engine LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 540 of 873

STEERING

1

ADJUSTMENT POWER STEERING BOX

Service repair no - 57.10.13

WARNING: Adjustments of steering box

should not be required while in warranty

period. If box is stiff or tight and within

warranty, it must be returned to manufacturer. No

attempt must be made to introduce backlash.

1.Apply park brake, select 'P' in automatic

transmission and chock wheels. Support chassis

front on axle stands.

2.Remove engine undertray.

3.Disconnect drag link from steering drop arm.

4.Check torque to turn.

See Fault diagnosis,

Stiff Steering Checklist

5.Centralise steering box.See Centralise

Steering Box

NOTE: Only check for no backlash when

steering box is in central position.

NOTE: If steering wheel is not straight, it

should be repositioned.

See Repair,

Steering Wheel

The adjustment of the steering box ensures

any preload or end float present on centre is

removed.

6.The adjustment is obtained by rocking the drop

arm about centre whilst an assistant slowly

tightens the steering box adjuster screw.

7.Tighten the locknut when all backlash has been

removed.

8.Repeat the check for backlash. If backlash exists

loosen locknut and repeat adjustment

procedure.

9.Turn steering wheel lock to lock and check no

tightness exists.

10.Ensure front wheels are aligned and in straight

ahead position.

See Front Wheel Alignment

11.Adjust drag link 924 mm between ball joint

centres.

12.Connect drag link. Tighten to

40 Nm.

13.Lower vehicle to ground level and remove

chocks.

14.Road test vehicle.

See Fault diagnosis, Road

Test Procedure

NOTE: If steering wheel is not in straight

ahead position when vehicle is travelling

in a straight line, drag link length is

incorrect and is pushing drop arm away from

central position.

Drag link adjust

15.Right hand drive vehicles - if steering wheel is to

right, drag link is too long. If steering wheel is to

left drag link is too short.

Left hand drive vehicles - if steering wheel is to

right, drag link is too short. If steering wheel is to

left drag link is too long.

16.Adjust drag link until steering wheel points

straight ahead when vehicle is travelling in a

straight line.

CENTRALISE STEERING BOX

1.To centralise the box, insert a suitable peg (hole

size 8.06 mm) into the rear of the drop arm and

into the steering box casing to enable rapid and

accurate setting on centre.

Page 542 of 873

STEERING

3

ADJUSTMENT FRONT WHEEL ALIGNMENT

Service repair no - 57.65.01

Checking Toe-out dimensions

NOTE: No Adjustment is provided for

castor, camber or swivel pin inclinations.

1.Set vehicle on level ground with road wheels

positioned straight ahead.

2.Push vehicle back and forwards to settle linkage.

3.Measure toe-out at horizontal centre-line of

wheels.

4.Check tightness of clamp bolt fixings. Tighten to

14 Nm.

Adjust

5.Loosen adjuster sleeve clamp.

6.Rotate adjuster to lengthen or shorten track rod.

7.Check toe-out setting as instructions 1 to 4.

When toe-out is correct, tap steering linkage ball

joint, in directions of arrows shown, to maximum

of their travel. This ensures full unrestricted

working travel.

8.Tighten clamp bolts to

14 Nm.

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.01

Adjust

NOTE: For details of drive belt adjust

procedure

See ENGINE, Repair, Drive

Belt

Page 544 of 873

57STEERING

2

REPAIR POWER STEERING BOX

Service repair no - 57.10.01

General precautions

1.Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

2.Disconnected ports and hoses must be plugged

to prevent ingress of dirt. If metal sediment is

found in system, establish cause rectify and

flush system.

3.Do not start engine until reservoir is full as pump

will be damaged.

4.Metric pipe fittings are used with 'O' ring pipe

ends on fittings to steering box.

5.Follow normal 'O' ring replacement procedure

whenever pipes are disconnected.

6.Ensure compatible metric components when

fitting replacement pipes.

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit air bag - if fitted or steering wheel trim pad.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1.Site vehicle on level surface.

2.Open bonnet[hood].

3.Remove filler cap from power steering fluid

reservoir.

4.Clean steering box.

5.Disconnect feed and return pipes from steering

box.

6.Plug open pipes and steering box ports to

prevent ingress of dirt.

7.Support chassis front on axle stands. Or raise

vehicle on a hoist.

WARNING: Ensure wheels are chocked,

parking brake is applied, and low range

selected.

Page 546 of 873

57STEERING

4

REPAIR

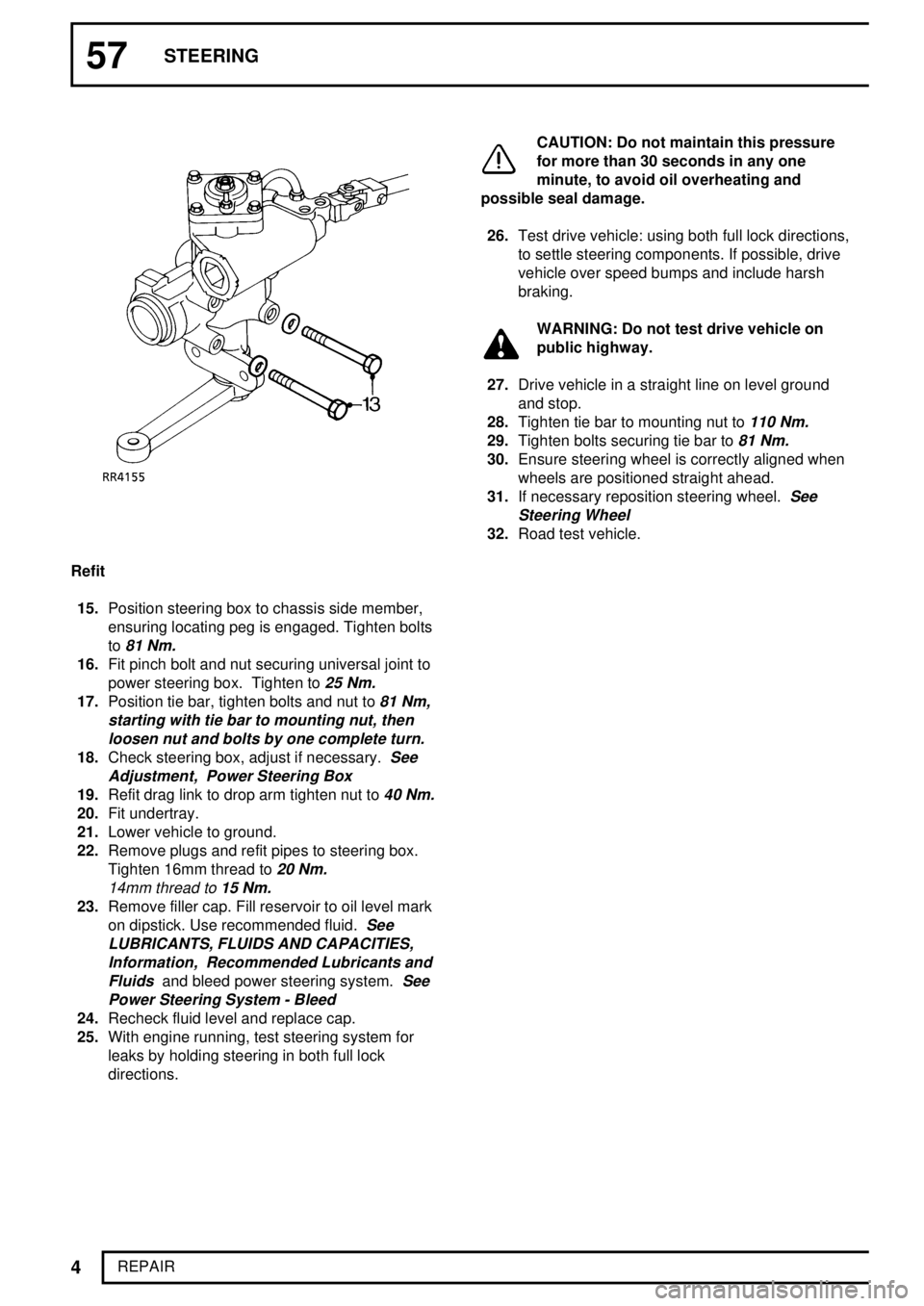

Refit

15.Position steering box to chassis side member,

ensuring locating peg is engaged. Tighten bolts

to

81 Nm.

16.Fit pinch bolt and nut securing universal joint to

power steering box. Tighten to

25 Nm.

17.Position tie bar, tighten bolts and nut to81 Nm,

starting with tie bar to mounting nut, then

loosen nut and bolts by one complete turn.

18.Check steering box, adjust if necessary.See

Adjustment, Power Steering Box

19.Refit drag link to drop arm tighten nut to40 Nm.

20.Fit undertray.

21.Lower vehicle to ground.

22.Remove plugs and refit pipes to steering box.

Tighten 16mm thread to

20 Nm.

14mm thread to15 Nm.

23.Remove filler cap. Fill reservoir to oil level mark

on dipstick. Use recommended fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

and bleed power steering system.See

Power Steering System - Bleed

24.Recheck fluid level and replace cap.

25.With engine running, test steering system for

leaks by holding steering in both full lock

directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute, to avoid oil overheating and

possible seal damage.

26.Test drive vehicle: using both full lock directions,

to settle steering components. If possible, drive

vehicle over speed bumps and include harsh

braking.

WARNING: Do not test drive vehicle on

public highway.

27.Drive vehicle in a straight line on level ground

and stop.

28.Tighten tie bar to mounting nut to

110 Nm.

29.Tighten bolts securing tie bar to81 Nm.

30.Ensure steering wheel is correctly aligned when

wheels are positioned straight ahead.

31.If necessary reposition steering wheel.

See

Steering Wheel

32.Road test vehicle.

Page 547 of 873

STEERING

5

REPAIR POWER STEERING SYSTEM - BLEED

Service repair no - 57.15.02

1.Ensure fluid in reservoir reaches dipstick

maximum.

2.Run engine to normal operating temperature.

3.Recheck and correct reservoir fluid level.

NOTE: During instructions 4 to 6, maintain

maximum fluid level in reservoir. Do not

increase engine speed or move steering

wheel.

4.With engine at idle speed, loosen bleed screw.

When fluid seeps past bleed screw retighten

screw.

5.Check fluid level.

6.Clean away fluid around bleed screw.

7.Check hose connections, pump and steering box

for fluid leaks by holding steering on full lock in

both directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute to avoid overheating fluid and

possibly damaging seals.

8.Carry out road test.POWER STEERING FLUID RESERVOIR

Service repair no - 57.15.08

Remove

1.Remove undertray.

2.Position drain tin beneath reservoir.

3.Loosen mounting bracket clamp bolt, raise

reservoir to gain access to pipe clamps.

4.Loosen clamps, disconnect feed and return

hoses from reservoir, allow fluid to drain.

CAUTION: Plug the connections.

5.Remove reservoir.

CAUTION: Discard fluid drained from

system. Do not allow fluid to contact

paintwork, if spilled, remove fluid and

clean area with warm water.

Page 548 of 873

57STEERING

6

REPAIR Refit

6.Position reservoir, connect feed and return

hoses and tighten clamps to

3 Nm.

7.Fit reservoir in clamp, tighten clamp bolt.

8.Fill reservoir to 'MAX' mark on dipstick with

power steering fluid.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

9.Fit undertray.

10.Bleed power steering system.

See Power

Steering System - Bleed

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.02

NOTE: For details of drive belt remove and

refit.

See ENGINE, Repair, Drive Belt

POWER STEERING PUMP - V8i

Service repair no - 57.20.14

NOTE: The power steering pump is not

serviceable. Fit new pump if worn or

damaged.

Remove

1.Disconnect battery negative lead.

2.Remove drive belt from steering pump.

See

ENGINE, Repair, Drive Belt

3.Remove undertray.

4.Remove fan blades and viscous coupling.

See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

5.Position drain tin beneath steering pump.

6.Using a 9 mm Allen key to restrain steering

pump pulley, remove 3 bolts securing pulley to

pump; remove pulley.

Page 549 of 873

STEERING

7

REPAIR 7.Loosen clamp securing reservoir hose to

steering pump; disconnect hose.

8.Disconnect high pressure pipe from steering

pump.

CAUTION: Plug the connections.

9.Release ht lead from clip

10.Remove 3 bolts securing steering pump.

Remove pump and recover engine lifting

bracket.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

11.Remove 5 bolts securing front mounting plate.

12.Fit front mounting plate to replacement steering

pump. Tighten bolts to

9 Nm.

Refit

13.Position steering pump and engine lifting plate,

fit bolts. Tighten to

35 Nm.Secure ht lead in

clip.

14.Connect high pressure pipe to steering pump,

tighten union to

20 Nm.

15.Connect reservoir hose to steering pump.

Tighten clamp to

3 Nm.

16.Position pulley to pump, coat threads of bolts

with Loctite 242.

17.Restrain pulley using a 9 mm Allen key, fit bolts.

Tighten to

10 Nm.

18.Fit drive belt.See ENGINE, Repair, Drive Belt

19.Fit fan blades and viscous coupling.See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

20.Fit undertray.

21.Reconnect battery negative lead.

22.Bleed power steering system.

See Power

Steering System - Bleed

POWER STEERING PUMP - Tdi

Service repair no - 57.20.14

Remove

1.Remove fan blades and viscous coupling.

See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

2.Restrain steering pump pulley, loosen but do not

remove 3 bolts securing pulley.

3.Remove drive belt.

See ENGINE, Repair,

Drive Belt

4.Remove 3 bolts securing steering pump pulley,

remove pulley.

5.Remove undertray.

6.Position drain tin beneath steering pump.

Page 550 of 873

57STEERING

8

REPAIR 7.Loosen clamp securing reservoir hose to

steering pump, disconnect hose.

8.Disconnect high pressure pipe from steering

pump.

CAUTION: Plug the connections.

9.Remove 4 bolts securing steering pump to

mounting bracket, remove pump.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

10.Remove 3 bolts securing mounting plate to

pump, remove plate.

11.Fit mounting plate to replacement steering

pump. Tighten bolts to

9 Nm.

Refit

12.Position steering pump, fit 3 bolts. Tighten to

35

Nm.

13.Connect high pressure pipe to steering pump.

Tighten to

20 Nm.

14.Connect reservoir hose to steering pump.

Tighten clamp to

3 Nm.

15.Position pulley to steering pump, coat threads of

bolts with Loctite 242; fit but do not fully tighten 3

bolts.

16.Fit drive belt.

See ENGINE, Repair, Drive Belt

17.Restrain steering pump pulley, tighten bolts to10

Nm.

18.Fit fan blades and viscous coupling.See

COOLING SYSTEM, Repair, Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

19.Fit undertray.

20.Bleed power steering system.

See Power

Steering System - Bleed

Page 594 of 873

BRAKES

3

DESCRIPTION AND OPERATION Description of components

1. ABS Modulator unit

To provide the ABS function a Modulator is positioned

within the system between the master cylinder and the

calipers. On both LHD and RHD vehicles it is sited on

the left inner wing [fender]. The Modulator has 8

solenoid valves, 2 for each wheel, 2 expanders and a

recirculation pump. It is non serviceable.

2. Servo/master cylinder

Actuation of the system is provided by a combined

master cylinder and servo assembly attached to the

pedal box, this provides pressure to opposed piston

calipers at each brake pad Twin piston at the front

axle, single piston at the rear.

3. Pressure reducing valve

To maintain the braking balance, pressure to the rear

axle is regulated by a Pressure Reducing Valve (PRV)

This PRV is of the failure bypass type, allowing full

system pressure to the rear axle in the event of a front

circuit failure. It is sited on the left inner wing [fender].

4. Electronic control unit - ECU

ABS control is provided by an electronic control unit

which is positioned on the passenger side of the

vehicle behind the dash panel/glove box.

The ECU, which is non-serviceable, is connected to

the ABS harness by a 35 way connector. non

serviceable.

The ECU continually monitors the brake system,

providing diagnostics in the event of a system

malfunction. Details of how to access the ECU

diagnostics are provided in the Electrical

Troubleshooting Manual.

5.& 6. Front and rear sensors/exciter rings - 4 off

A sensor is sited at each wheel, sensing a 60 tooth

exciter ring. When vehicle is in motion inductive

sensors send signals to ECU. Front exciter ring is

fitted to outside diameter of constant velocity joint

inside each front hub assembly. The rear exciter ring

is bolted to the rear of each brake disc bell.7. Diagnostic plug connection

A diagnostic plug is located behind the dash. To the

left of the steering column on LHD vehicles. To the

right of the steering column on RHD vehicles. It is a 5

way blue connector.

The location and identification of ABS electrical relays

are given in the Electrical Troubleshooting Manual.

For location and identification of ABS electrical fuses.

See ELECTRICAL, Repair, Fuse Box - Interioror.

See ELECTRICAL, Repair, Fuse Box - Engine

Compartment

ANTI-LOCK BRAKE SYSTEM - ABS

Manufactured by WABCO

Introduction

The purpose of ABS is to prevent vehicle wheels

locking during brake application, thus maintaining

vehicle steerability and stability. This allows vehicle to

be steered whilst brakes are applied, even under

emergency conditions, and to avoid obstacles where

there is sufficient space to redirect the vehicle.

WARNING: ABS is an aid to retaining

steering control and stability while

braking.

·ABS cannot defy the natural laws of physics

acting on the vehicle.

·ABS will not prevent accidents resulting from

excessive cornering speeds, following

another vehicle too closely or aquaplaning,

i.e. where a layer of water prevents adequate

contact between tyre and road surface.

·The additional control provided by ABS must

never be exploited in a dangerous or

reckless manner which could jeopardise the

safety of driver or other road users.

·The fitting of ABS does not imply that the

vehicle will always stop in a shorter stopping

distance.

Page 598 of 873

BRAKES

7

DESCRIPTION AND OPERATION BRAKE SERVO UNIT

Description

The power assistance for the brake system is

provided by a twin diaphragm suspended vacuum

servo.

A 'Suspended Vacuum' servo is one where, with the

engine running vacuum is present both sides of the

diaphragm or diaphragms when the brakes are fully

released or partially applied. The principal of having

vacuum both sides of the diaphragm has two main

advantages. First, it ensures instantaneous servo

response to the brake being applied or released and

second, it provides very accurate control of the

position of the diaphragm and therefore, the degree of

partial brake application.At full pedal depression, vacuum is present in front of

the diaphragm with atmospheric pressure on the rear.

Operation

Brakes released

With the brakes released depression is present both

sides of the diaphragms, in chambers 1,2,3 and 4.

The chambers comunicate by ports A, B, D via the

valve C which is shown fully released in RR3640M.