engine LAND ROVER DISCOVERY 1995 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 110 of 873

12ENGINE

2

DESCRIPTION AND OPERATION

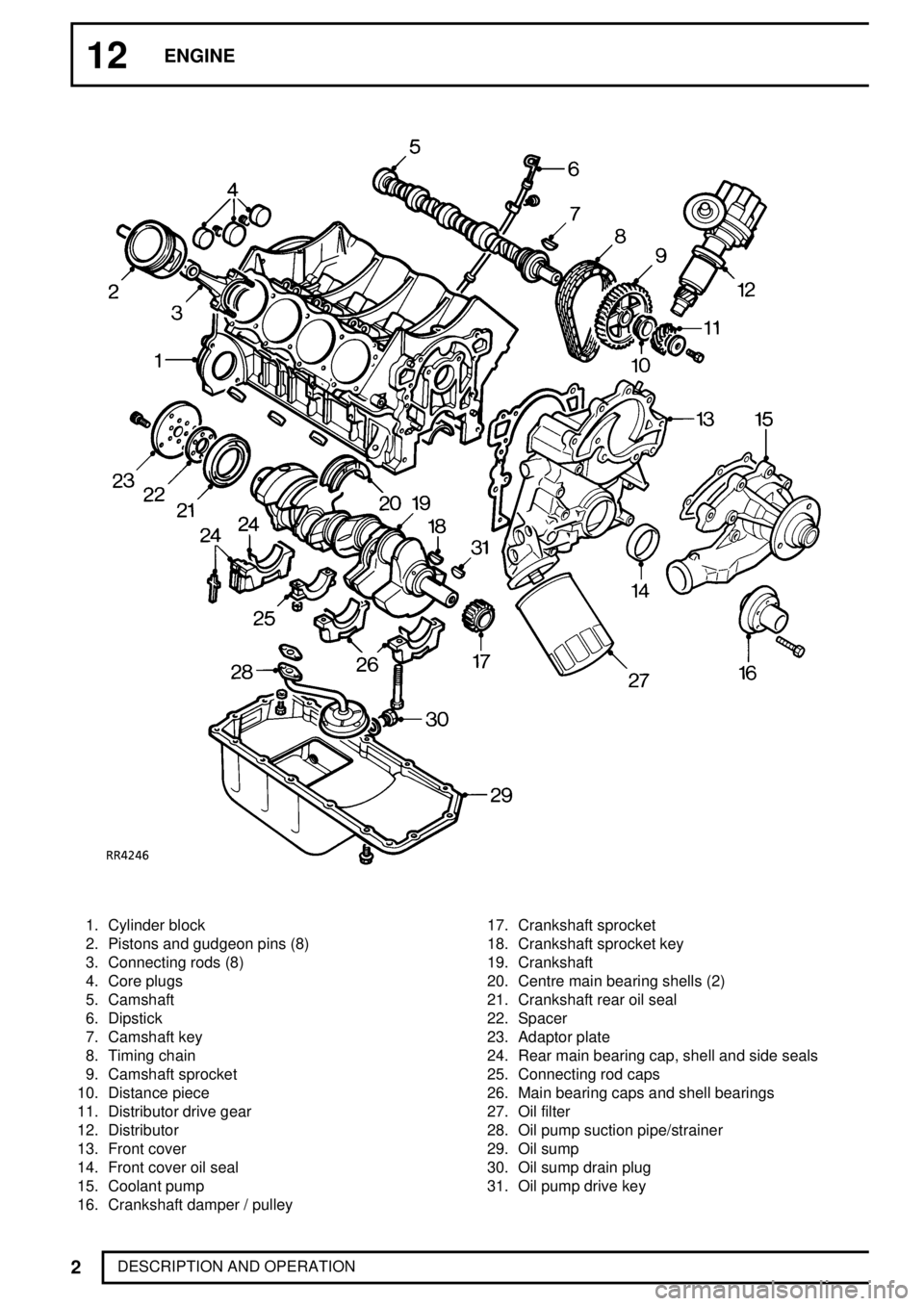

1. Cylinder block

2. Pistons and gudgeon pins (8)

3. Connecting rods (8)

4. Core plugs

5. Camshaft

6. Dipstick

7. Camshaft key

8. Timing chain

9. Camshaft sprocket

10. Distance piece

11. Distributor drive gear

12. Distributor

13. Front cover

14. Front cover oil seal

15. Coolant pump

16. Crankshaft damper / pulley17. Crankshaft sprocket

18. Crankshaft sprocket key

19. Crankshaft

20. Centre main bearing shells (2)

21. Crankshaft rear oil seal

22. Spacer

23. Adaptor plate

24. Rear main bearing cap, shell and side seals

25. Connecting rod caps

26. Main bearing caps and shell bearings

27. Oil filter

28. Oil pump suction pipe/strainer

29. Oil sump

30. Oil sump drain plug

31. Oil pump drive key

Page 112 of 873

12ENGINE

4

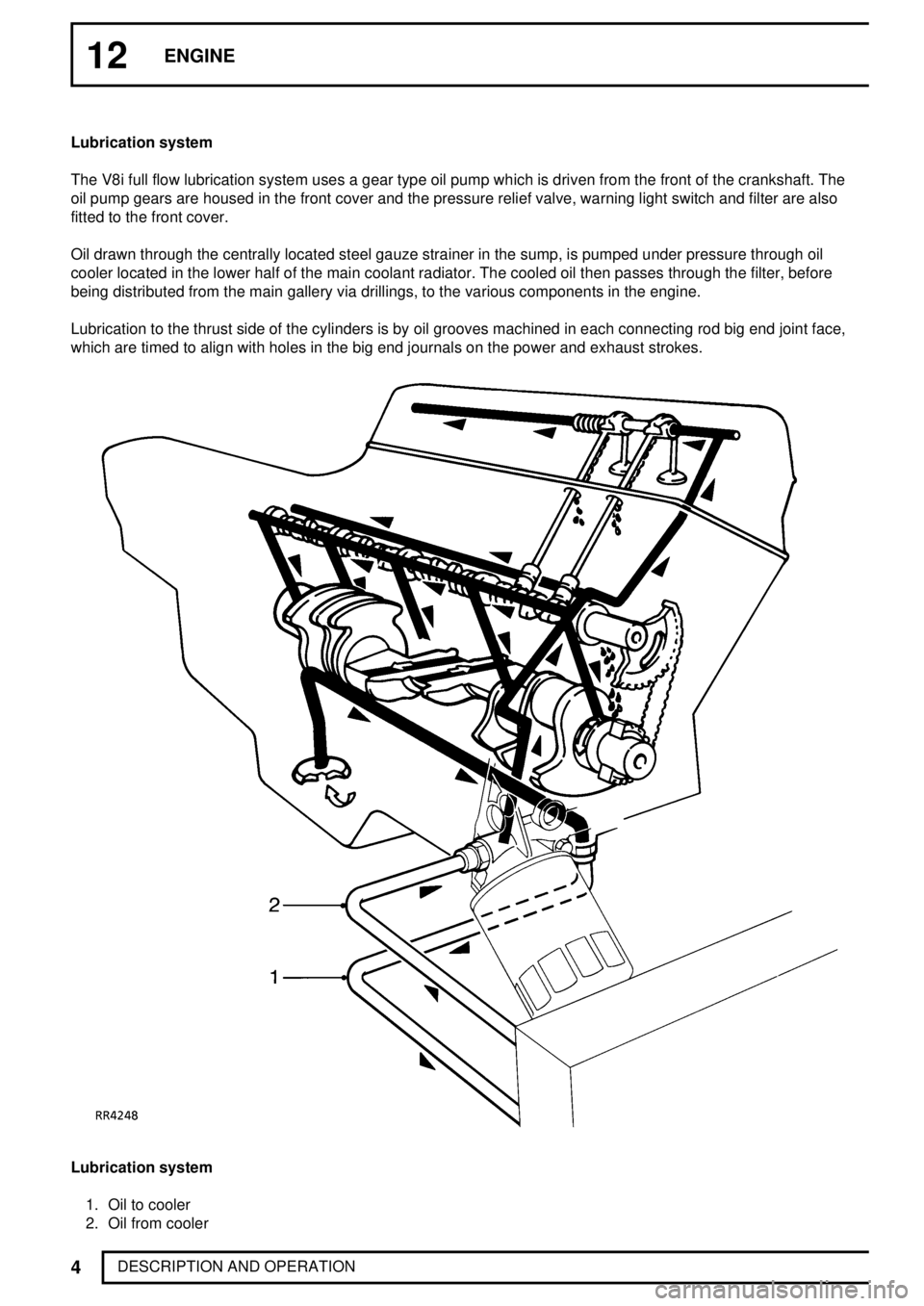

DESCRIPTION AND OPERATION Lubrication system

The V8i full flow lubrication system uses a gear type oil pump which is driven from the front of the crankshaft. The

oil pump gears are housed in the front cover and the pressure relief valve, warning light switch and filter are also

fitted to the front cover.

Oil drawn through the centrally located steel gauze strainer in the sump, is pumped under pressure through oil

cooler located in the lower half of the main coolant radiator. The cooled oil then passes through the filter, before

being distributed from the main gallery via drillings, to the various components in the engine.

Lubrication to the thrust side of the cylinders is by oil grooves machined in each connecting rod big end joint face,

which are timed to align with holes in the big end journals on the power and exhaust strokes.

Lubrication system

1. Oil to cooler

2. Oil from cooler

Page 113 of 873

V8i

5

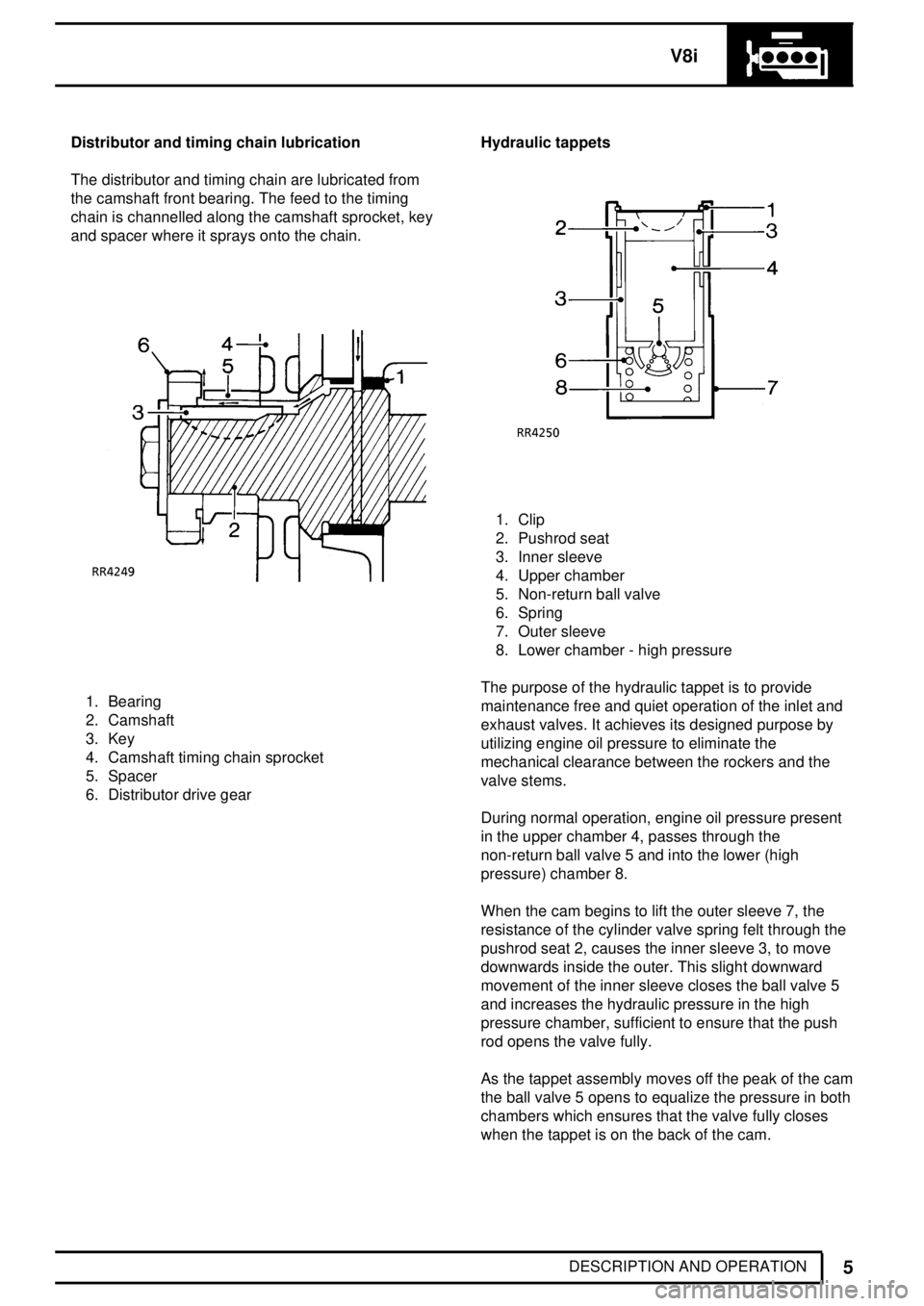

DESCRIPTION AND OPERATION Distributor and timing chain lubrication

The distributor and timing chain are lubricated from

the camshaft front bearing. The feed to the timing

chain is channelled along the camshaft sprocket, key

and spacer where it sprays onto the chain.

1. Bearing

2. Camshaft

3. Key

4. Camshaft timing chain sprocket

5. Spacer

6. Distributor drive gearHydraulic tappets

1. Clip

2. Pushrod seat

3. Inner sleeve

4. Upper chamber

5. Non-return ball valve

6. Spring

7. Outer sleeve

8. Lower chamber - high pressure

The purpose of the hydraulic tappet is to provide

maintenance free and quiet operation of the inlet and

exhaust valves. It achieves its designed purpose by

utilizing engine oil pressure to eliminate the

mechanical clearance between the rockers and the

valve stems.

During normal operation, engine oil pressure present

in the upper chamber 4, passes through the

non-return ball valve 5 and into the lower (high

pressure) chamber 8.

When the cam begins to lift the outer sleeve 7, the

resistance of the cylinder valve spring felt through the

pushrod seat 2, causes the inner sleeve 3, to move

downwards inside the outer. This slight downward

movement of the inner sleeve closes the ball valve 5

and increases the hydraulic pressure in the high

pressure chamber, sufficient to ensure that the push

rod opens the valve fully.

As the tappet assembly moves off the peak of the cam

the ball valve 5 opens to equalize the pressure in both

chambers which ensures that the valve fully closes

when the tappet is on the back of the cam.

Page 114 of 873

V8i

1

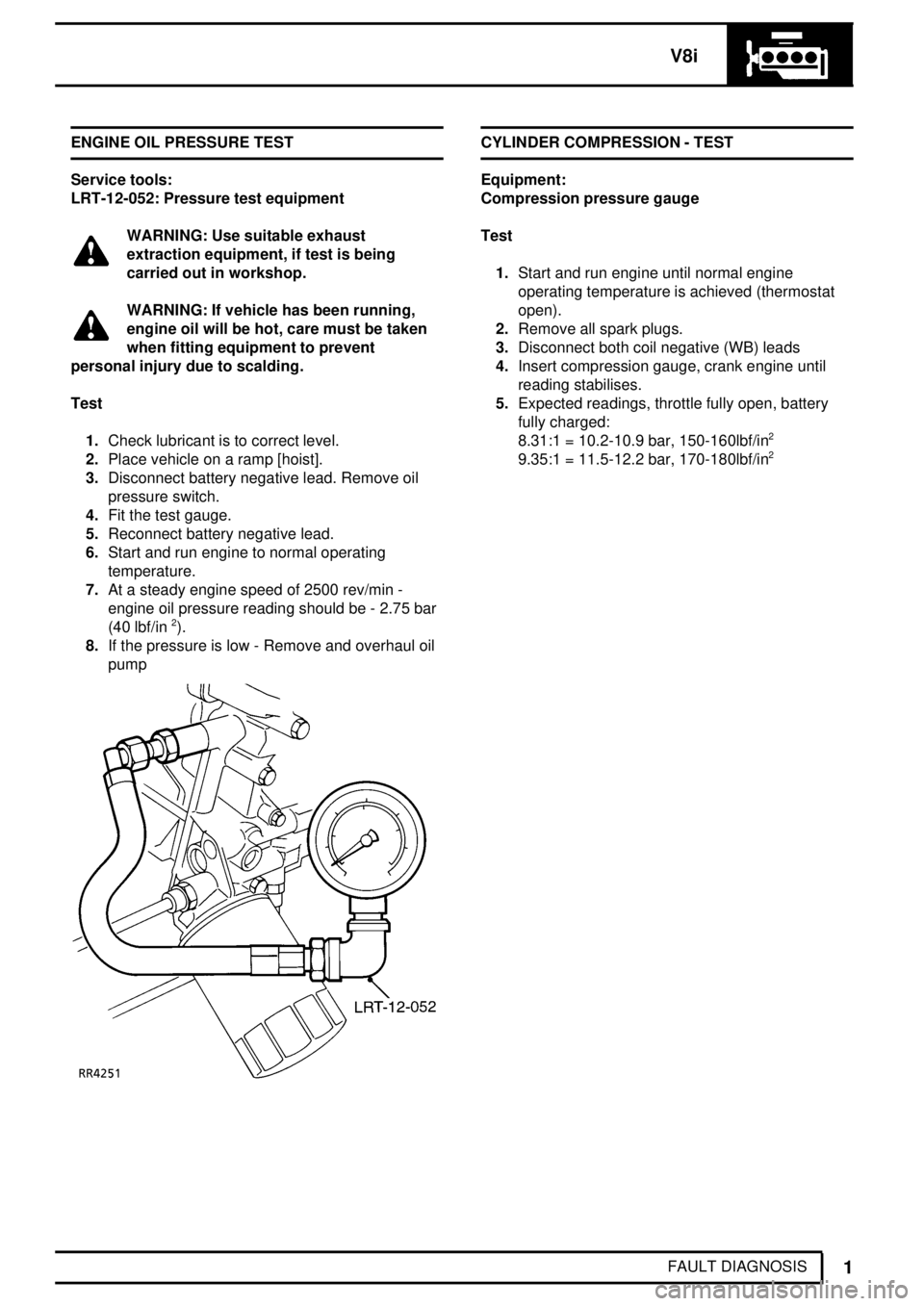

FAULT DIAGNOSIS ENGINE OIL PRESSURE TEST

Service tools:

LRT-12-052: Pressure test equipment

WARNING: Use suitable exhaust

extraction equipment, if test is being

carried out in workshop.

WARNING: If vehicle has been running,

engine oil will be hot, care must be taken

when fitting equipment to prevent

personal injury due to scalding.

Test

1.Check lubricant is to correct level.

2.Place vehicle on a ramp [hoist].

3.Disconnect battery negative lead. Remove oil

pressure switch.

4.Fit the test gauge.

5.Reconnect battery negative lead.

6.Start and run engine to normal operating

temperature.

7.At a steady engine speed of 2500 rev/min -

engine oil pressure reading should be - 2.75 bar

(40 lbf/in

2).

8.If the pressure is low - Remove and overhaul oil

pump

CYLINDER COMPRESSION - TEST

Equipment:

Compression pressure gauge

Test

1.Start and run engine until normal engine

operating temperature is achieved (thermostat

open).

2.Remove all spark plugs.

3.Disconnect both coil negative (WB) leads

4.Insert compression gauge, crank engine until

reading stabilises.

5.Expected readings, throttle fully open, battery

fully charged:

8.31:1 = 10.2-10.9 bar, 150-160lbf/in

2

9.35:1 = 11.5-12.2 bar, 170-180lbf/in2

Page 115 of 873

12ENGINE

2

FAULT DIAGNOSIS ENGINE NOISES

Excessive or obtrusive noise from the engine

compartment originates from three main sources:

A. The exhaust system, which makes an

unmistakable and easy to diagnose noise.

B. External components emit the greatest variety of

noises, but are also easy to diagnose by simply

removing the drive belt.

C. Engine internal mechanical noises which can

vary in volume and pitch and may be a

combination of, tapping - knocking or rumbling,

are the most difficult to diagnose. The following

is therefore a guide to diagnosis of engine

internal mechanical noises only.

Engine internal mechanical noises.

Single or multiple, light tapping noise, particularly

when engine is cold.

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Suspect valve operating mechanism.

3.To confirm diagnosis, remove the rocker covers

and with the engine idling, insert a feeler gauge

of 0,015mm between each rocker and valve

stem. A faulty valve operating mechanism will

emit a different noise when the feeler gauge is

inserted.

See Repair, Rocker Shaft Renew

Heavy knocking noise (particularly on load and

when engine is hot).

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty big end bearings. To

confirm diagnosis, short out the ignition to

each spark plug in turn. The noise will

disappear or be reduced when the

cylinder with the faulty big end is shorted

out.

4.If noise is not conclusively diagnosed, check the

security of the flywheel and crankshaft front

pulley. Temporarily release the drive belt to

reduce general noise level and use a

stethoscope to locate source of noise.

Heavy rumbling noise (particularly during hard

acceleration).

See Description and operation,

Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty main bearings. If noise is

not conclusively diagnosed, check the

security of the flywheel and crankshaft

front pulley. Temporarily release the drive

belt to reduce general noise level and use

a stethoscope to locate source of noise.

Page 116 of 873

V8i

3

FAULT DIAGNOSIS ENGINE STARTING PROBLEMS

Engine fails to crank in park or neutral (Automatic

Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES - Continue.

2.Is automatic transmission inhibitor switch faulty

or gear selection linkage incorrectly adjusted?

YES -

See AUTOMATIC GEARBOX, Repair,

Inhibitor Switch

,

NO -

See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine fails to crank (Manual Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES -See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine cranks but fails to start

1.Is the cranking speed fast enough (120 rpm)?

NO -

See INTRODUCTION, Information,

Jump Starting

If necessary also.See Electrical Trouble

Shooting Manual.

YES - Continue.

2.Is there combustion in any cylinder?

NO -

See ELECTRICAL, Fault diagnosis,

Lucas Constant Energy Ignition

System - V8i See Electrical Trouble

Shooting Manual.

YES - Continue.

3.Are the fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission control

If problem is not diagnosed repeat tests, starting

at 2.ENGINE RUNNING PROBLEMS

Engine runs at high speed but will not idle (stops)

Engine idle speed erratic Engine starts but stops

immediately

Engine stalls Engine misfires/hesitation

1.Multiport fuel injection.

See Electrical Trouble

Shooting Manual. See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy Ignition

System - V8i

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

If problem is not diagnosed continue.

2.Are HT leads correctly routed and clipped?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission Control

If problem is not diagnosed repeat tests, starting

at 1.

Engine lacks power/poor performance

1.Is throttle travel restricted or cable incorrectly

adjusted?

YES - Check thickness of carpets.

See FUEL

SYSTEM, Repair, Throttle Cable See

FUEL SYSTEM, Repair, Accelerator

Pedal

NO - Continue.

2.Are the Ignition and Multiport Fuel Injection

systems in order?

NO -

See Electrical Trouble Shooting

Manual.A1 See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy

Ignition System - V8i See

ELECTRICAL, Repair, Distributor - V8i

YES - Continue.

Page 117 of 873

12ENGINE

4

FAULT DIAGNOSIS 3.Are fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit

YES - Suspect valves held open by hydraulic

tappets due to high oil pressure.

See

Engine Oil Pressure Test

4.Is oil pressure high?

YES - Remove oil filter and cooler adaptor and

check pressure relief valve strainer gauze

for blockage and that the relief valve is

not stuck closed.

See Description and

operation, Description

NO - Carry out cylinder compression tests to

determine condition of head gaskets and

valves.

See Cylinder Compression -

Test

5.Are cylinder compressions satisfactory?

NO -

See Repair, Cylinder Heads - Renew

YES - Check brake vacuum connections.See

BRAKES, Description and operation,

Brake Servo Unit

Check heater/ventilation unit vacuum connections.

See HEATING AND VENTILATION, Description and

operation, Heating and Ventilation Unit

If problem is not diagnosed: Continue.

6.Are the brakes binding?

YES - Investigate cause of binding.

NO - Continue.

7.Automatic Transmission only. Is the Torque

Converter and Transmission operating correctly?

Carry out Road test, Static tests and Stall tests

to determine condition of Automatic

transmission.

If problem is not diagnosed: repeat tests starting at 1.Engine backfires into exhaust system

1.Are there any leaking joints/connections or holes

in the exhaust system?

YES -

See MANIFOLD AND EXHAUST

SYSTEM, Repair, Exhaust System

Complete

NO - Continue.

2.Is distributor fitted correctly, HT leads in correct

firing order and routed correctly?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is air fuel ratio correct?

NO - Check multiport fuel injection.

See

Electrical Trouble Shooting Manual.

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

Check the crank case and fuel tank ventilation

system.

See EMISSION CONTROL,

Description and operation, Emission Control

YES - Continue.

4.Are cylinder compressions satisfactory?

NO - Carry out compression test to check for

leaking gaskets valves etc.

See

Cylinder Compression - Test

See Repair, Cylinder Heads - Renew

If problem is not diagnosed: repeat tests starting

at 1.

Page 118 of 873

V8i

5

FAULT DIAGNOSIS Engine backfires into inlet system

1.Is the Distributor, HT connections and routing

correct?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

2.Is air fuel ratio correct?

NO - Check multiport fuel injection.

See

Electrical Trouble Shooting Manual.

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

Check the crank case and fuel tank ventilation

system.

See EMISSION CONTROL,

Description and operation, Emission Control

YES - Continue.

3.Are cylinder compressions satisfactory?

NO - Carry out compression test to check for

leaking gaskets valves etc.

See

Cylinder Compression - Test

For repairSee Repair, Cylinder Heads -

Renew

If problem is not diagnosed: repeat tests starting

at 1.

Page 120 of 873

12ENGINE

2

REPAIR Remove

1.Remove fan cowl upper.

2.Release drive belt tension by turning tensioner

clockwise.

3.With tension released, remove belt from

generator pulley.

4.Release tensioner pulley.

5.Remove drive belt. Mark direction of rotation on

belt if refitting

Refit

6.Clean drive belt pulley grooves and ensure

grooves are not damaged.

7.Position belt correctly around all pulleys except

generator. Illustrations RR3956 and RR3957

show correct drive belt run.

8.Turn drive belt tensioner clockwise.

9.Locate drive belt on generator pulley.

10.Ensure drive belt is squarely located on pulleys

with all grooves engaged.

11.Release tensioner to tension drive belt.

12.Fit upper fan cowl section.DRIVE BELT - CHECK TENSION

As the drive belt is automatically tensioned, no tension

check or adjustment should be necessary. If the drive

belt is believed to be slack carry out the following

checks:

1.Visually check drive belt tension.

2.Watch movement of tensioner with engine

running, 5 mm 'bounce' is normal. If tensioner

movement is 12 mm or more, fit a new tensioner.

See Drive Belt Tensioner

3.Inspect tensioner. Is the tensioner arm and

spring case in contact? If so fit a new tensioner.

4.Using a recognised drive belt tensioning gauge,

check belt tension several times, running engine

between checks. The checks should be made at

the same point on the belt, away from the

tensioner.

Drive belt tension, with used tensioner and used drive

belt should be more than:-

270N. Non air conditioning or

295N with air conditioning.

Page 122 of 873

12ENGINE

4

REPAIR CYLINDER HEAD GASKETS - RENEW

Service repair no - 12.29.01

1.Drain cooling system.

See COOLING SYSTEM,

Adjustment, Coolant

2.Remove inlet manifold.See FUEL SYSTEM,

Repair, Intake Manifold

3.Remove generator.

4.If fitted, remove compressor.

See AIR

CONDITIONING, Repair, Compressor

5.Remove rocker shafts.See Rocker Shaft

Renew

6.Remove push rods.

7.Remove both exhaust manifolds.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - V8i

8.Remove air cleaner assembly.See FUEL

SYSTEM, Repair, Air Cleaner Assembly

9.Remove air flow sensor.See FUEL SYSTEM,

Repair, Air Flow Sensor

10.Remove ground leads from rear of left hand

cylinder head

11.Right hand cylinder head - remove breather pipe

from lifting bracket.

12.Loosen cylinder head bolts, reversing tightening

sequence.

13.Remove cylinder heads.

14.Remove cylinder head gaskets.

15.Clean exhaust mating faces.

16.Clean head and block faces.

17.Fit new cylinder head gaskets, word TOP

uppermost. DO NOT use sealant.

18.Oil cylinder bores.

19.Clean threads of head bolts and lightly oil.

20.Locate cylinder heads on block.

21.Locate cylinder head bolts in position illustrated.

96 mm long bolts - 2, 4, 6, 7, 8, 9, 10

66 mm long bolts - 1, 3, 5

NOTE: There are no bolts fitted in the four

lower holes in each cylinder head.

NOTE: Left hand cylinder head illustrated,

arrow points to front of vehicle.

22.Tighten bolts progressively in sequence, shown

to

20 Nmthen a further 180°±5°

23.Reverse removal procedure. 1 to 11.