engine LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 16 of 873

01INTRODUCTION

14

INFORMATION LOCATION OF IDENTIFICATION NUMBERS

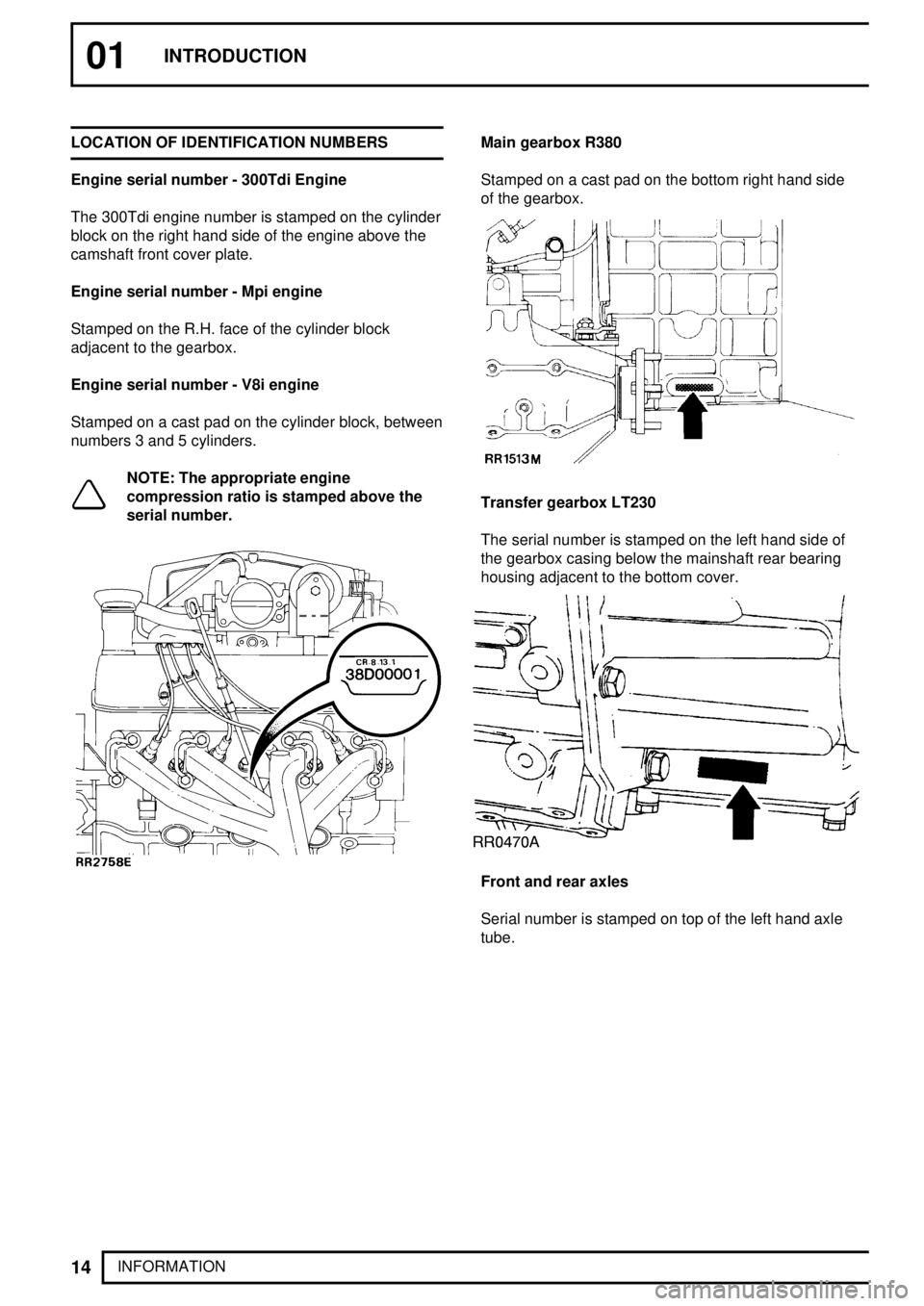

Engine serial number - 300Tdi Engine

The 300Tdi engine number is stamped on the cylinder

block on the right hand side of the engine above the

camshaft front cover plate.

Engine serial number - Mpi engine

Stamped on the R.H. face of the cylinder block

adjacent to the gearbox.

Engine serial number - V8i engine

Stamped on a cast pad on the cylinder block, between

numbers 3 and 5 cylinders.

NOTE: The appropriate engine

compression ratio is stamped above the

serial number.

Main gearbox R380

Stamped on a cast pad on the bottom right hand side

of the gearbox.

Transfer gearbox LT230

The serial number is stamped on the left hand side of

the gearbox casing below the mainshaft rear bearing

housing adjacent to the bottom cover.

Front and rear axles

Serial number is stamped on top of the left hand axle

tube.

Page 18 of 873

01INTRODUCTION

16

INFORMATION FAULT DIAGNOSTIC EQUIPMENT

TESTBOOK

Todays Land Rover Vehicles are equipped with a

large amount of electronics to provide the best

performance of the vehicles systems.

Diagnostic equipment named TESTBOOK is available

to expand the diagnostic abilities of the dealer

workshop. This repair manual is produced with

Testbook in mind.

Features of Testbook include :- Fully upgradable

support for the technician. Structured diagnostics to

accommodate all skill levels. Touch screen operation.

Direct print out of screen information and test results.

ELECTRICAL TROUBLESHOOTING MANUAL

The Electrical Troubleshooting Manual is a separate

publication that is intended for use by trained Land

Rover technicians as an aid to diagnosing electrical

concerns.

It provides circuit diagrams, system diagnosis flow

charts, electrical component location tables, electrical

component location views and circuit operation

details.READING THIS MANUAL

This manual is divided into sections shown on the

contents page, alongside a range of icons, familiar to

service technicians.

Relevant information is contained within each of these

sections. These are further divided into the following

sub-sections which appear at the foot of each page :-

Description and operation.

Fault diagnosis.

Adjustment.

Repair.

Overhaul.

Specifications, Torque.

Service tools.

To avoid repeating information through the sections,

where part of the repair operation impacts on another

section, a cross reference is given to direct the reader

to where the information is sited.

For example:

The maintenance section states the need to renew

V8i drive belt. A cross reference sites this information

in: Section: V8i Engine

- Sub-section: Repairs

- Heading: Drive belt renew.

Sections that contain derivatives such as engines are

further separated within that section.

American terminology.

A few words used in this manual differ to words used

in America. Where this occurs the American word is

placed inside brackets. For example: bonnet [hood],

wing [fender], ramp [hoist].

Page 19 of 873

GENERAL SPECIFICATION DATA

1

INFORMATION ENGINE 3.9 V8i

Type V8i.................................................................................

Number of cylinders Eight, two banks of four.........................................................

Bore 94,00 mm.................................................................................

Stroke 71,12 mm...............................................................................

Capacity 3950 cc...........................................................................

Compression ratio 8.13:1 or 9.35:1............................................................

Valve operation Overhead by push-rod................................................................

Maximum power - 8.13:1 127kW at 4550 rev/min............................

- 9.35:1 134kW at 4750 rev/min............................

Crankshaft

Main journal diameter 58,409-58,422 mm.......................................................

Minimum regrind diameter 57,393-57,406 mm...............................................

Crankpin journal diameter 50,800-50,812 mm................................................

Minimum regrind diameter 49,784-49,797 mm...............................................

Crankshaft end thrust/(end float) Taken on thrust washers of centre main bearing......................................

0,10-0,20 mm

Main bearings

Number and material 5, Lead-indium........................................................

Diametrical clearance 0,010-0,048 mm.......................................................

Undersize bearing shells 0,254 mm, 0,508 mm..................................................

Connecting rods

Type Horizontally split big-end, plain small-end.................................................................................

Length between centres 143,81-143,71 mm...................................................

Big-end bearings

Type and material Lead-indium............................................................

Diametrical clearance 0,015-0,055 mm.......................................................

End-float crankpin 0,15-0,36mm............................................................

Undersize bearing shells 0,254 mm, 0,508 mm..................................................

Piston pins

Length 72,67-72,79 mm..............................................................................

Diameter 22,215-22,220 mm..........................................................................

Fit-in connecting rod Press fit.........................................................

Clearance in piston 0,002-0,007 mm..........................................................

Page 20 of 873

04GENERAL SPECIFICATION DATA

2

INFORMATION Pistons

Clearance in bore, measured at bottom

of skirt at right angles to piston pin 0,018-0,041 mm...................................

Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Molybdenum barrel faced.....................................................

No 2 compression ring Tapered and marked 'T' or 'TOP'.....................................................

Width of compression rings 1,478-1,49 mm..............................................

Compression ring gap 0,40-0,65 mm......................................................

Oil control ring width 3,0 mm.........................................................

Oil control ring rail gap 0,38-1,40 mm.....................................................

Camshaft

Location Central...........................................................................

Bearings Tin - aluminium...........................................................................

Number of bearings 5..........................................................

Drive Chain 9,52 mm pitch x 54 pitches..................................................................................

TappetsHydraulic-self-adjusting ...........................................................................

Valves

Length: Inlet 116,59-117,35 mm..................................

Exhaust 116,59-117,35 mm...........................

Seat angle: Inlet 45°to 45 1/2° ..................................

Exhaust 45°to 45 1/2° ...........................

Head diameter: Inlet 39,75-40,00 mm..................................

Exhaust 34,226-34,480 mm...........................

Stem diameter: Inlet 8,664-8,679 mm..................................

Exhaust 8,651-8,666 mm...........................

Stem to guide clearance: Inlet 0,025-0,066 mm..................................

Exhaust 0,038-0,078 mm...........................

Valve lift (Inlet and Exhaust) 9,49 mm............................................

Valve spring length fitted 40,4 mm at pressure of 29,5 kg..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Eccentric rotor...................................................................

Oil pressure 2.75 bar (40 lb/in

2) at 2500 rev/min with engine at ......................................................................

running temperature

Oil filter-internal Wire screen, pump intake filter.................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

Page 21 of 873

GENERAL SPECIFICATION DATA

3

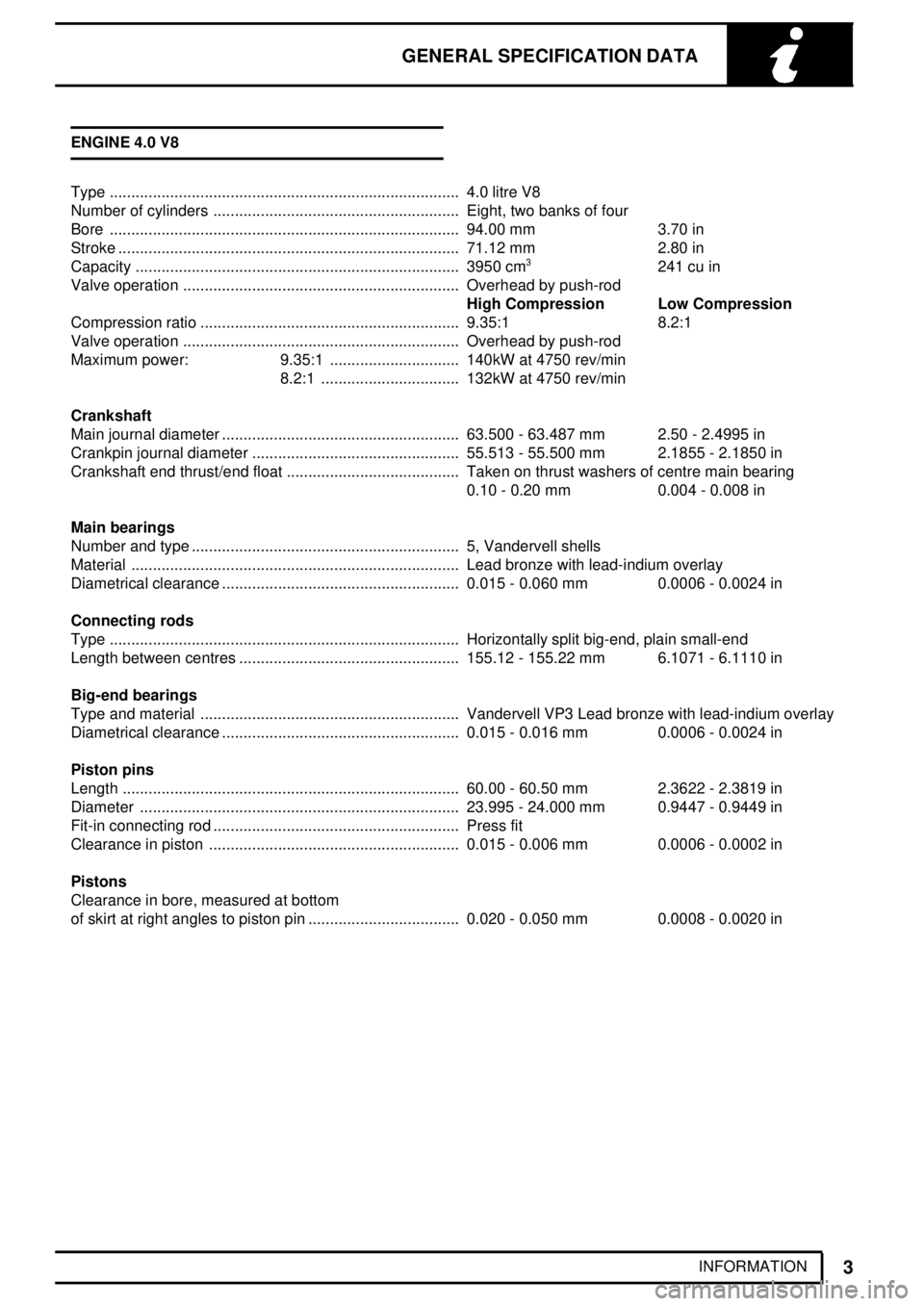

INFORMATION ENGINE 4.0 V8

Type 4.0 litre V8.................................................................................

Number of cylinders Eight, two banks of four.........................................................

Bore 94.00 mm................................................................................. 3.70 in

Stroke 71.12 mm............................................................................... 2.80 in

Capacity 3950 cm

3........................................................................... 241 cu in

Valve operation Overhead by push-rod................................................................

High Compression Low Compression

Compression ratio 9.35:1............................................................ 8.2:1

Valve operation Overhead by push-rod................................................................

Maximum power: 9.35:1 140kW at 4750 rev/min..............................

8.2:1 132kW at 4750 rev/min................................

Crankshaft

Main journal diameter 63.500 - 63.487 mm....................................................... 2.50 - 2.4995 in

Crankpin journal diameter 55.513 - 55.500 mm................................................ 2.1855 - 2.1850 in

Crankshaft end thrust/end float Taken on thrust washers of centre main bearing........................................

0.10 - 0.20 mm 0.004 - 0.008 in

Main bearings

Number and type 5, Vandervell shells..............................................................

Material Lead bronze with lead-indium overlay............................................................................

Diametrical clearance 0.015 - 0.060 mm....................................................... 0.0006 - 0.0024 in

Connecting rods

Type Horizontally split big-end, plain small-end.................................................................................

Length between centres 155.12 - 155.22 mm................................................... 6.1071 - 6.1110 in

Big-end bearings

Type and material Vandervell VP3 Lead bronze with lead-indium overlay............................................................

Diametrical clearance 0.015 - 0.016 mm....................................................... 0.0006 - 0.0024 in

Piston pins

Length 60.00 - 60.50 mm.............................................................................. 2.3622 - 2.3819 in

Diameter 23.995 - 24.000 mm.......................................................................... 0.9447 - 0.9449 in

Fit-in connecting rod Press fit.........................................................

Clearance in piston 0.015 - 0.006 mm.......................................................... 0.0006 - 0.0002 in

Pistons

Clearance in bore, measured at bottom

of skirt at right angles to piston pin 0.020 - 0.050 mm................................... 0.0008 - 0.0020 in

Page 22 of 873

04GENERAL SPECIFICATION DATA

4

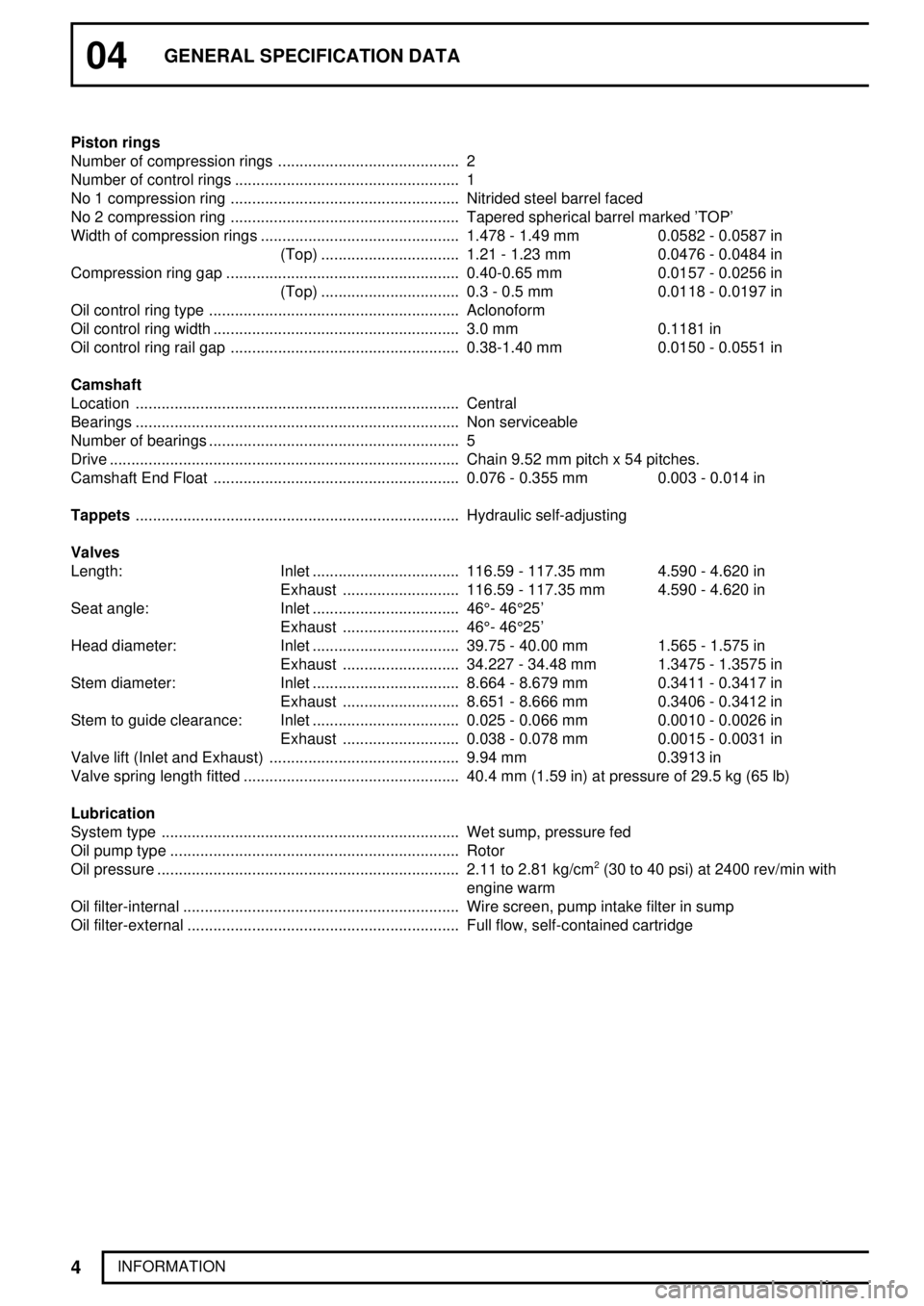

INFORMATION Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Nitrided steel barrel faced.....................................................

No 2 compression ring Tapered spherical barrel marked 'TOP'.....................................................

Width of compression rings 1.478 - 1.49 mm.............................................. 0.0582 - 0.0587 in

(Top) 1.21 - 1.23 mm................................ 0.0476 - 0.0484 in

Compression ring gap 0.40-0.65 mm...................................................... 0.0157 - 0.0256 in

(Top) 0.3 - 0.5 mm................................ 0.0118 - 0.0197 in

Oil control ring type Aclonoform..........................................................

Oil control ring width 3.0 mm......................................................... 0.1181 in

Oil control ring rail gap 0.38-1.40 mm..................................................... 0.0150 - 0.0551 in

Camshaft

Location Central...........................................................................

Bearings Non serviceable...........................................................................

Number of bearings 5..........................................................

Drive Chain 9.52 mm pitch x 54 pitches..................................................................................

Camshaft End Float 0.076 - 0.355 mm......................................................... 0.003 - 0.014 in

TappetsHydraulic self-adjusting ...........................................................................

Valves

Length: Inlet 116.59 - 117.35 mm.................................. 4.590 - 4.620 in

Exhaust 116.59 - 117.35 mm........................... 4.590 - 4.620 in

Seat angle: Inlet 46°-46°25' ..................................

Exhaust 46°-46°25' ...........................

Head diameter: Inlet 39.75 - 40.00 mm.................................. 1.565 - 1.575 in

Exhaust 34.227 - 34.48 mm........................... 1.3475 - 1.3575 in

Stem diameter: Inlet 8.664 - 8.679 mm.................................. 0.3411 - 0.3417 in

Exhaust 8.651 - 8.666 mm........................... 0.3406 - 0.3412 in

Stem to guide clearance: Inlet 0.025 - 0.066 mm.................................. 0.0010 - 0.0026 in

Exhaust 0.038 - 0.078 mm........................... 0.0015 - 0.0031 in

Valve lift (Inlet and Exhaust) 9.94 mm............................................ 0.3913 in

Valve spring length fitted 40.4 mm (1.59 in) at pressure of 29.5 kg (65 lb)..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Rotor...................................................................

Oil pressure 2.11 to 2.81 kg/cm

2(30 to 40 psi) at 2400 rev/min with ......................................................................

engine warm

Oil filter-internal Wire screen, pump intake filter in sump................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

Page 24 of 873

04GENERAL SPECIFICATION DATA

6

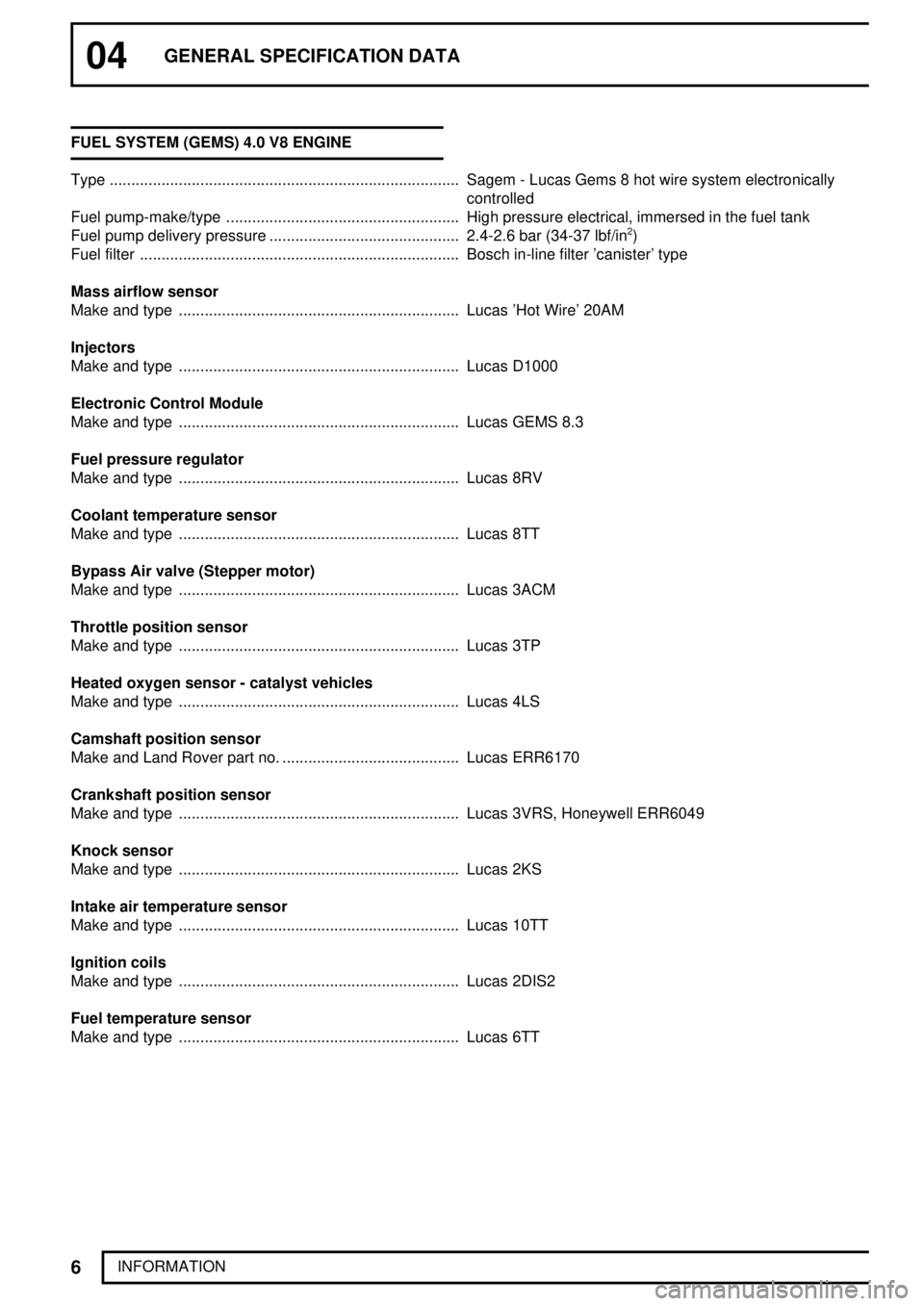

INFORMATION FUEL SYSTEM (GEMS) 4.0 V8 ENGINE

Type Sagem - Lucas Gems 8 hot wire system electronically.................................................................................

controlled

Fuel pump-make/type High pressure electrical, immersed in the fuel tank......................................................

Fuel pump delivery pressure 2.4-2.6 bar (34-37 lbf/in

2) ............................................

Fuel filter Bosch in-line filter 'canister' type..........................................................................

Mass airflow sensor

Make and type Lucas 'Hot Wire' 20AM.................................................................

Injectors

Make and type Lucas D1000.................................................................

Electronic Control Module

Make and type Lucas GEMS 8.3.................................................................

Fuel pressure regulator

Make and type Lucas 8RV.................................................................

Coolant temperature sensor

Make and type Lucas 8TT.................................................................

Bypass Air valve (Stepper motor)

Make and type Lucas 3ACM.................................................................

Throttle position sensor

Make and type Lucas 3TP.................................................................

Heated oxygen sensor - catalyst vehicles

Make and type Lucas 4LS.................................................................

Camshaft position sensor

Make and Land Rover part no. Lucas ERR6170.........................................

Crankshaft position sensor

Make and type Lucas 3VRS, Honeywell ERR6049.................................................................

Knock sensor

Make and type Lucas 2KS.................................................................

Intake air temperature sensor

Make and type Lucas 10TT.................................................................

Ignition coils

Make and type Lucas 2DIS2.................................................................

Fuel temperature sensor

Make and type Lucas 6TT.................................................................

Page 25 of 873

GENERAL SPECIFICATION DATA

7

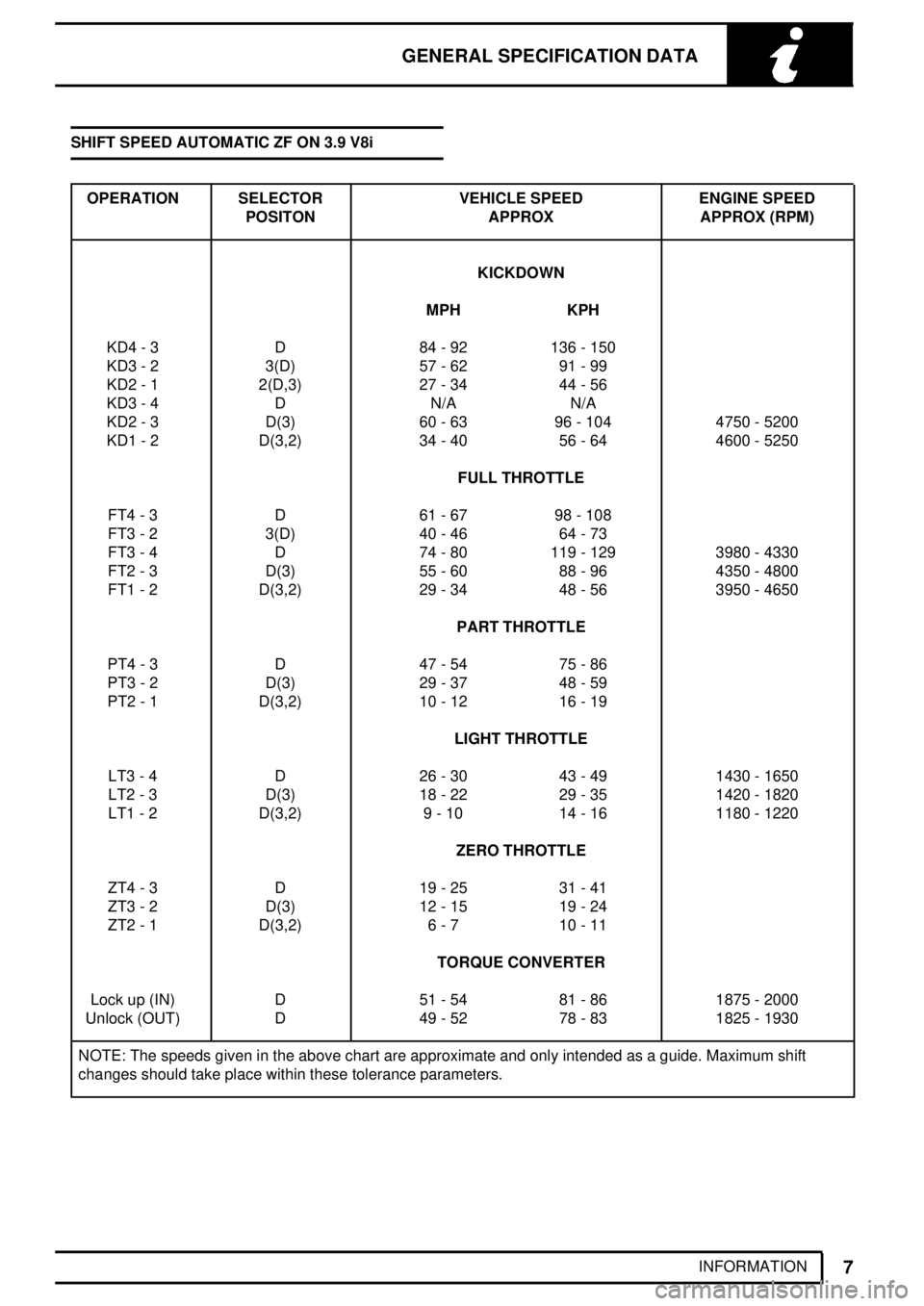

INFORMATION SHIFT SPEED AUTOMATIC ZF ON 3.9 V8i

OPERATION SELECTOR VEHICLE SPEED ENGINE SPEED

POSITON APPROX APPROX (RPM)

KICKDOWN

MPH KPH

KD4 - 3 D 84 - 92 136 - 150

KD3 - 2 3(D) 57 - 62 91 - 99

KD2 - 1 2(D,3) 27 - 34 44 - 56

KD3 - 4 D N/A N/A

KD2 - 3 D(3) 60 - 63 96 - 104 4750 - 5200

KD1 - 2 D(3,2) 34 - 40 56 - 64 4600 - 5250

FULL THROTTLE

FT4 - 3 D 61 - 67 98 - 108

FT3 - 2 3(D) 40 - 46 64 - 73

FT3 - 4 D 74 - 80 119 - 129 3980 - 4330

FT2 - 3 D(3) 55 - 60 88 - 96 4350 - 4800

FT1 - 2 D(3,2) 29 - 34 48 - 56 3950 - 4650

PART THROTTLE

PT4 - 3 D 47 - 54 75 - 86

PT3 - 2 D(3) 29 - 37 48 - 59

PT2 - 1 D(3,2) 10 - 12 16 - 19

LIGHT THROTTLE

LT3 - 4 D 26 - 30 43 - 49 1430 - 1650

LT2 - 3 D(3) 18 - 22 29 - 35 1420 - 1820

LT1 - 2 D(3,2) 9 - 10 14 - 16 1180 - 1220

ZERO THROTTLE

ZT4 - 3 D 19 - 25 31 - 41

ZT3 - 2 D(3) 12 - 15 19 - 24

ZT2 - 1 D(3,2) 6 - 7 10 - 11

TORQUE CONVERTER

Lock up (IN) D 51 - 54 81 - 86 1875 - 2000

Unlock (OUT) D 49 - 52 78 - 83 1825 - 1930

NOTE: The speeds given in the above chart are approximate and only intended as a guide. Maximum shift

changes should take place within these tolerance parameters.

Page 26 of 873

04GENERAL SPECIFICATION DATA

8

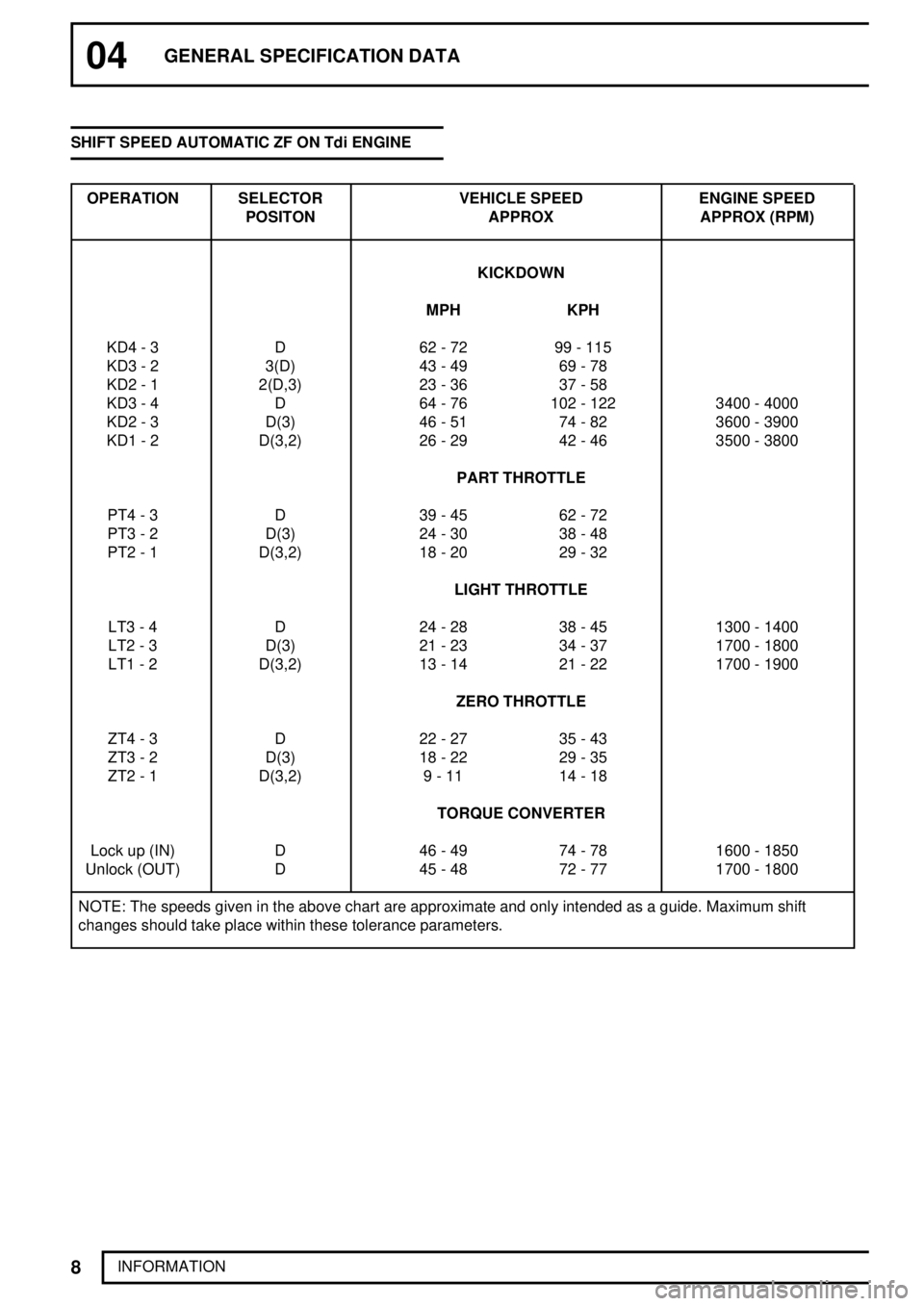

INFORMATION SHIFT SPEED AUTOMATIC ZF ON Tdi ENGINE

OPERATION SELECTOR VEHICLE SPEED ENGINE SPEED

POSITON APPROX APPROX (RPM)

KICKDOWN

MPH KPH

KD4 - 3 D 62 - 72 99 - 115

KD3 - 2 3(D) 43 - 49 69 - 78

KD2 - 1 2(D,3) 23 - 36 37 - 58

KD3 - 4 D 64 - 76 102 - 122 3400 - 4000

KD2 - 3 D(3) 46 - 51 74 - 82 3600 - 3900

KD1 - 2 D(3,2) 26 - 29 42 - 46 3500 - 3800

PART THROTTLE

PT4 - 3 D 39 - 45 62 - 72

PT3 - 2 D(3) 24 - 30 38 - 48

PT2 - 1 D(3,2) 18 - 20 29 - 32

LIGHT THROTTLE

LT3 - 4 D 24 - 28 38 - 45 1300 - 1400

LT2 - 3 D(3) 21 - 23 34 - 37 1700 - 1800

LT1 - 2 D(3,2) 13 - 14 21 - 22 1700 - 1900

ZERO THROTTLE

ZT4 - 3 D 22 - 27 35 - 43

ZT3 - 2 D(3) 18 - 22 29 - 35

ZT2 - 1 D(3,2) 9 - 11 14 - 18

TORQUE CONVERTER

Lock up (IN) D 46 - 49 74 - 78 1600 - 1850

Unlock (OUT) D 45 - 48 72 - 77 1700 - 1800

NOTE: The speeds given in the above chart are approximate and only intended as a guide. Maximum shift

changes should take place within these tolerance parameters.

Page 36 of 873

04GENERAL SPECIFICATION DATA

18

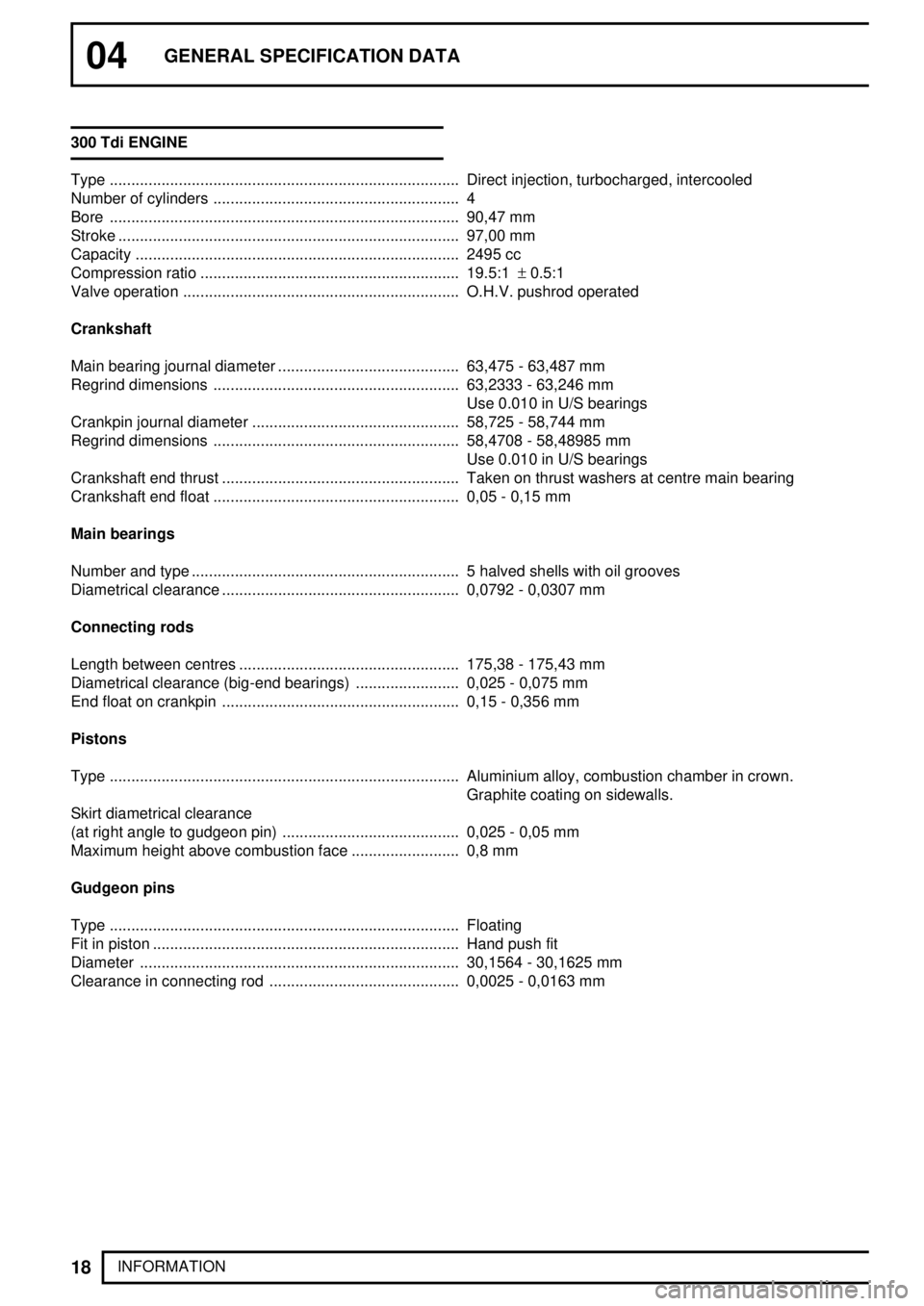

INFORMATION 300 Tdi ENGINE

Type Direct injection, turbocharged, intercooled.................................................................................

Number of cylinders 4.........................................................

Bore 90,47 mm.................................................................................

Stroke 97,00 mm...............................................................................

Capacity 2495 cc...........................................................................

Compression ratio 19.5:1±0.5:1 ............................................................

Valve operation O.H.V. pushrod operated................................................................

Crankshaft

Main bearing journal diameter 63,475 - 63,487 mm..........................................

Regrind dimensions 63,2333 - 63,246 mm.........................................................

Use 0.010 in U/S bearings

Crankpin journal diameter 58,725 - 58,744 mm................................................

Regrind dimensions 58,4708 - 58,48985 mm.........................................................

Use 0.010 in U/S bearings

Crankshaft end thrust Taken on thrust washers at centre main bearing.......................................................

Crankshaft end float 0,05 - 0,15 mm.........................................................

Main bearings

Number and type 5 halved shells with oil grooves..............................................................

Diametrical clearance 0,0792 - 0,0307 mm.......................................................

Connecting rods

Length between centres 175,38 - 175,43 mm...................................................

Diametrical clearance (big-end bearings) 0,025 - 0,075 mm........................

End float on crankpin 0,15 - 0,356 mm.......................................................

Pistons

Type Aluminium alloy, combustion chamber in crown..................................................................................

Graphite coating on sidewalls.

Skirt diametrical clearance

(at right angle to gudgeon pin) 0,025 - 0,05 mm.........................................

Maximum height above combustion face 0,8 mm.........................

Gudgeon pins

Type Floating.................................................................................

Fit in piston Hand push fit.......................................................................

Diameter 30,1564 - 30,1625 mm..........................................................................

Clearance in connecting rod 0,0025 - 0,0163 mm............................................