check oil LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 456 of 873

ZF

19

REPAIR 6.Screw in two bolts, diagonally opposite each

other. Tap lightly using a soft headed mallet to

remove pump assembly from intermediate plate.

7.Remove shaft sealing ring and 'O' ring from

pump housing and discard.

8.Using oil seal replacer LST108 fit shaft seal ring

into pump housing.

9.Fit 'O' ring onto circumference of pump housing.

10.Align dowel with hole in intermediate plate and

press pump housing home.11.Fit pump housing to intermediate plate, tighten

eight bolts to

10 Nm.

12.Place bell housing and intermediate plate

assembly on bench, front face up. Using oil

pump rotation sleeve LST111, check that pump

gears rotate freely.

13.Before fitting intermediate plate and bell housing

assembly,check that thrust washer and axial

cage are seated on A clutch housing.

14.Place gasket and disc washer onto bell housing

and intermediate plate assembly using

Petroleum Jelly.

15.Fit bell housing and intermediate plate assembly

to gearcase. Tighten twelve bolts to

46 Nm.

16.Place end float gauge LST111 onto pump

housing and check that axial play is between

0.2-0.4 mm. Replace existing washer, situated at

rear of intermediate plate, with a suitable washer

to give required end float.

17.Refit torque converter into housing using torque

converter handles 18G1501, checking that

dimension from converter fixing bolt boss to

converter housing face is 50 mm. This shows

converter is properly seated in housing.

18.Refit gearbox/transfer box assembly.

See

LT230T Transfer Gearbox

Page 457 of 873

44AUTOMATIC GEARBOX

20

REPAIR ELIMINATING LEAKS BETWEEN GEARBOX

HOUSING AND INTERMEDIATE PLATE

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Remove twelve hexagonal bolts (inner ring

pattern).

4.Remove bell housing/intermediate plate

assembly from gearbox case and discard

gasket.

5.Place new gasket onto intermediate plate using

Petroleum Jelly.

6.Before fitting bell housing assembly check that

thrust washer and axial cage are seated on A

clutch housing.

7.Fit bell housing assembly with disc washer to

gearcase. Tighten twelve bolts to

46Nm.

8.Place end-float gauge LST111 onto pump

housing and check that axial play is between

0.2-0.4 mm. Replace existing washer, situated at

rear of intermediate plate, with a suitable washer

to give required end-float.

9.Refit torque converter using torque converter

handles 18G1501. Checking that dimension

from converter fixing boss to converter housing

case is 50mm. This dimension shows converter

is properly seated.

10.Refit gearbox/transfer box assembly.

See

LT230T Transfer Gearbox

Page 458 of 873

ZF

21

REPAIR REPLACING PUMP

Service repair no - 44.32.01

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Remove twelve bolts (inner ring pattern).

4.Remove bell housing and pump assembly from

gearbox case, discard gasket.

5.Remove eight bolts on rear of pump.

6.Screw in two bolts,diagonally opposite each

other, tap lightly using a soft headed mallet to

free pump assembly from intermediate plate.

7.Fit new pump assembly, aligning dowel with hole

in intermediate plate, press pump housing home.

8.Secure pump housing to intermediate plate

using eight hexagonal bolts. Tighten to

10 Nm.

9.Place bell housing and intermediate plate

assembly on bench, front face up. Using oil

pump rotation sleeve LST111, check that pump

gears rotate freely.

10.Before replacing intermediate plate/bell housing

assembly check that thrust washer and axial

cage are seated on A clutch housing.

11.Place new gasket and disc washer onto bell

housing and intermediate plate assembly using

a Petroleum Jelly.

12.Fit bell housing and intermediate plate assembly,

tighten twelve bolts to

46 Nm.

Page 468 of 873

PROPELLER SHAFTS

1

FAULT DIAGNOSIS VIBRATION HARSHNESS

1.Check that the propeller shaft universal joints

and sliding splines are not siezed or worn and

that the shafts are correctly aligned.

NOTE: In the event that both shafts are

satisfactory, but the vibration/harshness is

still present, the transfer box operation

and balance of the road wheels should be

checked.

For transfer box operation.

See TRANSFER

GEARBOX, Fault diagnosis, LT230T Transfer Box

- Oil Leaks

For balance of road wheels.See WHEELS AND

TYRES, Repair, Wheel Balancing

Page 474 of 873

REAR AXLE AND FINAL DRIVE

1

FAULT DIAGNOSIS FAULT DIAGNOSIS

Complaint - Oil leaks

An external leak of lubrication from the hub seals can

be caused by a faulty internal seal. For example, if the

internal seals which separate the differential from the

hubs are faulty and the vehicle is operating or parked

on an embankment. Oil from the differential may flood

one hub causing a leak and leave the differential

lacking lubrication.

When a seal is found to be leaking check the axle

ventilation system, as a blockage can cause internal

pressure to force oil past the seals.

See 'Description and Operation' for illustrations of oil

seal locations.

When investigating hub seal leaks check the grease

for dilution with oil. Check also the differential level

and oil for metal particles and the condition of internal

seals.

If the vehicle is driven in deep water with defective oil

seals, water may contaminate the lubricants and raise

the differential level giving a false impression that the

housing has been overfilled with oil.

Do not assume that a high oil level in the

differential is due to over filling or, that a low level

is because of an external leak.

Page 482 of 873

51REAR AXLE AND FINAL DRIVE

4

OVERHAUL 35.Fit pinion outer bearing track to pinion housing.

Use service tools LRT-54-505 and LRT-54-507.

36.Fit pinion head bearing to pinion. Use service

tool LRT-54-502.

37.Fit pinion into its location without shims for

bearing pre-load.

38.Fit outer bearing, and spacer (front axle

differential only).

39.Fit driving flange, washer and nut.

40.Do not fit oil seal at this stage.

41.Tighten pinion flange nut until force required to

rotate pinion is

3Nmif new bearings are fitted.

This will pre-load bearings to check pinion height

dimension.

NOTE: If using original bearings, pre-load

figure is 1.5 Nm.

Drive pinion markings

NOTE: Markings on end face adjacent to

serial number are of no relevance to

servicing.

42.Figures marked on end face opposite to serial

number show in thousandths of an inch,

deviation from nominal, required to set pinion.

Pinions marked plus (+) must be set below

nominal. Pinions marked minus (-) must be set

above nominal. Unmarked pinions must be set at

nominal.

Page 484 of 873

51REAR AXLE AND FINAL DRIVE

6

OVERHAUL 48.Repeat on other bearing bore. Add readings

then halve sum to obtain mean reading. Note

whether trace pin has moved up or down from

zero.

A. Where trace pin moves down, reading is

equal to thickness of shims to remove, to

bring pinion to nominal.

B. Where trace pin moves up, reading is

equal to thickness of shims to add, to bring

pinion to nominal.

49.Before adjusting shim thickness: check pinion

face marking. If a plus (+) figure, subtract in

thousandths of an inch from shim thickness

figure.

50.If pinion has a minus (-) figure, add amount to

shim thickness figure.

Adjust shim thickness under pinion head bearing

track as necessary.

INCH MM

.001 = .025

.002 = .05

.003 = .075

.004 = .10

.005 = .125

.006 = .15

.007 = .175

.008 = .20

.009 = .225

.010 = .25

NOTE: Where dial indicator is metric

conversion must be made to inches when

measuring and selecting shims.

51.Recheck pinion height setting. If setting is

correct, mean reading of dial gauge will agree

with figure marked on pinion end face.

For example, with end face marking of +3, dial

gauge reading should indicate pinion is +0.003

in.Bearing pre-load adjustment

52.Remove the pinion flange, pinion, outer bearing

and spacer.

53.Slide new shim, of same thickness as original

(bearing pre-load) into position on pinion shaft. If

fitting a new shim use thickest shim 2.155 mm.

54.Fit pinion to pinion housing and fit outer bearing

and spacer (front differential only).

55.Fit driving flange, washer and nut.

56.Do not fit oil seal at this stage.

57.Tighten pinion flange nut to130 Nm.Force to

rotate pinion shaft is 3Nm using new bearings.

Change shim as necessary to obtain reading.

Thicker shim will reduce pre-load. Thinner shim

will increase pre-load.

NOTE: If using original bedded in

bearings, pre-load figure is 1.5 Nm.

58.Remove pinion flange.

Page 498 of 873

FRONT AXLE AND FINAL DRIVE

1

FAULT DIAGNOSIS FAULT DIAGNOSIS

Complaint - Oil leaks

An external leak of lubrication can be caused by a

faulty internal seal. For example, if the seals which

separate the differential from the swivel housings are

faulty and the vehicle is operating or parked on an

embankment, oil may leak across the axle leaving one

swivel with a high level and the other swivel and

differential lacking lubrication.

See 'Description and Operation' for illustrations of oil

seal locations.

When investigating leaks or checking oil levels, it is

essential that all the lubrication is drained from any

housing with a high level and that the other levels are

checked.

Swivel oil should be checked for signs of grease

leaking from the hub bearings and the hub grease

should not contain oil.

Check that the axle ventilation system is clear, as a

blockage can cause internal pressure to force oil past

the seals.

If the vehicle is driven in deep water with defective oil

seals, water may contaminate the lubricants and when

checked, give a false impression that the housing has

been overfilled with oil.

Do not assume that a high oil level is due to over

filling or, that a low level is because of an external

leak.

Page 508 of 873

54FRONT AXLE AND FINAL DRIVE

6

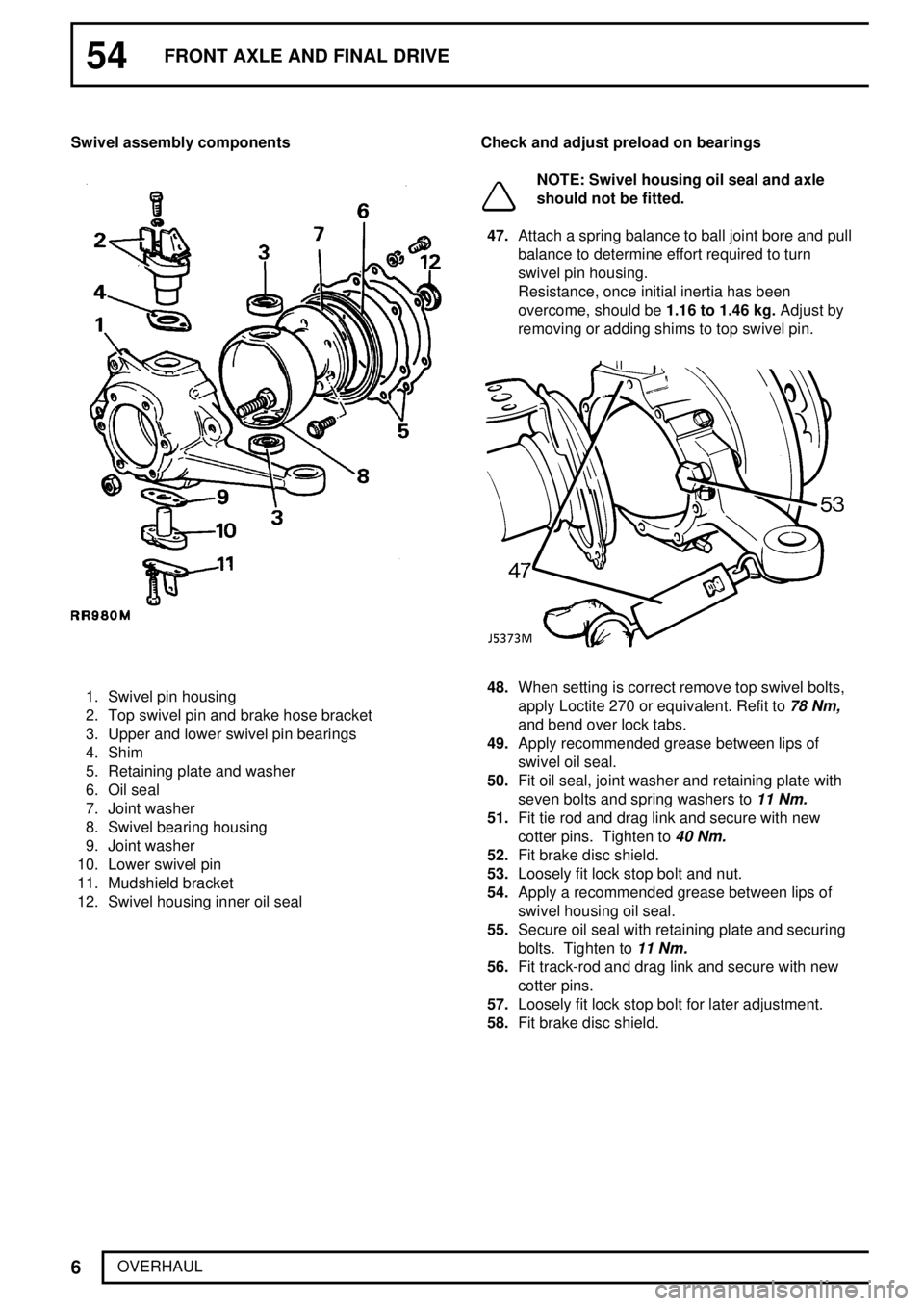

OVERHAUL Swivel assembly components

1. Swivel pin housing

2. Top swivel pin and brake hose bracket

3. Upper and lower swivel pin bearings

4. Shim

5. Retaining plate and washer

6. Oil seal

7. Joint washer

8. Swivel bearing housing

9. Joint washer

10. Lower swivel pin

11. Mudshield bracket

12. Swivel housing inner oil sealCheck and adjust preload on bearings

NOTE: Swivel housing oil seal and axle

should not be fitted.

47.Attach a spring balance to ball joint bore and pull

balance to determine effort required to turn

swivel pin housing.

Resistance, once initial inertia has been

overcome, should be1.16 to 1.46 kg.Adjust by

removing or adding shims to top swivel pin.

48.When setting is correct remove top swivel bolts,

apply Loctite 270 or equivalent. Refit to

78 Nm,

and bend over lock tabs.

49.Apply recommended grease between lips of

swivel oil seal.

50.Fit oil seal, joint washer and retaining plate with

seven bolts and spring washers to

11 Nm.

51.Fit tie rod and drag link and secure with new

cotter pins. Tighten to

40 Nm.

52.Fit brake disc shield.

53.Loosely fit lock stop bolt and nut.

54.Apply a recommended grease between lips of

swivel housing oil seal.

55.Secure oil seal with retaining plate and securing

bolts. Tighten to

11 Nm.

56.Fit track-rod and drag link and secure with new

cotter pins.

57.Loosely fit lock stop bolt for later adjustment.

58.Fit brake disc shield.

Page 509 of 873

FRONT AXLE AND FINAL DRIVE

7

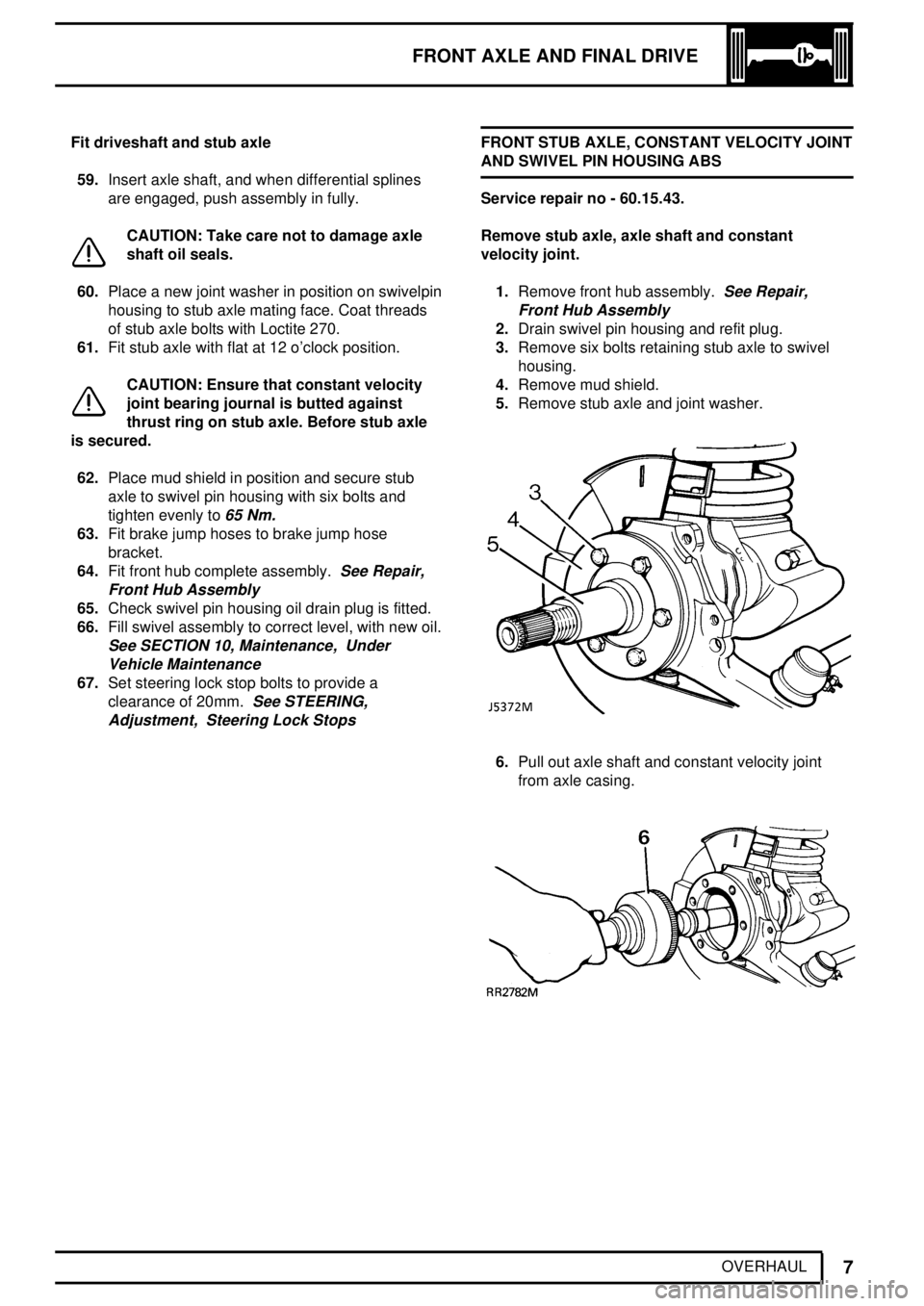

OVERHAUL Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 o'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle. Before stub axle

is secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with six bolts and

tighten evenly to

65 Nm.

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit front hub complete assembly.

See Repair,

Front Hub Assembly

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil.

See SECTION 10, Maintenance, Under

Vehicle Maintenance

67.Set steering lock stop bolts to provide a

clearance of 20mm.

See STEERING,

Adjustment, Steering Lock Stops

FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING ABS

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Drain swivel pin housing and refit plug.

3.Remove six bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Pull out axle shaft and constant velocity joint

from axle casing.