engine LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 426 of 873

ZF

1

FAULT DIAGNOSIS ZF AUTOMATIC GEARBOX

Before referring to fault symptoms, carry out initial

static checks first:

INITIAL STATIC CHECKS

Check start positions 'P' & 'N' only........................................................

Reverse lights 'R' only..................................................................

Gear engagements N-D,N-3,N-2,N-1,N-R..........................................................

Full throttle Engine switched off, check full travel at engine and at.......................................................................

pedal.

Oil level 'N' selected, engine running at normal running............................................................................

temperature.

Pressure test

2000 rev/min 10±0.3 bar, 150±5 lbf/in

2....................................................................

Idle pressure 6.9±0.3 bar, 100±5 lbf/in2at 665 to 735 rev/min. ....................................................................

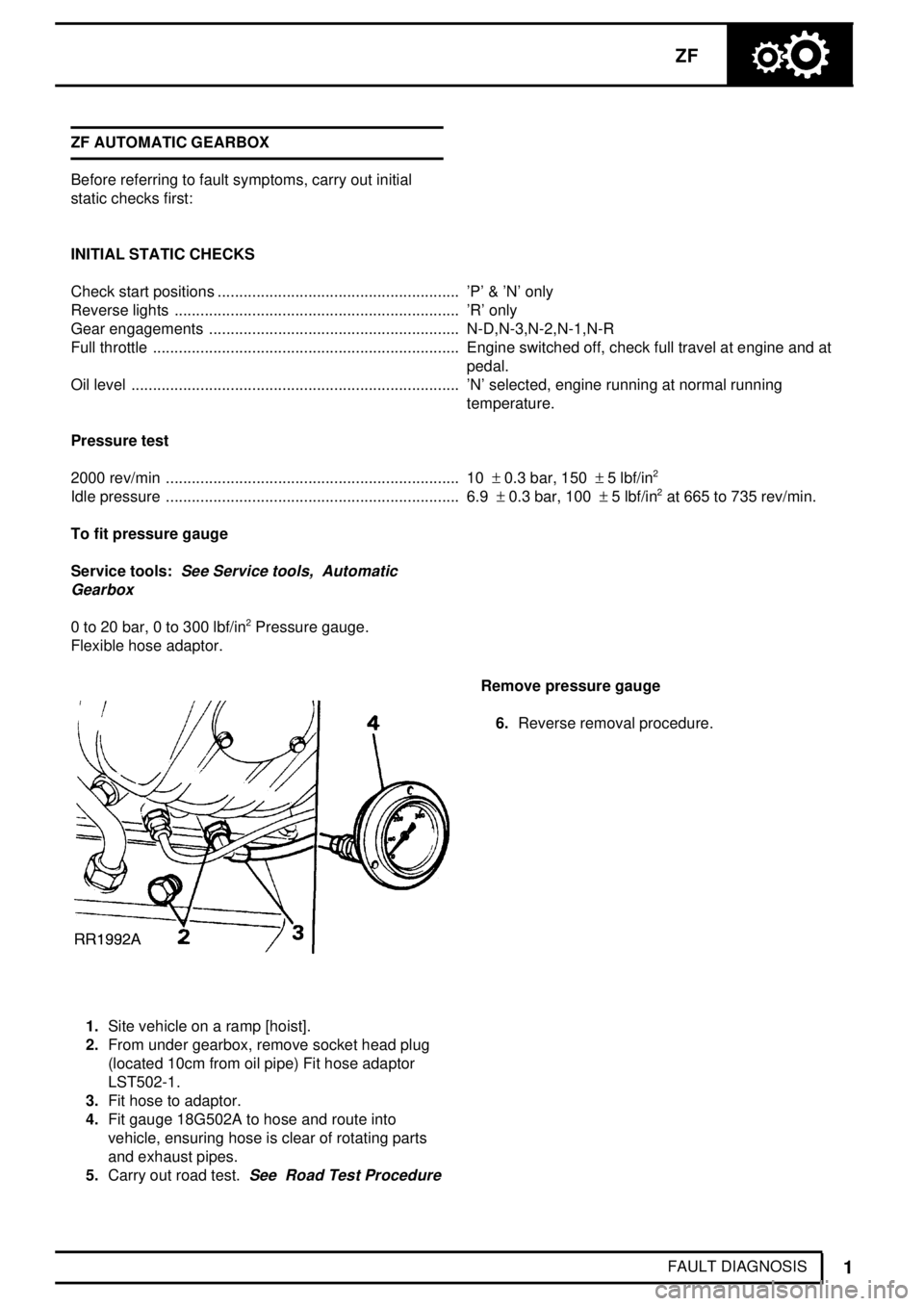

To fit pressure gauge

Service tools:

See Service tools, Automatic

Gearbox

0 to 20 bar, 0 to 300 lbf/in2Pressure gauge.

Flexible hose adaptor.

1.Site vehicle on a ramp [hoist].

2.From under gearbox, remove socket head plug

(located 10cm from oil pipe) Fit hose adaptor

LST502-1.

3.Fit hose to adaptor.

4.Fit gauge 18G502A to hose and route into

vehicle, ensuring hose is clear of rotating parts

and exhaust pipes.

5.Carry out road test.

See Road Test Procedure

Remove pressure gauge

6.Reverse removal procedure.

Page 427 of 873

44AUTOMATIC GEARBOX

2

FAULT DIAGNOSIS ROAD TEST PROCEDURE

Follow the procedure given commencing each test,

from a standing start, on a level road, in good weather

conditions.

ROADTEST 1 = CHECKS 1-2-3-4-5-6-7-8

D SELECTED KICKDOWN START FROM REST

CHECK 1

Check for clutch squeal and slip. Check pressure is

150lbf/in

2

CHECK 2

Check 1st to 2nd upshift speed and quality. Pressure

should fall to 120 lbf/in

2.

CHECK 3

Check 2nd-3rd upshift speed and quality. Pressure

should fall to 100 lbf/in

2

CHECK 4

Release throttle to allow simultaneous engagement

4th + DDC. Check shift quality and engine rpm drop of

approximately 500 rpm.

CHECK 5

To proceed to Check 5 release throttle and check

drop out speed of direct drive clutch to 4th.

CHECK 6

Check down shift speed and quality 4th to 3rd.

NOTE: This shift is usually very smooth

and difficult to detect.

CHECK 7

Check downshift speed and quality 3rd to 2nd.

CHECK 8

Check downshift speed and quality 2nd to 1st. Also

difficult to detect.

END OF ROADTEST 1ROADTEST 2 CHECKS = 9-10-11

D SELECTED FROM REST

FULL THROTTLE START

CHECK 9

Check 1st-2nd upshift speed and quality.

CHECK 10

Check 2nd 3rd upshift speed and quality.

CHECK 11

Check 3rd 4th and direct drive clutch upshift speed

and quality.

NOTE: 4th and the direct drive clutch

engage simultaneously.

END OF ROADTEST 2

Page 428 of 873

ZF

3

FAULT DIAGNOSIS ROADTEST 3 = CHECKS

12-13-14-15-16-17-18-19-20-21-22-23

D SELECTED FROM REST

LIGHT THROTTLE START

CHECK 12

Check 1st 2nd upshift speed and quality.

CHECK 13

Check 2nd 3rd upshift speed and quality.

CHECK 14

Check 3rd 4th upshift speed and quality.

NOTE: This shift is usually very difficult to

detect but can be confirmed by a 200 rpm

drop in engine speed.

CHECK 15

Check speed and quality of shift into direct drive

clutch, confirmed by 300 rpm drop in engine speed.

NOTE: An intermediate throttle position

engagement of 4th and the direct drive

clutch, which is indicated by a fall of

500rpm in engine speed.

CHECK 16

At approximately 88 kph (55 mph) depress throttle to

kickdown - gearbox should change down to 2nd -

release throttle to re-engage 4th direct drive clutch

continue to accelerate gently.

CHECK 17

At approximately 128 kph (80 mph) depress throttle to

kickdown - gearbox should change down to 3rd -

release throttle to re-engage 4th direct drive clutch

and continue to accelerate gently.CHECK 18

At approximately 138 kph (85 mph) select 3rd,

gearbox should change immediately down to 3rd.

Release throttle.

CHECK 19

De-accelerate to approximately 47 kph (30 mph)

depress throttle to kickdown - geabox should

downshift to 1st gear, continue accelerating at full

throttle until 3rd gear is attained. To do this you will

have repeated check 2 of Test 1.

CHECK 20

At 128 kph (80 mph) select 2nd no downshift should

occur. Release throttle.

CHECK 21

At 104 kph (65 mph) an automatic downshift into 2nd

gear should occur. Continue to de-accelerate.

CHECK 22

At 88 kph (55 mph) select 1st. No downshift should

occur. Continue to de-accelerate.

CHECK 23

With 1 selected 2nd gear engaged continue to

de-accelerate and at 45 kph (28 mph) the box should

automatically downshift to 1st gear after which no

upshifts will occur in this selector position.

END OF ROADTEST

Page 435 of 873

44AUTOMATIC GEARBOX

10

FAULT DIAGNOSIS FAULT SYMPTOMS

SYMPTOM 1 - Intermittent drive and high pitched

noise

FAULT - Low fluid level or restricted filter

SYMPTOM 2 - No drive in reverse

Select 'D'

ú No drive

FAULT - Continue with Symptom 3

ú Drives forward

FAULT - Reverse gear interlock valve

seized

Select '1'

ú No engine braking

FAULT - Clutch brake 3

SYMPTOM 3 - No drive from rest with 'D' selected

Select '1'

ú Vehicle drives

FAULT - No 2 freewheel

ú No drive

Carry out main line pressure check

ú Normal pressure

FAULT - Clutch A

ú No pressure

FAULT - Blocked filter or pump failure

ú Low pressure

FAULT - Restricted filter or sticking primary

regulator

SYMPTOM 4 - Slip in all forward gears

Carry out main line pressure check

ú No pressure

FAULT - Blocked filter or pump failure

ú Low pressure

FAULT - Restricted filter or sticking primary

regulator

ú Normal pressure

FAULT - Clutch 'A'SYMPTOM 5 - Harsh engagement 'N' to 'D'

Check engine idle speed

Carry out main line pressure check

ú High pressure

FAULT - Primary regulator stuck

ú Normal pressure

FAULT - Clutch 'A' or damper for clutch'A'

SYMPTOM 6 - Fierce shift or flare 1st to 2nd shift

Check engine idle speed

Carry out mainline pressure check

ú High pressure

FAULT - Continue with symptom 5

ú Normal pressure

FAULT - Modulator valve or dampers for

clutch brake CB1 and/or clutch brake CB2

FAULT - Clutch brake CB1 and/or clutch

brake CB2

SYMPTOM 7 - Fierce shift or flare 2nd to 3rd

Carry out mainline pressure check

ú High pressure

FAULT - Continue with symptom 5

ú Normal pressure

FAULT - Modulator valve or clutch 'B'

damper

FAULT - Clutch 'B'

SYMPTOM 8 - No 3rd gear

FAULT - 2-3 shift valve

FAULT - Clutch 'B'

SYMPTOM 9 - No 4th gear 'D' selected

FAULT - 4th to 3rd downshift valve stuck or

3rd to 4th upshift valve stuck

FAULT - Clutch brake 4

Page 436 of 873

ZF

11

FAULT DIAGNOSIS SYMPTOM 10 - None or harsh engagement of

direct drive clutch

NOTE: The direct drive clutch will only

engage if 4th gear is engaged at 40 to 45

mph.

Carry out road test pressure check with gauge

connected to torque converter.

ú Normal pressure

FAULT - Failed direct drive clutch

ú Pressures correct but remains high

FAULTS POSSIBLE -

Direct drive clutch and torque converter

control valve stuck

Hysteresis valve stuck

Direct drive clutch control valve stuck

SYMPTOM 11 - Direct drive clutch shift point

incorrect or at low speed

NOTE: Direct drive clutch engagement at

low speed will cause vibration in the

torque converter

Carry out mainline and torque converter pressure

check

ú Normal pressure

FAULT - Governor valve sticking

ú Low or incorrect pressure

FAULTS POSSIBLE -

Direct drive clutch and torque converter

control valve sticking.

Hysteresis valve stuck.

Direct drive clutch control valve stuck.

SYMPTOM 12 - Drives in 'D' but immediately

upshifts to 3rd

FAULT - 2nd to 3rd shift valve stuck.

SYMPTOM 13 - With 'D' selected vehicle starts in

2nd

FAULTS POSSIBLE -

1st and 2nd shift valve stuck.

Governor sleeve sticking.

SYMPTOM 14 - With 'D' selected vehicle starts in

3rd

FAULTS POSSIBLE -

1st to 2nd and 2nd to 3rd shift valves stuck.

Governor sleeve sticking.SYMPTOM 15 - No kickdown 4th to 3rd

FAULT - 4th to 3rd kickdown valve stuck.

SYMPTOM 16 - Upshifts/downshifts and kickdown

shifts at incorrect road speeds

Check throttle kickdown cable adjustment

Carry out main line pressure check

ú Normal pressure

FAULT - Governor valve sticking

ú Incorrect pressure

FAULTS POSSIBLE -

Incorrect throttle valve adjustment

Primary regulator sticking

SYMPTOM 17 - No upshifts at light throttle

FAULTS POSSIBLE

Governor valve sticking

Shift valves sticking

SYMPTOM 18 - No engine braking '3' selected 3rd

gear

FAULT - Clutch 'C'

SYMPTOM 19 - Delayed or no downshift occurs

when making a manual selection from '3' to '2'

FAULTS POSSIBLE -

2nd and 3rd upshift valve sticking.

Governor valve sticking.

'2' Position interlock valve sticking.

SYMPTOM 20 - At speeds below 28 mph when

making a manual selection from '2' to '1',

downshift is delayed or does not occur

FAULTS POSSIBLE -

Governor sticking.

1st to 2nd shift valve sticking.

'1' Position interlock valve sticking.

SYMPTOM 21 - '1' Selected 1st gear no engine

braking

FAULT - Clutch brake 3

SYMPTOM 22 - '2' Selected 2nd gear no engine

braking

FAULT - Clutch brake 1

SYMPTOM 23 - Vehicle drives forward in 'N'

FAULT - Clutch 'A' stuck

Page 438 of 873

ZF

1

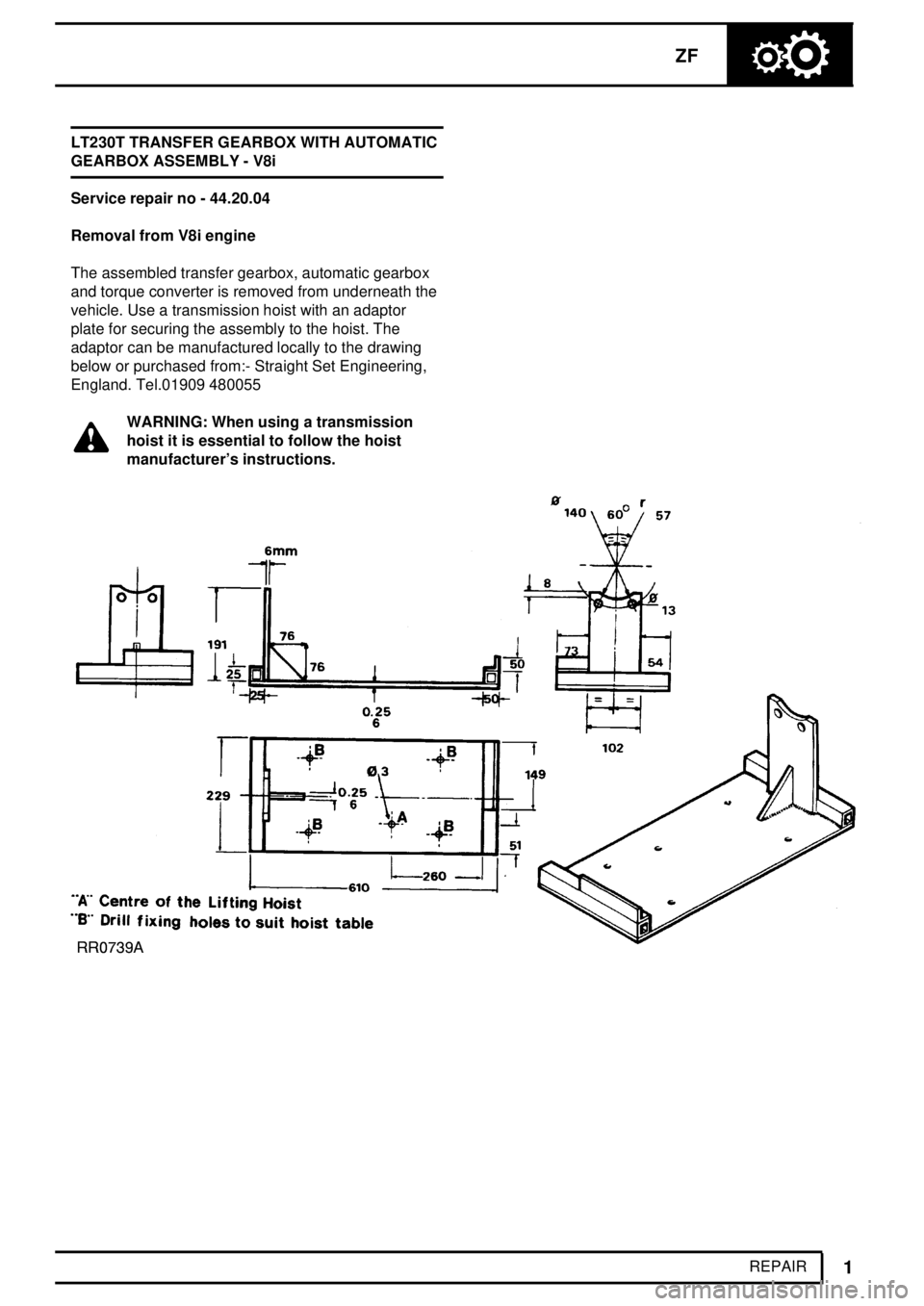

REPAIR LT230T TRANSFER GEARBOX WITH AUTOMATIC

GEARBOX ASSEMBLY - V8i

Service repair no - 44.20.04

Removal from V8i engine

The assembled transfer gearbox, automatic gearbox

and torque converter is removed from underneath the

vehicle. Use a transmission hoist with an adaptor

plate for securing the assembly to the hoist. The

adaptor can be manufactured locally to the drawing

below or purchased from:- Straight Set Engineering,

England. Tel.01909 480055

WARNING: When using a transmission

hoist it is essential to follow the hoist

manufacturer's instructions.

Page 440 of 873

ZF

3

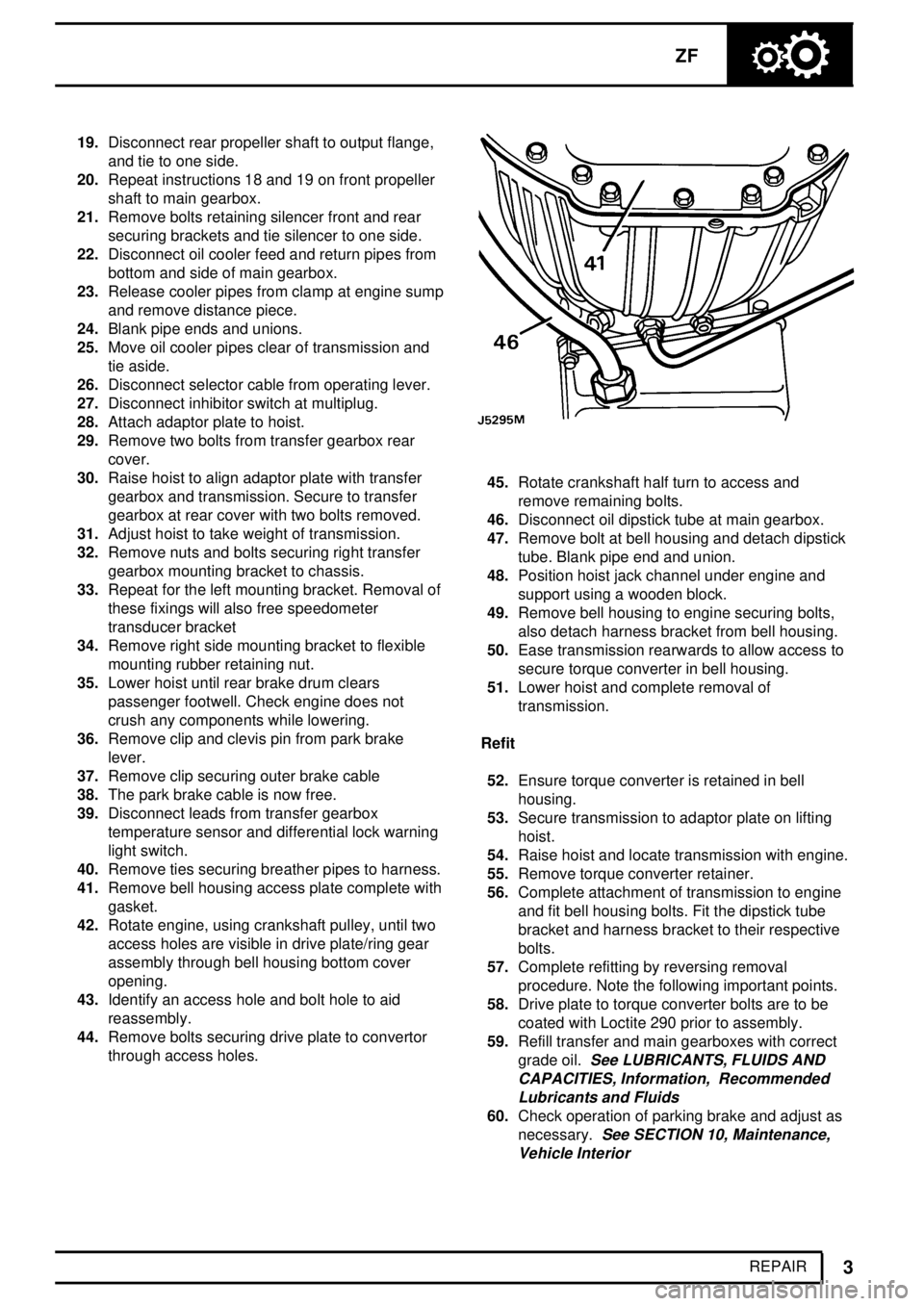

REPAIR 19.Disconnect rear propeller shaft to output flange,

and tie to one side.

20.Repeat instructions 18 and 19 on front propeller

shaft to main gearbox.

21.Remove bolts retaining silencer front and rear

securing brackets and tie silencer to one side.

22.Disconnect oil cooler feed and return pipes from

bottom and side of main gearbox.

23.Release cooler pipes from clamp at engine sump

and remove distance piece.

24.Blank pipe ends and unions.

25.Move oil cooler pipes clear of transmission and

tie aside.

26.Disconnect selector cable from operating lever.

27.Disconnect inhibitor switch at multiplug.

28.Attach adaptor plate to hoist.

29.Remove two bolts from transfer gearbox rear

cover.

30.Raise hoist to align adaptor plate with transfer

gearbox and transmission. Secure to transfer

gearbox at rear cover with two bolts removed.

31.Adjust hoist to take weight of transmission.

32.Remove nuts and bolts securing right transfer

gearbox mounting bracket to chassis.

33.Repeat for the left mounting bracket. Removal of

these fixings will also free speedometer

transducer bracket

34.Remove right side mounting bracket to flexible

mounting rubber retaining nut.

35.Lower hoist until rear brake drum clears

passenger footwell. Check engine does not

crush any components while lowering.

36.Remove clip and clevis pin from park brake

lever.

37.Remove clip securing outer brake cable

38.The park brake cable is now free.

39.Disconnect leads from transfer gearbox

temperature sensor and differential lock warning

light switch.

40.Remove ties securing breather pipes to harness.

41.Remove bell housing access plate complete with

gasket.

42.Rotate engine, using crankshaft pulley, until two

access holes are visible in drive plate/ring gear

assembly through bell housing bottom cover

opening.

43.Identify an access hole and bolt hole to aid

reassembly.

44.Remove bolts securing drive plate to convertor

through access holes.

45.Rotate crankshaft half turn to access and

remove remaining bolts.

46.Disconnect oil dipstick tube at main gearbox.

47.Remove bolt at bell housing and detach dipstick

tube. Blank pipe end and union.

48.Position hoist jack channel under engine and

support using a wooden block.

49.Remove bell housing to engine securing bolts,

also detach harness bracket from bell housing.

50.Ease transmission rearwards to allow access to

secure torque converter in bell housing.

51.Lower hoist and complete removal of

transmission.

Refit

52.Ensure torque converter is retained in bell

housing.

53.Secure transmission to adaptor plate on lifting

hoist.

54.Raise hoist and locate transmission with engine.

55.Remove torque converter retainer.

56.Complete attachment of transmission to engine

and fit bell housing bolts. Fit the dipstick tube

bracket and harness bracket to their respective

bolts.

57.Complete refitting by reversing removal

procedure. Note the following important points.

58.Drive plate to torque converter bolts are to be

coated with Loctite 290 prior to assembly.

59.Refill transfer and main gearboxes with correct

grade oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

60.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 441 of 873

44AUTOMATIC GEARBOX

4

REPAIR LT230T TRANSFER GEARBOX WITH AUTOMATIC

GEARBOX ASSEMBLY - Tdi

Service repair no - 44.20.04

Removal from Tdi engine

The assembled transfer gearbox, automatic gearbox

and torque converter is removed from underneath the

vehicle. Use a transmission hoist with an adaptor

plate for securing the assembly to the hoist.

WARNING: When using a transmission

hoist it is essential to follow the hoist

manufacturer's instructions.

Page 443 of 873

44AUTOMATIC GEARBOX

6

REPAIR 13.Remove starter.

14.Working through starter aperture note position of

torque converter flexible drive plate to facilitate

refitting.

15.Remove the four torque convertor to flexible

drive securing bolts, rotating engine to gain

access to each individual bolt.

16.Raise vehicle on four post ramp [hoist].

17.Drain lubrication oil from transfer and main

gearboxes.

18.Disconnect speedometer cable from transfer

gearbox and disconnect associated clipping.

19.Remove rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

20.Disconnect front propeller shaft at transfer

gearbox and tie to one side.

21.Remove exhaust front pipe.

22.Remove bolts securing front and centre silencer

mounting brackets and tie silencer to one side.

23.Disconnect oil cooler pipes from gearbox.

24.Blank off pipes and union connections.

25.Remove bolt securing retaining bracket to sump

and move cooler pipes aside.

26.Disconnect selector cable from lever on side of

gearbox.

27.Disconnect inhibitor switch multi-plug.

28.Disconnect park brake cable from linkage to park

brake lever.

29.Disconnect electrical connections from

differential lock switch on transfer gearbox.

30.Remove two lower bolts from transfer gearbox

input bearing support plate.

31.Assemble approved support cradle to

transmission hoist.32.Raise hoist and secure cradle to transfer

gearbox input bearing support plate using bolts

removed.

33.Disconnect gearbox mounting brackets from

chassis cross member.

34.Remove chassis cross member.

35.Lower transmission sufficiently to allow access

to items attached to top of gearbox.

36.Remove left hand gearbox mounting bracket

assembly.

37.Remove ties from breather pipes and harness.

38.Remove nut securing gearbox oil filler/dip stick

tube to bell housing.

39.Release union nut at gearbox sump and remove

filler/dipstick tube. Fit blanking plugs.

40.Support engine using a wooden block with a

suitable ramp [hoist] jack.

41.Remove nut securing kick down cable bracket to

bell housing.

42.Remove two bolts securing top of bell housing to

flywheel housing.

43.Remove nuts securing bell housing to flywheel

housing and withdraw transmission assembly

from engine.

44.Fit a suitable torque converter retaining strap to

the bell housing.

45.Remove hoist and transmission from under

vehicle.

46.Fit lifting eyes to transmission.

47.Using suitable chains and lifting tackle take

weight of transmission assembly.

48.Remove bolts securing transmission cradle to

transfer box and withdraw hoist complete with

cradle.

49.Refit bolts to cover plate.

Page 444 of 873

ZF

7

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids