clutch LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 187 of 1529

ENGINE - V8

12-2-32 REPAIRS

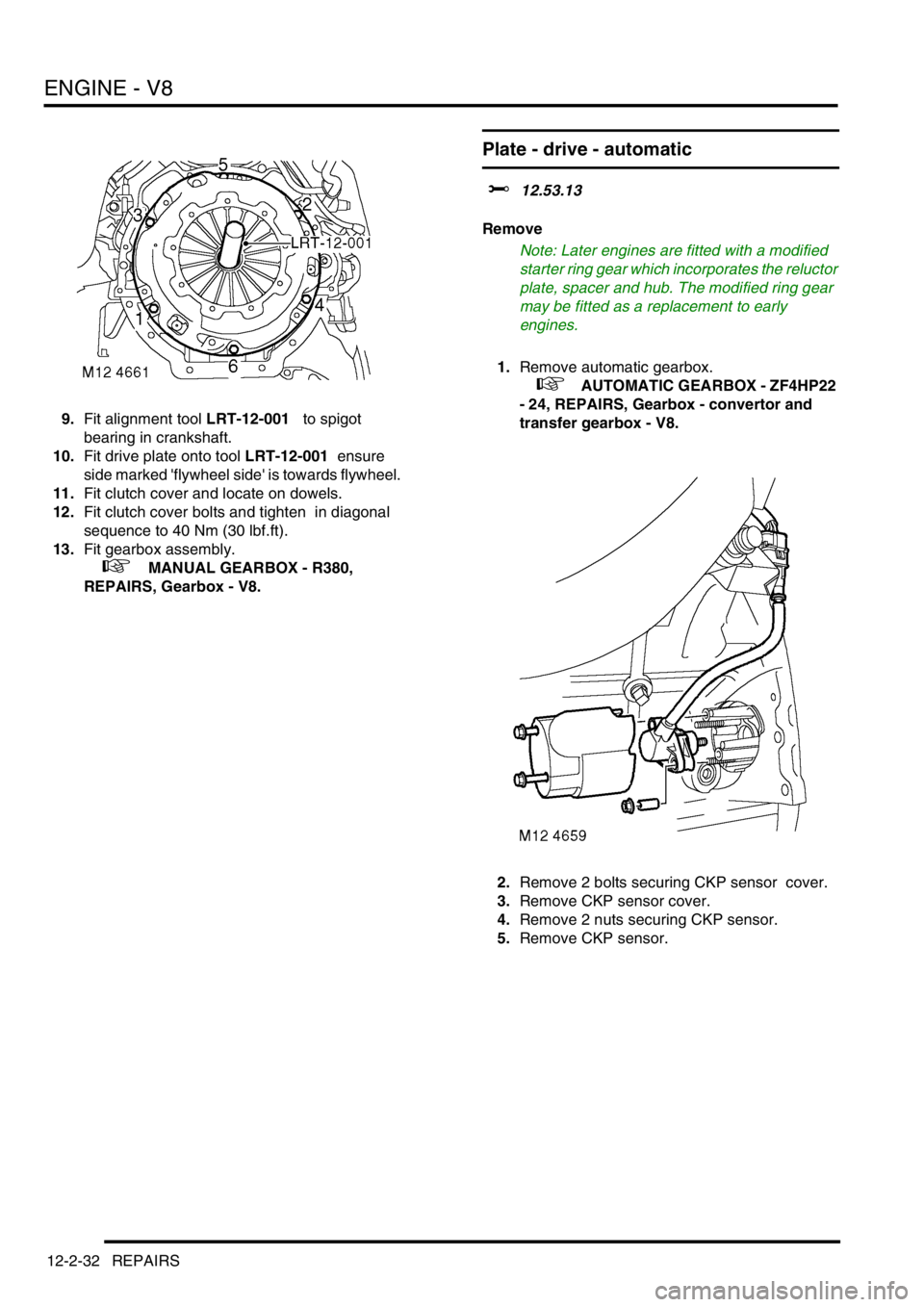

9.Fit alignment tool LRT-12-001 to spigot

bearing in crankshaft.

10.Fit drive plate onto tool LRT-12-001 ensure

side marked 'flywheel side' is towards flywheel.

11.Fit clutch cover and locate on dowels.

12.Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).

13.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Plate - drive - automatic

$% 12.53.13

Remove

Note: Later engines are fitted with a modified

starter ring gear which incorporates the reluctor

plate, spacer and hub. The modified ring gear

may be fitted as a replacement to early

engines.

1.Remove automatic gearbox.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gearbox - convertor and

transfer gearbox - V8.

2.Remove 2 bolts securing CKP sensor cover.

3.Remove CKP sensor cover.

4.Remove 2 nuts securing CKP sensor.

5.Remove CKP sensor.

Page 205 of 1529

ENGINE - V8

12-2-50 OVERHAUL

Reassembly

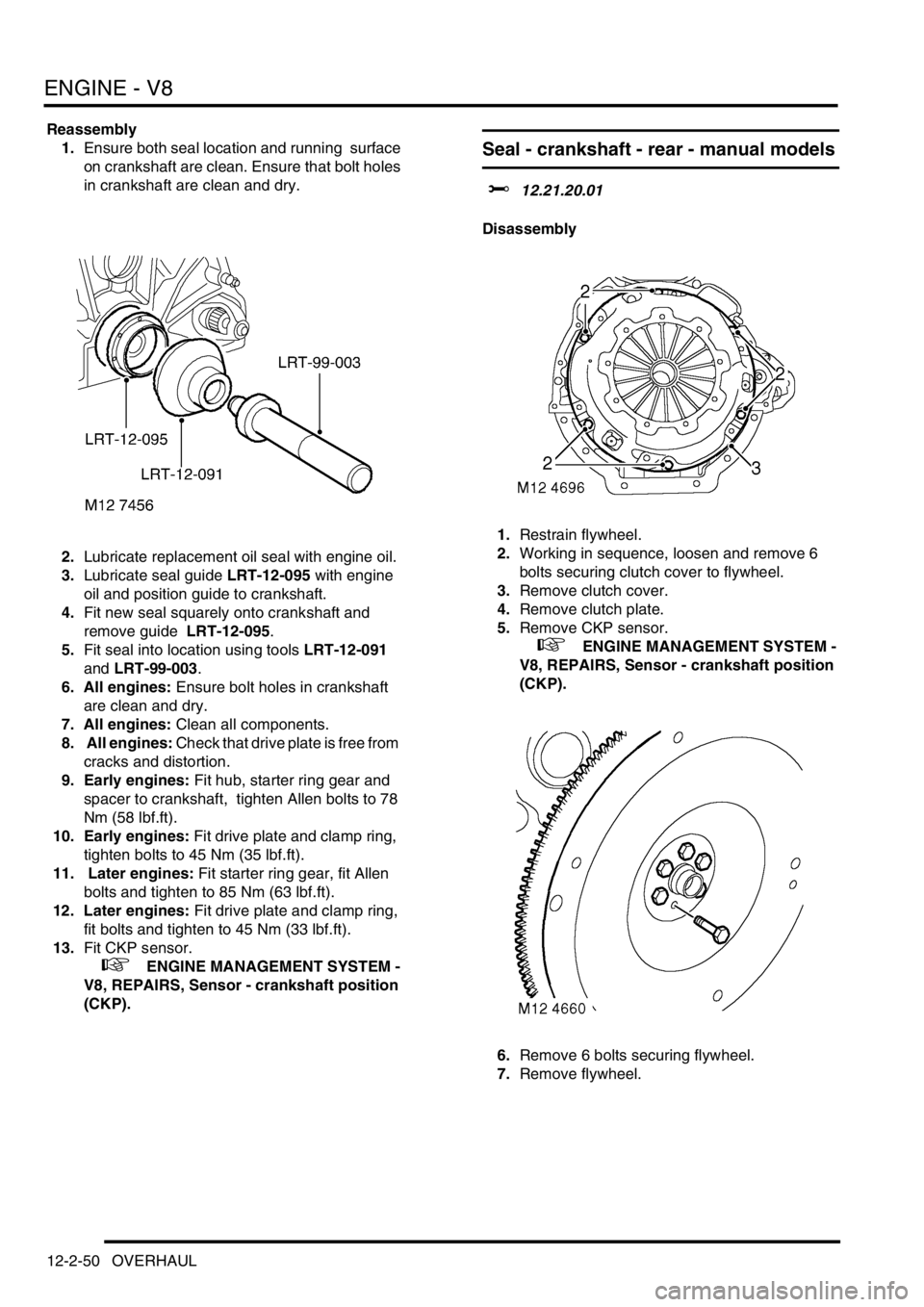

1.Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

in crankshaft are clean and dry.

2.Lubricate replacement oil seal with engine oil.

3.Lubricate seal guide LRT-12-095 with engine

oil and position guide to crankshaft.

4.Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5.Fit seal into location using tools LRT-12-091

and LRT-99-003.

6. All engines: Ensure bolt holes in crankshaft

are clean and dry.

7. All engines: Clean all components.

8. All engines: Check that drive plate is free from

cracks and distortion.

9. Early engines: Fit hub, starter ring gear and

spacer to crankshaft, tighten Allen bolts to 78

Nm (58 lbf.ft).

10. Early engines: Fit drive plate and clamp ring,

tighten bolts to 45 Nm (35 lbf.ft).

11. Later engines: Fit starter ring gear, fit Allen

bolts and tighten to 85 Nm (63 lbf.ft).

12. Later engines: Fit drive plate and clamp ring,

fit bolts and tighten to 45 Nm (33 lbf.ft).

13.Fit CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

Seal - crankshaft - rear - manual models

$% 12.21.20.01

Disassembly

1.Restrain flywheel.

2.Working in sequence, loosen and remove 6

bolts securing clutch cover to flywheel.

3.Remove clutch cover.

4.Remove clutch plate.

5.Remove CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

6.Remove 6 bolts securing flywheel.

7.Remove flywheel.

Page 206 of 1529

ENGINE - V8

OVERHAUL 12-2-51

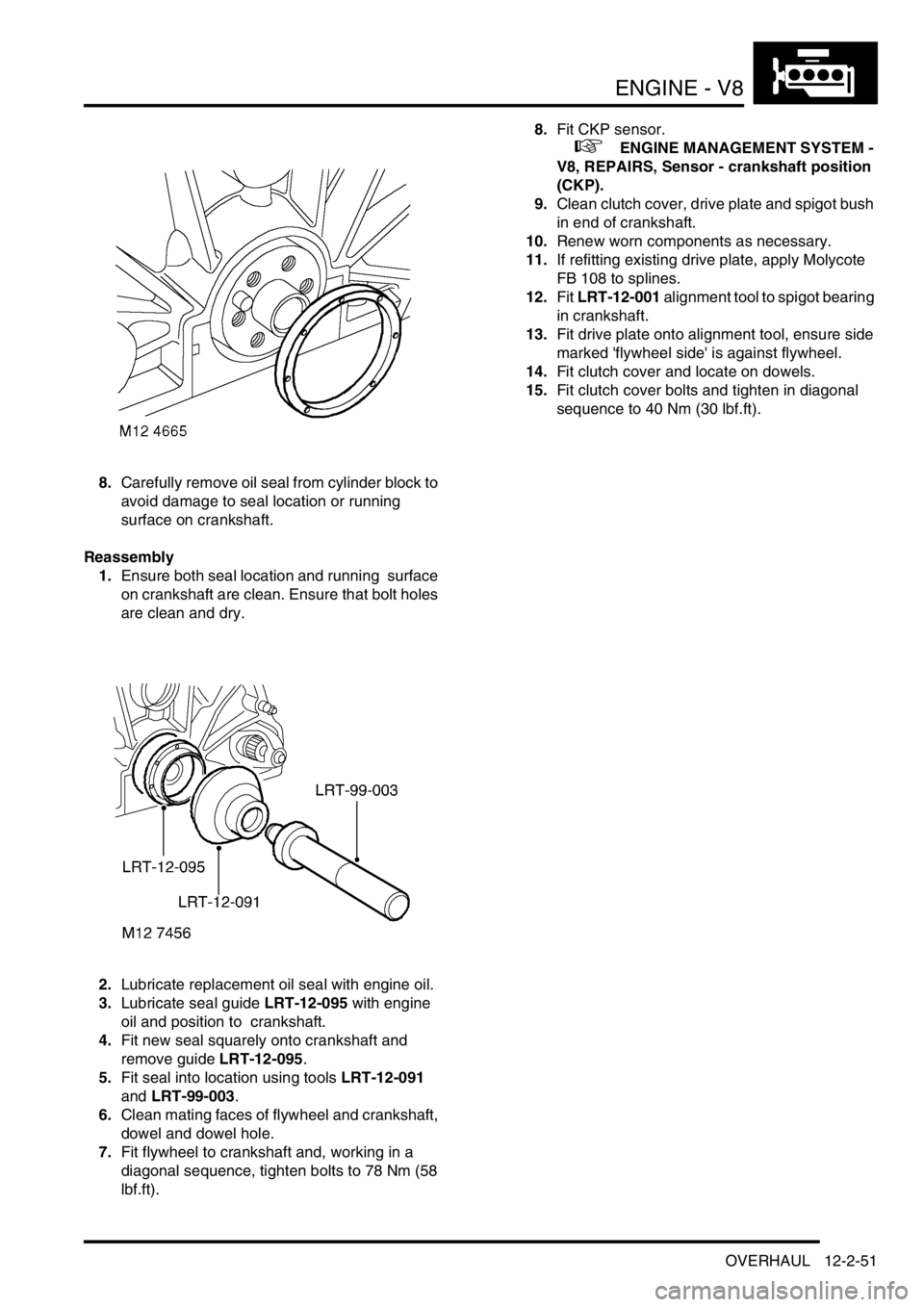

8.Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

Reassembly

1.Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

are clean and dry.

2.Lubricate replacement oil seal with engine oil.

3.Lubricate seal guide LRT-12-095 with engine

oil and position to crankshaft.

4.Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5.Fit seal into location using tools LRT-12-091

and LRT-99-003.

6.Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

7.Fit flywheel to crankshaft and, working in a

diagonal sequence, tighten bolts to 78 Nm (58

lbf.ft). 8.Fit CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

9.Clean clutch cover, drive plate and spigot bush

in end of crankshaft.

10.Renew worn components as necessary.

11.If refitting existing drive plate, apply Molycote

FB 108 to splines.

12.Fit LRT-12-001 alignment tool to spigot bearing

in crankshaft.

13.Fit drive plate onto alignment tool, ensure side

marked 'flywheel side' is against flywheel.

14.Fit clutch cover and locate on dowels.

15.Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).

Page 207 of 1529

ENGINE - V8

12-2-52 OVERHAUL

Bearing - spigot - crankshaft

$% 12.21.45.01

Disassembly

1.Remove 6 bolts securing clutch cover.

2.Remove clutch cover.

3.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4.Fit extractor to bush.

5.Remove bush from crankshaft. Reassembly

1.Clean bush register in rear of crankshaft.

2.Using a suitable drift, fit new bush to crankshaft

so that it is flush with or up to a maximum of 1.6

mm (0.06 in) below the end of the crankshaft.

3.Ream spigot bush to 19.117 + 0.025 − 0.00 mm

(0.75 + 0.001 − 0.00 in) .

4.Remove all traces of swarf on completion.

5.Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

6.Fit clutch cover to flywheel and tighten bolts by

diagonal slection to 40 Nm (30 lbf.ft).

Page 302 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-3

1Mass air flow/ inlet air temperature sensor

2Fuel injectors

3High tension leads/spark plugs

4Fuel pump relay

5ATC compressor clutch relay/ cooling fan relay

6Throttle position sensor

7Heated oxygen sensor

8Idle air control valve

9Ignition coils

10Engine coolant temperature sensor

11Crankshaft speed and position sensor

12Knock sensor

13Camshaft position sensor

Page 304 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-5

1Engine control module

2Crankshaft speed and position sensor

3Camshaft position sensor

4Engine coolant temperature sensor

5Mass air flow/ inlet air temperature sensor

6Throttle position sensor

7Heated oxygen sensors

8Fuel injectors

9Idle air control valve

10Fuel pump relay

11EVAP canister

12EVAP canister vent valve

13EVAP canister purge valve

14Fuel tank pressure sensor15Ignition coils

16Knock sensor

17Spark plugs

18High/ Low ratio switch

19Malfunction indication lamp

20Diagnostic connector

21Air temperature control clutch relay

22Air temperature control cooling fan relay

23ATC ECU

24CAN link to EAT

25SLABS ECU

26BCU

27Instrument cluster

28Thermostat monitoring sensor (where fitted)

Page 344 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-45

Malfunction Indicator Lamp (MIL)/ service engine soon warning lamp

The MIL/ service engine soon warning lamp is located in the instrument cluster. It illuminates to alert the driver to

system malfunctions. Service engine soon warning lamp is the name for this warning lamp in NAS only, it is called

MIL in all other markets.

During ignition a self-test function of the lamp is carried out. The lamp will illuminate for 3 seconds then it will

extinguish if no faults exist.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Input/Output

The MIL is supplied with battery voltage from the instrument cluster. When the ECM detects a fault, it provides an

earth path to illuminate the MIL. Output to the MIL is via pin 20 of connector C0637 of the ECM.

Air Temperature Control (ATC) request

The ATC request comes via the ATC switch located in the facia panel. When the driver operates the switch it acts as

a request from the ATC ECU to engage the ATC clutch to drive the system.

During periods of high driver demand such as hard acceleration or maximum rev/min the ATC clutch will be disabled

for a short time. This is to reduce the load on the engine.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

Page 345 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-46 DESCRIPTION AND OPERATION

Input/Output

The operation of the ATC request is via a switch being connected to earth. Voltage is supplied via pin 38 of connector

C0637 of the ECM, at the point at when the switch is pressed the connection is made and the ATC clutch is engaged.

The ATC request can fail as follows:

lOpen circuit.

lShort circuit to voltage supply.

lShort circuit to vehicle earth.

lWiring loom fault.

In the event of an ATC request failure, the ATC system does not work.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

P Code J2012 Description Land Rover Description

P1535 Air conditioning compressor request

malfunctionATC requested when not in standby mode

Page 346 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-47

ATC compressor clutch relay

The ATC compressor clutch relay is located in the engine compartment fuse box. It is a four pin normally open relay.

The relay must be energised to drive the ATC compressor clutch.

Input/Output

The ECM provides the earth for the relay coil to allow the relay contacts to close and the ATC clutch drive to receive

battery voltage. The ECM uses a transistor as a switch to generate an open circuit in the earth path of the relay coil.

When the ECM opens the earth path, the return spring in the relay will pull the contacts apart to shut down the ATC

clutch drive.

Input to the ATC clutch relay switching contacts is via fuse 6 located in the engine compartment fuse box. The relay

coils are supplied with battery voltage from the main relay, also located in the engine compartment fuse box. The earth

path for the relay coil is via pin 29 of the ECM C0657 connector. When the relay is energised the output from the

switching contacts goes directly to the ATC compressor clutch.

The ATC clutch relay can fail in the following ways:

lRelay open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lBroken return spring.

In the event of an ATC clutch relay failure, the ATC does not work.

Should a malfunction of the component occur, the following fault codes may be evident and can be retrieved by

TestBook.

P Code J2012 Description Land Rover Description

P1536 Air conditioning compressor request range/

performanceATC compressor clutch relay open circuit

P1537 Air conditioning compressor request low input ATC compressor clutch relay short to earth

P1538 Air conditioning compressor request high input ATC compressor clutch relay short to battery supply

Page 360 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-61

DESCRIPTION AND OPERAT ION

Cruise control component layout

1Cruise control ECU

2Cruise control master switch

3SET+ switch

4RES switch

5Brake pedal switch

6Clutch pedal switch7BCU

8Vacuum pump assembly

9Pneumatic actuator

10SLABS ECU

11Automatic gear selector lever