fuel pump LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 69 of 873

MAINTENANCE

7

MAINTENANCE

CHECK/ADJUST VALVE CLEARANCES. - Tdi

Valve adjustment.See GENERAL SPECIFICATION

DATA, Information, 300 Tdi Engine

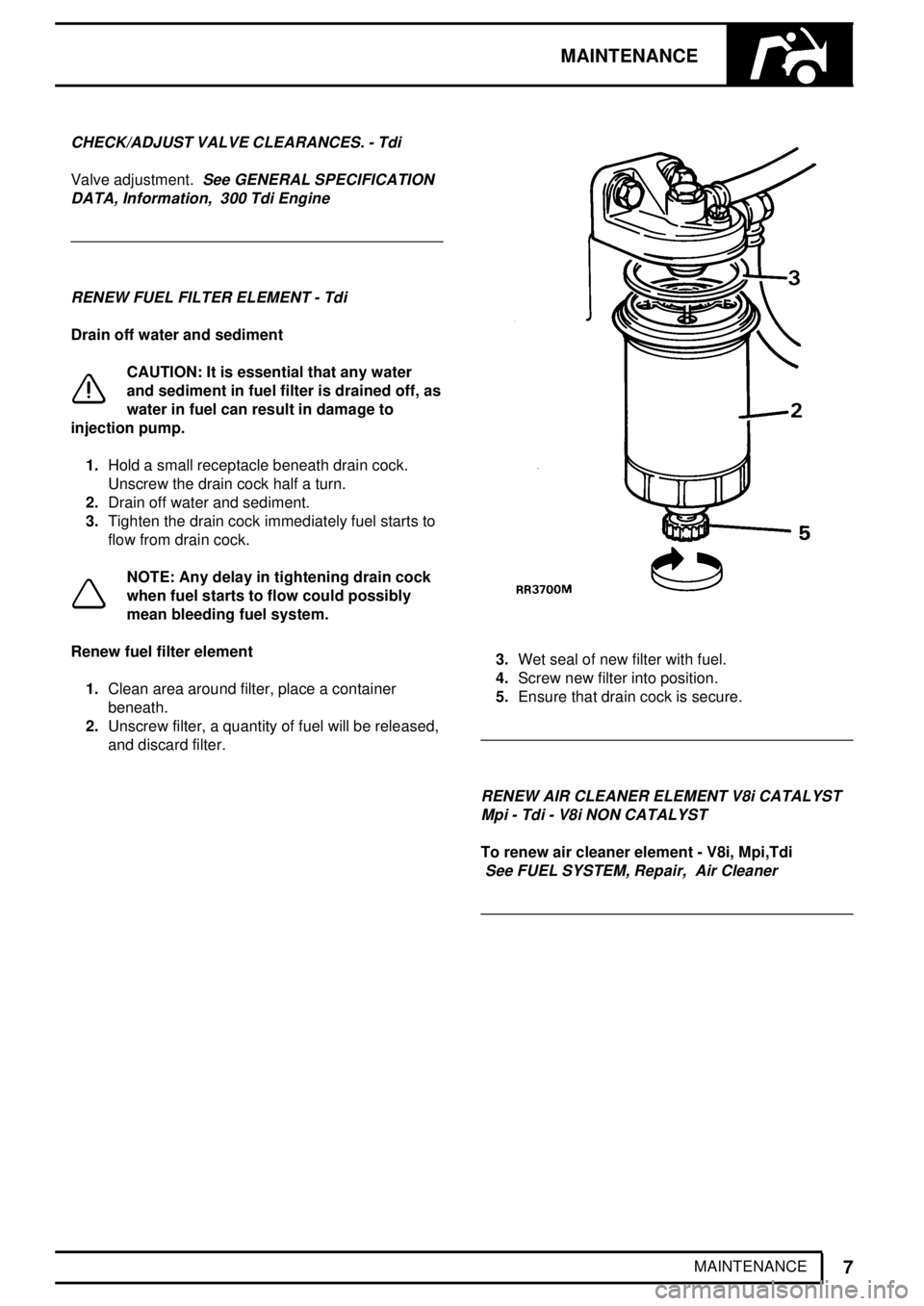

RENEW FUEL FILTER ELEMENT - Tdi

Drain off water and sediment

CAUTION: It is essential that any water

and sediment in fuel filter is drained off, as

water in fuel can result in damage to

injection pump.

1.Hold a small receptacle beneath drain cock.

Unscrew the drain cock half a turn.

2.Drain off water and sediment.

3.Tighten the drain cock immediately fuel starts to

flow from drain cock.

NOTE: Any delay in tightening drain cock

when fuel starts to flow could possibly

mean bleeding fuel system.

Renew fuel filter element

1.Clean area around filter, place a container

beneath.

2.Unscrew filter, a quantity of fuel will be released,

and discard filter.

3.Wet seal of new filter with fuel.

4.Screw new filter into position.

5.Ensure that drain cock is secure.

RENEW AIR CLEANER ELEMENT V8i CATALYST

Mpi - Tdi - V8i NON CATALYST

To renew air cleaner element - V8i, Mpi,Tdi

See FUEL SYSTEM, Repair, Air Cleaner

Page 79 of 873

MAINTENANCE

17

MAINTENANCE

CHECK/TIGHTEN FRONT AND REAR AXLE

SUSPENSION LINK FIXINGS, CHECK CONDITION

OF MOUNTING RUBBERS

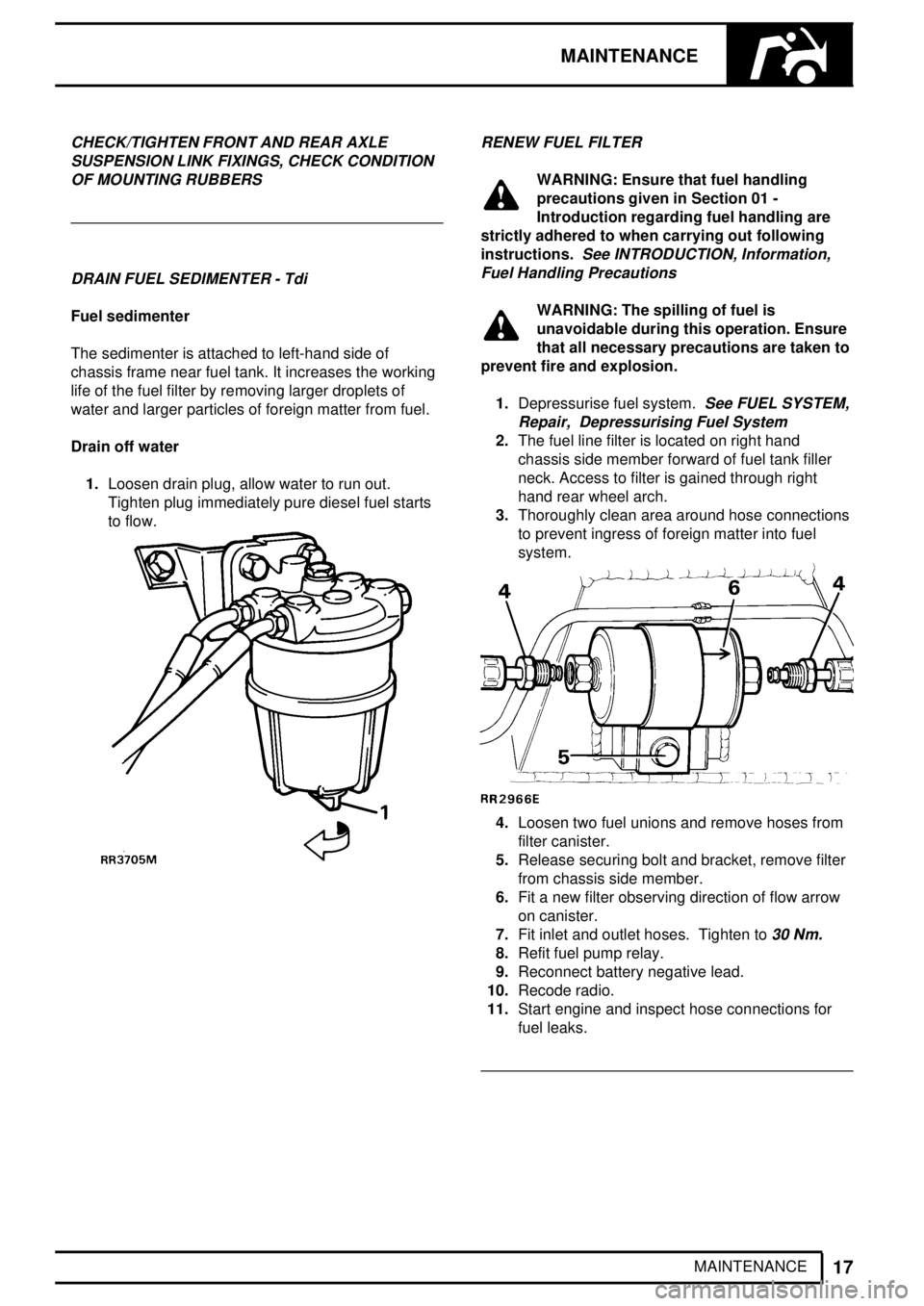

DRAIN FUEL SEDIMENTER - Tdi

Fuel sedimenter

The sedimenter is attached to left-hand side of

chassis frame near fuel tank. It increases the working

life of the fuel filter by removing larger droplets of

water and larger particles of foreign matter from fuel.

Drain off water

1.Loosen drain plug, allow water to run out.

Tighten plug immediately pure diesel fuel starts

to flow.

RENEW FUEL FILTER

WARNING: Ensure that fuel handling

precautions given in Section 01 -

Introduction regarding fuel handling are

strictly adhered to when carrying out following

instructions.

See INTRODUCTION, Information,

Fuel Handling Precautions

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

1.Depressurise fuel system.

See FUEL SYSTEM,

Repair, Depressurising Fuel System

2.The fuel line filter is located on right hand

chassis side member forward of fuel tank filler

neck. Access to filter is gained through right

hand rear wheel arch.

3.Thoroughly clean area around hose connections

to prevent ingress of foreign matter into fuel

system.

4.Loosen two fuel unions and remove hoses from

filter canister.

5.Release securing bolt and bracket, remove filter

from chassis side member.

6.Fit a new filter observing direction of flow arrow

on canister.

7.Fit inlet and outlet hoses. Tighten to

30 Nm.

8.Refit fuel pump relay.

9.Reconnect battery negative lead.

10.Recode radio.

11.Start engine and inspect hose connections for

fuel leaks.

Page 85 of 873

12ENGINE

4

REPAIR 22.Disconnect feed pipe and spill return pipe from

injector pump.

23.Disconnect both pipes from fuel lift pump.

24.Disconnect servo hose from vacuum pump.

25.Remove three retaining nuts and disconnect

exhaust down pipe.

26.Remove oil cooler pipes from oil filter adaptor.

27.If automatic transmission is fitted, disconnect

feed and return pipes at gearbox oil cooler.

Remove retaining bracket from LH side of

cylinder block and release both oil cooler pipes.

28.Support gearbox.

29.Disconnect ground strap from starter motor.

30.On vehicles with automatic transmission, remove

fixings and detach drive plate housing access

panel and gasket.31.Working through drive plate housing aperture

mark the torque convertor and drive plate to

facilitate reassembly.

32.Remove the four convertor to flexible drive

securing bolts, rotating crankshaft to gain access

to each individual bolt.

33.Fit engine lifting bracket to the two RH rear

cylinder head fixing bolts.

34.Using suitable hoist, fit lifting chains to engine.

35.Remove four bolts, from both sides, securing

front engine mounting brackets to cylinder block.

36.Remove two bolts, from both sides, securing

front engine mounting bracket to bell housing.

Page 91 of 873

12ENGINE

10

REPAIR

21.With lip side leading, drive-in seal squarely using

special tool LRT-12-082.

22.Refit gear.

FUEL INJECTION PUMP GEAR

Service repair no - 19.30.06

Remove

23.Slacken the three bolts on front of gear.

CAUTION: It is important to ensure that

when the injection pump is locked no

attempt must be made to rotate it. Take

care not to allow the crankshaft to be turned.24.Remove special tool pin from gear.

25.Remove three bolts and withdraw plate and

gear.

Refit

26.Fit gear and plate and secure with three bolts.

27.Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

Page 93 of 873

12ENGINE

12

REPAIR FRONT COVER/TIMING GEAR HOUSING GASKET

Service repair no - 12.65.10

Remove

1.Remove timing belt and gears.

See Camshaft

Drive Belt and Gears

2.Remove fuel injection pump.See FUEL

SYSTEM, Repair, Fuel Injection Pump and

Timing

3.Remove engine oil sump.See Oil Sump

4.Remove oil pick up strainer.See Oil Pick-Up

Strainer

5.Remove bolts securing timing gear housing to

block.

6.Withdraw timing gear housing complete with

gasket.

7.Clean all gasket material from mating faces.

Refit

8.Fit slave guide studs to locate gasket.

9.Fit new gasket, over slave studs, to cylinder

block.

10.Align flats on oil pump with flats on crankshaft.

11.Fit front cover to block taking care not to damage

oil seal.

12.Secure with bolts of correct length in locations

where slave studs are not fitted (ST3482).

13.Remove slave studs and fit correct length bolts.

14.Tighten to

25 Nm.

15.Fit oil pick-up strainer.See Oil Pick-Up

Strainer

16.Fit oil sump.See Oil Sump

17.Refit fuel injection pump.See FUEL SYSTEM,

Repair, Fuel Injection Pump and Timing

Page 101 of 873

![LAND ROVER DISCOVERY 1995 User Guide 12ENGINE

20

REPAIR CYLINDER HEAD GASKET

Service repair no - 12.29.02

Remove

1.Disconnect battery negative lead.

2.Remove bonnet [Hood].

See CHASSIS AND

BODY, Repair, Bonnet [Hood]

3.Drain coolant.

4.R LAND ROVER DISCOVERY 1995 User Guide 12ENGINE

20

REPAIR CYLINDER HEAD GASKET

Service repair no - 12.29.02

Remove

1.Disconnect battery negative lead.

2.Remove bonnet [Hood].

See CHASSIS AND

BODY, Repair, Bonnet [Hood]

3.Drain coolant.

4.R](/img/64/57248/w960_57248-100.png)

12ENGINE

20

REPAIR CYLINDER HEAD GASKET

Service repair no - 12.29.02

Remove

1.Disconnect battery negative lead.

2.Remove bonnet [Hood].

See CHASSIS AND

BODY, Repair, Bonnet [Hood]

3.Drain coolant.

4.Remove air cleaner assembly.

See FUEL

SYSTEM, Repair, Air Cleaner

5.Detach crankcase ventilation valve and side

breather hose from rocker cover and move to

one side.

6.Remove injection pipes.

7.Disconnect spill rail from fuel injectors.

8.Remove fuel injectors and sealing washers.

Identify each injector to the location from which it

is removed.

See FUEL SYSTEM, Repair,

Injectors

9.Remove inter-connecting harness from glow

plugs.

10.Remove glow plugs.

See FUEL SYSTEM,

Repair, Glow Plugs

11.Remove top hose, radiator to thermostat.

12.Disconnect by-pass hose from thermostat.

13.Disconnect hose, thermostat to water pump.

14.Disconnect water temperature sensor lead.

15.Remove hose inter-cooler to induction manifold.

16.Remove induction manifold.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Exhaust

Manifold - Tdi

17.Remove exhaust manifold and turbocharger

assembly.

See MANIFOLD AND EXHAUST

SYSTEM, Repair, Exhaust Manifold - Tdi

18.Disconnect heater hose from water pump and

move heater rail aside.

19.Disconnect heater hose from rear of cylinder

head.

20.Remove bolt securing air cleaner mounting

bracket to support strut.

21.Remove bolt securing harness bracket to

cylinder head.

22.Remove rear lifting bracket, this will also release

clips securing transmission and engine breather

pipes and multiplug. Note loose spacer under

clip securing engine breather pipe and multiplug.

Page 105 of 873

Tdi

1

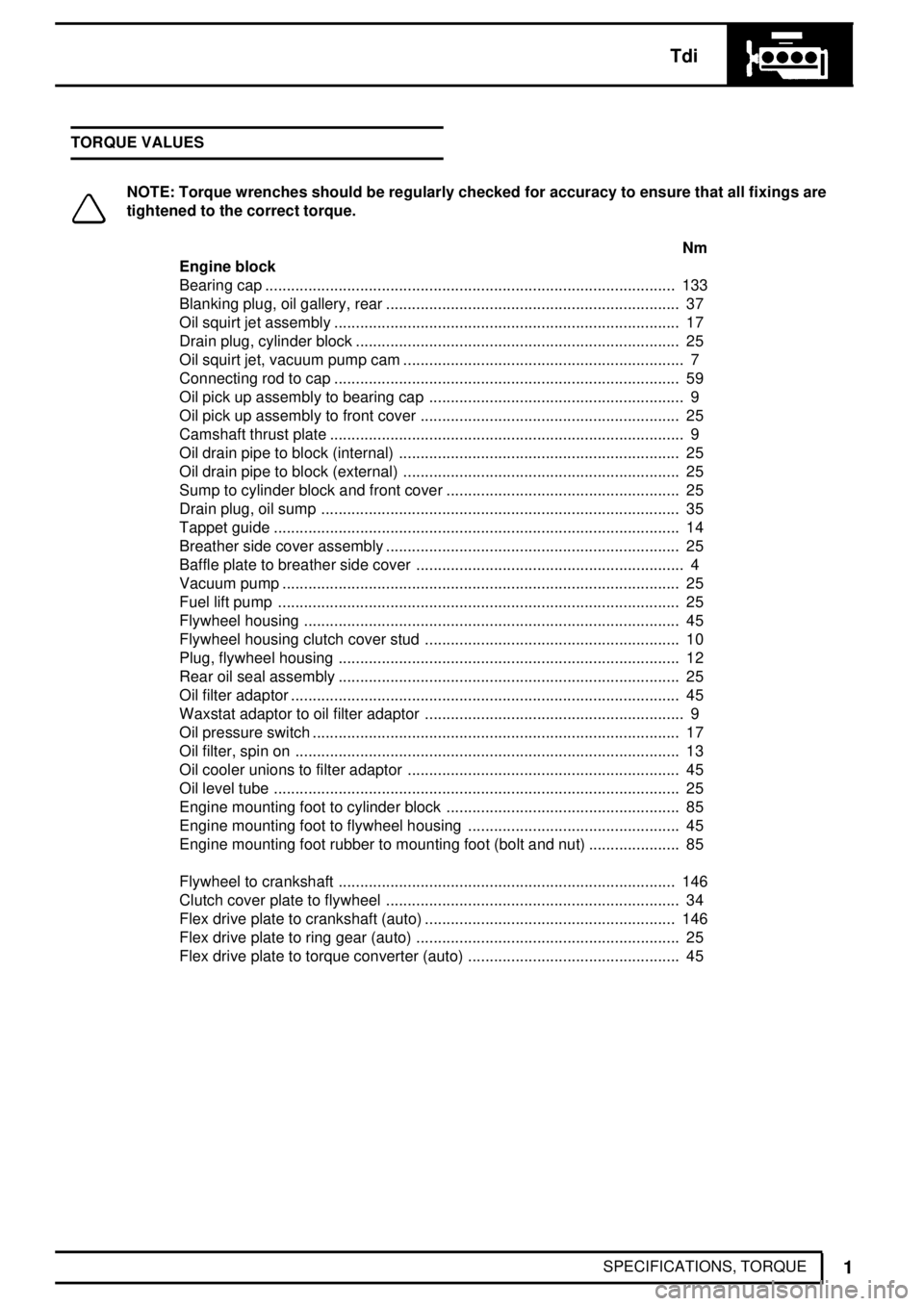

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Engine block

Bearing cap 133...............................................................................................

Blanking plug, oil gallery, rear 37....................................................................

Oil squirt jet assembly 17................................................................................

Drain plug, cylinder block 25...........................................................................

Oil squirt jet, vacuum pump cam 7.................................................................

Connecting rod to cap 59................................................................................

Oil pick up assembly to bearing cap 9...........................................................

Oil pick up assembly to front cover 25............................................................

Camshaft thrust plate 9..................................................................................

Oil drain pipe to block (internal) 25.................................................................

Oil drain pipe to block (external) 25................................................................

Sump to cylinder block and front cover 25......................................................

Drain plug, oil sump 35...................................................................................

Tappet guide 14..............................................................................................

Breather side cover assembly 25....................................................................

Baffle plate to breather side cover 4..............................................................

Vacuum pump 25............................................................................................

Fuel lift pump 25.............................................................................................

Flywheel housing 45.......................................................................................

Flywheel housing clutch cover stud 10...........................................................

Plug, flywheel housing 12...............................................................................

Rear oil seal assembly 25...............................................................................

Oil filter adaptor 45..........................................................................................

Waxstat adaptor to oil filter adaptor 9............................................................

Oil pressure switch 17.....................................................................................

Oil filter, spin on 13.........................................................................................

Oil cooler unions to filter adaptor 45...............................................................

Oil level tube 25..............................................................................................

Engine mounting foot to cylinder block 85......................................................

Engine mounting foot to flywheel housing 45.................................................

Engine mounting foot rubber to mounting foot (bolt and nut) 85.....................

Flywheel to crankshaft 146..............................................................................

Clutch cover plate to flywheel 34....................................................................

Flex drive plate to crankshaft (auto) 146..........................................................

Flex drive plate to ring gear (auto) 25.............................................................

Flex drive plate to torque converter (auto) 45.................................................

Page 106 of 873

12ENGINE

2

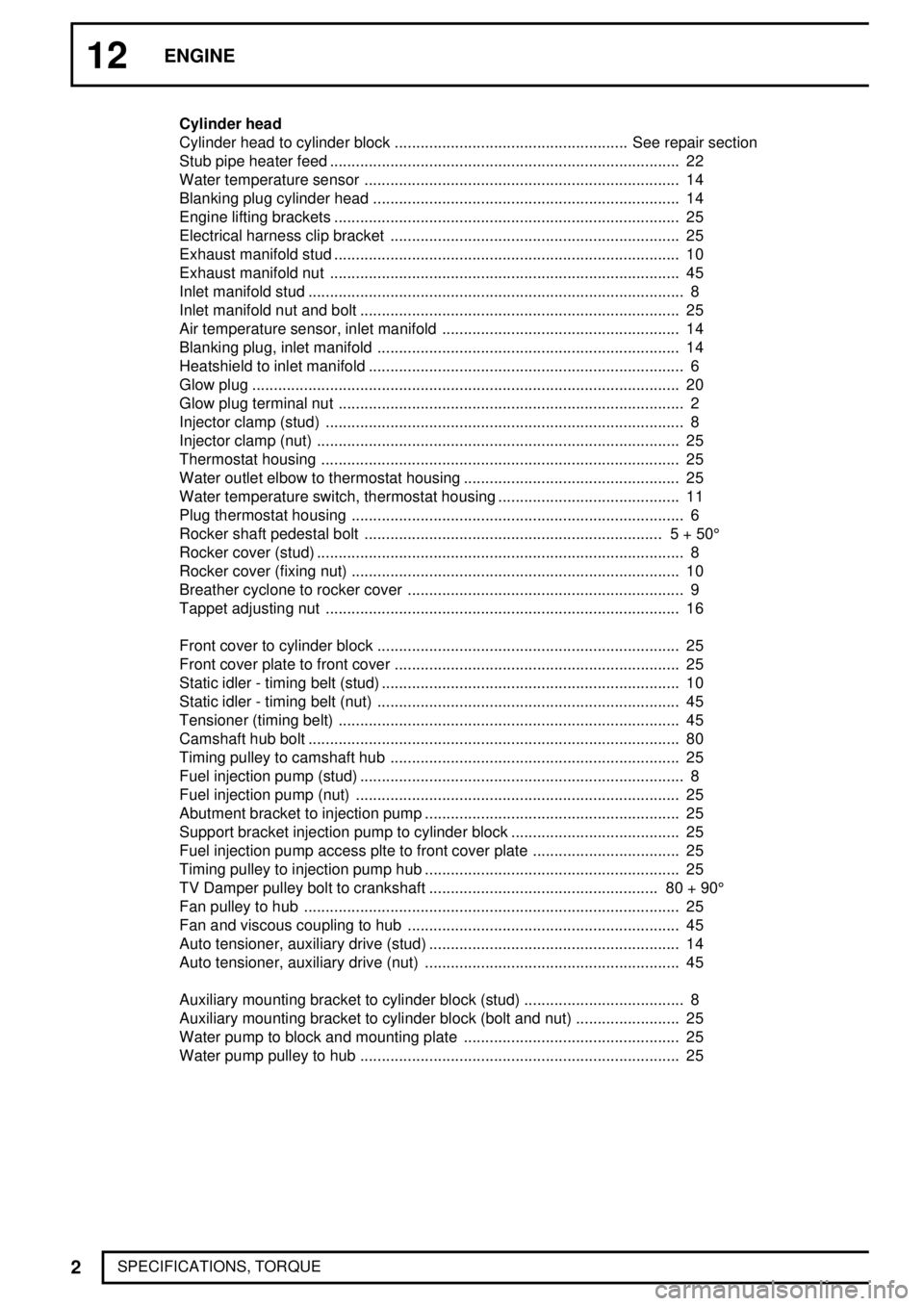

SPECIFICATIONS, TORQUECylinder head

Cylinder head to cylinder block See repair section......................................................

Stub pipe heater feed 22.................................................................................

Water temperature sensor 14.........................................................................

Blanking plug cylinder head 14.......................................................................

Engine lifting brackets 25................................................................................

Electrical harness clip bracket 25...................................................................

Exhaust manifold stud 10................................................................................

Exhaust manifold nut 45.................................................................................

Inlet manifold stud 8.......................................................................................

Inlet manifold nut and bolt 25..........................................................................

Air temperature sensor, inlet manifold 14.......................................................

Blanking plug, inlet manifold 14......................................................................

Heatshield to inlet manifold 6.........................................................................

Glow plug 20...................................................................................................

Glow plug terminal nut 2................................................................................

Injector clamp (stud) 8...................................................................................

Injector clamp (nut) 25....................................................................................

Thermostat housing 25...................................................................................

Water outlet elbow to thermostat housing 25..................................................

Water temperature switch, thermostat housing 11..........................................

Plug thermostat housing 6.............................................................................

Rocker shaft pedestal bolt 5 + 50° .....................................................................

Rocker cover (stud) 8.....................................................................................

Rocker cover (fixing nut) 10............................................................................

Breather cyclone to rocker cover 9................................................................

Tappet adjusting nut 16..................................................................................

Front cover to cylinder block 25......................................................................

Front cover plate to front cover 25..................................................................

Static idler - timing belt (stud) 10.....................................................................

Static idler - timing belt (nut) 45......................................................................

Tensioner (timing belt) 45...............................................................................

Camshaft hub bolt 80......................................................................................

Timing pulley to camshaft hub 25...................................................................

Fuel injection pump (stud) 8...........................................................................

Fuel injection pump (nut) 25...........................................................................

Abutment bracket to injection pump 25...........................................................

Support bracket injection pump to cylinder block 25.......................................

Fuel injection pump access plte to front cover plate 25..................................

Timing pulley to injection pump hub 25...........................................................

TV Damper pulley bolt to crankshaft 80 + 90° .....................................................

Fan pulley to hub 25.......................................................................................

Fan and viscous coupling to hub 45...............................................................

Auto tensioner, auxiliary drive (stud) 14..........................................................

Auto tensioner, auxiliary drive (nut) 45...........................................................

Auxiliary mounting bracket to cylinder block (stud) 8.....................................

Auxiliary mounting bracket to cylinder block (bolt and nut) 25........................

Water pump to block and mounting plate 25..................................................

Water pump pulley to hub 25..........................................................................

Page 107 of 873

Tdi

3

SPECIFICATIONS, TORQUE Turbo charger oil drain adaptor to block 42....................................................

Oil drain pipe to turbocharger 25....................................................................

Turbocharger oil drain pipe to adaptor 38.......................................................

Turbocharger oil feed pipe adaptor to block 25...............................................

Turbocharger oil feed pipe to adaptor 25........................................................

Oil feed pipe to turbocharger 19.....................................................................

Turbocharger to cylinder head (stud) 10.........................................................

Turbocharger to cylinder head (nut) 45...........................................................

Turbocharger to blanking plate 25..................................................................

Turbocharger to EGR valve 25.......................................................................

EGR delivery tube to valve 25........................................................................

EGR delivery tube to mixing tube 25..............................................................

Fuel lift pump to filter (union) 15.....................................................................

Fuel filter from lift pump (banjo bolt) 33...........................................................

Fuel filter to fuel injection pump (banjo bolt) 33..............................................

Fuel injection pump from fuel filter (banjo bolt) 25..........................................

Injector pipes to injectors and fuel injection pump 29.....................................

Spill rail to injectors (banjo bolt) 10.................................................................

Spill rail to injection pump (banjo bolt) 25.......................................................

Boost pipe injection pump (banjo bolt) 10.......................................................

Plug, rear of injection pump 29.......................................................................

PAS pump to mounting plate 25.....................................................................

PAS pump mounting plate to auxiliaries mounting bracket 25........................

PAS pump pulley to hub 25............................................................................

Generator to auxiliaries mounting bracket 25.................................................

Starter motor (bolt and nut) 45........................................................................

Tachometer electrical connection 4...............................................................

Air conditioning compressor

Compressor mounting bracket to front cover 45.............................................

Compressor to mounting bracket (stud) 8......................................................

Compressor to mounting bracket (nut) 25......................................................

Belt tensioner pulley to tensioner arm 45........................................................

Belt tensioner assembly to front cover plate 25..............................................

Idler pulley to front cover plate 45...................................................................

Compressor belt guard (nut) 25......................................................................

Sensors to water outlet elbow (air/con) 25......................................................

Blanking plug, water outlet elbow (air/con) 25................................................

Generator mounting bracket to front cover 45................................................

Generator to mounting bracket 85..................................................................

Generator pulley to hub 95.............................................................................

Generator belt guard 25..................................................................................

Page 109 of 873

V8i

1

DESCRIPTION AND OPERATION DESCRIPTION

The V8i engine has cast aluminium cylinder heads

and cylinder block. The two banks of steel cylinder

liners which are pressed down to stops in the block,

are set at 90°to one another. The three ringed

aluminium pistons transmit the power through the

connecting rods to a cast iron five bearing crankshaft,

which drives the centrally located camshaft via a

duplex type chain.

The electronic ignition distributor is driven by a gear

off the front of the camshaft and the lubrication oil

pump is driven by a gear off the front of the

crankshaft. The overhead inlet and exhaust valves are

operated by rocker shafts, pushrods and self adjusting

hydraulic tappets.

Multiport fuel injection ensures that engine

performance, economy and exhaust emissions are

automatically correct for the demands of highway and

off road operation.