ABS LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 529 of 873

STEERING

3

FAULT DIAGNOSIS STEERING DAMPER

The power steering system, as well as reducing the

effort required to manoeuvre the vehicle when

parking, also helps to dampen any deflections of the

road wheels, being transmitted back to the steering

wheel.

When operating the vehicle off road, the road wheels

are often deflected by ruts and boulders causing the

steering wheel to turn left and right. This phenomenon

is known as 'steering kickback'. To subdue the effects

of 'steering kickback', a hydraulic damper is fitted in

the steering linkage between the track rod and the

differential casing. The damper, which offers the same

resistance in extension and compression, is sealed for

life.

Steering damper check

Check the condition operation of the hydraulic

steering damper as follows:

Check procedure

1.Inspect damper for casing damage or leaks.

2.Clamp one end of the damper horizontally in a

vice using soft jaws. Compress and extend the

unit by hand. Resistance should be equal in both

directions.

3.If it is felt that the unit is outside acceptable

limits, fit a new steering damperSTEERING FAULTS

Symptom:-

Excessive kickback through steering wheel - when

driven on rough terrain.

1.Is the steering damper in good working order?

See Steering Damper

NO - Renew unit.See Repair, Steering

Damper

YES - Continue.

2.Is there any looseness or free play in the

steering ball joints and linkage?

YES -

See Steering Linkage Inspect

NO - Continue.

3.Is there any looseness or worn bushes in front

suspension?

YES -

See FRONT SUSPENSION, Repair,

Radius Arm

NOTE: When replacing suspension bushes

ALL bushes and fixings must be replaced.

NO - Continue.

4.Is the steering exceptionally light/sensitive when

driven on good road surface?

YES - See fault symptom -Steering

excessively light/sensitive and

freeplay at steering wheel.

NO - Suspect axle swivel resistance.

5.Check the resistance of the axle swivels.

See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing Non ABS See FRONT

AXLE AND FINAL DRIVE, Overhaul, Front

Stub Axle, Constant Velocity Joint and

Swivel Pin Housing ABS

Page 530 of 873

57STEERING

4

FAULT DIAGNOSIS Symptom:-

Fluid leaks from steering box seals.

CAUTION: The steering wheel must not be

held on full lock for more than 30 seconds

in one minute, as this may overheat the

fluid and cause damage to the oil seals.

1.Check fluid level.

See Repair, Power Steering

Fluid Reservoir

Check fluid pressure.See Power Steering

System - Test

2.Is pressure high?

YES - Renew pump.

See Repair, Power

steering Pump

If oil seal leaks persist after renewing the

pump.

See Overhaul, Power Steering

Box

NO -See Overhaul, Power Steering Box

Symptom:-

Insufficient power assistance - castor return

action normal.

1.Are tyres correct type and pressure?

NO -

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres

YES - Continue.

2.Is fluid level correct?

NO - Check fluid level

See Repair, Power

Steering Fluid Reservoir

YES - Check system for air locks.See Repair,

Power Steering System - Bleed

3.Is pressure correct?

NO - Check fluid pressure.

See Power

Steering System - Test

If pressure is not correct after bleeding

the system, renew pump.

See Repair,

Power Steering Pump

YES -See Overhaul, Power Steering Box

Symptom:-

Steering heavy - stiff, poor castor return action.

1.Are tyres correct type and pressure?

NO -

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres

YES - Check universal joints for seizure and

correct alignment.

See Repair, Lower

Steering Shaft and Universal Joints

Check power steering box adjustments.

See Overhaul, Power Steering Box

2.Is the power assistance satisfactory?

NO - See fault symptomInsufficient

assistance, (castor return action

normal).

YES - Disconnect drag link from drop arm and

check steering column and box for

stiffness.

See Repair, Drag Link and

Drag Link Ends

3.Is the steering stiff with the drag link

disconnected?

NO - Check steering ball joints for seizure and

axle swivels lubrication and resistance.

See Repair, Drag Link and Drag Link

Ends See FRONT AXLE AND FINAL

DRIVE, Overhaul, Front Stub Axle,

Constant Velocity Joint and Swivel Pin

Housing Non ABS See FRONT AXLE

AND FINAL DRIVE, Overhaul, Front

Stub Axle, Constant Velocity Joint and

Swivel Pin Housing ABS

YES - Disconnect the lower steering shaft and

check the column and box for stiffness.

See Repair, Lower Steering Shaft and

Universal Joints

4.Is the steering column stiff to turn when

disconnected from the box?

NO - Remove and overhaul box.

See

Overhaul, Power Steering Box

YES - Adjust steering column.See Stiff

Steering Checklist

Page 531 of 873

STEERING

5

FAULT DIAGNOSIS Symptom :-

Steering excessively light/sensitive. Excessive

freeplay at steering wheel.

1.Are steering box adjustments correct?

NO -

See Adjustment, Power Steering Box

WARNING: Adjustments of steering box

should not be required while in warranty

period. If box is within warranty, it must be

returned to manufacturer. No attempt must be

made to introduce backlash.

YES - Suspect worn panhard rod or radius arm

bushes Check condition of ball joints and

the lower steering column shaft universal

joints for wear.

See Repair, Lower

Steering Shaft and Universal Joints

Symptom :-

Steering vibration, road wheel shimmy - wobble.

Vibration through the steering linkage powerful

enough to induce high frequency oscillation of the

steering wheel, is generally caused by out of balance

road wheels. However there are a number of other

possible causes of this symptom which if severe, may

be described as shimmy or wobble. Regardless of the

terminology used by the owner/driver to describe the

symptoms, the following diagnostic checks should be

carried out in the order presented.

1.Check the tyres and balance of the road wheels.

See GENERAL SPECIFICATION DATA,

Information, Wheels and Tyres See

WHEELS AND TYRES, Fault diagnosis, Fault

- Symptoms See WHEELS AND TYRES,

Repair, Wheel Balancing

2.Check the steering hydraulic damper function.

See Steering Damper

3.Check steering column universal joints for wear

and correct alignment.

See Repair, Lower

Steering Shaft and Universal Joints

4.Check steering linkage ball joints for wear,

correct alignment and security, including steering

box and tie rod.

See Steering Linkage Inspect

5.Check all front suspension rubbers for wear.

Check all fixing torques, including radius arm

bushes, panhard rod and anti-roll [sway] bar.

See FRONT SUSPENSION, Repair, Panhard

Rod See FRONT SUSPENSION, Repair,

Radius Arm See FRONT SUSPENSION,

Repair, Anti-Roll[Sway] Bar Assembly See

FRONT SUSPENSION, Repair, Front Shock

Absorber

6.Fit new radius arm bushes using NTC 6860. Fit

harmonic damper if vehicle has air suspension.

Fit new nuts, bolts and washers.

7. Coil spring vehicles only- If problem persists

fit damper kit STC 241 (2 off front) and STC

1474 (2 off rear). Road test vehicle.

8.Check the power steering box adjustments and

operation.

See Overhaul, Power Steering Box

9.Check the hub bearing end floats and determine

the condition of the hub bearings. As applicable.

See FRONT AXLE AND FINAL DRIVE, Repair,

Front Hub Assembly

10.Check the resistance and condition of the

swivels.

See FRONT AXLE AND FINAL

DRIVE, Description and operation,

Description

If problem is not diagnosed: Repeat

checks starting at 1.

11.Carry out a full steering geometry check.

See

INTRODUCTION, Information, Steering

Page 532 of 873

57STEERING

6

FAULT DIAGNOSIS STEERING STABILITY AND VEER UNDER

BRAKING

Possible cause:

Incorrectly set, swivel pin bearing preload. There are

three different settings for these bearings dependant

on model year and if fitted with ABS brakes.

Remedy.

1.Establish model year of vehicle.

2.If fitted with or without antilock brakes.

3.Follow instructions to overhaul front stub axle,

constant velocity joint and swivel pin non ABS,

or with ABS as appropriate.

See FRONT AXLE AND FINAL DRIVE,

Overhaul, Front Stub Axle, Constant Velocity

Joint and Swivel Pin Housing Non ABS See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing ABS

1. GENERAL STEERING

1.Carry out visual and safety checks.

See Visual

and Safety Checks

2.Road test vehicle.See Road Test Procedure

3.Is problem resolved?

YES - end

NO - continue

4.Is problem stiff steering?

YES -

See Stiff Steering Checklist

NO- Goto6.

5.Is problem resolved?

YES - end

NO - go to 8.

6.Is problem steering niggle ?

YES - Replace radius arm bushes, arm and

axle.

See FRONT SUSPENSION,

Repair, Radius Arm

NO - go to 8.

7.Is problem resolved?

YES - end

NO - continue.

8.Centralise steering box.

See Adjustment,

Centralise Steering Box

9.Is problem resolved?

YES - end

NO - continue.

10.Check, adjust if necessary, steering geometry.

11.Is problem resolved?

YES - end

NO - continue.

12.Categorise the remaining problems into one or

more of the following descriptions:

See 2. Steering Veer

See 3. Veer Under Braking

See 4. Directional Stability

Page 534 of 873

57STEERING

8

FAULT DIAGNOSIS 4. DIRECTIONAL STABILITY

From 1. GENERAL STEERING:

1.Is directional stability concern when vehicle is

towing?

YES - Check towing/vehicle loading parameters

in Owner's Handbook.

NO - go to 3.

2.Is problem resolved?

YES - end

NO - continue.

3.Check condition of rear trailing link/chassis

bushes.

4.Is problem resolved?

YES - end

NO - continue.

5.Check condition of front and rear shock

absorbers. If in doubt change units in pairs, side

to side.

6.Is problem resolved?

YES - end

NO - continue.

7.Check steering damper.

See Steering Damper

8.Is problem resolved?

YES - end

NO - continue.

9.Check wheel balance

10.Is problem resolved?

YES - end

NO - contact local technical office.POWER STEERING FLUID LEAKS

1.Is fluid level correct?

YES - go to 3.

NO - Refill or drain to correct level. Bleed

system, check for leaks.

See Repair,

Power Steering System - Bleed

2.Is problem resolved?

YES - end

NO - continue.

3.Are hoses or joints leaking? Check on full lock

with engine at 2000 rev/min.

YES - loosen and retorque joints.

NO - go to 6.

4.Does leak remain?

YES - change PAS pipe.

NO - end.

5.Does leak remain?

YES - suspect seal in component. Check and

replace as necessary.

NO - end.

6.Is oil escaping from filler cap?

YES - bleed system.

See Repair, Power

Steering System - Bleed

NO - go to 8.

7.Is oil still escaping from filler cap?

YES - go back to 1.

NO - end.

8.Is oil leaking from PAS pump?

YES - go to 10.

NO - continue.

9.Is oil leaking from PAS box?

YES - go to 10.

NO - end.

10.Clean unit, add tracer dye to system. Retest

11.Is oil still leaking?

YES - establish leak point. Repair or replace

unit as necessary.

NO - end.

Page 537 of 873

STEERING

11

FAULT DIAGNOSIS STIFF STEERING CHECKLIST

NOTE: Having completed visual checks

and steering assessment and confirmed

that vehicle steering load is incorrect carry

out the following procedure in order shown.

Steering wheel 'torque to turn' loads

1.Raise vehicle so both front wheels free.

2.With engine off, centralise steering wheel, and

remove air bag, if fitted or steering wheel pad.

Using torque wrench on column nut, check

torque required to turn the steering wheel one

turn in each direction.

3.Record readings obtained in each direction.

Compare figures obtained with the specified

figures:

Without ABS

4.40 Nm.

With ABS4.65 Nm.

NOTE: If figures are in excess of those

specified carry out steering box tie bar

reset below. If figures are as specified.

See Visual Check and Basic Adjustments

Steering box tie bar reset

1.Loosen the three tie bar fixings one complete

turn.

2.Drive vehicle carefully a short distance (within

the dealership) applying full lock in both

directions in order to settle steering components.

Drive vehicle over speed bumps and include

harsh braking if possible.

WARNING: Do not drive on public

highway.

3.Near end of 2. ensure vehicle is driven in a

straight line on level ground and halted.

4.Tighten panhard rod mounting arm nut,

110 Nm.

5.Tighten the two fixings tie bar to steering box,81

Nm.

6.Recheck steering wheel torque to turn. If torque

reading is still greater than specified, carry out

steering shaft universal joint lubrication.Lower steering shaft universal joint lubrication

1.Check lower steering shaft is correctly phased.

See Repair, Lower Steering Shaft and

Universal Joints

2.Lubricate universal joints with an anti-seizure

type penetrating spray. Work the joints to ensure

full penetration of the spray by driving vehicle

and steering from lock to lock.

3.If steering stiffness still persists carry out swivel

pin preload setting.

Swivel pin preload setting

The swivel pin preload setting must be checked and

set following the workshop manual procedure.

1.NON ABS vehicles.

See FRONT AXLE AND

FINAL DRIVE, Overhaul, Front Stub Axle,

Constant Velocity Joint and Swivel Pin

Housing Non ABS

Note that a pull load of 1.16 - 1.46 kg is required

after the axle shaft and swivel housing seal have

been removed.

2.ABS vehicles.

See FRONT AXLE AND FINAL

DRIVE, Overhaul, Front Stub Axle, Constant

Velocity Joint and Swivel Pin Housing ABS

Note that a torque to turn of 2.0 - 2.8 Nm is

required after the axle shaft and swivel housing

seal have been removed.

3.If steering stiffness still persists carry out

steering column alignment.

Page 538 of 873

57STEERING

12

FAULT DIAGNOSIS Steering column alignment

1.Place vehicle on level ground. Measure the

angle of lower steering shaft using a Pernumeter

placed on the shaft between the universal joints.

The angle should measure a minimum of 12Ê.

2.If necessary, realign the shaft. Release the five

fixings securing the steering column. Position

column as required. Tighten the fixings evenly,

27 Nm.

3.Loosen the three screws securing lower steering

column shroud to upper shroud ensure lower

shroud is clipped to upper shroud. Reposition

shroud, tighten screws.

4.Recheck steering column angle.

Steering box adjustment

1.Check steering box adjustment.

See

Adjustment, Power Steering Box

Steering damper check

1.Check condition of steering damper

See

Steering Damper

VISUAL CHECK AND BASIC ADJUSTMENTS

NOTE: It is important that the following

instructions are carried out in the

sequence shown and the results recorded.

1.Road springs - check that road springs are

correctly seated and are to correct specification

for vehicle. For spring specification.

See

GENERAL SPECIFICATION DATA,

Information, Road Springs Data

2.Ride height - measure trim height from wheel

centre to wheelarch eyebrow. Record results on

data sheet.

3.Check/top up power steering fluid

See Repair,

Power Steering Fluid Reservoir

4.Check tension and condition of drive belt.See

ENGINE, Repair, Drive Belt

5.Track rod/drag link - check condition of track rod,

drag link and ball joints.

See Repair, Drag Link

and Drag Link Ends

If either component is damaged, check operation

of steering damper and steering box for

smoothness. Replace all damaged or worn

components that impair the operation of the

steering system.

6.Suspension bushes - examine all steering and

suspension bushes for signs of wear and

deterioration. Also check all fixings for torque

relaxation. Tighten to correct torque value.

See

FRONT SUSPENSION, Specifications, torque,

Torque Values

7.Oil leaks - check front and rear axle hubs for

leak and repair as necessary.

8.Brake system - check brake system for leaks,

pipe condition, pad wear/contamination, disc

wear/condition and ABS sensors for correct

fitting.

9.Hub end float - check movement in the hubs by

rocking the wheels.

10.Check front wheel alignment. Vehicles displaying

a tendency to veer more than considered

allowable, it is permissible to set the front track

to parallel.

11.Having completed all the above checks and

adjustments, road test vehicle.

See Road Test

Procedure

Attempting to reproduce the symptoms

established earlier. If symptoms still exist refer to

relevant Diagnostic Chart.

Page 559 of 873

STEERING

17

REPAIR 3.Bend back tabs on locking washer and remove

drop arm using extractor LRT-57-012. Loosen

drop arm securing nut, but do not remove before

using extractor.

4.Remove nut, discard locking washer.

Refit

5.Centralise steering box.

See Adjustment,

Centralise Steering Box

6.Fit drop arm, align master splines.

7.Fit a new tab washer and drop arm fixing nut.

Tighten to

176 Nm,bend over tab.

8.Fit drag link. Tighten ball joint nut

40 Nm.

STEERING DAMPER

Service repair no - 57.55.21

Remove

1.Site vehicle on a ramp [hoist].

2.Remove fixings at differential case bracket.

3.Remove fixings at track rod bracket.

4.Remove steering damper.

Refit

5.Reverse removal procedure. 1 to 4.

Page 562 of 873

STEERING

1

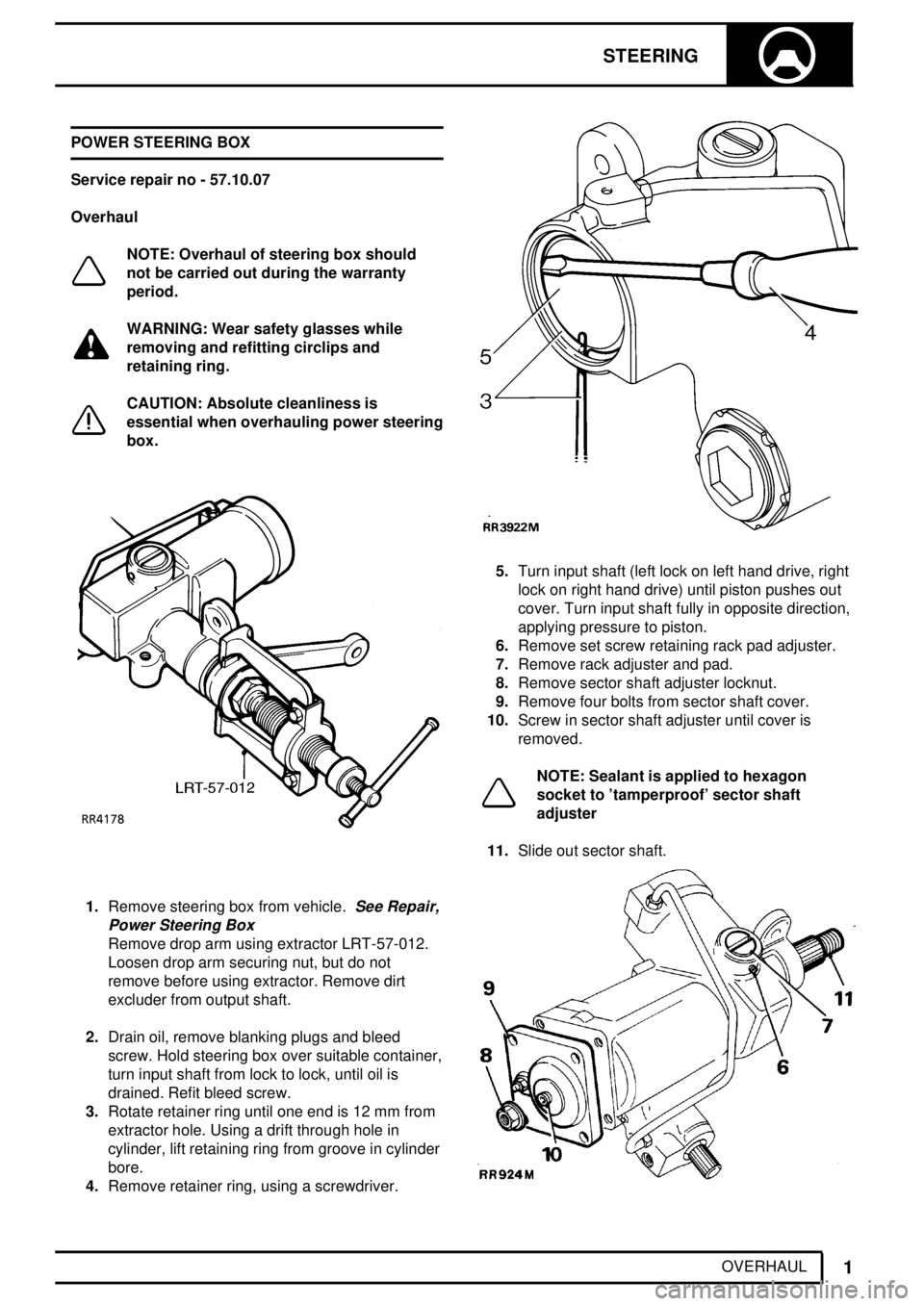

OVERHAUL POWER STEERING BOX

Service repair no - 57.10.07

Overhaul

NOTE: Overhaul of steering box should

not be carried out during the warranty

period.

WARNING: Wear safety glasses while

removing and refitting circlips and

retaining ring.

CAUTION: Absolute cleanliness is

essential when overhauling power steering

box.

1.Remove steering box from vehicle.See Repair,

Power Steering Box

Remove drop arm using extractor LRT-57-012.

Loosen drop arm securing nut, but do not

remove before using extractor. Remove dirt

excluder from output shaft.

2.Drain oil, remove blanking plugs and bleed

screw. Hold steering box over suitable container,

turn input shaft from lock to lock, until oil is

drained. Refit bleed screw.

3.Rotate retainer ring until one end is 12 mm from

extractor hole. Using a drift through hole in

cylinder, lift retaining ring from groove in cylinder

bore.

4.Remove retainer ring, using a screwdriver.

5.Turn input shaft (left lock on left hand drive, right

lock on right hand drive) until piston pushes out

cover. Turn input shaft fully in opposite direction,

applying pressure to piston.

6.Remove set screw retaining rack pad adjuster.

7.Remove rack adjuster and pad.

8.Remove sector shaft adjuster locknut.

9.Remove four bolts from sector shaft cover.

10.Screw in sector shaft adjuster until cover is

removed.

NOTE: Sealant is applied to hexagon

socket to 'tamperproof' sector shaft

adjuster

11.Slide out sector shaft.

Page 566 of 873

STEERING

5

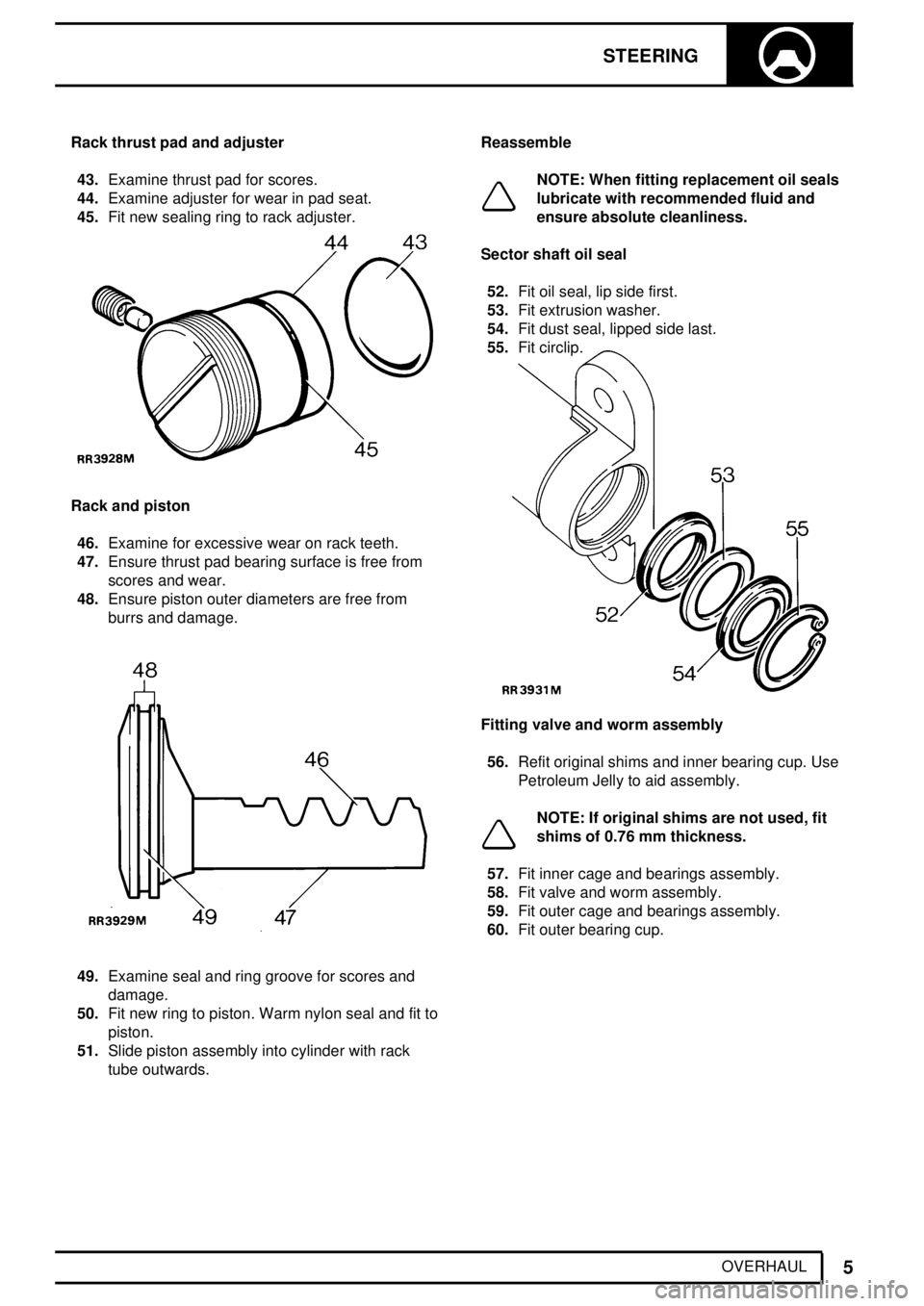

OVERHAUL Rack thrust pad and adjuster

43.Examine thrust pad for scores.

44.Examine adjuster for wear in pad seat.

45.Fit new sealing ring to rack adjuster.

Rack and piston

46.Examine for excessive wear on rack teeth.

47.Ensure thrust pad bearing surface is free from

scores and wear.

48.Ensure piston outer diameters are free from

burrs and damage.

49.Examine seal and ring groove for scores and

damage.

50.Fit new ring to piston. Warm nylon seal and fit to

piston.

51.Slide piston assembly into cylinder with rack

tube outwards.Reassemble

NOTE: When fitting replacement oil seals

lubricate with recommended fluid and

ensure absolute cleanliness.

Sector shaft oil seal

52.Fit oil seal, lip side first.

53.Fit extrusion washer.

54.Fit dust seal, lipped side last.

55.Fit circlip.

Fitting valve and worm assembly

56.Refit original shims and inner bearing cup. Use

Petroleum Jelly to aid assembly.

NOTE: If original shims are not used, fit

shims of 0.76 mm thickness.

57.Fit inner cage and bearings assembly.

58.Fit valve and worm assembly.

59.Fit outer cage and bearings assembly.

60.Fit outer bearing cup.