fuel pump LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 116 of 873

V8i

3

FAULT DIAGNOSIS ENGINE STARTING PROBLEMS

Engine fails to crank in park or neutral (Automatic

Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES - Continue.

2.Is automatic transmission inhibitor switch faulty

or gear selection linkage incorrectly adjusted?

YES -

See AUTOMATIC GEARBOX, Repair,

Inhibitor Switch

,

NO -

See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine fails to crank (Manual Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES -See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine cranks but fails to start

1.Is the cranking speed fast enough (120 rpm)?

NO -

See INTRODUCTION, Information,

Jump Starting

If necessary also.See Electrical Trouble

Shooting Manual.

YES - Continue.

2.Is there combustion in any cylinder?

NO -

See ELECTRICAL, Fault diagnosis,

Lucas Constant Energy Ignition

System - V8i See Electrical Trouble

Shooting Manual.

YES - Continue.

3.Are the fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission control

If problem is not diagnosed repeat tests, starting

at 2.ENGINE RUNNING PROBLEMS

Engine runs at high speed but will not idle (stops)

Engine idle speed erratic Engine starts but stops

immediately

Engine stalls Engine misfires/hesitation

1.Multiport fuel injection.

See Electrical Trouble

Shooting Manual. See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy Ignition

System - V8i

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

If problem is not diagnosed continue.

2.Are HT leads correctly routed and clipped?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission Control

If problem is not diagnosed repeat tests, starting

at 1.

Engine lacks power/poor performance

1.Is throttle travel restricted or cable incorrectly

adjusted?

YES - Check thickness of carpets.

See FUEL

SYSTEM, Repair, Throttle Cable See

FUEL SYSTEM, Repair, Accelerator

Pedal

NO - Continue.

2.Are the Ignition and Multiport Fuel Injection

systems in order?

NO -

See Electrical Trouble Shooting

Manual.A1 See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy

Ignition System - V8i See

ELECTRICAL, Repair, Distributor - V8i

YES - Continue.

Page 117 of 873

12ENGINE

4

FAULT DIAGNOSIS 3.Are fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit

YES - Suspect valves held open by hydraulic

tappets due to high oil pressure.

See

Engine Oil Pressure Test

4.Is oil pressure high?

YES - Remove oil filter and cooler adaptor and

check pressure relief valve strainer gauze

for blockage and that the relief valve is

not stuck closed.

See Description and

operation, Description

NO - Carry out cylinder compression tests to

determine condition of head gaskets and

valves.

See Cylinder Compression -

Test

5.Are cylinder compressions satisfactory?

NO -

See Repair, Cylinder Heads - Renew

YES - Check brake vacuum connections.See

BRAKES, Description and operation,

Brake Servo Unit

Check heater/ventilation unit vacuum connections.

See HEATING AND VENTILATION, Description and

operation, Heating and Ventilation Unit

If problem is not diagnosed: Continue.

6.Are the brakes binding?

YES - Investigate cause of binding.

NO - Continue.

7.Automatic Transmission only. Is the Torque

Converter and Transmission operating correctly?

Carry out Road test, Static tests and Stall tests

to determine condition of Automatic

transmission.

If problem is not diagnosed: repeat tests starting at 1.Engine backfires into exhaust system

1.Are there any leaking joints/connections or holes

in the exhaust system?

YES -

See MANIFOLD AND EXHAUST

SYSTEM, Repair, Exhaust System

Complete

NO - Continue.

2.Is distributor fitted correctly, HT leads in correct

firing order and routed correctly?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is air fuel ratio correct?

NO - Check multiport fuel injection.

See

Electrical Trouble Shooting Manual.

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

Check the crank case and fuel tank ventilation

system.

See EMISSION CONTROL,

Description and operation, Emission Control

YES - Continue.

4.Are cylinder compressions satisfactory?

NO - Carry out compression test to check for

leaking gaskets valves etc.

See

Cylinder Compression - Test

See Repair, Cylinder Heads - Renew

If problem is not diagnosed: repeat tests starting

at 1.

Page 123 of 873

V8i

5

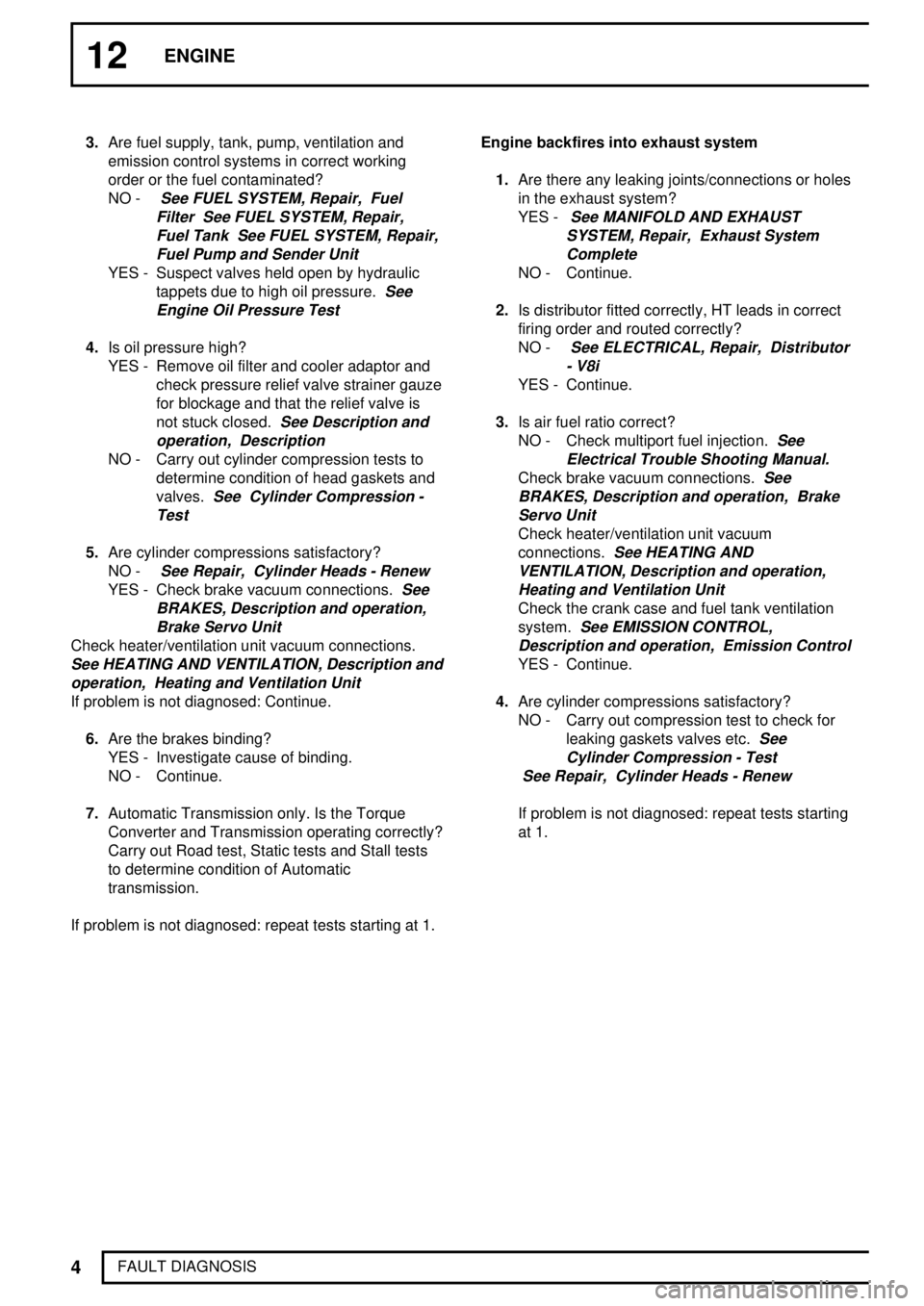

REPAIR CYLINDER HEADS - RENEW

Service repair no - 12.29.15

1.Remove cylinder heads and gaskets.

See

Cylinder Head Gaskets - Renew

2.Remove spark plugs.

3.Using spring compressor LRT-12-034, remove

seals, valves, collets, springs and caps.

CAUTION: Keep components in fitted

order

4.From left hand cylinder head, remove earth lead

studs.

5.Remove three bolts securing power steering

pump mounting bracket to cylinder head.

6.Remove four bolts securing generator mounting

bracket to cylinder head.

7.Right hand cylinder head, remove rear lifting

bracket.

8.Fit lifting bracket to new right hand cylinder

head.

9.Fit mounting brackets and earth lead studs to

new cylinder head. Tighten bolts to

30 Nm.

10.Regrind valves- refer to engine overhaul

publication

11.Lubricate valve stems, fit valves, springs, and

caps. Fit new inlet and exhaust valve stem seals.

12.Using spring compressor LRT-12-034, compress

springs, fit collets. Tap valve to check correct

collet seating.

13.Fit spark plugs.

14.Fit cylinder heads with new gaskets.

See

Cylinder Head Gaskets - Renew

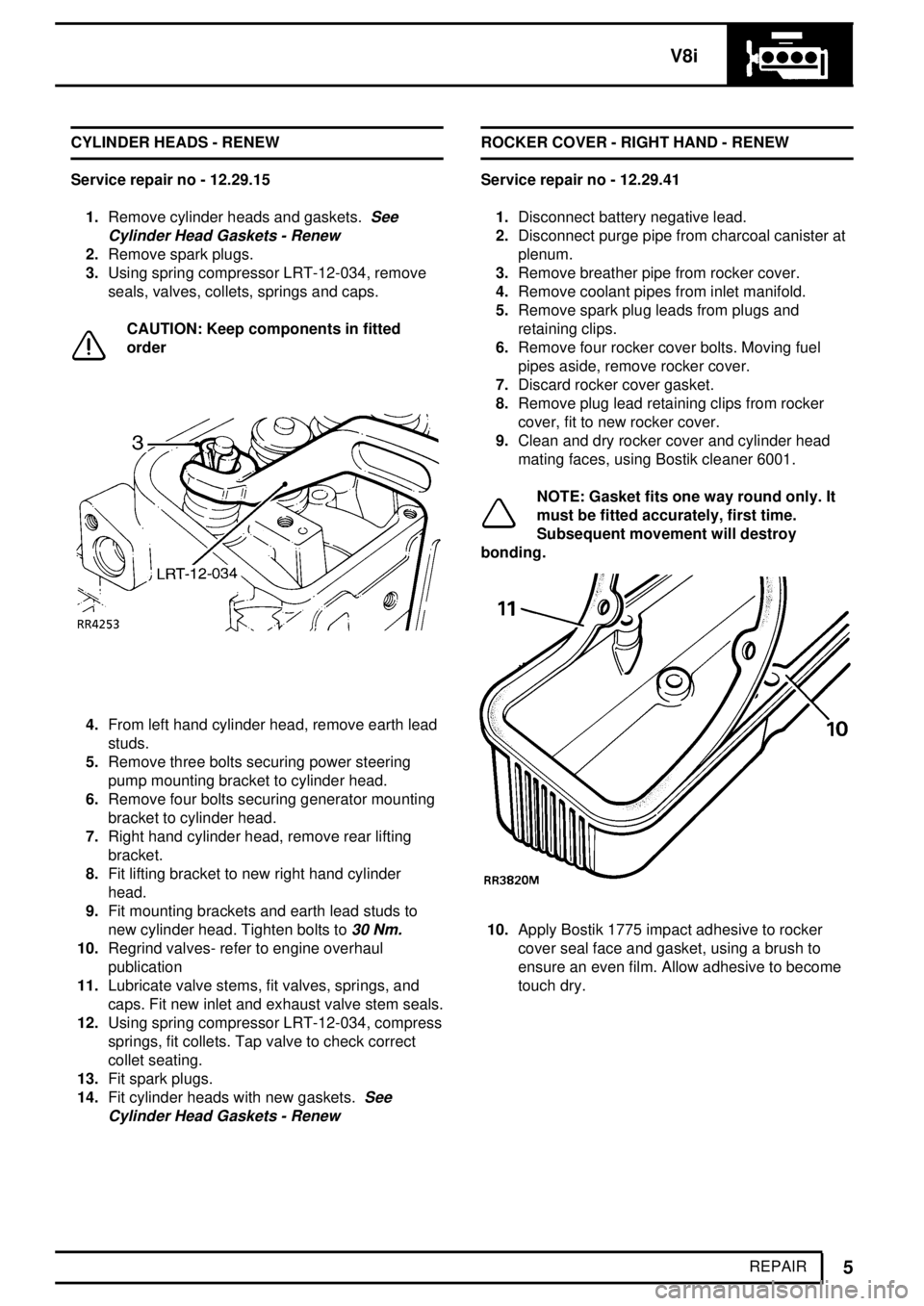

ROCKER COVER - RIGHT HAND - RENEW

Service repair no - 12.29.41

1.Disconnect battery negative lead.

2.Disconnect purge pipe from charcoal canister at

plenum.

3.Remove breather pipe from rocker cover.

4.Remove coolant pipes from inlet manifold.

5.Remove spark plug leads from plugs and

retaining clips.

6.Remove four rocker cover bolts. Moving fuel

pipes aside, remove rocker cover.

7.Discard rocker cover gasket.

8.Remove plug lead retaining clips from rocker

cover, fit to new rocker cover.

9.Clean and dry rocker cover and cylinder head

mating faces, using Bostik cleaner 6001.

NOTE: Gasket fits one way round only. It

must be fitted accurately, first time.

Subsequent movement will destroy

bonding.

10.Apply Bostik 1775 impact adhesive to rocker

cover seal face and gasket, using a brush to

ensure an even film. Allow adhesive to become

touch dry.

Page 131 of 873

V8i

13

REPAIR

NOTE: Release bolts securing compressor

mounting bracket to engine and remove

bracket to enable temporary lifting eye

ETC 5964 to be fitted. Secure lifting eye to

mounting bracket fixing points with suitable bolts

of equivalent size, pitch and thread. Leave lifting

eye attached until engine is reinstalled in vehicle.

15.Place drain tray underneath vehicle.

16.Disconnect hose from reservoir to power

steering pump. Secure hose end above level of

fluid reservoir to avoid unnecessary loss of fluid.

17.Disconnect power steering pump to power

steering box hose. Seal hose and pump

openings with masking tape to prevent ingress of

dirt. Wipe away any fluid spillage from chassis or

steering box.

18.Disconnect fuel temperature and coolant

temperature sensor multi-plugs.

19.Disconnect leads from coil.

20.Identify each injector multi-plug for re-assembly

and disconnect plugs from injectors.

21.Manoeuvre harness from behind fuel rails and

place to one side clear of engine assembly.

22.Remove two clamps securing gearbox oil cooler

pipes to engine block.

23.Remove engine mounting fixings on both sides

of cylinder block.

24.Fit lifting chains to engine lifting eyes as shown

in illustration RR1780E.

1. L/H Front chain 356mm total overall length.

2. R/H Front chain 330mm total overall length.

3. R/H Rear chain 457mm total overall length.

NOTE: All chain dimensions are measured

from end of lifting hook to end of last link

in chain.

25.Fit chain lifting eye to a suitable engine hoist.

Raise hoist high enough to enable engine

mountings to be removed, and withdraw rubber

mountings.

26.Lower hoist until engine rests securely on engine

mounting brackets. Remove lifting chains and

hoist.

27.Disconnect two heater hoses located on top of

right hand rocker cover.

28.Remove ground strap from rear of left hand

cylinder head. DO NOT remove from retaining

clip.

29.Remove all electrical harnesses from retaining

clips at rear of engine.

30.Remove transmission breather pipes from

retaining clip on rear lifting eye.

31.Remove top two bolts securing bell housing to

cylinder block.

32.Raise front of vehicle, lower vehicle on to axle

stands.

33.Remove bell housing bottom cover. Remove

gasket from bell housing face.

34.Remove nuts securing exhaust downpipes to

manifolds, remove heat shield from right hand

side downpipe.

35.Remove electrical leads from starter motor

solenoid. Disconnect multi-plug from oil level

sensor on side of sump, if fitted.

NOTE: Instructions 37, 38 and 39 refer to

automatic vehicles only.

36.With assistance rotate engine at crankshaft

pulley until two access holes in drive plate/ring

gear assembly are visible.

37.Remove two bolts visible through access holes.

Mark one access hole and one bolt hole to

ensure unit is reassembled in its original position

38.Rotate crankshaft 180Ê until two remaining

access holes are visible, remove two bolts.

Page 140 of 873

12ENGINE

4

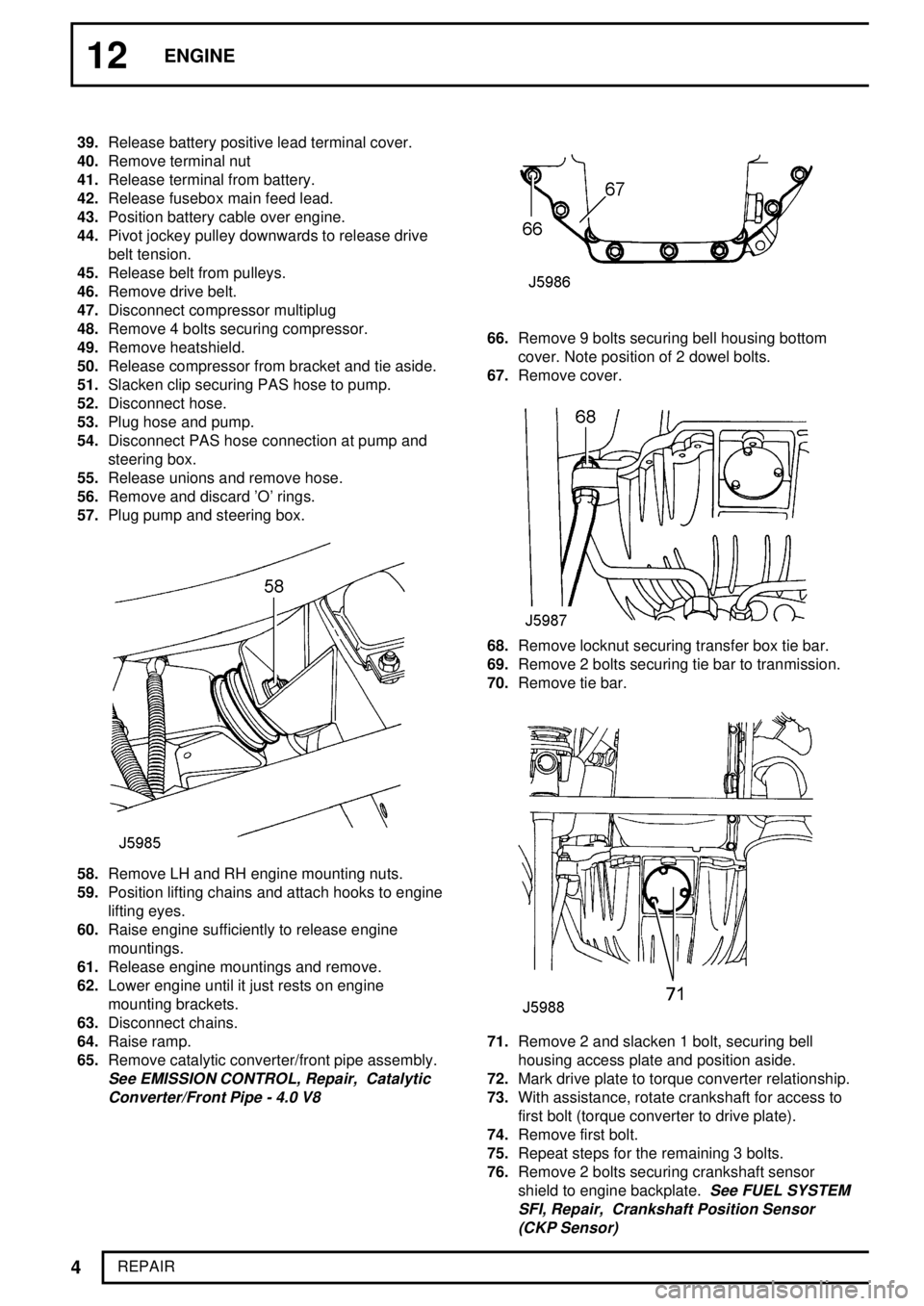

REPAIR 39.Release battery positive lead terminal cover.

40.Remove terminal nut

41.Release terminal from battery.

42.Release fusebox main feed lead.

43.Position battery cable over engine.

44.Pivot jockey pulley downwards to release drive

belt tension.

45.Release belt from pulleys.

46.Remove drive belt.

47.Disconnect compressor multiplug

48.Remove 4 bolts securing compressor.

49.Remove heatshield.

50.Release compressor from bracket and tie aside.

51.Slacken clip securing PAS hose to pump.

52.Disconnect hose.

53.Plug hose and pump.

54.Disconnect PAS hose connection at pump and

steering box.

55.Release unions and remove hose.

56.Remove and discard 'O' rings.

57.Plug pump and steering box.

58.Remove LH and RH engine mounting nuts.

59.Position lifting chains and attach hooks to engine

lifting eyes.

60.Raise engine sufficiently to release engine

mountings.

61.Release engine mountings and remove.

62.Lower engine until it just rests on engine

mounting brackets.

63.Disconnect chains.

64.Raise ramp.

65.Remove catalytic converter/front pipe assembly.

See EMISSION CONTROL, Repair, Catalytic

Converter/Front Pipe - 4.0 V8

66.Remove 9 bolts securing bell housing bottom

cover. Note position of 2 dowel bolts.

67.Remove cover.

68.Remove locknut securing transfer box tie bar.

69.Remove 2 bolts securing tie bar to tranmission.

70.Remove tie bar.

71.Remove 2 and slacken 1 bolt, securing bell

housing access plate and position aside.

72.Mark drive plate to torque converter relationship.

73.With assistance, rotate crankshaft for access to

first bolt (torque converter to drive plate).

74.Remove first bolt.

75.Repeat steps for the remaining 3 bolts.

76.Remove 2 bolts securing crankshaft sensor

shield to engine backplate.

See FUEL SYSTEM

SFI, Repair, Crankshaft Position Sensor

(CKP Sensor)

Page 143 of 873

4.0 V8

7

REPAIR 171.Route drive belt around pulleys.

172.Pivot tensioner downwards.

173.Align belt to tensioner and release tensioner.

174.Connect battery positive lead and tighten.

175.Secure terminal cover.

176.Align gearbox breather pipe, clip to engine lifting

eye and fit bolt. Tighten to

9 Nm.

177.Align and secure engine harness brackets to

inlet manifold and fit nuts. Tighten to

9 Nm.

178.Connect injector multiplugs.

179.Connect air intake temperature sensor multiplug.

180.Connect fuel temperature sensor multiplug.

181.Connect coolant temperature multiplug.

182.Connect temperature gauge connector.

183.Connect oil pressure switch Lucar.

184.Connect camshaft sensor multiplug and secure

to bracket.

185.Fit ignition coil bracket.

See FUEL SYSTEM

SFI, Repair, Ignition Coils

186.Position heater hose/pipe assembly.

187.Connect hose to inlet manifold.

188.Align pipe to bracket and fit bolt. Tighten to

9

Nm.

189.Tighten hose clip.

190.Connect heater return hose and tighten clip.

191.Remove plugs from fuel feed and return hose

connections.

192.Clean feed unions.

193.Connect return hose and tighten clip.

194.Connect feed hose union and tighten.

195.Remove cloth.

196.Connect purge hose.

197.Connect leads to generator, tighten terminal nuts

and fit cover.

198.Connect sensing Lucar.

199.Connect servo vacuum hose.

200.Position expansion tank and secure with fixings.

201.Connect hose and tighten clip.

202.Lower ramp.

203.Fit mass air flow sensor.

See FUEL SYSTEM

SFI, Repair, Mass Air Flow Sensor (MAF

Sensor)

204.Fit plenum chamber.See FUEL SYSTEM SFI,

Repair, Plenum Chamber

205.Fit radiator.See COOLING SYSTEM, Repair,

Radiator

206.Fit bonnet.See CHASSIS AND BODY, Repair,

Bonnet [Hood]

207.Reconnect battery negative lead.

208.Bleed power steering system.

See STEERING,

Repair, Power Steering System - Bleed

209.Drain engine oil and refill.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids - USA

Vehicles

210.Start engine. Check for fuel, coolant and oil

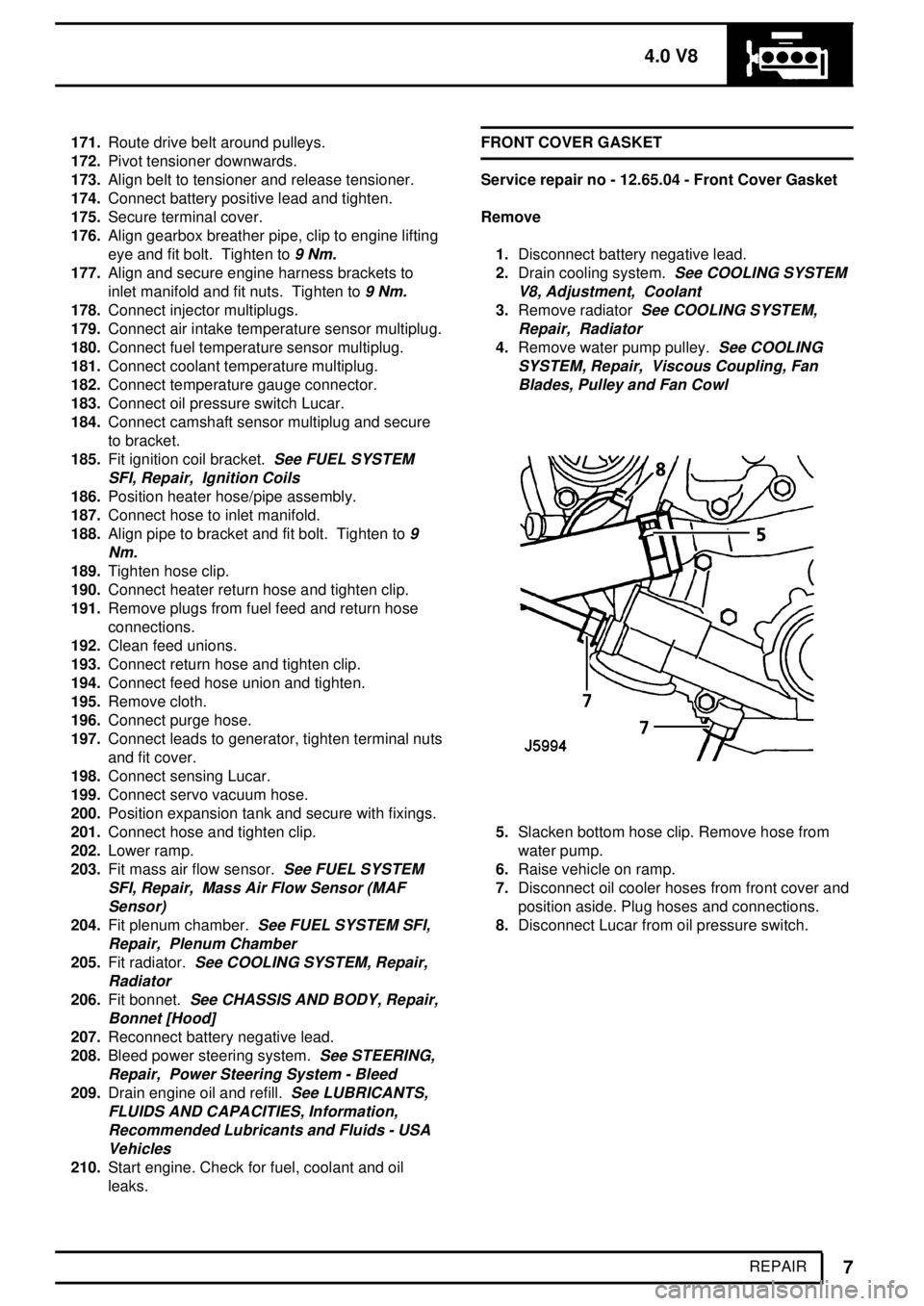

leaks.FRONT COVER GASKET

Service repair no - 12.65.04 - Front Cover Gasket

Remove

1.Disconnect battery negative lead.

2.Drain cooling system.

See COOLING SYSTEM

V8, Adjustment, Coolant

3.Remove radiatorSee COOLING SYSTEM,

Repair, Radiator

4.Remove water pump pulley.See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

5.Slacken bottom hose clip. Remove hose from

water pump.

6.Raise vehicle on ramp.

7.Disconnect oil cooler hoses from front cover and

position aside. Plug hoses and connections.

8.Disconnect Lucar from oil pressure switch.

Page 144 of 873

12ENGINE

8

REPAIR

9.Disconnect multiplug from camshaft sensor.

See FUEL SYSTEM SFI, Repair, Camshaft

Position Sensor (CMP Sensor)

10.Remove 9 bolts securing front cover.

11.Remove 2 bolts securing sump to front cover.

12.Loosen 4 bolts securing sump adjacent to front

cover (2 each side).

13.Release front cover assembly.

14.Remove oil seal.

15.Remove and discard gasket.Refit

16.Clean sealant from threads of cover bolts.

17.Clean old sealant from front cover and block joint

face.

CAUTION: Use a plastic scraper.

18.Apply Hylosil jointing compound to gasket

position on cover and block.

19.Fit new gasket to block face.

20.Ensure oil seal register in cover is clean.

21.Lubricate outer face of NEW oil seal.

22.Using LRT-12-089, fit seal to cover.

23.Lubricate oil pump drive gear and position in

pump with groove away from engine.

24.Locate alignment tool LRT-12-090 on front cover

and oil pump drive gear.

25.Position front cover over crankshaft.

26.Press and rotate tool to engage drive gear until

drive gear keyway aligns with Woodruff key.

27.Fit cover to cylinder block.

Page 164 of 873

![LAND ROVER DISCOVERY 1995 Owners Manual 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S LAND ROVER DISCOVERY 1995 Owners Manual 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S](/img/64/57248/w960_57248-163.png)

12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.See COOLING SYSTEM,

Repair, Radiator - Mpi

4.Remove bonnet [hood].See CHASSIS AND

BODY, Repair, Bonnet [Hood]

5.Drain engine oil.

6.Position absorbent cloth around fuel pipe to fuel

rail union.

Unscrew union to relieve pressure.

CAUTION: Plug the connections

7.Release clip and disconnect hose from coolant

pump.

8.Release clip and disconnect hose from heater

rail.

Page 166 of 873

12ENGINE

8

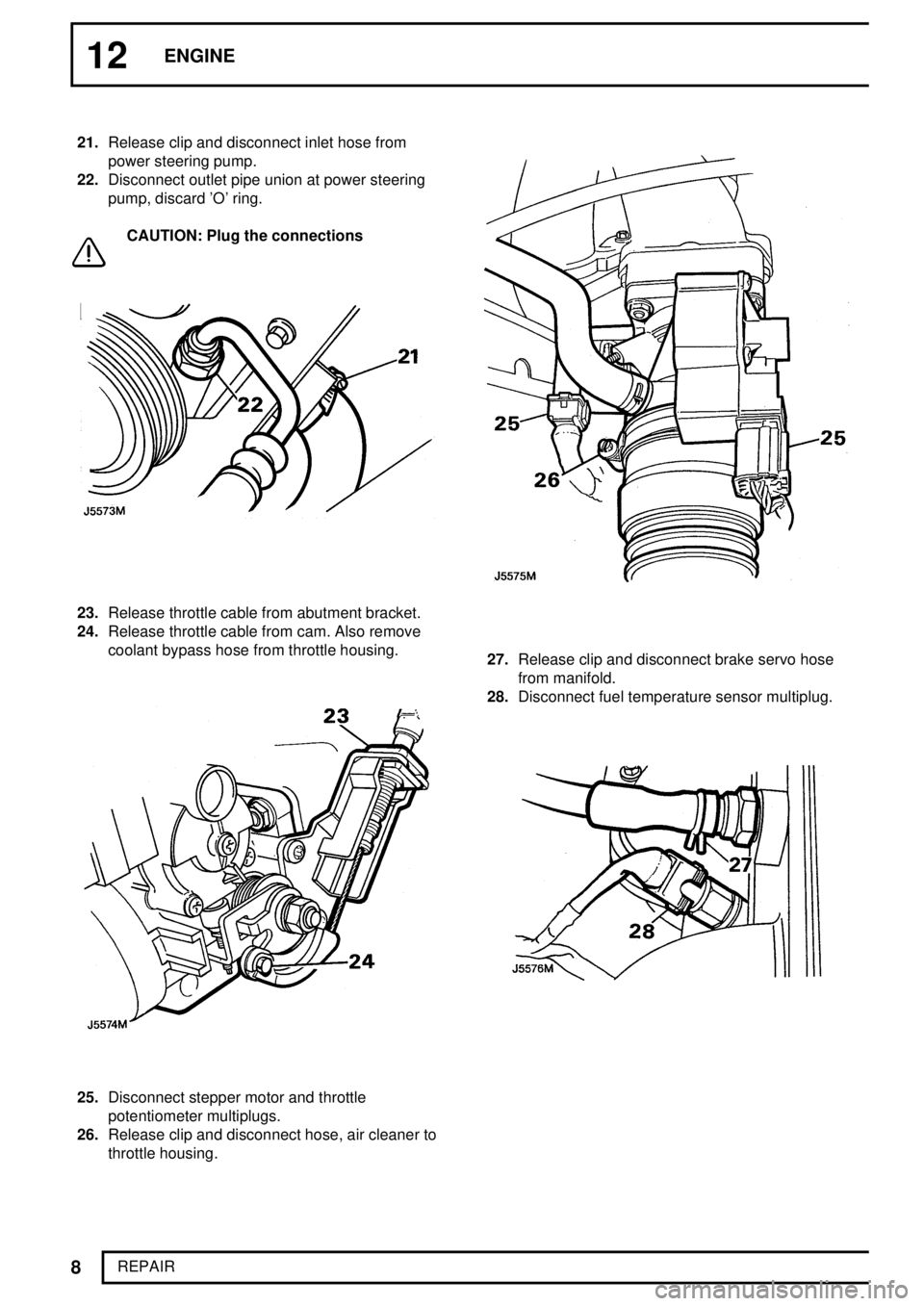

REPAIR 21.Release clip and disconnect inlet hose from

power steering pump.

22.Disconnect outlet pipe union at power steering

pump, discard 'O' ring.

CAUTION: Plug the connections

23.Release throttle cable from abutment bracket.

24.Release throttle cable from cam. Also remove

coolant bypass hose from throttle housing.

25.Disconnect stepper motor and throttle

potentiometer multiplugs.

26.Release clip and disconnect hose, air cleaner to

throttle housing.

27.Release clip and disconnect brake servo hose

from manifold.

28.Disconnect fuel temperature sensor multiplug.

Page 171 of 873

Mpi

13

REPAIR 19.Connect crankshaft sensor, knock sensor, air

conditioning compressor, fuel injector harness,

inlet manifold air temperature and fuel

temperature sensor multiplugs.

20.Connect fuel hose to pressure regulator and

secure with clip.

21.Fit and tighten fuel pipe to fuel rail union.

22.Connect multiplugs to throttle housing.

23.Connect vacuum hose to manifold.

24.Connect oil pressure switch multiplug.

25.Connect brake servo hose to manifold, secure

with clip.

26.Connect throttle cable to cam.

27.Position engine harness and connect breather

hose to inlet manifold, secure with clip.

28.Connect coolant temperature sensor multiplugs,

secure harness with cable tie.

29.Connect oxygen sensor multiplug, secure

harness with cable tie.

30.Connect alternator harness.

31.Connect heater hose to heater rail and secure

with clip.

32.Connect hose to coolant pump and secure with

clip.

33.Connect inlet hose to power steering pump and

secure with clip.

34.Fit and tighten outlet pipe union to power

steering pump.

35.Connect bypass and top hose, secure with clip.

36.Connect air cleaner to throttle housing hose and

secure with clip.

37.Remove engine lifting bracket.

38.Position spark plug cover and secure with

screws.

39.Fill engine with oil.

40.Fit bonnet [hood].

See CHASSIS AND BODY,

Repair, Bonnet [Hood]

41.Fit radiator.See COOLING SYSTEM, Repair,

Radiator - Mpi

42.Adjust throttle cable.See FUEL SYSTEM,

Adjustment, Throttle Cable Adjustment

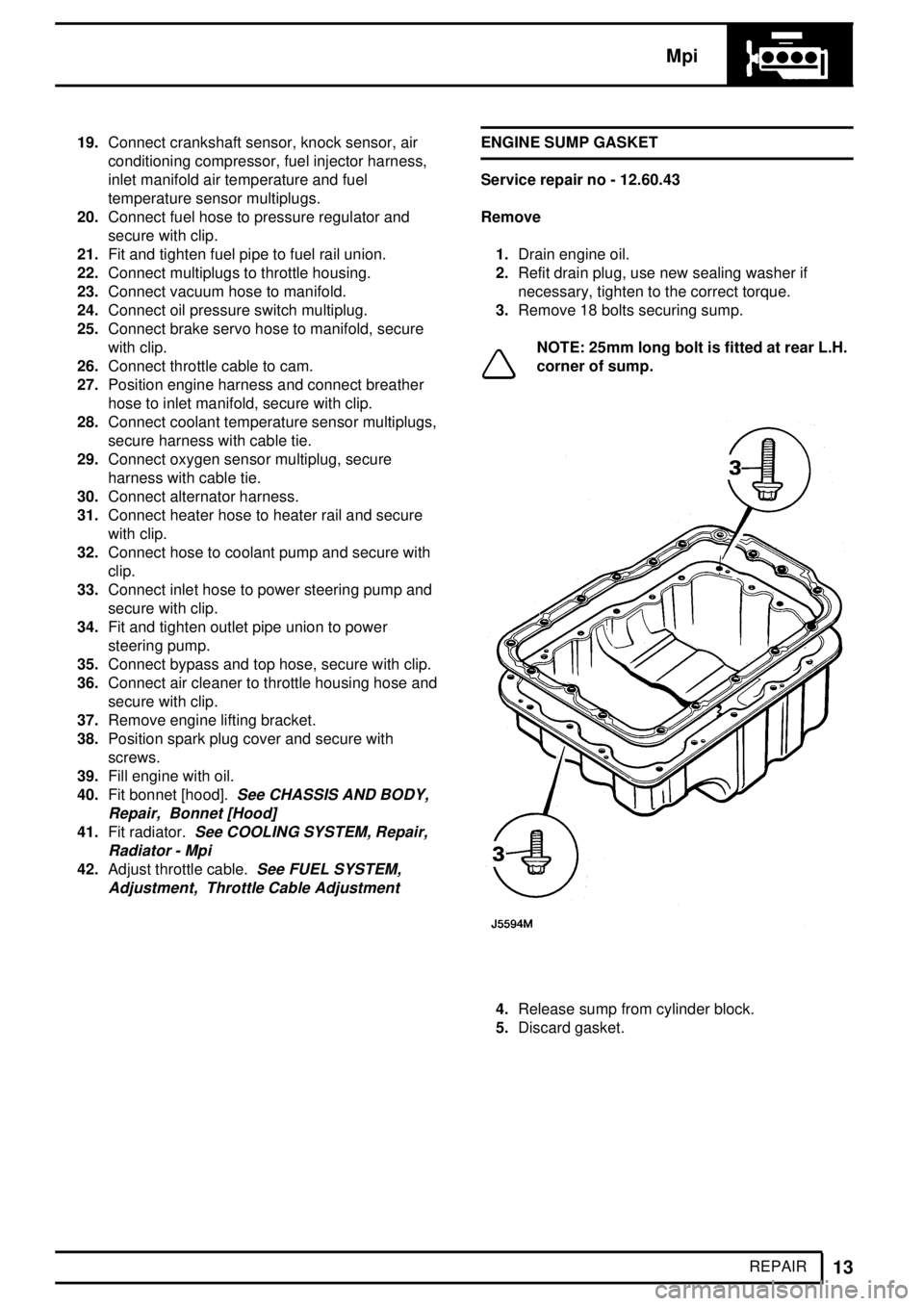

ENGINE SUMP GASKET

Service repair no - 12.60.43

Remove

1.Drain engine oil.

2.Refit drain plug, use new sealing washer if

necessary, tighten to the correct torque.

3.Remove 18 bolts securing sump.

NOTE: 25mm long bolt is fitted at rear L.H.

corner of sump.

4.Release sump from cylinder block.

5.Discard gasket.