.Position cloth around ECT sensor to absorb

coolant spillage.

4.Remove ECT sensor.

5.Remove sealing washer and discard.

Refit

6.Clean sealing washer, sensor threads and

sensor location.

7.Coat sensor threads with Loctite 577 and fit new

sealing washer.

8.Fit ECT sensor. Tighten to

20 Nm.

9.Fit spring clip to multiplug and connect multiplug

to ECT sensor.

10.Top up cooling system.

11.Run engine to normal operating temperature.

Check for leaks around ECT sensor.CRANKSHAFT POSITION SENSOR (CKP SENSOR)

Service repair no - 18.30.12

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove 2 bolts securing sensor/shield to engine

backplate.

4.Remove sensor/shield.

5.Remove shield.

6.Disconnect sensor multiplug and remove sensor.

7.Remove spacer from sensor.

CAUTION: All vehicles have a spacer fitted

to the sensor. Ensure spacer is correctly

refitted.

Refit

8.Clean mating faces.

9.Fit spacer to sensor.

10.Position sensor and connect multiplug.

11.Position shield to sensor and align sensor/shield

to engine backplate.

12.Fit bolts. Tighten to

6 Nm.

13.Lower ramp.

14.Reconnect battery negative lead.