ignition LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 909 of 1529

RESTRAINT SYSTEMS

75-6 DESCRIPTION AND OPERATION

Seat belt pretensioners

The seat belt pretensioners are located within the front seat belt anchors and are controlled by the DCU. They are

pyrotechnic devices that, when deployed, tighten the front seat belts. This works in conjunction with the airbag

module(s) to protect front seat occupants in the event of an accident.

The DCU regularly applies a test current to the seat belt pretensioner squibs to confirm continuity of the ignition

circuitry.

The DCU is capable of detecting a short to ground, a short to battery and an open circuit for the squibs. It will also

identify if the configuration of the DCU differs from that actually fitted to the vehicle.

The DCU also stores the following additional information on each fault:

lA count indicating the number of times the fault has occurred.

lA start time and an end time for the fault to indicate duration of the fault.

Page 911 of 1529

RESTRAINT SYSTEMS

75-8 DESCRIPTION AND OPERATION

Diagnostic and Control Unit (DCU)

The SRS DCU is an electronic single point crash sensor. It is capable of sensing if a crash has taken place. If all the

relevant parameters are met, then the DCU deploys the airbag(s) and seat belt pretensioners.

The DCU is bolted to the transmission tunnel beneath the centre console in the area of the handbrake.

The DCU performs the following functions:

lInternal self test, system monitoring and fault detection.

lSRS warning lamp operation.

lSystem deployment.

Self test, system monitoring and fault detection

The DCU performs a self-test during start-up and then continually during operation of the system. The following

components are tested:

lThe decelerometer.

lThe electromechanical safing sensor.

lThe microprocessor.

lThe continuity of squib ignition circuits.

lThe SRS warning lamp.

If the DCU detects a fault, it stores the fault code in memory. Diagnose the DCU with TestBook. The DCU cannot

be serviced. It must be replaced if it is faulty.

SRS warning lamp operation

The DCU controls the SRS warning lamp contained in the instrument cluster.

System deployment

The DCU determines when the system deploys based on inputs from both the decelerometer and the

electromechanical safing sensor. Both are located within the DCU. Neither are serviceable.

The electromechanical safing sensor uses a magnet and ball bearing system to provide a mechanical confirmation of

vehicle deceleration. The ball bearing is held in place by the magnet. The strength of the magnet is calibrated such

that the force required for the ball bearing to move away from the magnet will only occur if the vehicle decelerates

suddenly, as in an accident.

The SRS deploys only if both the decelerometer reading and the safing sensor operation occur at the same time.

Page 912 of 1529

RESTRAINT SYSTEMS

DESCRIPTION AND OPERATION 75-9

Operation - SRS

The diagnostic and control unit (DCU) controls the SRS system. The DCU is located beneath the centre console close

to the handbrake area. The DCU contains both an electronic deceleration sensor as well as an electromechanical

safing sensor. When the electronic deceleration sensor within the DCU detects rapid deceleration of the vehicle, it

compares the deceleration rate with stored values in its' memory. If the deceleration rate exceeds the stored value

and the electromechanical safing sensor triggers, the DCU deploys the airbag and the seat belt pretensioners. The

DCU will not deploy the airbags and seat belt pretensioners unless both sensors trigger.

The SRS has diagnostic capabilities through TestBook. In the event that a fault is detected, the DCU alerts the driver

by illuminating a warning lamp in the instrument cluster.

The DCU controls the following:

lSRS warning lamp.

lDrivers airbag module.

lPassenger airbag module (where fitted).

lDriver seat belt pretensioner.

lPassenger seat belt pretensioner.

WARNING: The integrity of the SRS system are critical for safety reasons. Ensure the following precautions

are always adhered to:

lNever install used SRS components from another vehicle or attempt to repair an SRS component.

lWhen repairing an SRS system only use genuine new parts.

lNever apply electrical power to an SRS component unless instructed to do so as part of an approved test

procedure.

lSpecial Torx bolts are necessary for installing the airbag module - do not use other bolts. Ensure bolts

are tightened to the correct torque.

lAlways use new fixings when replacing an SRS component.

lEnsure the SRS Diagnostic Control Unit (DCU) is always installed correctly. There must not be any gap

between the DCU and the bracket to which it is mounted. An incorrectly mounted DCU could cause the

system to malfunction.

System deployment

The airbag and seat belt pretensioners deploy to protect the front seat occupants when the DCU senses a rapid

vehicle deceleration. The system deploys when the following conditions are met:

lThe ignition switch is on.

lThe vehicle decelerates beyond a threshold defined within the DCU.

lThe electromechanical safing sensor within the DCU triggers.

When all of the above conditions are met, the DCU deploys the airbag(s) and seat belt pretensioners. If the above

conditions are not met, the DCU will not deploy the system.

Component replacement policy

After an impact which deploys the airbags and pretensioners, the following components must be renewed:

lDCU.

lDriver and passenger airbag modules.

lDriver and passenger buckle pretensioners.

lRotary coupler.

lFlyleads (where applicable) connecting airbags and pre-tensioners to SRS harness

SRS warning lamp

The SRS warning lamp illuminates for 5 seconds during system readiness check on starting the engine. The SRS

warning lamp extinguishes for one second after the system readiness check is performed. If a fault is present the

warning lamp then illuminates continuously. If no fault is present, the SRS warning lamp remains extinguished. If a

system fault occurs in excess of two seconds after the readiness check has been completed, the SRS warning lamp

illuminates for that ignition cycle. It remains illuminated for a minimum of 12 seconds ± 4 seconds for all fault

conditions.

The SRS warning lamp will only illuminate for low voltage concerns while the low voltage condition is present. If the

low voltage condition is corrected, the SRS warning lamp extinguishes and the fault is recorded in the DCU's memory.

Page 1000 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-3

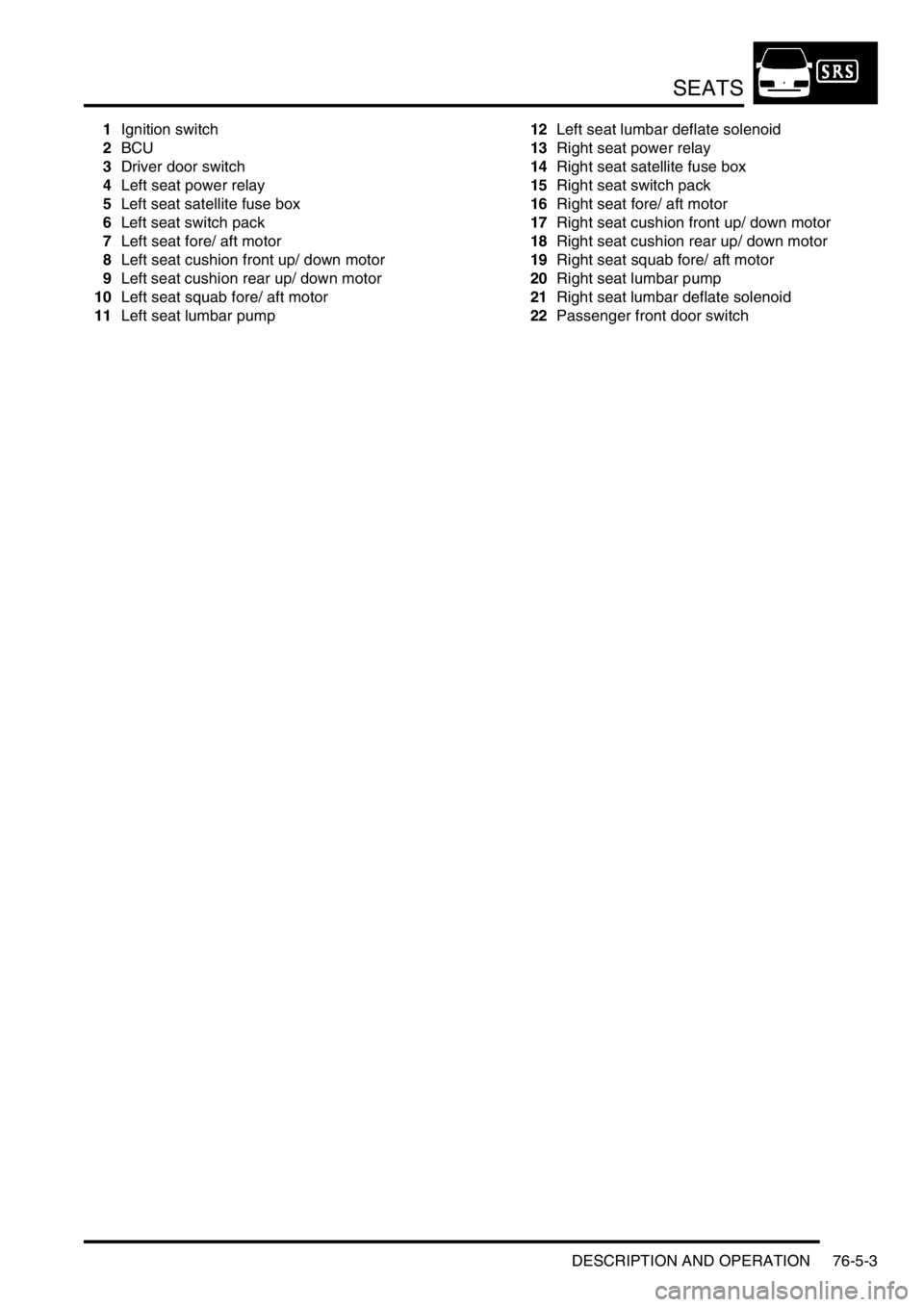

1Ignition switch

2BCU

3Driver door switch

4Left seat power relay

5Left seat satellite fuse box

6Left seat switch pack

7Left seat fore/ aft motor

8Left seat cushion front up/ down motor

9Left seat cushion rear up/ down motor

10Left seat squab fore/ aft motor

11Left seat lumbar pump12Left seat lumbar deflate solenoid

13Right seat power relay

14Right seat satellite fuse box

15Right seat switch pack

16Right seat fore/ aft motor

17Right seat cushion front up/ down motor

18Right seat cushion rear up/ down motor

19Right seat squab fore/ aft motor

20Right seat lumbar pump

21Right seat lumbar deflate solenoid

22Passenger front door switch

Page 1005 of 1529

SEATS

76-5-8 DESCRIPTION AND OPERATION

Operation - electric seats

Seat power relay enable line

The BCU provides the seat power relays with an earth supply to the relay coil that enables the relay operation. When

this seat power relay enable line is active, the seat power relay energises allowing seat operation.

In order for the seat power relay to be active the BCU must detect either of the following condition options:

lIgnition switch in position II.

lIgnition switch in position II or driver's door within 45 seconds of opening.

Seat fore/ aft movement

When the cushion switch is operated and the seat power relay enable line is operating, power and earth are supplied

to the motor in the seat, allowing the seat to move forward or backward depending on switch position. The motor

drives a gear wheel along a gear rack connected to the seat base. Sliding the cushion switch forward causes the motor

to drive the seat forward. Sliding the cushion switch rearward reverses polarity of the voltage at the seat motor, driving

the seat rearward.

Seat cushion front up/ down movement

When the cushion switch is operated and the seat power relay enable line is operating, power and earth are supplied

to the motor in the seat, allowing the front of the seat cushion to move upward or downward depending on switch

position. The motor drives a gear wheel along a gear rack connected to the seat base. Sliding the front of the cushion

switch upward causes the motor to drive the seat upward. Sliding the front of the cushion switch downward reverses

polarity of the voltage at the seat motor driving the seat downward.

Seat cushion rear up/ down movement

When the cushion switch is operated and the seat power relay enable line is operating, power and earth are supplied

to the motor in the seat, allowing the seat to move upwards or downwards depending on switch position. The motor

drives a gear wheel along a gear rack connected to the seat base. Sliding the rear of the cushion switch upward

causes the motor to drive the seat upward. Sliding the rear of the cushion switch downward reverses polarity of the

voltage at the seat motor driving the seat downward.

Squab fore/ aft movement

When the squab switch is operated and the seat power relay enable line is operating, power and earth is supplied to

the motor in the squab, allowing the squab to move forward or backward depending on switch position. The motor

drives a gear wheel along a rotary gear rack connected to the squab. Sliding the squab switch forward causes the

motor to drive the squab forward. Sliding the squab switch rearward reverses polarity of the voltage at the seat motor

driving the squab rearward.

Lumbar inflate/ deflate

Sliding the squab switch upwards when the seat power relay enable line is operating applies voltage to the lumbar

pump. The lumbar pump inflates the lumbar bladder, increasing lumbar support. The lumbar pump and the normally

closed lumbar deflate solenoid hold the air in the bladder. Sliding the squab switch downwards applies voltage to the

deflate solenoid, venting the air in the lumbar bladder to atmosphere, decreasing lumbar support.

Diagnostics

TestBook can only verify that the seat power relay line is enabled. It cannot determine the status of the system or any

of the components.

Page 1008 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-11

Description - heated seats

Heated seats

The heated seat system is available on both manual seats and electric seats. The electrical sub-system consists of

the following components:

lSeat heater switches.

lSeat heater elements.

lTemperature control unit (if electric seats are fitted).

lTemperature sensor (if electric seats are fitted).

lThermostat (if manual seats are fitted).

Seat heater switches

The seat heater switches supply an ignition feed to either the temperature control unit (vehicles with electric seats) or

directly to the seat heater elements (vehicles with manual seats). When a seat heater switch is operated, current flows

to the seat heater elements causing them to heat the seat.

The ignition feed comes from fuse 15 in the passenger compartment fuse box.

Seat heater elements

The seat heater elements are located in the seat cushion and squab. The cushion and squab heater elements are

wired in series. Total power consumption at 13.5 volts is approximately 115 Watts.

The cushion heater element has an input feed from the temperature control unit or heater switch and an output to the

squab heater element, which outputs to earth.

Page 1009 of 1529

SEATS

76-5-12 DESCRIPTION AND OPERATION

Temperature control unit

The temperature control unit is only fitted to vehicles with electric seats. Feed back of the seat temperature is via a

Negative Temperature Coefficient (NTC) sensor within the seat cushion. Resistance of this sensor changes with the

temperature of the seat cushion allowing the temperature control unit to lower or raise the voltage to the seat heater

elements to raise or lower their temperature.

An ignition feed is supplied via the seat heater switch. The temperature sensor supplies an input. Output is a supply

to the cushion heater element and an earth.

Thermostat

On vehicles with non electric seats, the temperature is controlled by a thermostat located in the seat cushion. The

thermostat interrupts the power supply when it reaches a pre-determined temperature.

Page 1037 of 1529

SUNROOF

76-6-6 DESCRIPTION AND OPERATION

Front sunroof switch

The front sunroof switch is located in the roof console above the windscreen in front of the front sunroof. It controls

the front sunroof motor via the sunroof ECU.

The front sunroof switch supplies an earth signal to the sunroof ECU. The pin at the ECU that receives the earth

signal determines whether ECU causes the sunroof to open or close.

TestBook cannot monitor the state of the front sunroof switch.

The following table lists the values which can be measured at the listed ECU pins when the conditions outlined are

met:

Signal values (connector connected)

Connector/Pin

No.Condition Resistance, ohms

C0784-2 Ignition in position II, front sunroof switch released > 10,000

C0784-2 Ignition in position II, front sunroof switch open < 0.5

C0785-7 Ignition in position II, front sunroof switch released > 10,000

C0785-7 Ignition in position II, front sunroof switch closed < 0.5

Page 1038 of 1529

SUNROOF

DESCRIPTION AND OPERATION 76-6-7

Front sunroof motor and microswitch

The front sunroof motor is located within the front sunroof assembly. The sunroof ECU controls the front sunroof

motor.

The sunroof ECU determines the direction the sunroof motor runs. A battery signal to one side of the motor and an

earth to the other side of the motor causes the motor to turn in one direction, reversing the polarity through the same

pins causes the motor to turn in the opposite direction.

The following table lists the values which can be measured at the listed ECU pins when the conditions outlined are

met:

Signal values (connector connected)

Connector/Pin

No.Condition Voltage Resistance, ohms

C0785-5 Ignition in position II, rear of front sunroof switch

pressed+voltage to C0785-

5

C0785-1 Ignition in position II, front of front sunroof switch

pressed+voltage to C0785-

1< 0.5

C0784-8 Ignition in position II, sunroof fully closed +V Batt

C0784-8 Ignition in position II, sunroof not closed > 10,0000

Page 1039 of 1529

SUNROOF

76-6-8 DESCRIPTION AND OPERATION

Rear sunroof - front switch

The rear sunroof front switch is located in the roof console above the windscreen in front of the front sunroof. It

controls the rear sunroof motor via the sunroof ECU.

The rear sunroof front switch supplies an earth signal to the sunroof ECU. The pin at the ECU that receives the earth

signal determines whether ECU causes the sunroof to open or close.

TestBook cannot monitor the state of the rear sunroof front switch.

The following table lists the values which can be measured at the listed ECU pins when the conditions outlined are

met:

Signal values (connector connected)

Connector/Pin

No.Condition Ohms

C0784-7 Ignition in position II, rear sunroof front switch released > 10,000

C0784-7 Ignition in position II, rear sunroof front switch open < 0.5

C0785-8 Ignition in position II, rear sunroof front switch released > 10,000

C0785-8 Ignition in position II, rear sunroof front switch closed < 0.5