check oil LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 134 of 873

V8i

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Engine

Adaptor plate to crankshaft 84........................................................................

Generator and power steering mounting bracket to cylinder head 30............

Cylinder head:

Stage 1: 20.............................................................................................

Stage 2: - Further 180°±5°

Drive plate to converter 39..............................................................................

Engine mountings to engine and chassis 55..................................................

Engine mounting rubbers to brackets 30........................................................

Flexible drive plate to crankshaft adaptor plate 41.......................................... **

Flywheel to crankshaft bolts 78....................................................................... **

Lifting eye to cylinder heads 39......................................................................

Main bearing cap rear bolts 92....................................................................... *

Oil sump drain plug 40....................................................................................

Oil sump to cylinder block 18..........................................................................

Rocker cover to cylinder head 9....................................................................

Rocker shaft bracket to cylinder head 38........................................................

Spark plug 21..................................................................................................

Starter motor attachment 44...........................................................................

* These bolts must have threads coated in lubricant EXP16A before assembly.

** These bolts must have threads coated in sealant Loctite 270

METRIC Nm

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................

NOTE: Torque values above are for all screws and bolts used except for those specified.

Page 143 of 873

4.0 V8

7

REPAIR 171.Route drive belt around pulleys.

172.Pivot tensioner downwards.

173.Align belt to tensioner and release tensioner.

174.Connect battery positive lead and tighten.

175.Secure terminal cover.

176.Align gearbox breather pipe, clip to engine lifting

eye and fit bolt. Tighten to

9 Nm.

177.Align and secure engine harness brackets to

inlet manifold and fit nuts. Tighten to

9 Nm.

178.Connect injector multiplugs.

179.Connect air intake temperature sensor multiplug.

180.Connect fuel temperature sensor multiplug.

181.Connect coolant temperature multiplug.

182.Connect temperature gauge connector.

183.Connect oil pressure switch Lucar.

184.Connect camshaft sensor multiplug and secure

to bracket.

185.Fit ignition coil bracket.

See FUEL SYSTEM

SFI, Repair, Ignition Coils

186.Position heater hose/pipe assembly.

187.Connect hose to inlet manifold.

188.Align pipe to bracket and fit bolt. Tighten to

9

Nm.

189.Tighten hose clip.

190.Connect heater return hose and tighten clip.

191.Remove plugs from fuel feed and return hose

connections.

192.Clean feed unions.

193.Connect return hose and tighten clip.

194.Connect feed hose union and tighten.

195.Remove cloth.

196.Connect purge hose.

197.Connect leads to generator, tighten terminal nuts

and fit cover.

198.Connect sensing Lucar.

199.Connect servo vacuum hose.

200.Position expansion tank and secure with fixings.

201.Connect hose and tighten clip.

202.Lower ramp.

203.Fit mass air flow sensor.

See FUEL SYSTEM

SFI, Repair, Mass Air Flow Sensor (MAF

Sensor)

204.Fit plenum chamber.See FUEL SYSTEM SFI,

Repair, Plenum Chamber

205.Fit radiator.See COOLING SYSTEM, Repair,

Radiator

206.Fit bonnet.See CHASSIS AND BODY, Repair,

Bonnet [Hood]

207.Reconnect battery negative lead.

208.Bleed power steering system.

See STEERING,

Repair, Power Steering System - Bleed

209.Drain engine oil and refill.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids - USA

Vehicles

210.Start engine. Check for fuel, coolant and oil

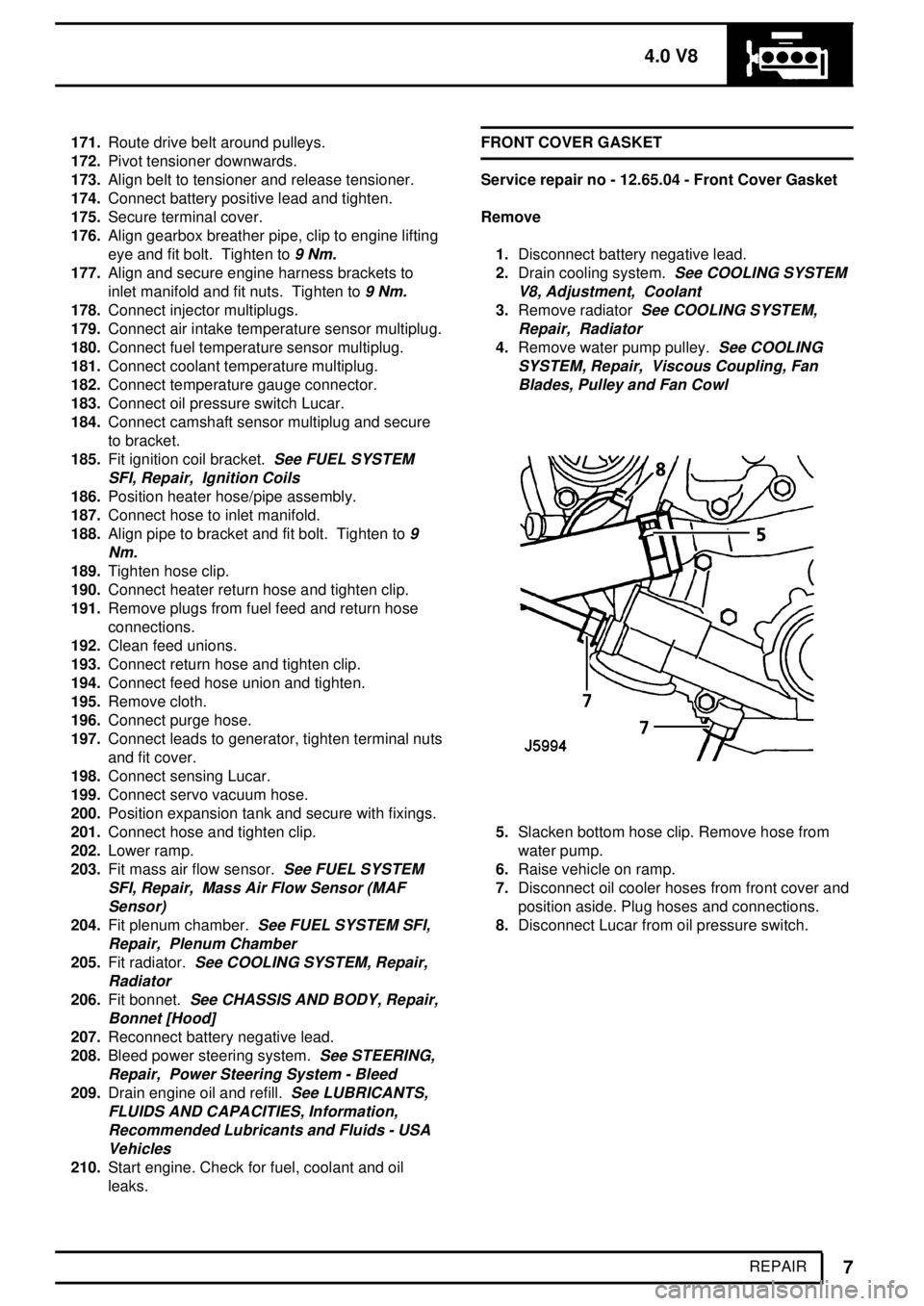

leaks.FRONT COVER GASKET

Service repair no - 12.65.04 - Front Cover Gasket

Remove

1.Disconnect battery negative lead.

2.Drain cooling system.

See COOLING SYSTEM

V8, Adjustment, Coolant

3.Remove radiatorSee COOLING SYSTEM,

Repair, Radiator

4.Remove water pump pulley.See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

5.Slacken bottom hose clip. Remove hose from

water pump.

6.Raise vehicle on ramp.

7.Disconnect oil cooler hoses from front cover and

position aside. Plug hoses and connections.

8.Disconnect Lucar from oil pressure switch.

Page 145 of 873

4.0 V8

9

REPAIR 28.Remove alignment tool LRT-12-090.

29.Apply a small amount of Loctite 242 to threads

and refit front cover bolts. Tighten to

22 Nm.

30.Fit sump bolts. Tighten to23 Nm.

31.Connect camshaft sensor multiplug.

32.Connect Lucar to oil pressure switch terminal.

33.Remove plugs from oil cooler pipes and cover.

34.Fit new 'O' ring seals, reconnect oil cooler pipes.

Tighten to

15 Nm.

CAUTION: Over tightening of oil cooler

pipe unions can crack front cover.

35.Refit bottom hose to water pump. Tighten clip.

36.Refit water pump pulley.

See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

37.Refit radiator assembly.See COOLING

SYSTEM, Repair, Radiator

38.Refill cooling system.See COOLING SYSTEM

V8, Adjustment, Coolant

39.Check/top-up engine oil.

40.Lower ramp.

41.Reconnect battery negative lead.

Page 172 of 873

12ENGINE

14

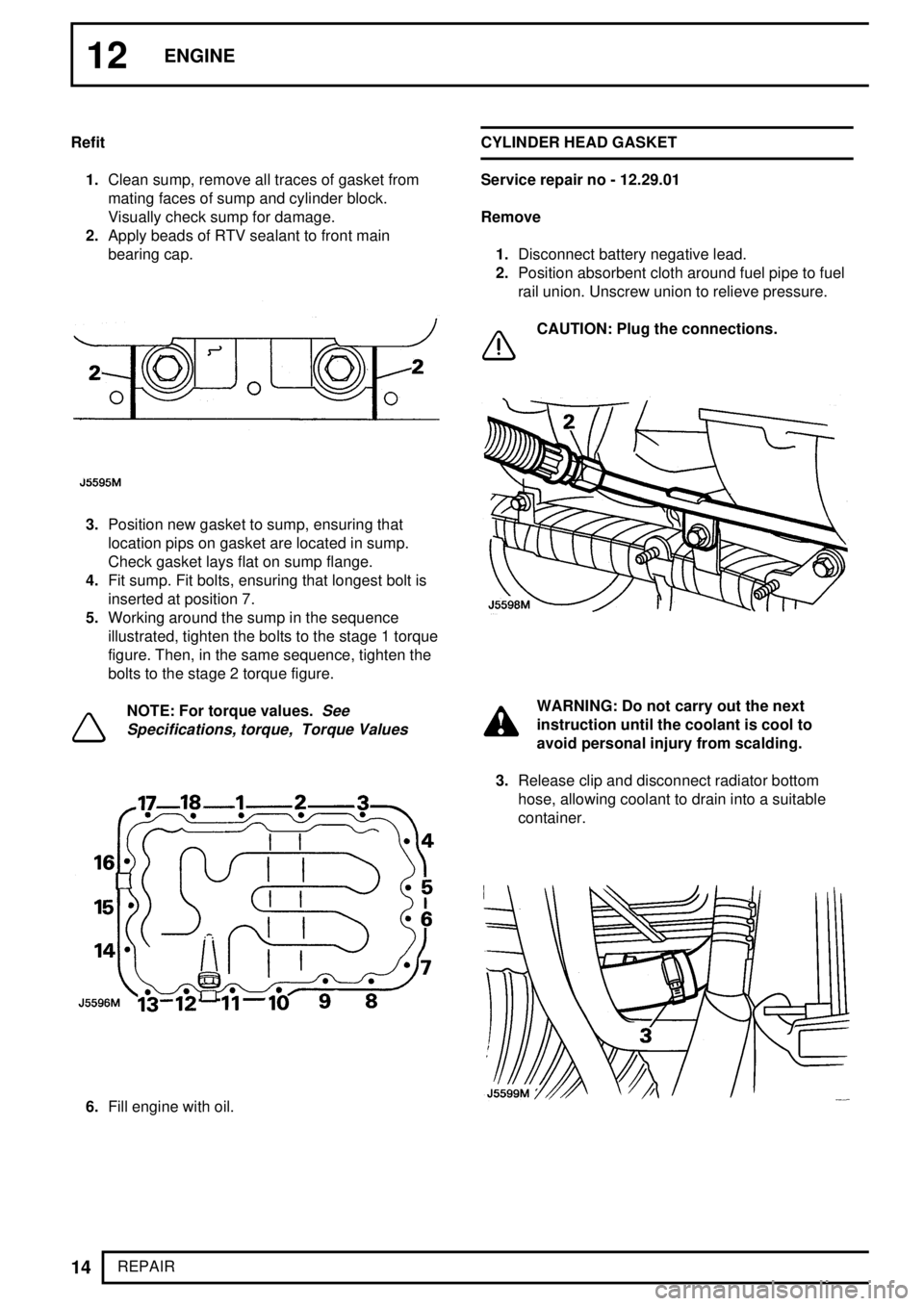

REPAIR Refit

1.Clean sump, remove all traces of gasket from

mating faces of sump and cylinder block.

Visually check sump for damage.

2.Apply beads of RTV sealant to front main

bearing cap.

3.Position new gasket to sump, ensuring that

location pips on gasket are located in sump.

Check gasket lays flat on sump flange.

4.Fit sump. Fit bolts, ensuring that longest bolt is

inserted at position 7.

5.Working around the sump in the sequence

illustrated, tighten the bolts to the stage 1 torque

figure. Then, in the same sequence, tighten the

bolts to the stage 2 torque figure.

NOTE: For torque values.See

Specifications, torque, Torque Values

6.Fill engine with oil.CYLINDER HEAD GASKET

Service repair no - 12.29.01

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve pressure.

CAUTION: Plug the connections.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

3.Release clip and disconnect radiator bottom

hose, allowing coolant to drain into a suitable

container.

Page 175 of 873

Mpi

17

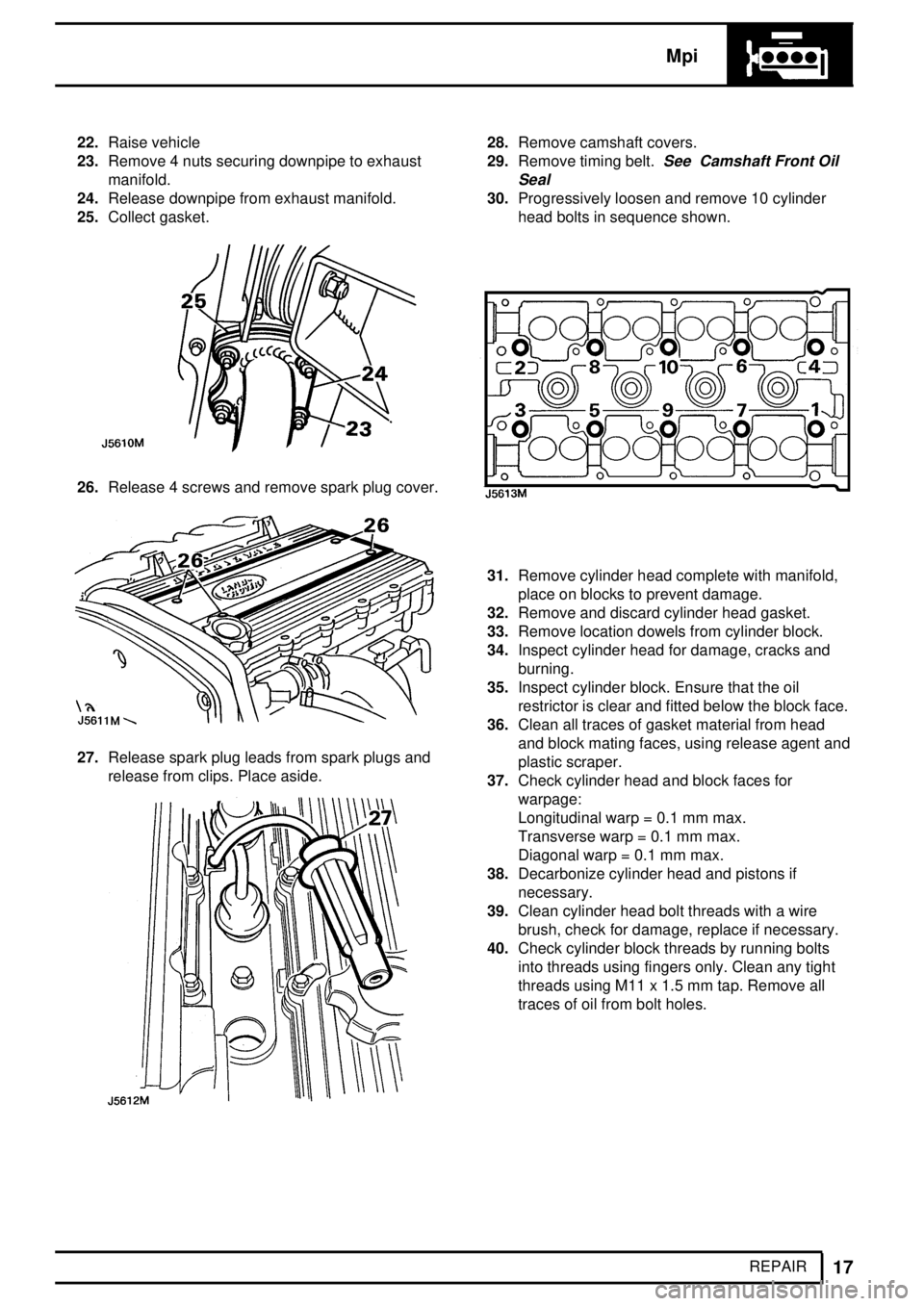

REPAIR 22.Raise vehicle

23.Remove 4 nuts securing downpipe to exhaust

manifold.

24.Release downpipe from exhaust manifold.

25.Collect gasket.

26.Release 4 screws and remove spark plug cover.

27.Release spark plug leads from spark plugs and

release from clips. Place aside.

28.Remove camshaft covers.

29.Remove timing belt.

See Camshaft Front Oil

Seal

30.Progressively loosen and remove 10 cylinder

head bolts in sequence shown.

31.Remove cylinder head complete with manifold,

place on blocks to prevent damage.

32.Remove and discard cylinder head gasket.

33.Remove location dowels from cylinder block.

34.Inspect cylinder head for damage, cracks and

burning.

35.Inspect cylinder block. Ensure that the oil

restrictor is clear and fitted below the block face.

36.Clean all traces of gasket material from head

and block mating faces, using release agent and

plastic scraper.

37.Check cylinder head and block faces for

warpage:

Longitudinal warp = 0.1 mm max.

Transverse warp = 0.1 mm max.

Diagonal warp = 0.1 mm max.

38.Decarbonize cylinder head and pistons if

necessary.

39.Clean cylinder head bolt threads with a wire

brush, check for damage, replace if necessary.

40.Check cylinder block threads by running bolts

into threads using fingers only. Clean any tight

threads using M11 x 1.5 mm tap. Remove all

traces of oil from bolt holes.

Page 181 of 873

Mpi

23

REPAIR CHECK CAMSHAFT DRIVE BELT

Service repair no - 12.65.17

CAUTION: This check must be carried out

at the service intervals specified and

whenever carrying out any repair which

requires the timing belt to be disturbed. Pay

particular attention for signs of belt splitting at

base of teeth.

1.Remove 5 bolts securing timing belt upper cover

2.Remove upper cover.

3.Using a socket and extension bar on the

crankshaft pulley bolt, rotate engine to allow the

timing belt to be inspected.

CAUTION: Do not use camshaft gears or

retaining bolts to rotate engine.

4.Check timing belt condition, renew any belt that

shows signs of oil contamination, cracking,

fraying or splitting at base of teeth.

CAUTION: Cause of oil contamination, if

present, must be rectified.

5.Clean timing belt upper cover.

6.Position upper cover.

7.Fit upper cover securing bolts.

Page 182 of 873

Mpi

1

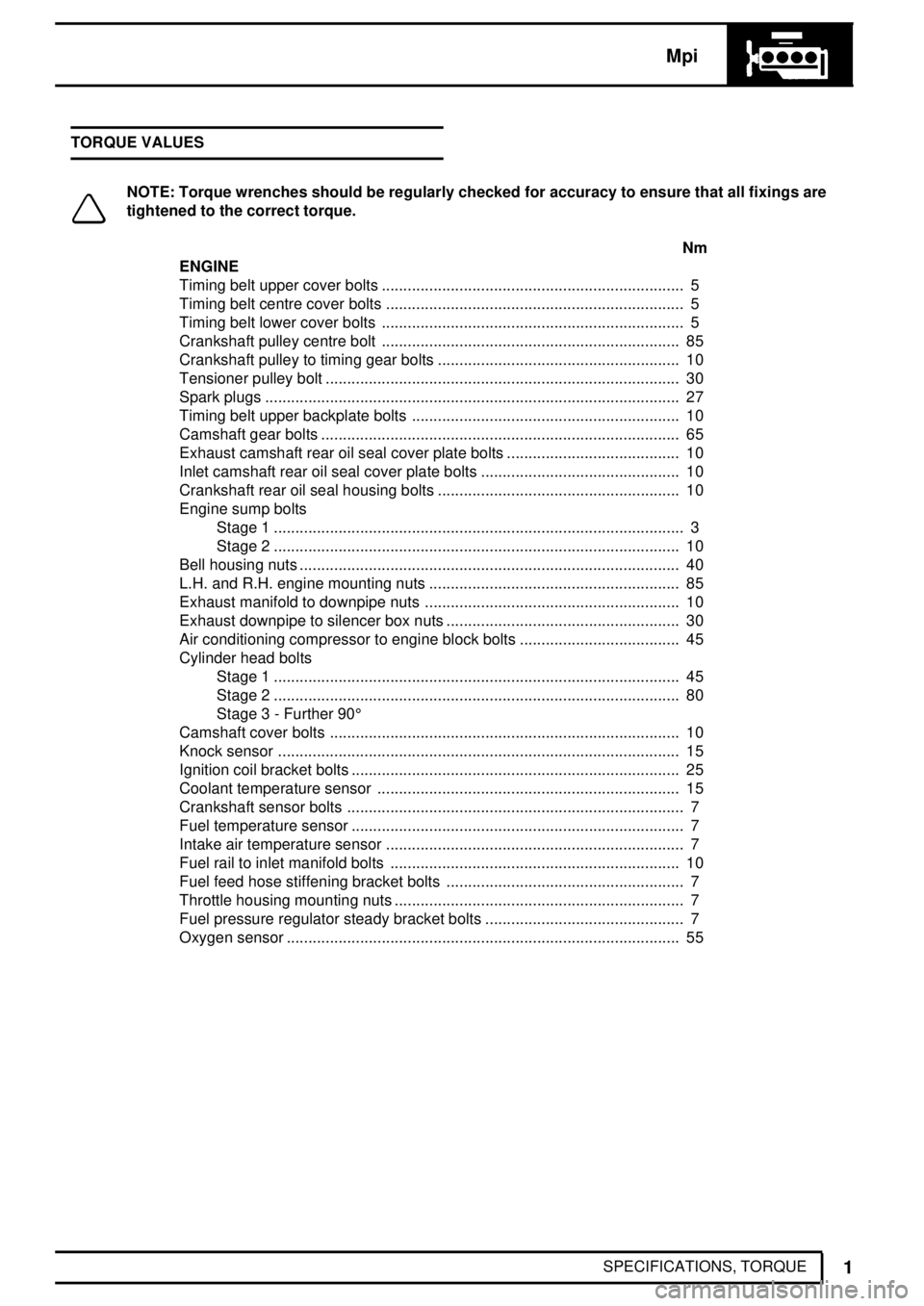

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

ENGINE

Timing belt upper cover bolts 5......................................................................

Timing belt centre cover bolts 5.....................................................................

Timing belt lower cover bolts 5......................................................................

Crankshaft pulley centre bolt 85.....................................................................

Crankshaft pulley to timing gear bolts 10........................................................

Tensioner pulley bolt 30..................................................................................

Spark plugs 27................................................................................................

Timing belt upper backplate bolts 10..............................................................

Camshaft gear bolts 65...................................................................................

Exhaust camshaft rear oil seal cover plate bolts 10........................................

Inlet camshaft rear oil seal cover plate bolts 10..............................................

Crankshaft rear oil seal housing bolts 10........................................................

Engine sump bolts

Stage 1 3...............................................................................................

Stage 2 10..............................................................................................

Bell housing nuts 40........................................................................................

L.H. and R.H. engine mounting nuts 85..........................................................

Exhaust manifold to downpipe nuts 10...........................................................

Exhaust downpipe to silencer box nuts 30......................................................

Air conditioning compressor to engine block bolts 45.....................................

Cylinder head bolts

Stage 1 45..............................................................................................

Stage 2 80..............................................................................................

Stage 3 - Further 90°

Camshaft cover bolts 10.................................................................................

Knock sensor 15.............................................................................................

Ignition coil bracket bolts 25............................................................................

Coolant temperature sensor 15......................................................................

Crankshaft sensor bolts 7..............................................................................

Fuel temperature sensor 7.............................................................................

Intake air temperature sensor 7.....................................................................

Fuel rail to inlet manifold bolts 10...................................................................

Fuel feed hose stiffening bracket bolts 7.......................................................

Throttle housing mounting nuts 7...................................................................

Fuel pressure regulator steady bracket bolts 7..............................................

Oxygen sensor 55...........................................................................................

Page 220 of 873

Tdi

3

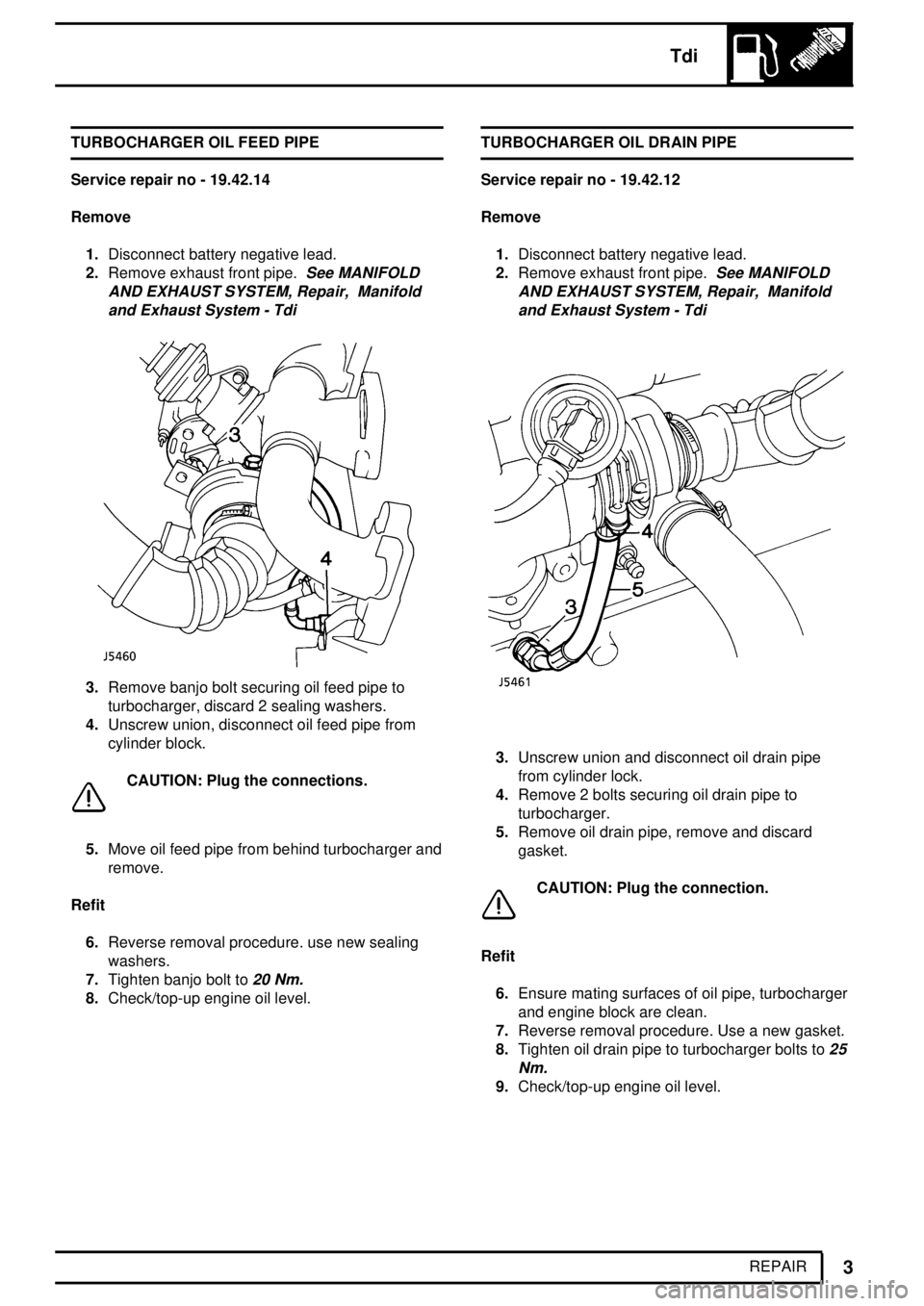

REPAIR TURBOCHARGER OIL FEED PIPE

Service repair no - 19.42.14

Remove

1.Disconnect battery negative lead.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Manifold

and Exhaust System - Tdi

3.Remove banjo bolt securing oil feed pipe to

turbocharger, discard 2 sealing washers.

4.Unscrew union, disconnect oil feed pipe from

cylinder block.

CAUTION: Plug the connections.

5.Move oil feed pipe from behind turbocharger and

remove.

Refit

6.Reverse removal procedure. use new sealing

washers.

7.Tighten banjo bolt to

20 Nm.

8.Check/top-up engine oil level.TURBOCHARGER OIL DRAIN PIPE

Service repair no - 19.42.12

Remove

1.Disconnect battery negative lead.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Manifold

and Exhaust System - Tdi

3.Unscrew union and disconnect oil drain pipe

from cylinder lock.

4.Remove 2 bolts securing oil drain pipe to

turbocharger.

5.Remove oil drain pipe, remove and discard

gasket.

CAUTION: Plug the connection.

Refit

6.Ensure mating surfaces of oil pipe, turbocharger

and engine block are clean.

7.Reverse removal procedure. Use a new gasket.

8.Tighten oil drain pipe to turbocharger bolts to

25

Nm.

9.Check/top-up engine oil level.

Page 221 of 873

19FUEL SYSTEM

4

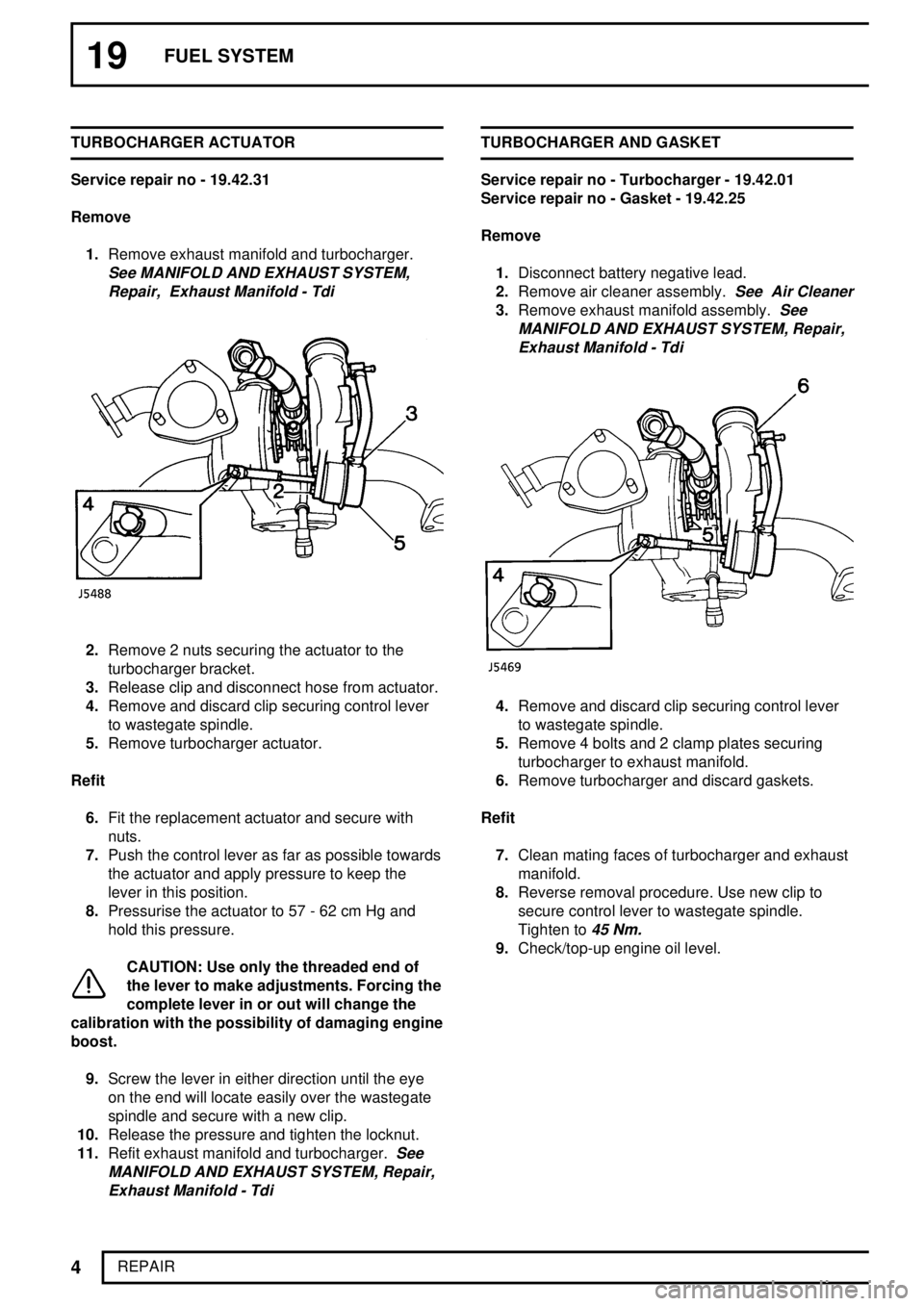

REPAIR TURBOCHARGER ACTUATOR

Service repair no - 19.42.31

Remove

1.Remove exhaust manifold and turbocharger.

See MANIFOLD AND EXHAUST SYSTEM,

Repair, Exhaust Manifold - Tdi

2.Remove 2 nuts securing the actuator to the

turbocharger bracket.

3.Release clip and disconnect hose from actuator.

4.Remove and discard clip securing control lever

to wastegate spindle.

5.Remove turbocharger actuator.

Refit

6.Fit the replacement actuator and secure with

nuts.

7.Push the control lever as far as possible towards

the actuator and apply pressure to keep the

lever in this position.

8.Pressurise the actuator to 57 - 62 cm Hg and

hold this pressure.

CAUTION: Use only the threaded end of

the lever to make adjustments. Forcing the

complete lever in or out will change the

calibration with the possibility of damaging engine

boost.

9.Screw the lever in either direction until the eye

on the end will locate easily over the wastegate

spindle and secure with a new clip.

10.Release the pressure and tighten the locknut.

11.Refit exhaust manifold and turbocharger.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - Tdi

TURBOCHARGER AND GASKET

Service repair no - Turbocharger - 19.42.01

Service repair no - Gasket - 19.42.25

Remove

1.Disconnect battery negative lead.

2.Remove air cleaner assembly.

See Air Cleaner

3.Remove exhaust manifold assembly.See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - Tdi

4.Remove and discard clip securing control lever

to wastegate spindle.

5.Remove 4 bolts and 2 clamp plates securing

turbocharger to exhaust manifold.

6.Remove turbocharger and discard gaskets.

Refit

7.Clean mating faces of turbocharger and exhaust

manifold.

8.Reverse removal procedure. Use new clip to

secure control lever to wastegate spindle.

Tighten to

45 Nm.

9.Check/top-up engine oil level.

Page 289 of 873

19FUEL SYSTEM

6

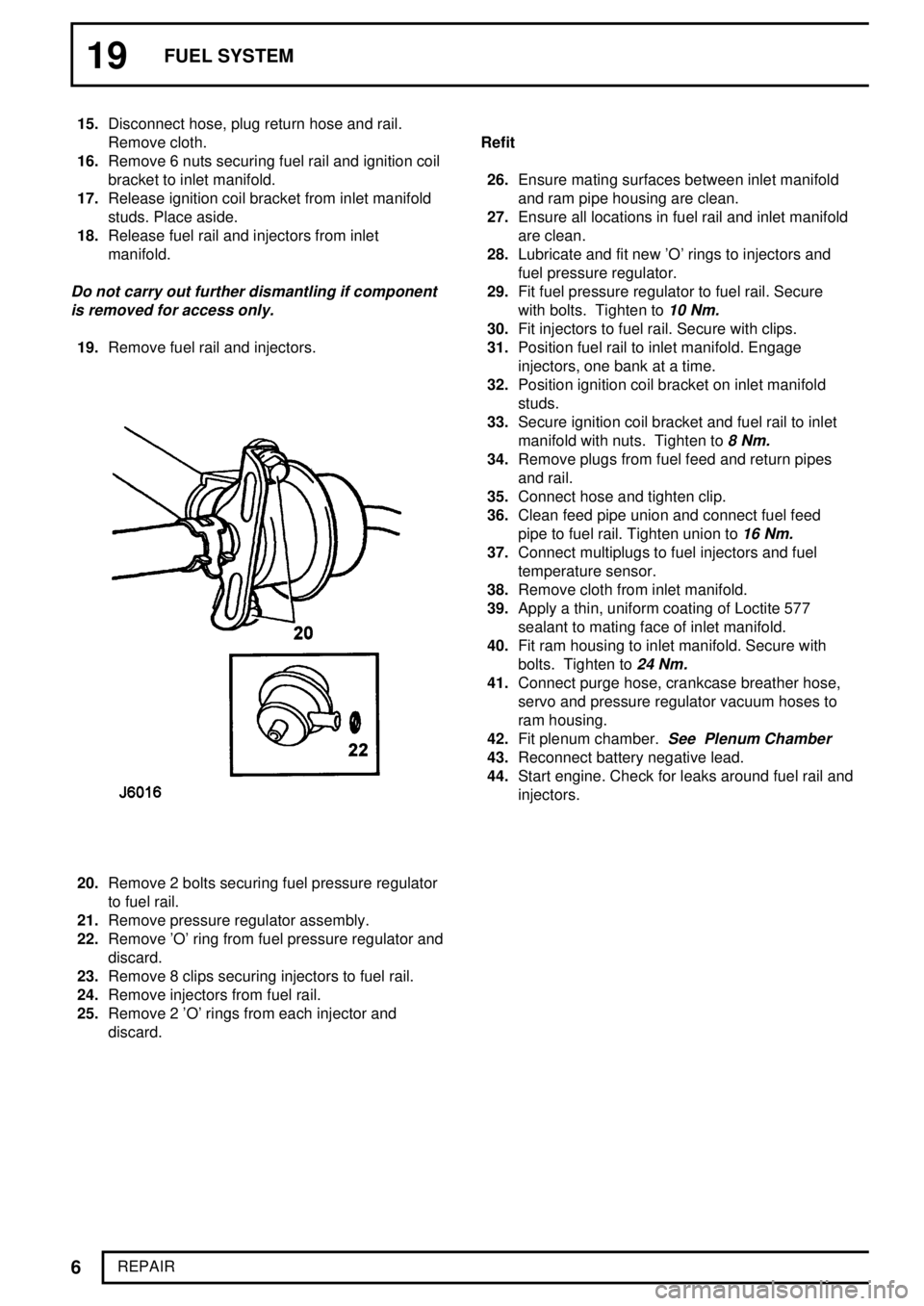

REPAIR 15.Disconnect hose, plug return hose and rail.

Remove cloth.

16.Remove 6 nuts securing fuel rail and ignition coil

bracket to inlet manifold.

17.Release ignition coil bracket from inlet manifold

studs. Place aside.

18.Release fuel rail and injectors from inlet

manifold.

Do not carry out further dismantling if component

is removed for access only.

19.Remove fuel rail and injectors.

20.Remove 2 bolts securing fuel pressure regulator

to fuel rail.

21.Remove pressure regulator assembly.

22.Remove 'O' ring from fuel pressure regulator and

discard.

23.Remove 8 clips securing injectors to fuel rail.

24.Remove injectors from fuel rail.

25.Remove 2 'O' rings from each injector and

discard.Refit

26.Ensure mating surfaces between inlet manifold

and ram pipe housing are clean.

27.Ensure all locations in fuel rail and inlet manifold

are clean.

28.Lubricate and fit new 'O' rings to injectors and

fuel pressure regulator.

29.Fit fuel pressure regulator to fuel rail. Secure

with bolts. Tighten to

10 Nm.

30.Fit injectors to fuel rail. Secure with clips.

31.Position fuel rail to inlet manifold. Engage

injectors, one bank at a time.

32.Position ignition coil bracket on inlet manifold

studs.

33.Secure ignition coil bracket and fuel rail to inlet

manifold with nuts. Tighten to

8 Nm.

34.Remove plugs from fuel feed and return pipes

and rail.

35.Connect hose and tighten clip.

36.Clean feed pipe union and connect fuel feed

pipe to fuel rail. Tighten union to

16 Nm.

37.Connect multiplugs to fuel injectors and fuel

temperature sensor.

38.Remove cloth from inlet manifold.

39.Apply a thin, uniform coating of Loctite 577

sealant to mating face of inlet manifold.

40.Fit ram housing to inlet manifold. Secure with

bolts. Tighten to

24 Nm.

41.Connect purge hose, crankcase breather hose,

servo and pressure regulator vacuum hoses to

ram housing.

42.Fit plenum chamber.

See Plenum Chamber

43.Reconnect battery negative lead.

44.Start engine. Check for leaks around fuel rail and

injectors.