engine LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 364 of 873

V8i

1

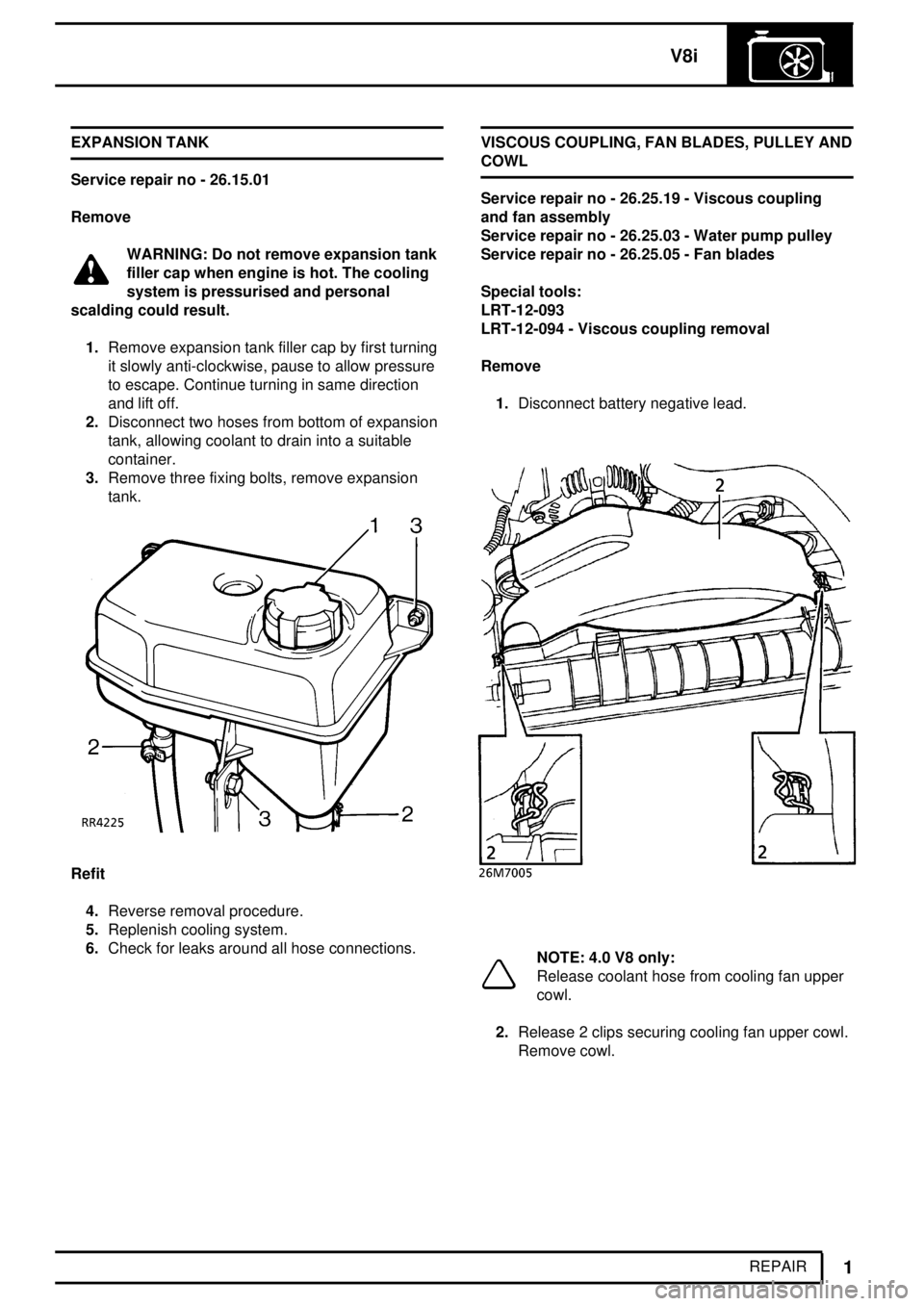

REPAIR EXPANSION TANK

Service repair no - 26.15.01

Remove

WARNING: Do not remove expansion tank

filler cap when engine is hot. The cooling

system is pressurised and personal

scalding could result.

1.Remove expansion tank filler cap by first turning

it slowly anti-clockwise, pause to allow pressure

to escape. Continue turning in same direction

and lift off.

2.Disconnect two hoses from bottom of expansion

tank, allowing coolant to drain into a suitable

container.

3.Remove three fixing bolts, remove expansion

tank.

Refit

4.Reverse removal procedure.

5.Replenish cooling system.

6.Check for leaks around all hose connections.VISCOUS COUPLING, FAN BLADES, PULLEY AND

COWL

Service repair no - 26.25.19 - Viscous coupling

and fan assembly

Service repair no - 26.25.03 - Water pump pulley

Service repair no - 26.25.05 - Fan blades

Special tools:

LRT-12-093

LRT-12-094 - Viscous coupling removal

Remove

1.Disconnect battery negative lead.

NOTE: 4.0 V8 only:

Release coolant hose from cooling fan upper

cowl.

2.Release 2 clips securing cooling fan upper cowl.

Remove cowl.

Page 367 of 873

26COOLING SYSTEM

4

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Drain cooling system.

See Adjustment,

Coolant

2.Remove viscous coupling and fan assembly.

See Viscous Coupling, Fan Blades, Pulley

and Fan Cowl

3.Release 2 clips and remove fan cowl.

4.Disconnect radiator top hoses.

5.Disconnect four transmission and engine oil

cooler connections to radiator end tanks. Note oil

spillage will occur when connections are

loosened. Blank off exposed oil connections.

6.Disconnect transmission oil temperature sensor.

7.Remove radiator securing brackets from each

side.

8.Remove radiator unit by lifting from its location.

Check condition of rubber mounting pads.Refit

9.Reverse removal procedure.

10.Clean unions and apply sealant.

11.Lubricate new 'O' rings before fitting.

12.Check radiator sealing strips are securely

located.

13.Transfer oil cooler adaptors if fitting new radiator.

14.Ensure that oil cooler connections are tightened

to

30 Nm.before fitting fan blades and cowl.

15.Clean coolant/oil spillage from vehicle.

16.Check all connections for coolant/oil leaks.

Page 369 of 873

26COOLING SYSTEM

6

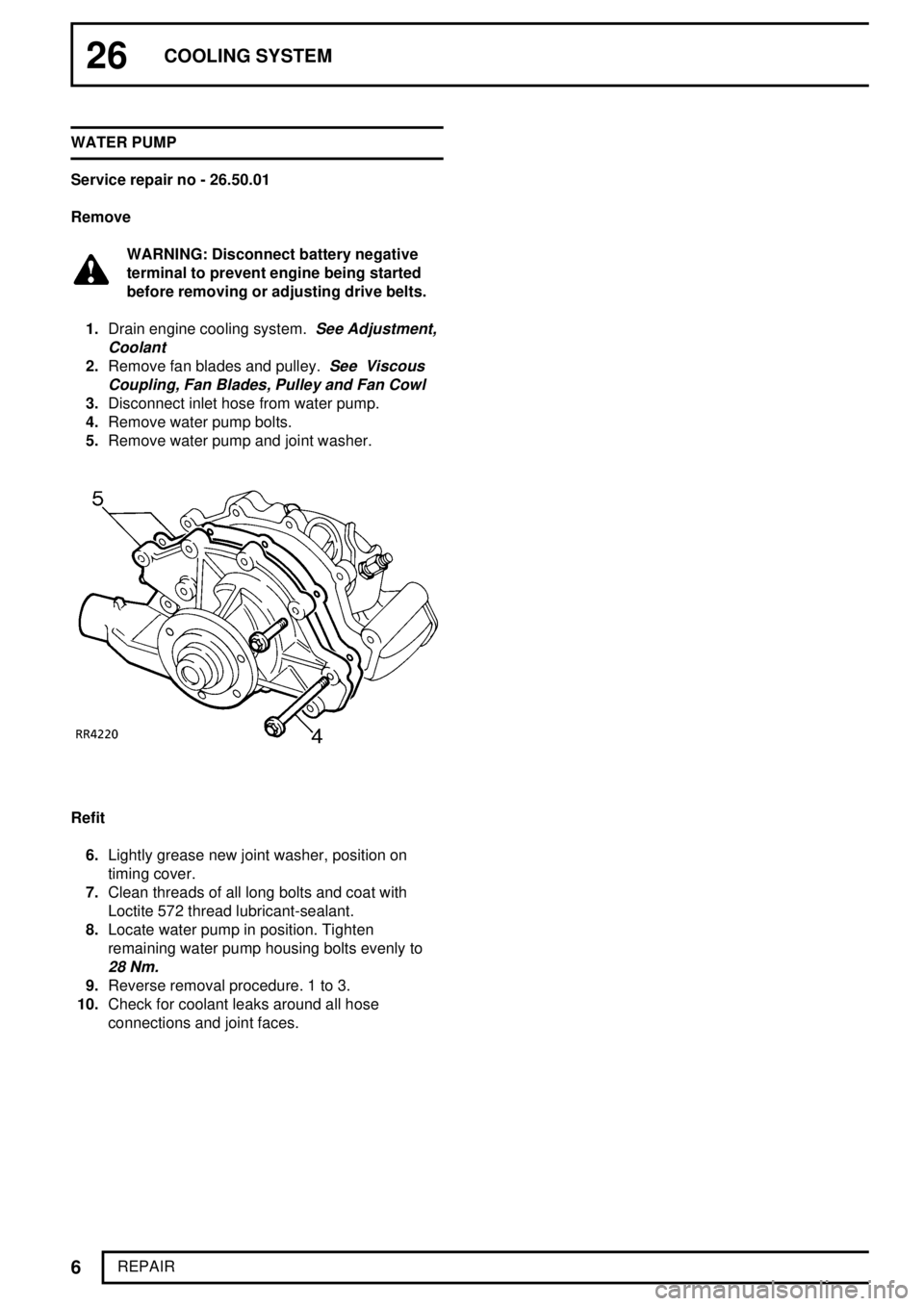

REPAIR WATER PUMP

Service repair no - 26.50.01

Remove

WARNING: Disconnect battery negative

terminal to prevent engine being started

before removing or adjusting drive belts.

1.Drain engine cooling system.

See Adjustment,

Coolant

2.Remove fan blades and pulley.See Viscous

Coupling, Fan Blades, Pulley and Fan Cowl

3.Disconnect inlet hose from water pump.

4.Remove water pump bolts.

5.Remove water pump and joint washer.

Refit

6.Lightly grease new joint washer, position on

timing cover.

7.Clean threads of all long bolts and coat with

Loctite 572 thread lubricant-sealant.

8.Locate water pump in position. Tighten

remaining water pump housing bolts evenly to

28 Nm.

9.Reverse removal procedure. 1 to 3.

10.Check for coolant leaks around all hose

connections and joint faces.

Page 376 of 873

MANIFOLD AND EXHAUST SYSTEM

1

DESCRIPTION AND OPERATION CATALYTIC CONVERTERS - V8i

Description

Catalytic converters which form part of the engine

emission control system, are designed to 'clean' the

exhaust gases, by closely controlling the fuel air ratio

delivered to the engine and converting the residual

exhaust compounds into products more acceptable to

the environment.

The front section of the exhaust system to each

cylinder bank contain the ceramic elements of the

catalytic converters. The oxygen sensors which

transmit information to the fuel ECU for control of the

mixture, are located in the exhaust down pipes.

The Hydrocarbons (HC), Nitogen oxides (NO

x) and

Carbon monoxide (CO) emitted by the engine react

with the catalytic element and exhaust temperature to

convert the toxic gas, into Nitrogen (N), Carbon

dioxide (CO

2) and water vapour.Should the engine be supplied with a rich mixture

causing high CO in the exhaust gas, the ceramic

element will become coated and the useful life of the

catalyst reduced. If the mixture is too weak, excess

oxygen in the exhaust gas will cause the catalysts to

burn out.

1. Catalysts

2. Lambda oxygen sensors

Page 380 of 873

30MANIFOLD AND EXHAUST SYSTEM

4

REPAIR EXHAUST MANIFOLD - Tdi

Service repair no - 30.15.10

Remove

1.Disconnect battery negative lead.

2.Remove heat shield from rear of air intake

manifold.

3.Release dip stick tube from cylinder block.

4.Disconnect the intake hose from the manifold.

5.Remove the two bolts and two nuts securing the

intake manifold to the cylinder head and

withdraw the inlet manifold.

6.Remove air filter inlet pipe to turbo unit.

7.Remove intercooler pipe from turbo to

intercooler.

8.Disconnect the EGR pipe from the inlet manifold

hose.

9.Remove the three fixings at the exhaust pipe

flange.

10.Release the turbo charger oil pipes from the

cylinder block.

11.Remove the turbo boost pipes.

12.Remove seven bolts securing the exhaust

manifold, release the heater rail and remove the

manifold gasket, complete with turbo unit.

13.Remove four bolts and disconnect diaphragm

rod from manifold, and remove turbo charger if

necessary.

Refit

14.Reverse removal procedure. 1 to 12. Use a new

manifold and exhaust flange gaskets.

15.Reconnect battery negative lead. Start engine

and check for leaks.

Page 382 of 873

30MANIFOLD AND EXHAUST SYSTEM

6

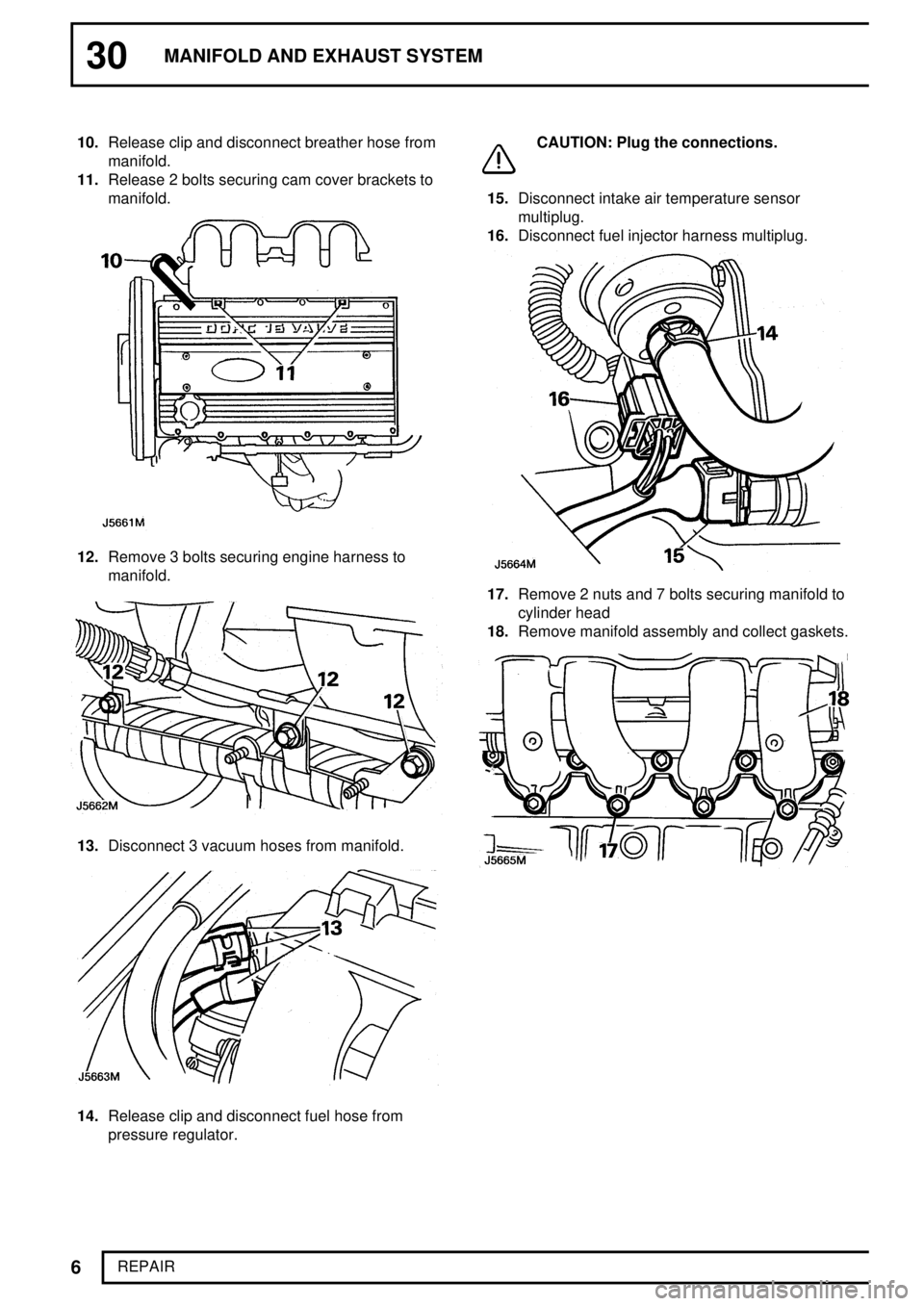

REPAIR 10.Release clip and disconnect breather hose from

manifold.

11.Release 2 bolts securing cam cover brackets to

manifold.

12.Remove 3 bolts securing engine harness to

manifold.

13.Disconnect 3 vacuum hoses from manifold.

14.Release clip and disconnect fuel hose from

pressure regulator.

CAUTION: Plug the connections.

15.Disconnect intake air temperature sensor

multiplug.

16.Disconnect fuel injector harness multiplug.

17.Remove 2 nuts and 7 bolts securing manifold to

cylinder head

18.Remove manifold assembly and collect gaskets.

Page 383 of 873

MANIFOLD AND EXHAUST SYSTEM

7

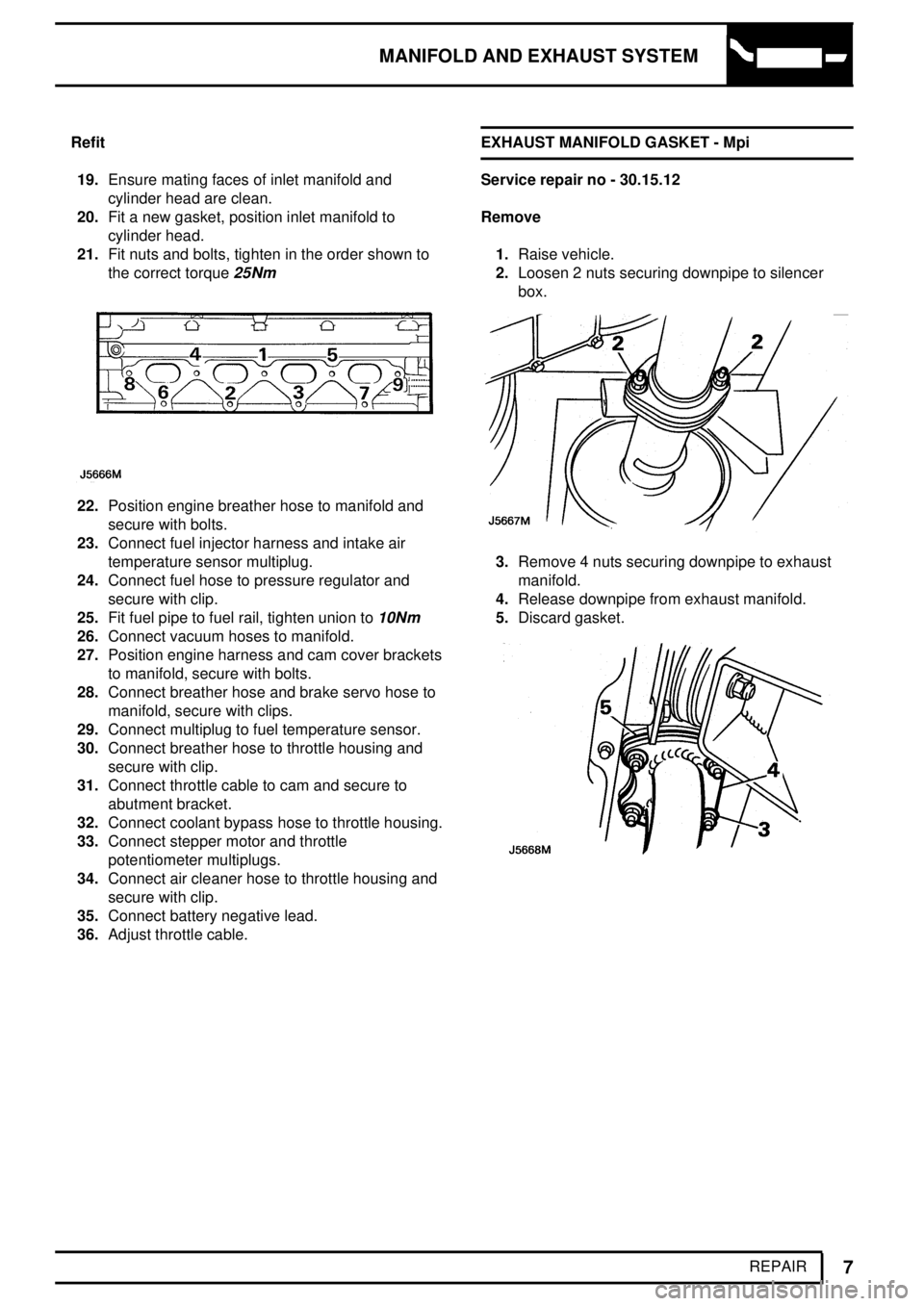

REPAIR Refit

19.Ensure mating faces of inlet manifold and

cylinder head are clean.

20.Fit a new gasket, position inlet manifold to

cylinder head.

21.Fit nuts and bolts, tighten in the order shown to

the correct torque

25Nm

22.Position engine breather hose to manifold and

secure with bolts.

23.Connect fuel injector harness and intake air

temperature sensor multiplug.

24.Connect fuel hose to pressure regulator and

secure with clip.

25.Fit fuel pipe to fuel rail, tighten union to

10Nm

26.Connect vacuum hoses to manifold.

27.Position engine harness and cam cover brackets

to manifold, secure with bolts.

28.Connect breather hose and brake servo hose to

manifold, secure with clips.

29.Connect multiplug to fuel temperature sensor.

30.Connect breather hose to throttle housing and

secure with clip.

31.Connect throttle cable to cam and secure to

abutment bracket.

32.Connect coolant bypass hose to throttle housing.

33.Connect stepper motor and throttle

potentiometer multiplugs.

34.Connect air cleaner hose to throttle housing and

secure with clip.

35.Connect battery negative lead.

36.Adjust throttle cable.EXHAUST MANIFOLD GASKET - Mpi

Service repair no - 30.15.12

Remove

1.Raise vehicle.

2.Loosen 2 nuts securing downpipe to silencer

box.

3.Remove 4 nuts securing downpipe to exhaust

manifold.

4.Release downpipe from exhaust manifold.

5.Discard gasket.

Page 388 of 873

CLUTCH

1

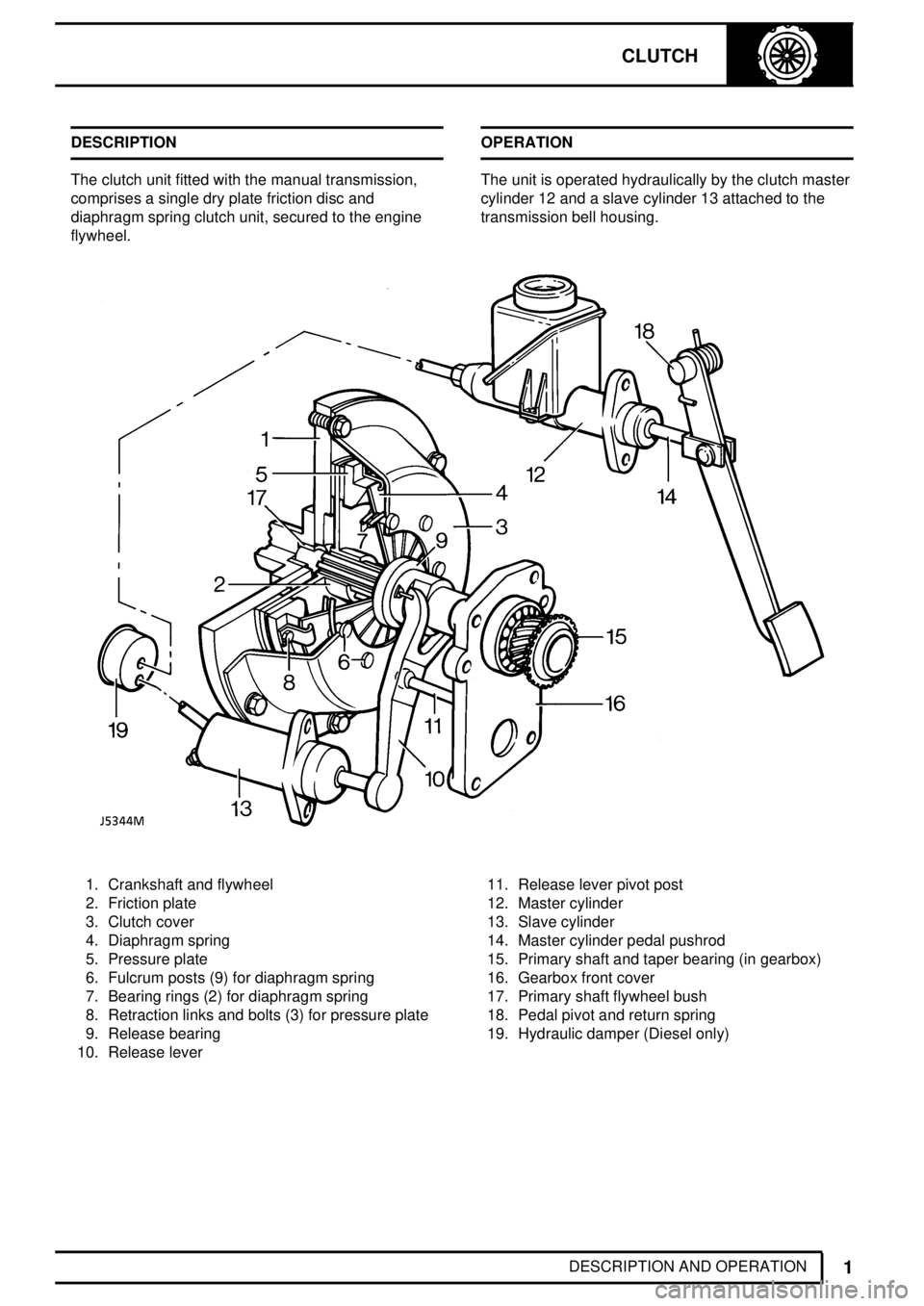

DESCRIPTION AND OPERATION DESCRIPTION

The clutch unit fitted with the manual transmission,

comprises a single dry plate friction disc and

diaphragm spring clutch unit, secured to the engine

flywheel.OPERATION

The unit is operated hydraulically by the clutch master

cylinder 12 and a slave cylinder 13 attached to the

transmission bell housing.

1. Crankshaft and flywheel

2. Friction plate

3. Clutch cover

4. Diaphragm spring

5. Pressure plate

6. Fulcrum posts (9) for diaphragm spring

7. Bearing rings (2) for diaphragm spring

8. Retraction links and bolts (3) for pressure plate

9. Release bearing

10. Release lever11. Release lever pivot post

12. Master cylinder

13. Slave cylinder

14. Master cylinder pedal pushrod

15. Primary shaft and taper bearing (in gearbox)

16. Gearbox front cover

17. Primary shaft flywheel bush

18. Pedal pivot and return spring

19. Hydraulic damper (Diesel only)

Page 389 of 873

33CLUTCH

2

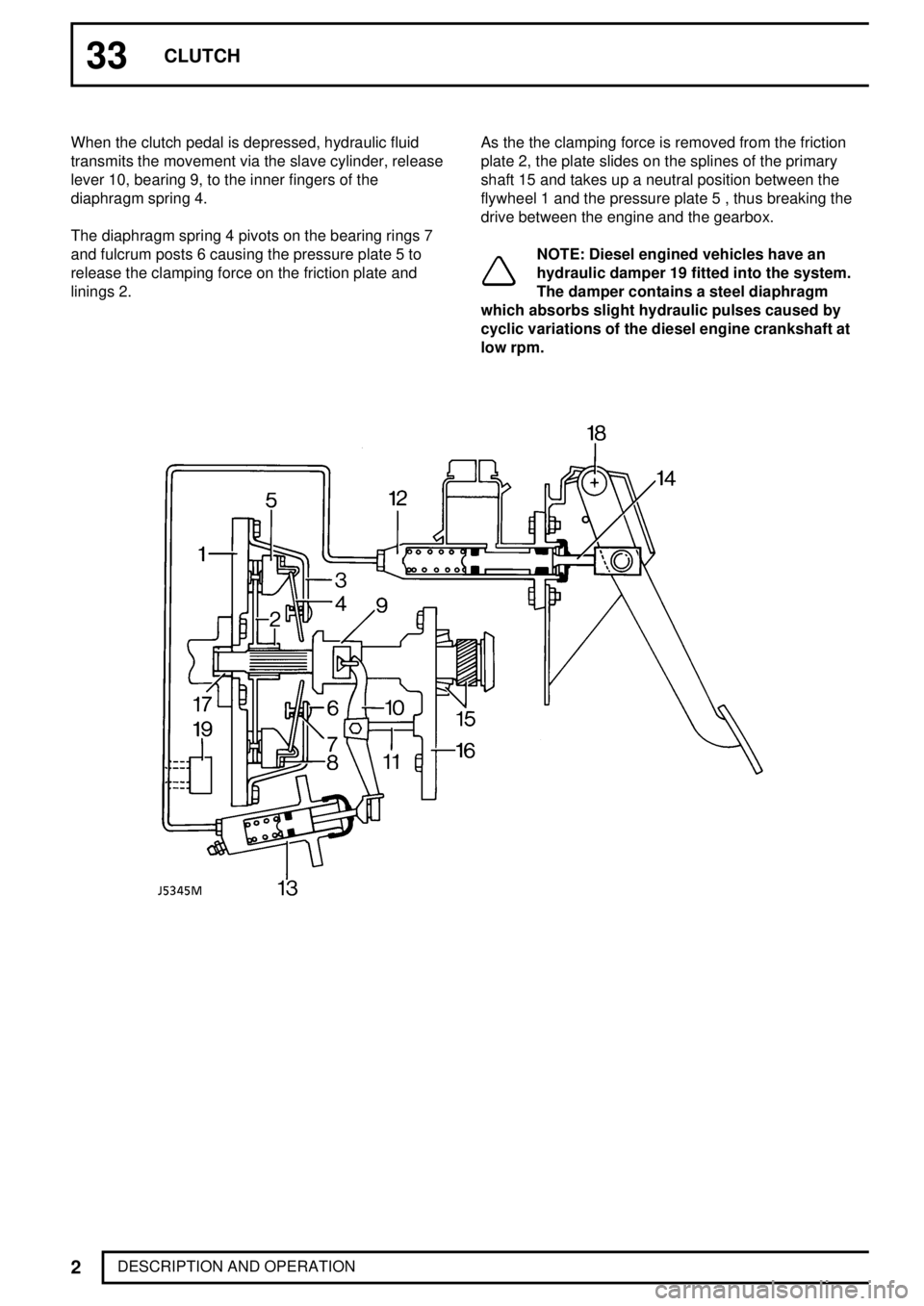

DESCRIPTION AND OPERATION When the clutch pedal is depressed, hydraulic fluid

transmits the movement via the slave cylinder, release

lever 10, bearing 9, to the inner fingers of the

diaphragm spring 4.

The diaphragm spring 4 pivots on the bearing rings 7

and fulcrum posts 6 causing the pressure plate 5 to

release the clamping force on the friction plate and

linings 2.As the the clamping force is removed from the friction

plate 2, the plate slides on the splines of the primary

shaft 15 and takes up a neutral position between the

flywheel 1 and the pressure plate 5 , thus breaking the

drive between the engine and the gearbox.

NOTE: Diesel engined vehicles have an

hydraulic damper 19 fitted into the system.

The damper contains a steel diaphragm

which absorbs slight hydraulic pulses caused by

cyclic variations of the diesel engine crankshaft at

low rpm.

Page 390 of 873

CLUTCH

1

FAULT DIAGNOSIS CLUTCH ASSEMBLY CONDITIONS

For the clutch to operate correctly as described and

illustrated in the "Description and Operation", it is

important the following conditions are satisfied:-

A. The primary shaft 15 must be free in the

crankshaft spigot bush 17.

B. The friction plate 2 must be able to slide easily

on the splines on the primary shaft 15, to a

position where it does not contact either the

flywheel or the pressure plate.

C. The friction plate must not be distorted or the

linings contaminated with oil, which may cause it

to stick or continue to run in contact with the

flywheel or pressure plate.

A number of faults can develop in the operation of the

clutch for a variety of reasons and although most

faults are due to normal wear at high mileage,

problems can also occur if the unit has been renewed

by an unskilled operator.

Recognising and diagnosing a particular clutch fault is

therefore of paramount importance in ensuring, that

the problem is rectified at the first attempt.

Problems which develop in the clutch are as follows:-

A. Clutch spin/drag

B. Clutch slip

C. Clutch judder/fierceCLUTCH SPIN - DRAG

Symptoms

Clutch spin is that, with engine running and clutch

pedal depressed, the gears cannot be immediately

engaged without making a grinding noise. This

indicates the clutch is not making a clean break.

However, if the clutch pedal is held depressed for

several seconds the friction plate will eventually break

free from the engine and the gear will engage silently.

Clutch spin as it becomes more severe develops into

clutch drag, making the silent engagement of a gear

impossible, regardless of how long the pedal is held

depressed.

CLUTCH SLIP

Symptoms

Clutch slip is most evident climbing a hill or when the

vehicle is moving off from stationary with a heavy

load. As the clutch is released slip occurs between the

engine and the transmission, allowing the engine

speed to increase without a corresponding increase in

vehicle speed.

Clutch slip can develop to the stage where no power

is transmitted through the clutch as the pedal is

released.

CLUTCH JUDDER - FIERCE

Symptoms

Clutch judder or fierce engagement, like slip, is most

likely to occur when the vehicle is moving off from

stationary. As the clutch pedal is released the vehicle

will move rapidly or in a series of jerks, which can not

be controlled even by careful operation of the clutch

by the driver.

It should be noted that a vehicle may display all the

symptoms or any combination of the symptoms

described, depending on the driving conditions vehicle

load and operating temperatures.