wheel LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 2 of 873

01

04

05

07

09

10

12

17

19

26

30

33

37

41

44

47

51

54

57

60

64

74

70

75

76

80

82

84

86

Workshop manual

DISCOVERY

This manual covers vehicles from

1995 model year

01 INTRODUCTION

04 GENERAL SPECIFICATION DATA

05 ENGINE TUNING DATA

07 GENERAL FITTING REMINDERS

09 LUBRICANTS, FLUIDS AND CAPACITIES

10 MAINTENANCE

12 ENGINE Tdi

12 ENGINE 3.9 V8

12 ENGINE 4.0 V8

12 ENGINE Mpi

17 EMISSION CONTROL

19 FUEL SYSTEM Tdi

19 FUEL SYSTEM MFI

19 FUEL SYSTEM SFI

19 FUEL SYSTEM Mpi

19 CRUISE CONTROL

26 COOLING SYSTEM Tdi

26 COOLING SYSTEM V8

26 COOLING SYSTEM Mpi

30 MANIFOLD AND EXHAUST SYSTEM

33 CLUTCH

37 MANUAL GEARBOX

41 TRANSFER GEARBOX

44 AUTOMATIC GEARBOX

47 PROPELLER SHAFTS

51 REAR AXLE AND FINAL DRIVE

54 FRONT AXLE AND FINAL DRIVE

57 STEERING

60 FRONT SUSPENSION

64 REAR SUSPENSION

70 BRAKES

74 WHEELS AND TYRES

75 SUPPLEMENTARY RESTRAINT SYSTEM

76 CHASSIS AND BODY

80 HEATING AND VENTILATION

82 AIR CONDITIONING

84 WIPERS AND WASHERS

86 ELECTRICAL

Published by Rover Technical Communication

Ó1996 Rover Group Limited

Publication Part No. LRL 0079 ENG (2nd Edition)

Page 6 of 873

01INTRODUCTION

4

INFORMATION ACCESSORIES AND CONVERSIONS

DO NOT FITunapproved accessories or conversions,

as they could affect the safety of the vehicle.

Land Rover will not accept liability for death, personal

injury, or damage to property which may occur as a

direct result of the fitting of non-approved conversions

to the vehicle.

WHEELS AND TYRES

WARNING: DO NOT replace the road

wheels with any type other than genuine

Land Rover wheels which are designed for

multi-purpose on and off road use and have very

important relationships with the proper operation

of the suspension system and vehicle handling.

Replacement tyres must be of the make and sizes

recommended for the vehicle, and all tyres must

be the same make, ply rating and tread pattern.

STEAM CLEANING

To prevent consequential rusting, any steam cleaning

within the engine bayMUSTbe followed by careful

re-waxing of the metallic components affected.

Particular attention must be given to the steering

column, engine water pipes, hose clips and ignition

coil clamp.

SPECIFICATION

The specification details and instructions set out in

this Manual apply only to a range of vehicles and not

to any one. For the specification of a particular vehicle

purchasers should consult their Dealer

The Manufacturer reserve the right to vary their

specifications with or without notice, and at such times

and in such manner as they think fit. Major as well as

minor changes may be involved in accordance with

the Manufacturer's policy of constant product

improvement.

Whilst every effort is made to ensure the accuracy of

the particulars contained in this Manual, neither the

Manufacturer or Dealer, by whom this Manual is

supplied, shall in any circumstances be held liable for

any inaccuracy or the consequences thereof.SPECIAL SERVICE TOOLS

The use of approved special service tools is

important. They are essential if service operations are

to be carried out efficiently, and safely. Where special

tools are specified,only these tools should be used

to avoid the possibility of personal injury or

damage to the components.Also the amount of time

which they save can be considerable.

Every special tool is designed with the close

co-operation of Land Rover, and no tool is put into

production which has not been tested and approved

by us. New tools are only introduced where an

operation cannot be satisfactorily carried out using

existing tools or standard equipment. The user is

therefore assured that the tool is necessary and that it

will perform accurately, efficiently and safely.

Special tools bulletins will be issued periodically giving

details of new tools as they are introduced.

All orders and enquiries from the United Kingdom

should be sent direct to V. L. Churchill. Overseas

orders should be placed with the local V. L. Churchill

distributor, where one exists. Countries where there is

no distributor may order direct from:

V. L. Churchill Limited,

PO Box 3,

Daventry, Northants,

England, NN11 4NF.

The tools recommended in this Workshop Manual are

listed in a multi-language illustrated catalogue,

obtainable from:

Messers. V. L. Churchill at the above address,

or from:

Land Rover Merchandising Service,

PO Box 534,

Erdington,

Birmingham, B24 0Q5,

COPYRIGHT

ÓLand Rover 1996

All rights reserved. No part of this publication may be

produced, stored in a retrieval system or transmitted

in any form, electronic, mechanical, recording or other

means without prior written permission of Land Rover.

Page 7 of 873

INTRODUCTION

5

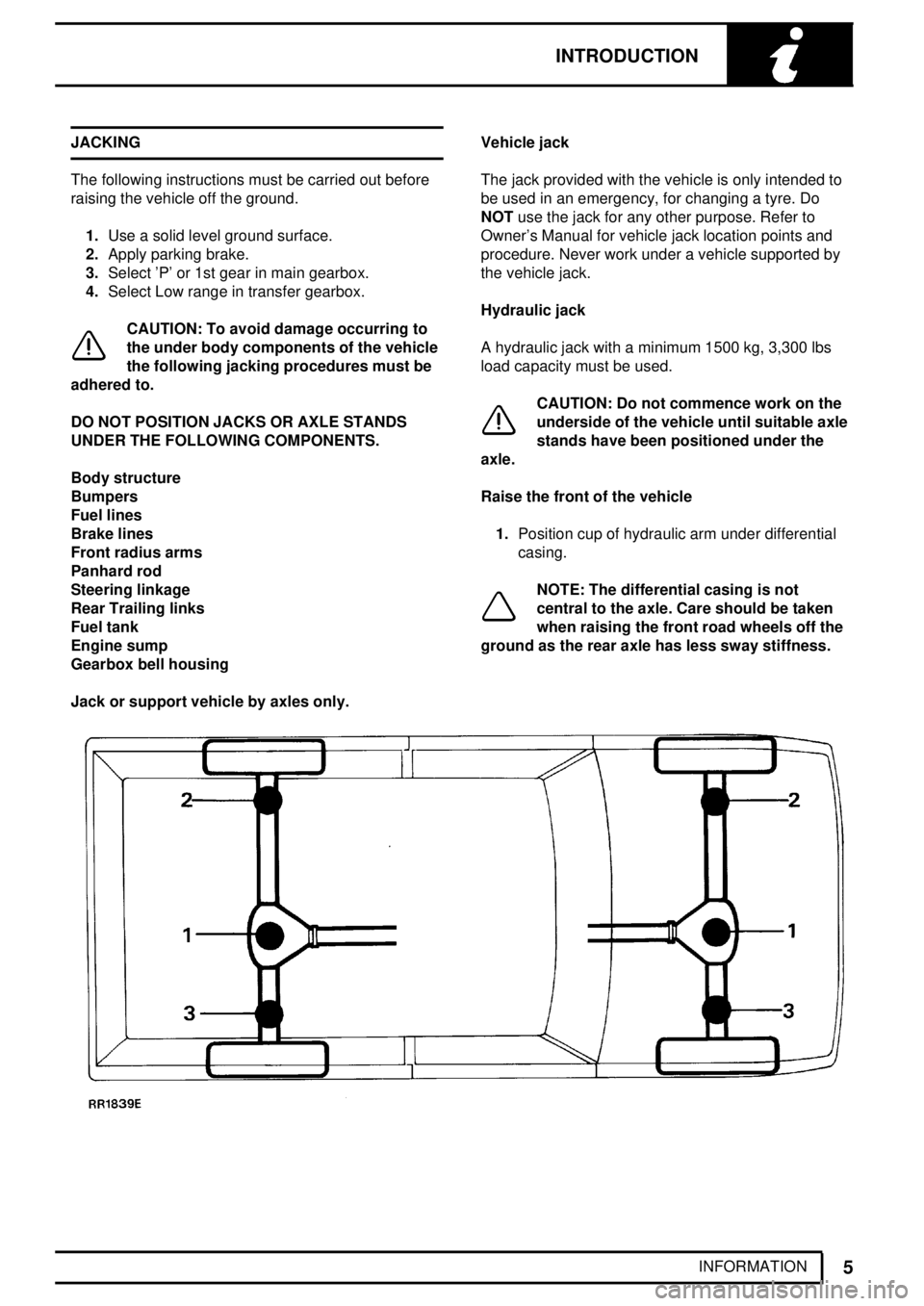

INFORMATION JACKING

The following instructions must be carried out before

raising the vehicle off the ground.

1.Use a solid level ground surface.

2.Apply parking brake.

3.Select 'P' or 1st gear in main gearbox.

4.Select Low range in transfer gearbox.

CAUTION: To avoid damage occurring to

the under body components of the vehicle

the following jacking procedures must be

adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS.

Body structure

Bumpers

Fuel lines

Brake lines

Front radius arms

Panhard rod

Steering linkage

Rear Trailing links

Fuel tank

Engine sump

Gearbox bell housing

Jack or support vehicle by axles only.Vehicle jack

The jack provided with the vehicle is only intended to

be used in an emergency, for changing a tyre. Do

NOTuse the jack for any other purpose. Refer to

Owner's Manual for vehicle jack location points and

procedure. Never work under a vehicle supported by

the vehicle jack.

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used.

CAUTION: Do not commence work on the

underside of the vehicle until suitable axle

stands have been positioned under the

axle.

Raise the front of the vehicle

1.Position cup of hydraulic arm under differential

casing.

NOTE: The differential casing is not

central to the axle. Care should be taken

when raising the front road wheels off the

ground as the rear axle has less sway stiffness.

Page 8 of 873

01INTRODUCTION

6

INFORMATION 2.Raise front road wheels to enable an axle stand

to be installed under left hand axle tube.

3.Position an axle stand under right hand axle

tube, carefully lower jack until axle sits securely

on both axle stands, remove trolley jack.

4.Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5.Reverse procedure when removing vehicle from

stands.

Raise rear of vehicle

1.Position cup of hydraulic arm under differential

casing.

2.Raise vehicle to enable axle stands to be

installed under left and right hand axle tubes.

3.Lower jack until axle sits securely on axle

stands, remove trolley jack.

4.Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5.Reverse procedure when removing vehicle from

stands.

HYDRAULIC VEHICLE RAMP (FOUR POST)

Use only a 'drive on' type ramp which supports vehicle

by its own road wheels. If a 'wheel-free' condition is

required, use a 'drive on' ramp incorporating a

'wheel-free' system that supports under axle casings.

Alternatively, place vehicle on a firm, flat floor and

support on axle stands.

TWO POST VEHICLE RAMPS

The manufacturer of LAND ROVER VEHICLES

DOES NOT recommend using 'Two Post' ramps

that employ four adjustable support arms. These

are NOT considered safe for Land Rover vehicles.

If vehicle is installed on a Two Post ramp

responsibility for safety of vehicle and personnel

performing service operations is in the hands of

the Service Provider.DYNAMOMETER TESTING - NON ANTI-LOCK

BRAKE VEHICLES

Viscous coupling

The front and rear axles cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively locking the centre differential

automatically if slip occurs at any wheel.

WARNING: DO NOT attempt to drive

individual wheels with vehicle supported

on floor jacks or stands.

Four wheel dynamometers

Provided that front and rear dynamometer rollers are

rotating at identical speeds and that normal workshop

safety standards are applied, there is no speed

restriction during testing except any that may apply to

the tyres.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

If brake testing on a single axle rig is necessary it

must be carried out with propeller shaft to rear axle

removed, AND neutral selected in BOTH main

gearbox and transfer gearbox. When checking brakes,

run engine at idle speed to maintain servo vacuum.

If checking engine performance, the transfer box must

be in high range and propeller shaft to stationary axle

must be removed.

Page 9 of 873

INTRODUCTION

7

INFORMATION DYNAMOMETER TESTING - VEHICLES WITH

ANTI-LOCK BRAKES (ABS)

WARNING: Do not attempt to test ABS

function on a dynamometer

Four wheel dynamometers

NOTE: Before testing a vehicle on a four

wheel dynamometer disconnect the valve

relay.

See Electrical Trouble Shooting

Manual.

The ABS function will not work, the ABS warning

light will illuminate. Normal braking will be

available.

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing except any that may apply to the tyres.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

NOTE: ABS will not function on a two

wheel dynamometer. The ABS light will

illuminate during testing. Normal braking

will be available.

If brake testing on a single rig is necessary it must be

carried out with propeller shaft to the rear axle

removed, AND neutral selected in BOTH main and

transfer boxes.

If checking engine performance, the transfer box must

be in high range and drive shaft to stationary axle

removed.

TOWING

CAUTION: The vehicle has permanent

four-wheel drive. The following towing

instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes.

1.Turn ignition key turn to position '1' to release

steering lock.

2.Select neutral in main gearbox and transfer

gearbox.

3.Secure tow rope, chain or cable to towing eye.

4.Release the parking brake.

CAUTION: The brake servo and power

assisted steering system will not be

functional without the engine running.

Greater pedal pressure will be required to apply

the brakes, the steering system will require

greater effort to turn the front road wheels.

The vehicle tow connection should be used only

in normal road conditions, 'snatch' recovery

should be avoided.

Suspended tow by breakdown vehicle

CAUTION: To prevent vehicle damage,

front or rear propeller shaft MUST BE

removed, dependent upon which axle is

being trailed.

1.Mark propeller shaft drive flanges at transfer

gearbox and axles with identification lines to

enable the propeller shaft to be refitted in its

original position.

2.Remove the propeller shaft fixings, remove the

shaft from the vehicle.

3.If the front axle is to be trailed turn ignition key to

position '1' to release steering lock.

CAUTION: The steering wheel and/or

linkage must be secured in a straight

ahead position. DO NOT use the steering

lock mechanism for this purpose.

Page 14 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 01INTRODUCTION

12

INFORMATION VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are stamped

on a plate located under the bonnet [hood] r LAND ROVER DISCOVERY 1995 Workshop Manual 01INTRODUCTION

12

INFORMATION VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are stamped

on a plate located under the bonnet [hood] r](/img/64/57248/w960_57248-13.png)

01INTRODUCTION

12

INFORMATION VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are stamped

on a plate located under the bonnet [hood] riveted to

the front of the engine compartment.

Vehicle Identification Number Plate (UK, Australia,

R.O.W., Europe)

A.Build date (Australia). Type approval

B.VIN (17 digits)

C.Maximum permitted laden weight for vehicle

D.Maximum vehicle and trailer weight

E.Maximum road weight-front axle

F.Maximum road weight-rear axle

The number is also stamped on the right side of the

chassis forward of the spring mounting turret.

Vehicle Identification Number Plate (Saudi Arabia)

A.Year of manufacture

B.Month of manufacture

C.Maximum vehicle weight

D.Maximum road weight-front axle

E.Maximum road weight-rear axle

F.VIN (17 digits)

The vehicle identification number identifies the

manufacturer, model range, wheel base, body type,

engine, steering, transmission, model year and place

of manufacture. The following example shows the

coding process.

SALWorld manufacturer identifier

LHRange Rover or

LJDiscovery

GClass 100 inch

B2 door

F300 Tdi or

VV8i Petrol

85 speed LHD or

75 speed RHD

M1995 MY

ASolihull site

Page 15 of 873

INTRODUCTION

13

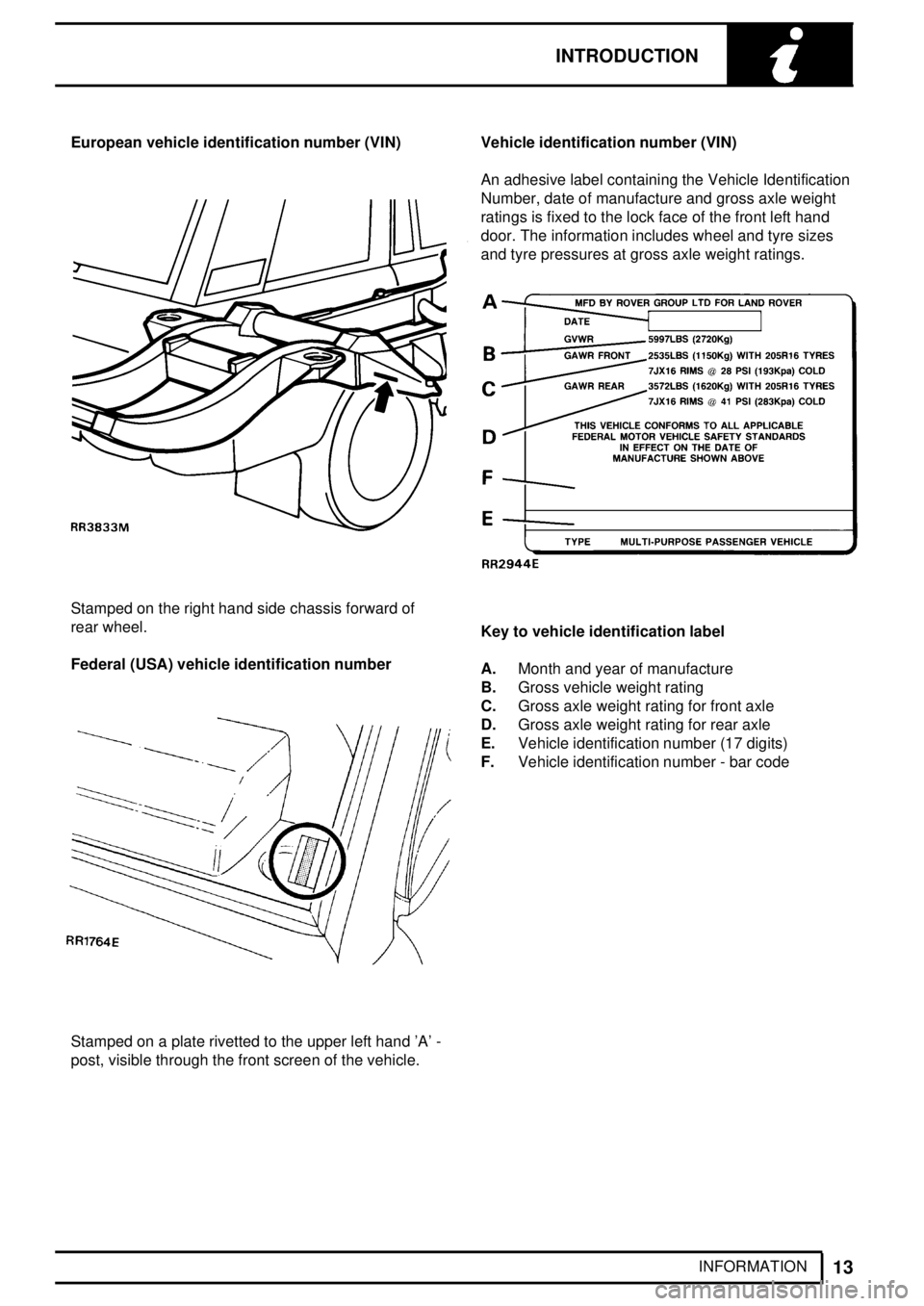

INFORMATION European vehicle identification number (VIN)

Stamped on the right hand side chassis forward of

rear wheel.

Federal (USA) vehicle identification number

Stamped on a plate rivetted to the upper left hand 'A' -

post, visible through the front screen of the vehicle.Vehicle identification number (VIN)

An adhesive label containing the Vehicle Identification

Number, date of manufacture and gross axle weight

ratings is fixed to the lock face of the front left hand

door. The information includes wheel and tyre sizes

and tyre pressures at gross axle weight ratings.

Key to vehicle identification label

A.Month and year of manufacture

B.Gross vehicle weight rating

C.Gross axle weight rating for front axle

D.Gross axle weight rating for rear axle

E.Vehicle identification number (17 digits)

F.Vehicle identification number - bar code

Page 28 of 873

04GENERAL SPECIFICATION DATA

10

INFORMATION COOLING SYSTEM 3.9 V8i

System type Pressurised, spill return, thermostatically controlled.....................................................................

water and anti-freeze mixture. Pump assisted thermo

syphon. Coolant radiator combined with oil cooler.

Fan and viscous coupling assembly 11 blade axial flow 433mm diameter.................................

Pump type Centifugal, impellor, belt driven.........................................................................

Thermostat opening 88 degrees..........................................................

Expansion tank cap pressure 15 p.s.i. (system pressure)............................................

STEERING

Power steering box

Make/type Adwest Varamatic - worm and roller box........................................................................

Ratio Variable: straight ahead 19.3:1 on lock 14.3:1.................................................................................

Steering wheel turns, lock-to-lock 3.375....................................

Steering pump

Make/type -V8i ZF - Unicorn.................................................................

Make/type - Mpi & Tdi Hobourn-Eaton series 500......................................................

Steering geometry

Steering wheel diameter 405mm..................................................

Steering wheel diameter airbag model 400mm.............................

Toe-out measurement 0 to 2mm toe out......................................................

Toe-out included angle 0Ê to 0Ê 16'.....................................................

Camber angle 0Ê.................................................................. Check with vehicle in static..............

unladen condition, that is, vehicle

with water,

Castor angle 3Ê..................................................................... oil and five gallons of fuel. Rock..............

the vehicle up and down at the

front to allow

Swivel pin inclination static 7Ê............................................... it to take up a position..............

Page 30 of 873

04GENERAL SPECIFICATION DATA

12

INFORMATION SHOCK ABSORBERS

Type Telescopic, double-acting non-adjustable.................................................................................

Bore diameter 35.47mm...................................................................

BRAKES

Front service brake

Type Outboard discs with four piston calipers.................................................................................

Operation Hydraulic, servo assisted self-adjusting.........................................................................

Pad material non asbestos.....................................................................

Rear service brake

Type Outboard discs with two piston calipers.................................................................................

Operation Hydraulic, servo assisted, self-adjusting.........................................................................

Pad material non asbestos.....................................................................

Parking brake

Type Mechanical-cable operated drum brake on the rear of.................................................................................

the transfer gearbox output shaft

Lining material non asbestos..................................................................

Servo/master cylinder non ABS

Manufacturer Lucas....................................................................

Servo type LSC 115........................................................................

Master cylinder type AS/AS.........................................................

Anti-lock brake system

Manufacturer/type Wabco 4 wheel sensed add on anti-lock brake............................................................

system.

Servo/master cylinder ABS

Manufacturer Lucas....................................................................

Master cylinder type CV/CV.........................................................

Page 35 of 873

GENERAL SPECIFICATION DATA

17

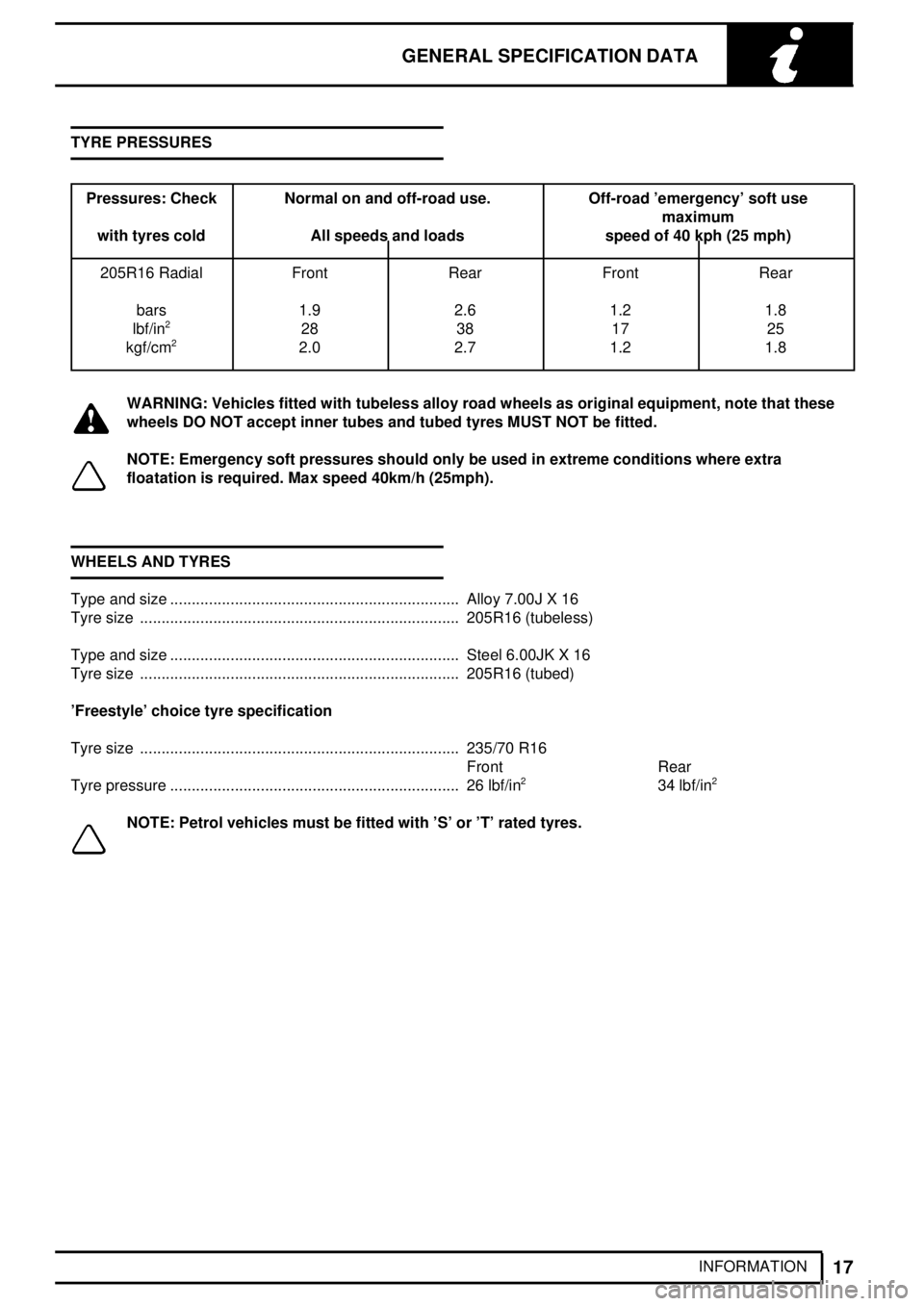

INFORMATION TYRE PRESSURES

Pressures: Check Normal on and off-road use. Off-road 'emergency' soft use

maximum

with tyres cold All speeds and loads speed of 40 kph (25 mph)

205R16 Radial Front Rear Front Rear

bars 1.9 2.6 1.2 1.8

lbf/in

228 38 17 25

kgf/cm22.0 2.7 1.2 1.8

WARNING: Vehicles fitted with tubeless alloy road wheels as original equipment, note that these

wheels DO NOT accept inner tubes and tubed tyres MUST NOT be fitted.

NOTE: Emergency soft pressures should only be used in extreme conditions where extra

floatation is required. Max speed 40km/h (25mph).

WHEELS AND TYRES

Type and size Alloy 7.00J X 16...................................................................

Tyre size 205R16 (tubeless)..........................................................................

Type and size Steel 6.00JK X 16...................................................................

Tyre size 205R16 (tubed)..........................................................................

'Freestyle' choice tyre specification

Tyre size 235/70 R16..........................................................................

Front Rear

Tyre pressure 26 lbf/in

2................................................................... 34 lbf/in2

NOTE: Petrol vehicles must be fitted with 'S' or 'T' rated tyres.