electrical LAND ROVER DISCOVERY 1995 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 353 of 873

Tdi

1

REPAIR VISCOUS COUPLING, FAN BLADES, PULLEY AND

FAN COWL

Service repair no - 26.25.03/05

Viscous coupling -Remove1to3

Fan blades -Remove1to4

Fan cowl -Remove1to3

Fan pulley -Remove1to6

Remove

WARNING: Disconnect battery negative

terminal to prevent engine being started

before removing or adjusting drive belt.

1.Slacken nut securing viscous coupling/fan blade

assembly to pulley.

NOTE: Nut securing viscous unit to pulley

has a left hand thread. Release by turning

clockwise when viewed from front of

viscous unit.

2.Drop viscous unit and fan assembly into bottom

of cowling

3.Remove two fixings clips from top of cowling and

lift cowling complete with viscous unit and fan

out of lower mountings.

4.Remove fan blades from viscous coupling if

necessary.

5.Remove serpentine drive belt and, if fitted, air

conditioning compressor belt.

6.Remove pulley fixings, remove pulley.

NOTE: The serpentine belt is removed by

using a hexagonal socket and tommy bar

on the auto-tensioning pulley nut. Whilst

tensioning the device the belt can be removed.

7.Reverse removal procedure. Ensure fan blades

are fitted correctly. Fan is marked 'front' and

should be fitted with word 'front' closest to

radiator. Tighten to

30 Nm.

8.Refit drive belt.See ENGINE, Repair, Drive

Belt

THERMOSTAT

Service repair no - 26.45.01

Remove

1.Partially drain cooling system, until coolant level

is below thermostat housing.

2.Disconnect hose from thermostat housing.

3.Disconnect electrical connections to water

temperature switch.

4.Remove outlet elbow.

5.Withdraw thermostat.

Test

6.Note rating of thermostat is 88°C. Place

thermostat in a container half full of water. Heat

water, observe temperature at which thermostat

begins to open. Thermostat is satisfactory if its

open between 85°C and 89°C.

Refit

7.Insert thermostat with jiggle pin/vent hole upper

most (12 o'clock position) .

8.Fit the outlet elbow and new joint washer.

Tighten to

28 Nm.

9.Reverse removal procedure. 1 to 3.

10.Check for coolant leaks around all connections

and joint faces.

Page 360 of 873

V8i

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Drive Belt -

Check Tension

YES - Continue.

3.Is ignition timing correct?

NO -

See ELECTRICAL, Adjustment,

Ignition Timing

YES - Continue.

4.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant Requirements

NO - Continue.

5.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

6.Are there any external leaks, from water pump,

engine gaskets or the heater unit?

YES - Investigate and rectify.

See Adjustment,

Coolant Requirements

NO - Continue.

7.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue.8.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 11,

otherwise: Continue.

9.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.K5

NO - Rectify.

YES - Continue.

10.Is temperature sender and gauge giving

accurate readings?

NO - Substitute parts and compare readings.

YES - Continue.

11.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If the coolant only, or both systems are contaminated,

suspect cylinder head gaskets or radiator.

If only the lubrication stystem is contaminated with

coolant, suspect inlet manifold or front cover gaskets.

Page 361 of 873

26COOLING SYSTEM

2

FAULT DIAGNOSIS ENGINE RUNS COLD

Before conducting any cooling system diagnosis:

See

Description and operation, Engine cooling

1.Check operation of viscous unit.See

Description and operation, Viscous Fan

Is viscous unit operating correctly?

NO -

See Repair, Viscous coupling, fan

blades, pulley and fan cowl

YES - Continue.

2.Is thermostat correct type and operating?

See

Repair, Thermostat

If problem is not diagnosed: Continue.

3.Are the air conditioning fans operating

continuously?

YES -

See Electrical Trouble Shooting

Manual.

NO - Continue.

4.Is temperature sender and gauge giving

accurate readings? Substitute parts and

compare readings. If problem is not diagnosed

repeat tests, starting at 1.

Page 366 of 873

V8i

3

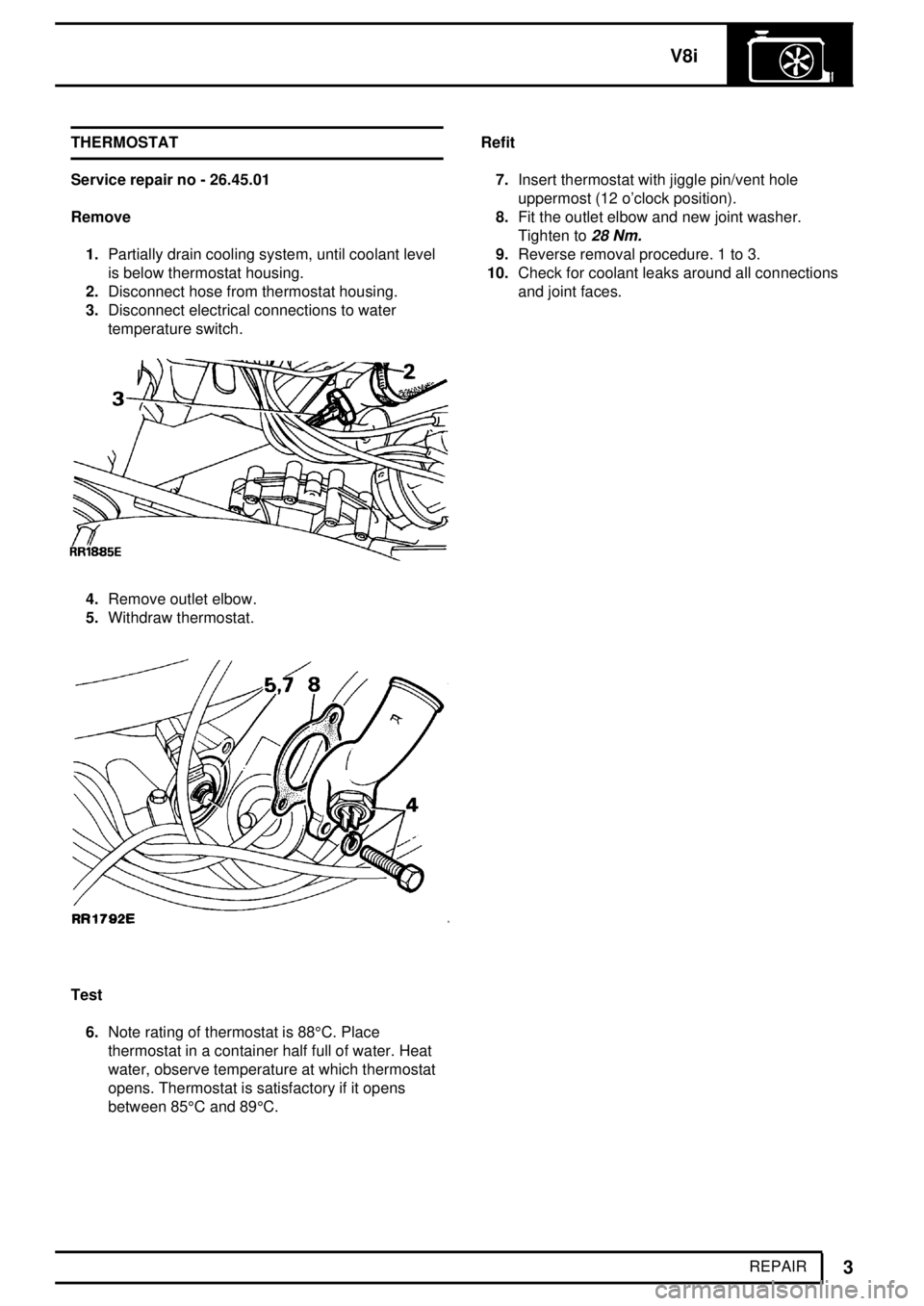

REPAIR THERMOSTAT

Service repair no - 26.45.01

Remove

1.Partially drain cooling system, until coolant level

is below thermostat housing.

2.Disconnect hose from thermostat housing.

3.Disconnect electrical connections to water

temperature switch.

4.Remove outlet elbow.

5.Withdraw thermostat.

Test

6.Note rating of thermostat is 88°C. Place

thermostat in a container half full of water. Heat

water, observe temperature at which thermostat

opens. Thermostat is satisfactory if it opens

between 85°C and 89°C.Refit

7.Insert thermostat with jiggle pin/vent hole

uppermost (12 o'clock position).

8.Fit the outlet elbow and new joint washer.

Tighten to

28 Nm.

9.Reverse removal procedure. 1 to 3.

10.Check for coolant leaks around all connections

and joint faces.

Page 414 of 873

41TRANSFER GEARBOX

2

FAULT DIAGNOSIS PROCEDURE

Prior to road test

1.Check oil level in transfer box is correct.

2.Check tightness of level and drain plugs.

3.Check breather system for blockage. To validate

the system the pipe must be removed,

inspected, rectified as necessary and refitted.

4.Remove all traces of oil from exterior of transfer

box.

Take vehicle for short road test.

5.Identify source of leaks and rectify as follows.

Front or rear output seal leaking:-

1.Drain the oil and remove the leaking output

flange.

2.Inspect the seal track on the flange for surface

damage. If damaged renew component.

3.Remove and discard the oil seal.

4.Inspect the seal locating bore and remove any

sharp edges which may damage the new oil

seal.

5.Fit new seal.

6.Fit the output flange and all the other parts.

7.Add oil to correct level into the gearbox.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

Cover plate gasket leaking.

1.Drain the oil and remove the leaking cover plate.

2.Remove all traces of joint sealant from both joint

faces.

3.Degrease all components and apply a thin film of

Hylomar sealant, to both joint faces.

4.Apply thread sealant to the bolts which come

into contact with gearbox oil.

5.Refit cover plate.

CAUTION: Care must be taken not to

overtighten the fixings.Leak between the main and transfer gearboxes.

1.Site vehicle onto a ramp [hoist].

2.Select neutral in transfer box and select 4th gear

in the main gearbox.

3.Run engine at 2000 rpm with the clutch/drive

engaged.

4.Observe joint between the main and transfer

boxes.

5.If oil leak is found establish if it is gear oil.

6.If so, the leak is originating from the transfer box.

7.Check the two inner (main/transfer) bolts are oil

tight, as these holes are tapped through into the

main transfer case.

8.Remove the transfer box to inspect the

mainshaft collar seal track condition, and the

front face of the transfer case for porosity.

See

Repair, LT230T Transfer Gearbox

9.If these areas require servicing, the transfer

gearbox input seal must also be renewed.

CAUTION: Avoid damaging the new seal

lip and ensure the seal is fitted flush with

the machined face. Also ensure the new

seal is not damaged when refitting the transfer

gearbox.

10.If red A.T.F type oil is seen leaking during the

workshop test, investigate the main gearbox for

cause of leak.

Detent plug or electrical switch leaks.

1.Detent plugs and electrical switches do not

usually leak. It must be noted that they fit into

open tapped holes in the transfer case and

therefore should be considered when looking for

the source of the leak.

Page 418 of 873

41TRANSFER GEARBOX

4

REPAIR SHIFTLOCK SOLENOID/NEUTRAL SWITCH

Service repair no - 41.10.63/64

This is sited on top of the transfer gearbox. Access to

the component is gained through the transmission

tunnel aperture.

Remove

1.Disconnect battery negative lead.

2.Remove centre console.

See CHASSIS AND

BODY, Repair, Centre Console

3.Remove rear passenger heater air ducts.

4.Remove insulation pad.

5.Remove four screws and remove main gear

lever assembly.

6.Drill out rivets and remove tunnel blanking plate.

7.Disconnect solenoid multiplug.

8.Remove four retaining bolts and remove shiftlock

solenoid cover.

9.Remove solenoid and spring washer.

10.Clean joint sealant from mating faces.

KEY

1. Gearlever

2. Transmission tunnel aperture

3. Transfer gearbox

4. Bolt

5. Switch

6. Solenoid

7. Electrical connectionsRefit

1.Apply Hylosil or equivalent sealant to mating

faces.

2.Ensure solenoid plug lead is located in cover

recess.

3.Reverse removal procedure.

4.Fit four solenoid bolts. Tighten to

9Nm.

Neutral switch, audible alarm

1.Disconnect neutral switch electrical plug.

2.Remove neutral switch from transfer box.

Refit

3.Apply Hylomar PL32/L20 or SL500 sealant to

neutral switch.

4.Reverse removal procedure.

5.Switch - Tighten to

25Nm.

Page 442 of 873

ZF

5

REPAIR Remove

1.Select low range with transfer gear lever.

2.Remove knob and gaiter from transfer gear

lever.

3.Disconnect battery terminals.

4.Remove insulation pad from rocker cover and

inlet manifold.

5.On LH drive vehicles only, disconnect multi-plug

from top of brake fluid reservoir.

6.Release electrical harness from clips along top

of bulkhead and pull over to one side.7.Remove bolt securing transfer and main gearbox

breather pipe clip to rear of cylinder head.

8.Disconnect kick down cable at fuel injection

pump.

9.Drain coolant from cooling system.

10.Disconnect top hose from radiator.

11.Disconnect turbo charger hose from inter-cooler.

12.Remove starter heat shield.

Page 443 of 873

44AUTOMATIC GEARBOX

6

REPAIR 13.Remove starter.

14.Working through starter aperture note position of

torque converter flexible drive plate to facilitate

refitting.

15.Remove the four torque convertor to flexible

drive securing bolts, rotating engine to gain

access to each individual bolt.

16.Raise vehicle on four post ramp [hoist].

17.Drain lubrication oil from transfer and main

gearboxes.

18.Disconnect speedometer cable from transfer

gearbox and disconnect associated clipping.

19.Remove rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

20.Disconnect front propeller shaft at transfer

gearbox and tie to one side.

21.Remove exhaust front pipe.

22.Remove bolts securing front and centre silencer

mounting brackets and tie silencer to one side.

23.Disconnect oil cooler pipes from gearbox.

24.Blank off pipes and union connections.

25.Remove bolt securing retaining bracket to sump

and move cooler pipes aside.

26.Disconnect selector cable from lever on side of

gearbox.

27.Disconnect inhibitor switch multi-plug.

28.Disconnect park brake cable from linkage to park

brake lever.

29.Disconnect electrical connections from

differential lock switch on transfer gearbox.

30.Remove two lower bolts from transfer gearbox

input bearing support plate.

31.Assemble approved support cradle to

transmission hoist.32.Raise hoist and secure cradle to transfer

gearbox input bearing support plate using bolts

removed.

33.Disconnect gearbox mounting brackets from

chassis cross member.

34.Remove chassis cross member.

35.Lower transmission sufficiently to allow access

to items attached to top of gearbox.

36.Remove left hand gearbox mounting bracket

assembly.

37.Remove ties from breather pipes and harness.

38.Remove nut securing gearbox oil filler/dip stick

tube to bell housing.

39.Release union nut at gearbox sump and remove

filler/dipstick tube. Fit blanking plugs.

40.Support engine using a wooden block with a

suitable ramp [hoist] jack.

41.Remove nut securing kick down cable bracket to

bell housing.

42.Remove two bolts securing top of bell housing to

flywheel housing.

43.Remove nuts securing bell housing to flywheel

housing and withdraw transmission assembly

from engine.

44.Fit a suitable torque converter retaining strap to

the bell housing.

45.Remove hoist and transmission from under

vehicle.

46.Fit lifting eyes to transmission.

47.Using suitable chains and lifting tackle take

weight of transmission assembly.

48.Remove bolts securing transmission cradle to

transfer box and withdraw hoist complete with

cradle.

49.Refit bolts to cover plate.

Page 444 of 873

ZF

7

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 459 of 873

44AUTOMATIC GEARBOX

22

REPAIR

13.Place end-float gauge LST111 onto pump

housing and check that axial play is between

0.2-0.4 mm. Replace existing washer, situated at

rear of intermediate plate, with suitable washer

to give required end-float.

NOTE: If damage is apparent to bolts they

should be replaced.

14.Refit torque converter into housing using torque

converter handles 18G1501. Check dimension

converter fixing boss to converter housing face is

50 mm. This shows converter is properly seated

in housing.

15.Refit gearbox/transfer box assembly.

See

LT230T Transfer Gearbox

GEAR SELECTOR-INTERLOCK

For remove and refit of gear selector interlock.

See

ELECTRICAL, Repair, Gear Selector-Interlock