electrical LAND ROVER DISCOVERY 1995 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 713 of 873

76CHASSIS AND BODY

46

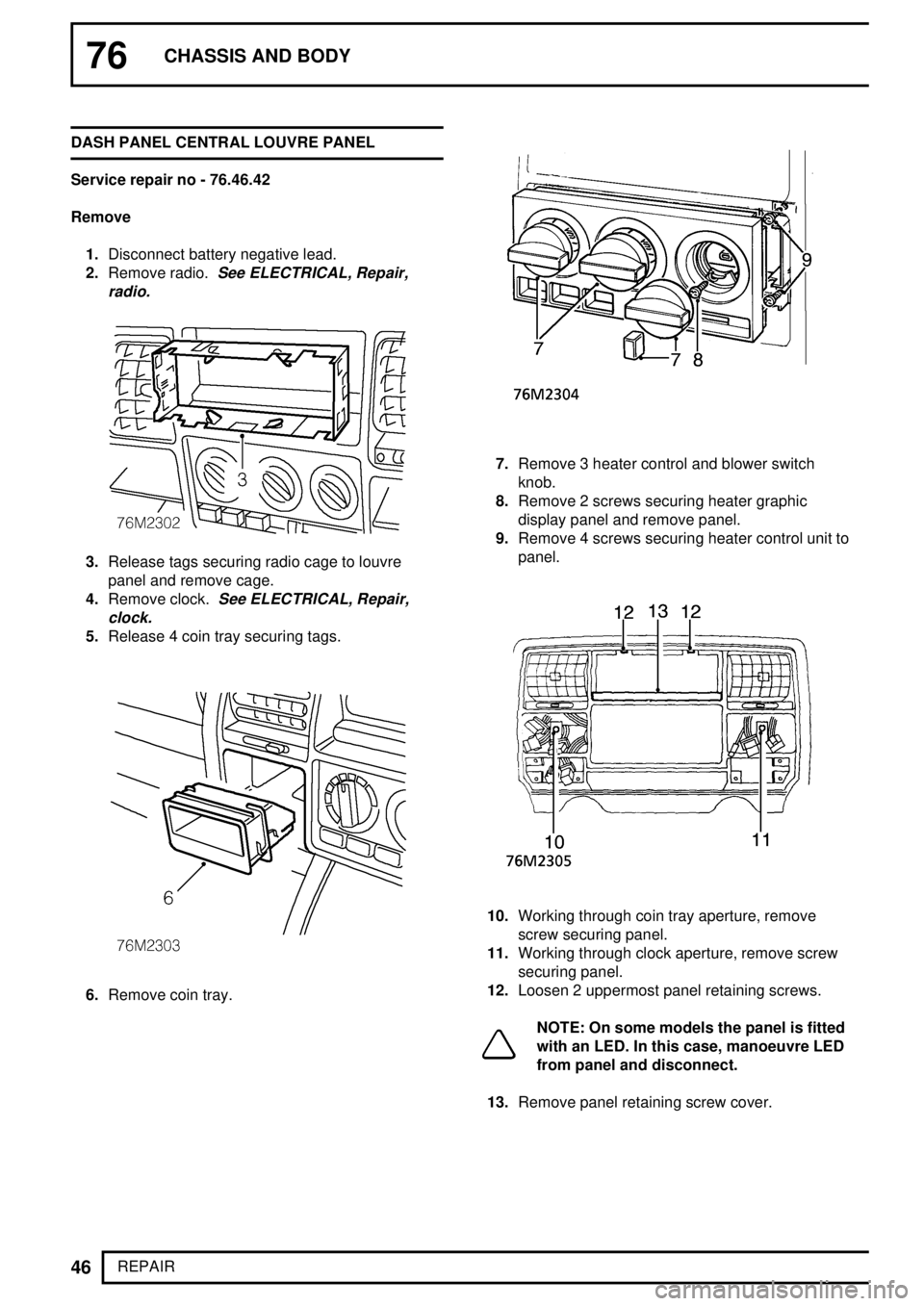

REPAIR DASH PANEL CENTRAL LOUVRE PANEL

Service repair no - 76.46.42

Remove

1.Disconnect battery negative lead.

2.Remove radio.

See ELECTRICAL, Repair,

radio.

3.Release tags securing radio cage to louvre

panel and remove cage.

4.Remove clock.

See ELECTRICAL, Repair,

clock.

5.Release 4 coin tray securing tags.

6.Remove coin tray.

7.Remove 3 heater control and blower switch

knob.

8.Remove 2 screws securing heater graphic

display panel and remove panel.

9.Remove 4 screws securing heater control unit to

panel.

10.Working through coin tray aperture, remove

screw securing panel.

11.Working through clock aperture, remove screw

securing panel.

12.Loosen 2 uppermost panel retaining screws.

NOTE: On some models the panel is fitted

with an LED. In this case, manoeuvre LED

from panel and disconnect.

13.Remove panel retaining screw cover.

Page 714 of 873

CHASSIS AND BODY

47

REPAIR

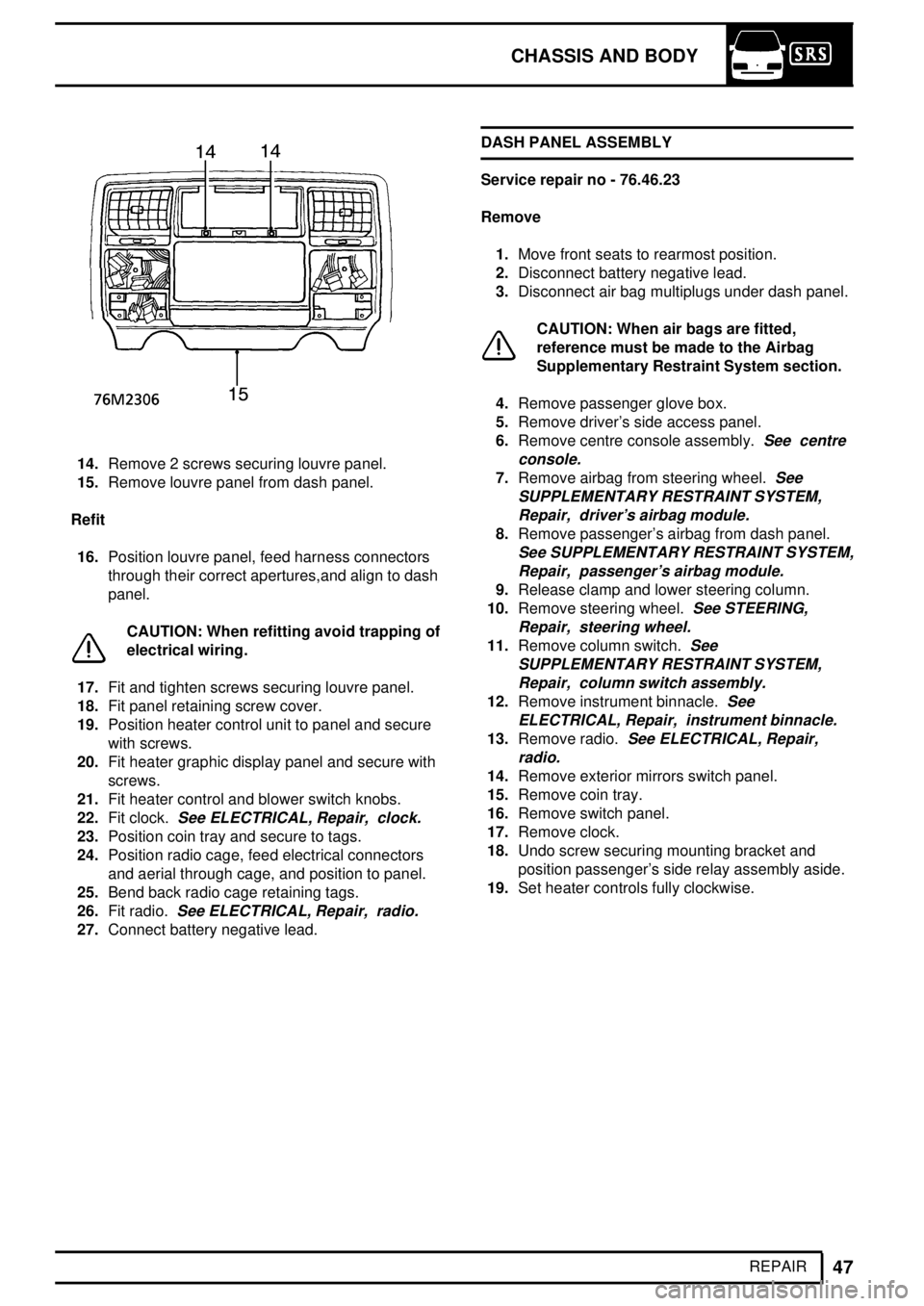

14.Remove 2 screws securing louvre panel.

15.Remove louvre panel from dash panel.

Refit

16.Position louvre panel, feed harness connectors

through their correct apertures,and align to dash

panel.

CAUTION: When refitting avoid trapping of

electrical wiring.

17.Fit and tighten screws securing louvre panel.

18.Fit panel retaining screw cover.

19.Position heater control unit to panel and secure

with screws.

20.Fit heater graphic display panel and secure with

screws.

21.Fit heater control and blower switch knobs.

22.Fit clock.

See ELECTRICAL, Repair, clock.

23.Position coin tray and secure to tags.

24.Position radio cage, feed electrical connectors

and aerial through cage, and position to panel.

25.Bend back radio cage retaining tags.

26.Fit radio.

See ELECTRICAL, Repair, radio.

27.Connect battery negative lead.DASH PANEL ASSEMBLY

Service repair no - 76.46.23

Remove

1.Move front seats to rearmost position.

2.Disconnect battery negative lead.

3.Disconnect air bag multiplugs under dash panel.

CAUTION: When air bags are fitted,

reference must be made to the Airbag

Supplementary Restraint System section.

4.Remove passenger glove box.

5.Remove driver's side access panel.

6.Remove centre console assembly.

See centre

console.

7.Remove airbag from steering wheel.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, driver's airbag module.

8.Remove passenger's airbag from dash panel.

See SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, passenger's airbag module.

9.Release clamp and lower steering column.

10.Remove steering wheel.

See STEERING,

Repair, steering wheel.

11.Remove column switch.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, column switch assembly.

12.Remove instrument binnacle.See

ELECTRICAL, Repair, instrument binnacle.

13.Remove radio.See ELECTRICAL, Repair,

radio.

14.Remove exterior mirrors switch panel.

15.Remove coin tray.

16.Remove switch panel.

17.Remove clock.

18.Undo screw securing mounting bracket and

position passenger's side relay assembly aside.

19.Set heater controls fully clockwise.

Page 716 of 873

CHASSIS AND BODY

49

REPAIR Refit

CAUTION: When refitting avoid trapping

electrical wiring.

29.Reverse removal procedure.

30.With assistance: Position dash panel and

connect dash harness multiplugs to fusebox and

main harness.

31.Reverse removal procedure. Ensure dash panel

upper bracket studs are located before the 4

lower brackets.

32.Reverse removal procedure. Disconnect

glovebox switch Lucars to ease fitting of relay

bracket.WINDSCREEN GLASS

Service repair no - 76.81.01

Information

The following equipment is required:

·Cutting wire and handles

·Windscreen repair kit (see Technical

Bulletin).

See Electrical Trouble Shooting

Manual.Windscreen Glass Replacement.

·Sealant applicator gun.

·Suction cup lifters.

The following materials are included in the windscreen

repair kit:

·Glass cleaning solvent - 'Betawipe' Glass

activator (yellow cap).

·Cotton buds.

·Glass primer - 'Betaprime'(green cap).

·Body primer - 'Betaprime' paint/plastic

primer (red cap).

·Betaseal Adhesive sealant.

NOTE: The adhesive sealant cures in 6 to 8

hours

CAUTION: Once existing sealant is cut, the

exposed surfaces oxidises in

approximately 90 minutes. The refit

procedure must be completed within this time

span to prevent the sealant oxidising, to effect a

satisfactory joint.

CAUTION: If the windscreen aperture body

flange shows signs of corrosion it must be

treated with anti corrosion primer and

repainted. Newly painted areas must then be left

for 8 hours or more before applying adhesive

sealant.

Page 717 of 873

![LAND ROVER DISCOVERY 1995 Manual Online 76CHASSIS AND BODY

50

REPAIR

NOTE: If heated front screen: 2 electrical

multiplug connectors are located under

the decker [cowl] panel. To access release

decker panel.

Remove

1.Remove windscreen wiper LAND ROVER DISCOVERY 1995 Manual Online 76CHASSIS AND BODY

50

REPAIR

NOTE: If heated front screen: 2 electrical

multiplug connectors are located under

the decker [cowl] panel. To access release

decker panel.

Remove

1.Remove windscreen wiper](/img/64/57248/w960_57248-716.png)

76CHASSIS AND BODY

50

REPAIR

NOTE: If heated front screen: 2 electrical

multiplug connectors are located under

the decker [cowl] panel. To access release

decker panel.

Remove

1.Remove windscreen wiper arms.

See WIPERS

AND WASHERS, Repair, wiper arms -

windscreen.

2.Remove rear view mirror and stickers from

glass.

3.Remove'A'post finishers.

4.Fit protective cover over dash panel and apply

masking tape to protect'A'posts.

5.Ease one end of bottom finisher away from

glass, pull to disengage finisher flange and

remove.

6.Lift lip of LH'A'post finisher and release sealing

strip along its length, pull to disengage finisher

flange from glass and remove.7.Remove RH'A'post finisher.

8.Remove header finisher.

9.Apply masking tape to protect paint finish around

glass.

10.Prepare cutting wire in handle'A'.Bend end of

wire to handle and tape over end.

11.Force cutting wire through sealer from inside and

100mm (3 7/8 in) from a top corner. Use a

needle if necessary to make a pilot hole.

12.Attach handle'B'.Allow 200mm (7 7/8 in) of wire

between handles, tape over end of wire.

13. With an assistant on the inside:Wedge the

tube of the handle'A'between glass and body

flange 100mm (3 7/8 in) ahead of hole in sealer.

14. From the outside:Carefully cut sealer from

flange using a straight pull away from the glass.

Continue in 100mm (3 7/8 in) steps around the

glass, use a sawing action at the corners.

CAUTION: Along the bottom edge, great

care must be taken to cut up to the 2

supports, positions indicated on the

obscuration band (See item 18).

15.Remove handle'B', withdraw the cutting wire

and insert it through the sealer between the

supports. Refit handle'B'.

Page 726 of 873

CHASSIS AND BODY

59

REPAIR

9.Remove 5 trim studs securing trim panel.

10.Remove trim panel.

Refit

11.Fit and align trim panel.

12.Fit trim panel retaining studs.

13.Position load space cover mounting bracket and

secure with screws.

14.Fold rear seat squab back and secure to latch.

15.Position load space cover to mounting brackets

and secure.

16.Fit 'E' post trim casing.

See 'E' post trim

casing - lh - with rear air conditioning fitted.

17.Fit fold down rear seat belts.See rear fold

down seat belts - lh - with rear air

conditioning fitted.

18.Fit rear fold down seat.See rear fold down

seats.

'E' POST TRIM CASING - RH

Service repair no - 76.13.13/03

Remove

1.Remove rear speaker.

See ELECTRICAL,

Repair, rear speaker.

2.Release 2 'E' post finisher retaining studs from

alpine light trim.

3.Release 2 'E' post finisher retaining clips from

lower trim panel.

4.Remove 'E' post finisher.

Refit

5.Position 'E' post finisher clips to lower trim panel.

6.Secure 'E' post finisher studs to alpine light trim.

7.Fit rear speaker.

See ELECTRICAL, Repair,

rear speaker.

Page 727 of 873

76CHASSIS AND BODY

60

REPAIR 'E' POST TRIM CASING - LH - WITH REAR AIR

CONDITIONING FITTED

Service repair no - 76.13.13/20

Remove

1.Remove rear speaker.

See ELECTRICAL,

Repair, rear speaker.

2.Release 2 trim casing retaining screw covers.

3.Remove 2 screws securing trim casing.

4.Remove trim casing.

Refit

5.Fit and align trim casing.

6.Fit and tighten screws securing trim casing and

fit covers.

7.Fit rear speaker.

See ELECTRICAL, Repair,

rear speaker.

ALPINE LIGHT TRIM CASING - LH - WITH REAR

AIR CONDITIONING FITTED

Service repair no - 76.13.20/20

Remove

1.Remove 'E' post trim casing.

See 'E' post trim

casing - lh - with rear air conditioning fitted.

2.Remove rear seat belt anchorage retaining bolt

cover.

3.Remove bolt securing rear seat belt anchorage.

4.Remove 2 trim studs securing trim casing.

5.Release trim casing from 2 retaining studs.

6.Remove trim casing.

Refit

7.Fit and align trim casing and secure with studs.

8.Fit 2 trim studs securing trim casing.

9.Position seat belt anchorage, fit bolt and tighten

to

20 Nm (15 lbf ft).

10.Fit cover to seat belt anchorage bolt.

11.Fit 'E' post trim casing.

See 'E' post trim

casing - lh - with rear air conditioning fitted.

Page 740 of 873

HEATING AND VENTILATION

3

DESCRIPTION AND OPERATION

Controls set for unheated air to footwells and face level vents

Heater and ventilation operation

The heating and ventilation system contains a heater

matrix, which is connected to the engine cooling

system, and a 4 speed fan for air distribution. Engine

coolant is circulated through the heater matrix

continuously, except when the temperature controls

are set to COLD.

Recirculated air

When the recirculation switch is pressed, an electrical

servo operates and fully closes the fresh air intake

flap.

Fresh air

When the recirculation switch is returned to the OFF

position, the electrical servo returns and fully opens

the fresh air intake flap.Heated air

Temperature output is controlled by the temperature

controls which move the air direction and temperature

flaps independently to increase or decrease the

volume of air flow through the heater matrix.

V8 Engine:When both controls are in the cold

position, the coolant valve is turned off.

Face level vent flap

Control at face level, flap fully open. All other vents

closed.

Control at face and foot level, flaps half open.

Unless an air conditioning unit is fitted, only fresh or

re-circulated air is available from the face level vents.

Demist vent flap

Control at demist, flap fully open. All other vents

closed.

Control at demist and foot level, flaps half open.

Page 759 of 873

82AIR CONDITIONING

4

FAULT DIAGNOSISFAULT CAUSE REMEDY

E.

NOISY

EXPANSION

VALVE

(steady hissing)1. Low refrigerant charge; evident by

bubbles in sight glass.1. Leak test. Repair or replace

components as required.

F.1. Expansion valve not operating 1. Refer to C-2, C-3, D-1

INSUFFICIENTproperly. and E.

COOLING2. Low refrigerant charge-evident 2. Refer to B-1 and E.

by bubbles in sight glass.

3. Compressor not pumping. 3. Refer to B-2 and B-3

G.1. Belt tension. 1. Adjust belt tension.

COMPRESSOR2. Excessive head pressure. 2. Refer to A-1 through

BELTA-4 and C-6.

SLIPPING3. Incorrect alignment of pulleys 3. Repair as needed.

or worn belt not riding properly.

4. Nicked or broken pulley. 4. Replace as needed.

5. Seized compressor. 5. Replace compressor.

1. Loose or missing mounting bolts. 1. Repair as necessary.

2. Broken mounting bracket. 2. Replace bracket.

3. Loose flywheel or clutch 3. Repair as necessary.

retaining bolt.

H.4. Rough idler pulley bearing. 4. Replace bearing.

ENGINE5. Bent, loose, or improperly 5. Repair as necessary.

NOISEmounted engine drive pulley.

AND/OR6. Defective compressor bearing. 6. Replace bearing.

VIBRATION7. Insecure mountings of 7. Repair as necessary.

accessories; generator, power

steering, air filter, etc.

8. Excessive head pressure. 8. Refer to A-1, A-2, A-3

A-4 and C-6.

9. Incorrect compressor oil level. 9. Refer to compressor Oil

Level Check.

HEATER AND AIR CONDITIONING - CIRCUIT

DIAGRAMS

1.For details of heating and air conditioning

electrics

See Electrical Trouble Shooting

Manual.

Page 770 of 873

AIR CONDITIONING

5

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Disconnect battery negative lead.

2.Recover refrigerant from air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

3.Remove screws retaining centre panel to fan

cowl

4.Remove centre panel.

V8i engine illustrated

5.Remove 2 bolts securing hose flanges to

compressor.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.6.Disconnect high pressure hose from

compressor.

7.Disconnect low pressure hose from compressor.

8.Remove 'O' ring from each flange.

9.Disconnect electrical lead from compressor

clutch.

10.Release drive belt from compressor pulley.

See

ENGINE, Repair, Drive Belt

11.Remove 4 bolts securing compressor to

mounting bracket.

12.Remove compressor from mounting bracket.

Refit

13.New compressor to be fitted: Drain oil from new

compressor outlet port. Drain and measure oil

from old compressor. Measure new oil equal to

amount drained from old compressor, add 30 ml

extra to this amount and refill new compressor

through outlet port.

14.Locate compressor in mounting bracket, fit bolts.

Tighten to

25 Nm.

15.Connect electrical lead to compressor clutch.

16.Fit new 'O' rings to high and low pressure hose

flanges, lubricate with refrigerant oil.

17.Engage hose flanges, fit bolts. Tighten to

10

Nm.

18.Fit compressor drive belt.See ENGINE, Repair,

Drive Belt

19.Fit centre panel to fan cowl.

20.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

21.Perform a leak test on disturbed joints.

22.Carry out a functional check.

Page 771 of 873

82AIR CONDITIONING

6

REPAIR CONDENSER

Service repair no - 82.15.07

Remove

1.Disconnect battery negative lead.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

2.Recover refrigerant from system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

3.Remove front grille panel.

4.Remove battery.

See ELECTRICAL, Repair,

Battery

5.Remove radiator and oil coolers assembly.See

COOLING SYSTEM, Repair, Radiator

6.Disconnect high and low pressure pipes at

condenser unions.

7.Discard 'O' ring seal from each union.

8.Remove 2 bolts securing condenser to body.

9.Pull condenser into radiator area.

10.Disconnect multiplug from each fan lead.

11.Remove condenser assembly.

Do not carry out

further dismantling if component is removed

for access only.

Blank off inlet and outlet ports.