clutch LAND ROVER DISCOVERY 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 75 of 1529

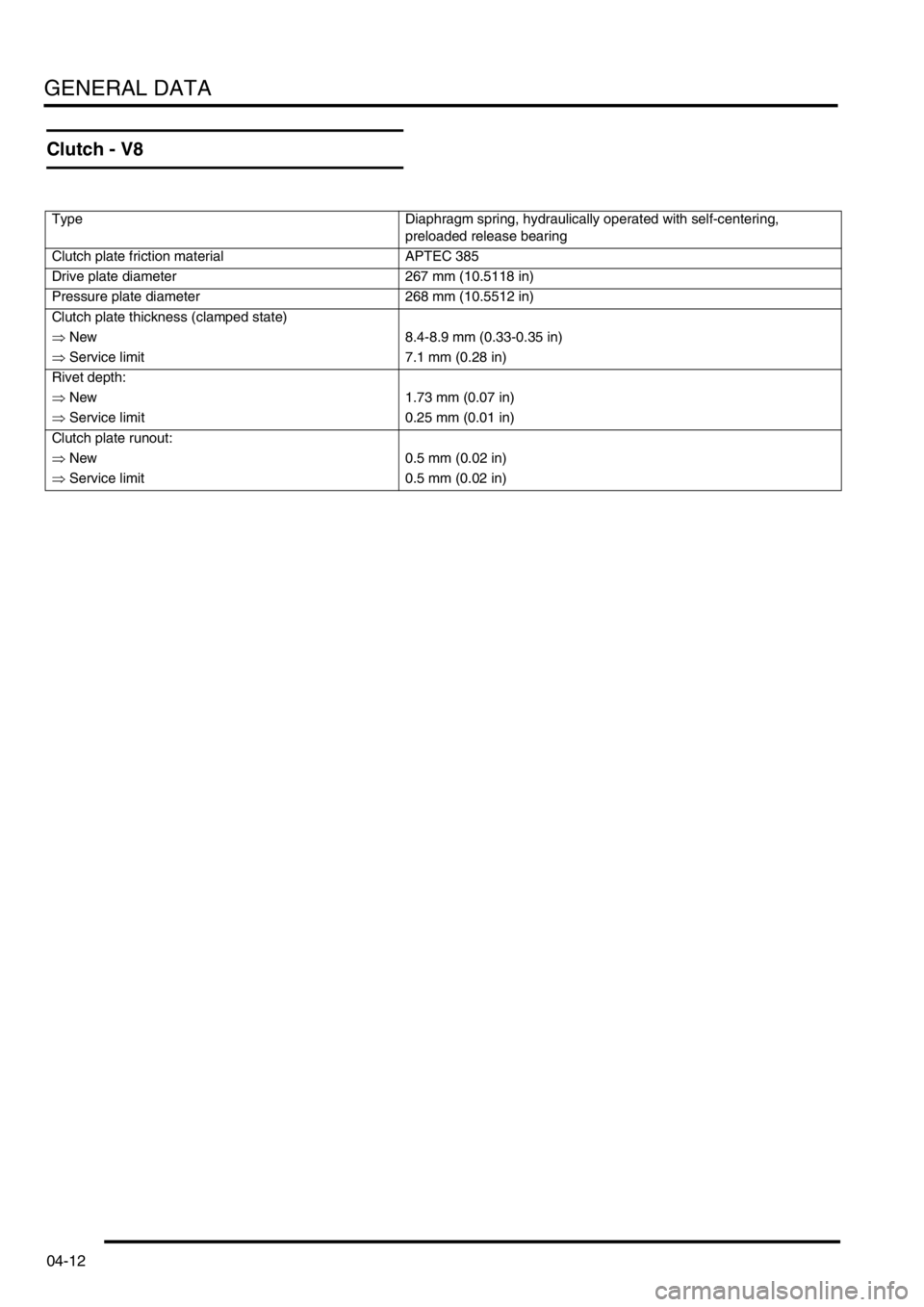

GENERAL DATA

04-12

Clutch - V8

Type Diaphragm spring, hydraulically operated with self-centering,

preloaded release bearing

Clutch plate friction material APTEC 385

Drive plate diameter 267 mm (10.5118 in)

Pressure plate diameter 268 mm (10.5512 in)

Clutch plate thickness (clamped state)

⇒ New 8.4-8.9 mm (0.33-0.35 in)

⇒ Service limit 7.1 mm (0.28 in)

Rivet depth:

⇒ New 1.73 mm (0.07 in)

⇒ Service limit 0.25 mm (0.01 in)

Clutch plate runout:

⇒ New 0.5 mm (0.02 in)

⇒ Service limit 0.5 mm (0.02 in)

Page 100 of 1529

TORQUE WRENCH SETTINGS

06-9

Clutch

TORQUE DESCRIPTION METRIC IMPERIAL

Clutch bleed screw 9 Nm (7 lbf.ft)

Clutch cover nuts Td5 25 Nm (18 lbf.ft)

Clutch cover bolts V8 40 Nm (30 lbf.ft)

Clutch master cylinder to pedal box 25 Nm (18 lbf.ft)

Hydraulic pipe union 18 Nm (13 lbf.ft)

Clutch release bearing pivot point bolt 8 Nm (6 lbf.ft)

Slave cylinder25 Nm (18 lbf.ft)

Page 101 of 1529

TORQUE WRENCH SETTINGS

06-10

Manual gearbox - R380

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Bias spring adjustment plate bolts + 25 Nm (18 lbf.ft)

Gearbox to engine bolts 45 Nm (33 lbf.ft)

Coolant pipe housing bolts 25 Nm (18 lbf.ft)

Breather pipe banjo bolt 15 Nm (11 lbf.ft)

Gear lever extension clamp bolt 25 Nm (18 lbf.ft)

Gearbox mounting bolts 85 Nm (63 lbf.ft)

Gearbox mounting nuts 48 Nm (37 lbf.ft)

Seal housing bolts 18 Nm (13 lbf.ft)

Bearing sleeve bolts 25 Nm (18 lbf.ft)

Fork bolt7 Nm (5.2 lbf.ft)

Reverse light switch 24 Nm (18 lbf.ft)

Extension housing bolts + 25 Nm (18 lbf.ft)

Gear selector housing bolts + 25 Nm (18 lbf.ft)

Oil pump to housing Torx screws 6 Nm (4.4 lbf.ft)

Gear change lever yoke Allen screw + 25 Nm (18 lbf.ft)

5th gear stake nut 350 Nm (258 lbf.ft)

Spool retainer bolts 8 Nm (6 lbf.ft)

Centre plate detent spring and ball Torx screw 25 Nm (18 lbf.ft)

Selector lever to housing bolts + 25 Nm (18 lbf.ft)

Clutch \ Bell housing bolts 73 Nm (54 lbf.ft)

Page 119 of 1529

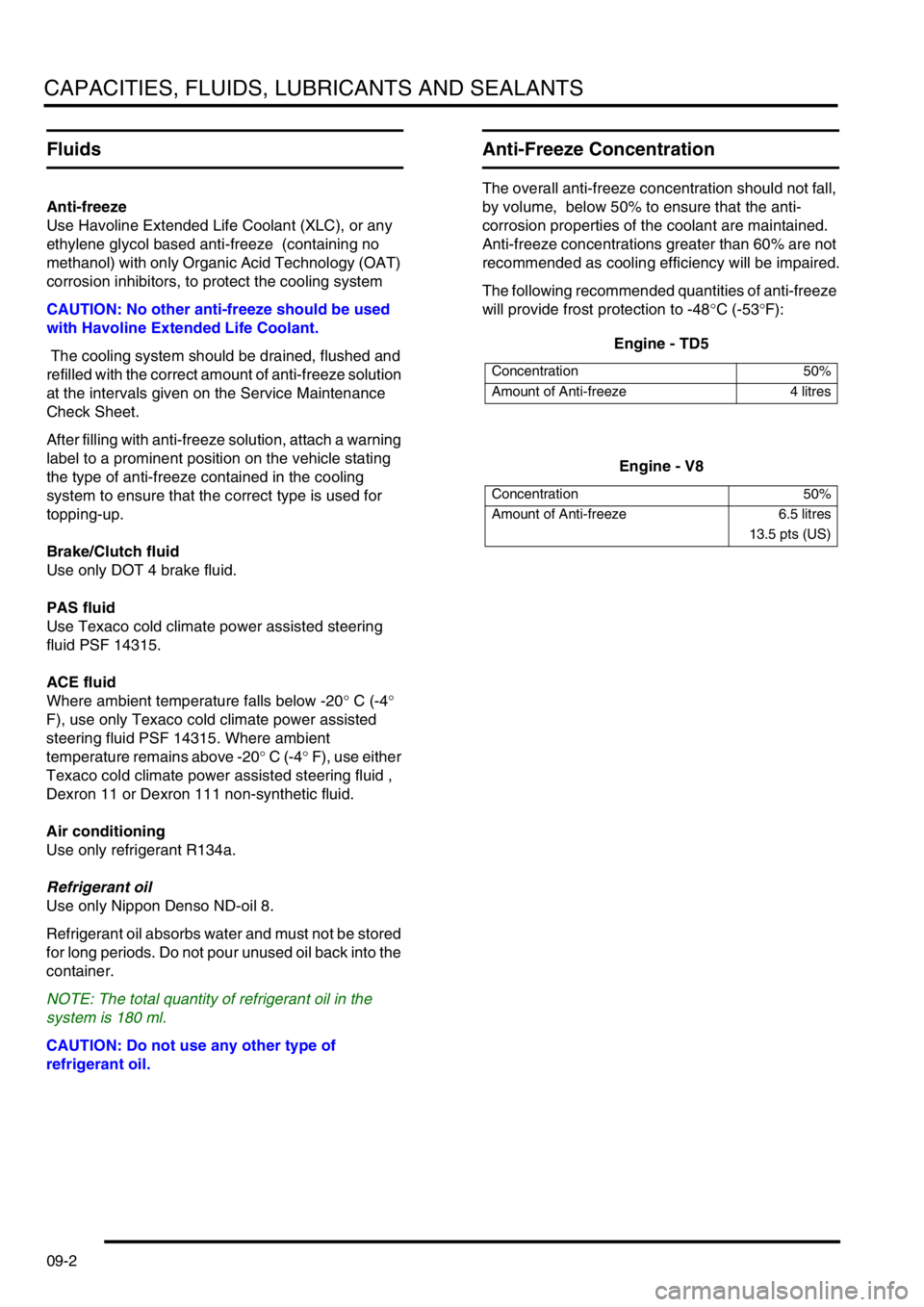

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

Fluids

Anti-freeze

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze solution

at the intervals given on the Service Maintenance

Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

Brake/Clutch fluid

Use only DOT 4 brake fluid.

PAS fluid

Use Texaco cold climate power assisted steering

fluid PSF 14315.

ACE fluid

Where ambient temperature falls below -20° C (-4°

F), use only Texaco cold climate power assisted

steering fluid PSF 14315. Where ambient

temperature remains above -20° C (-4° F), use either

Texaco cold climate power assisted steering fluid ,

Dexron 11 or Dexron 111 non-synthetic fluid.

Air conditioning

Use only refrigerant R134a.

Refrigerant oil

Use only Nippon Denso ND-oil 8.

Refrigerant oil absorbs water and must not be stored

for long periods. Do not pour unused oil back into the

container.

NOTE: The total quantity of refrigerant oil in the

system is 180 ml.

CAUTION: Do not use any other type of

refrigerant oil.

Anti-Freeze Concentration

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

The following recommended quantities of anti-freeze

will provide frost protection to -48°C (-53°F):

Engine - TD5

Engine - V8

Concentration 50%

Amount of Anti-freeze 4 litres

Concentration 50%

Amount of Anti-freeze 6.5 litres

13.5 pts (US)

Page 124 of 1529

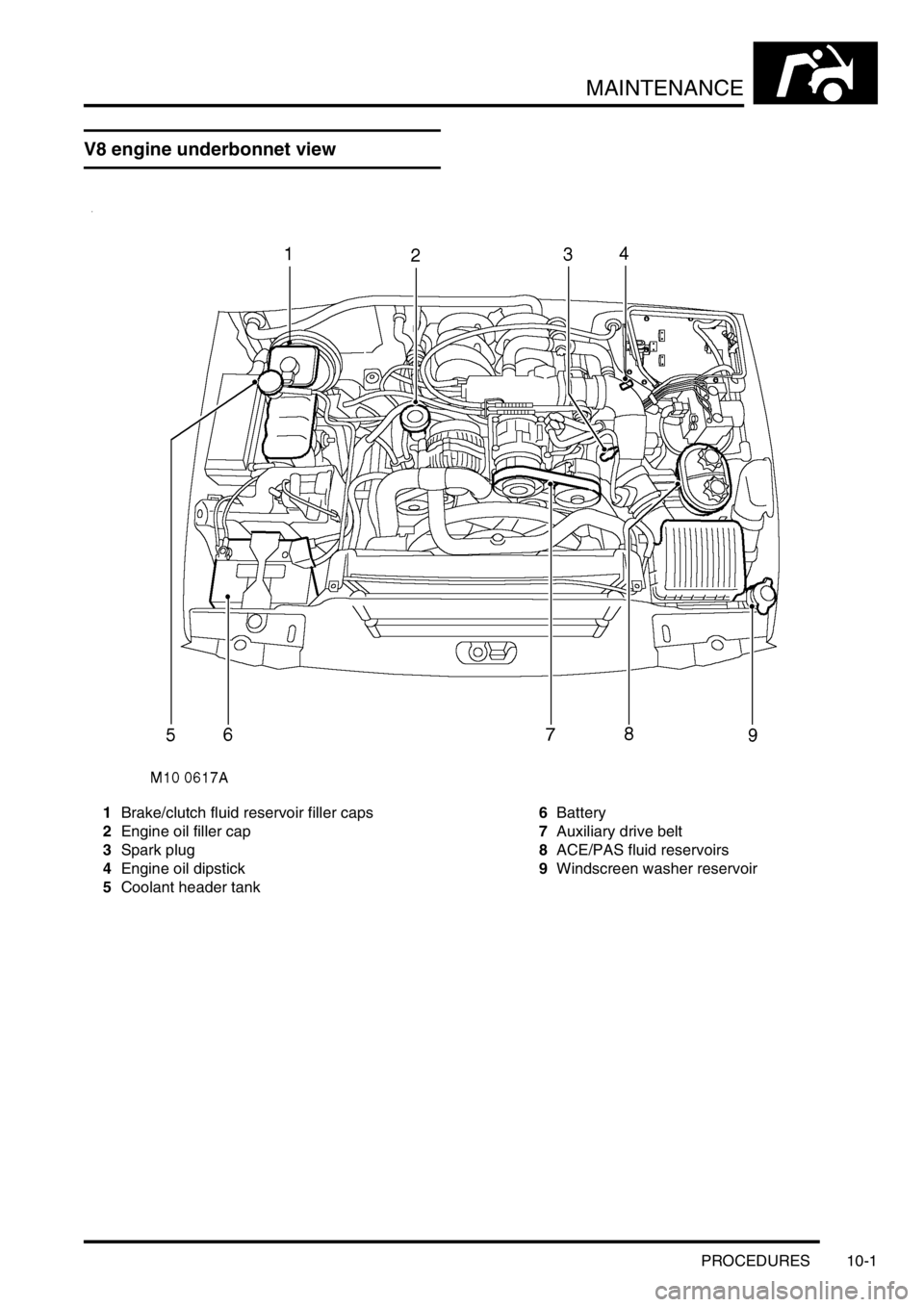

MAINTENANCE

PROCEDURES 10-1

MAINTENANCE PROCEDURES

V8 engine underbonnet view

1Brake/clutch fluid reservoir filler caps

2Engine oil filler cap

3Spark plug

4Engine oil dipstick

5Coolant header tank6Battery

7Auxiliary drive belt

8ACE/PAS fluid reservoirs

9Windscreen washer reservoir

Page 125 of 1529

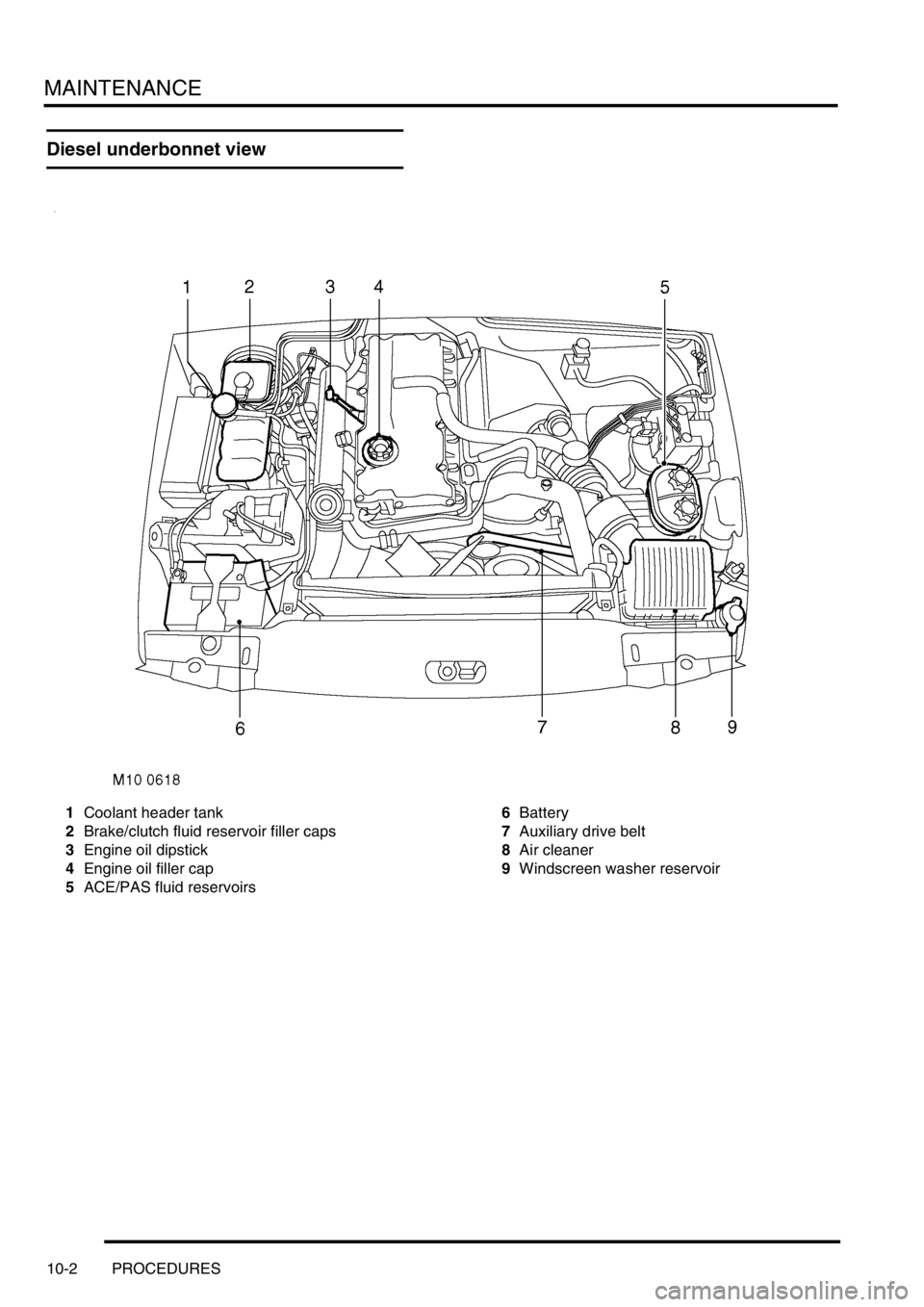

MAINTENANCE

10-2 PROCEDURES

Diesel underbonnet view

1Coolant header tank

2Brake/clutch fluid reservoir filler caps

3Engine oil dipstick

4Engine oil filler cap

5ACE/PAS fluid reservoirs6Battery

7Auxiliary drive belt

8Air cleaner

9Windscreen washer reservoir

Page 135 of 1529

MAINTENANCE

10-12 PROCEDURES

Fluid reservoirs

Check/top-up — Brake/Clutch reservoir

1.Check fluid level in brake/clutch fluid reservoirs.

2.Clean area around filler cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.

Check/top-up — PAS/ACE reservoirs

1.Check fluid level in PAS and ACE fluid

reservoirs.

2.Clean area around filler cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.Check/top-up — Washer reservoir

1.Check fluid level in windscreen washer

reservoir.

2.Clean area around filler cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.

Page 147 of 1529

MAINTENANCE

10-24 PROCEDURES

Brake hose, brake, fuel, ACE, clutch

pipes and unions/electrical harnesses

Check – General

1.Check brake servo hose for cracks, leaks and

chafing.

2.Check brake, clutch pipes and unions for

chafing, leaks and corrosion and that all pipes

and hoses are correctly routed and secure.

3.Check electrical harnesses for chafing and

damage.

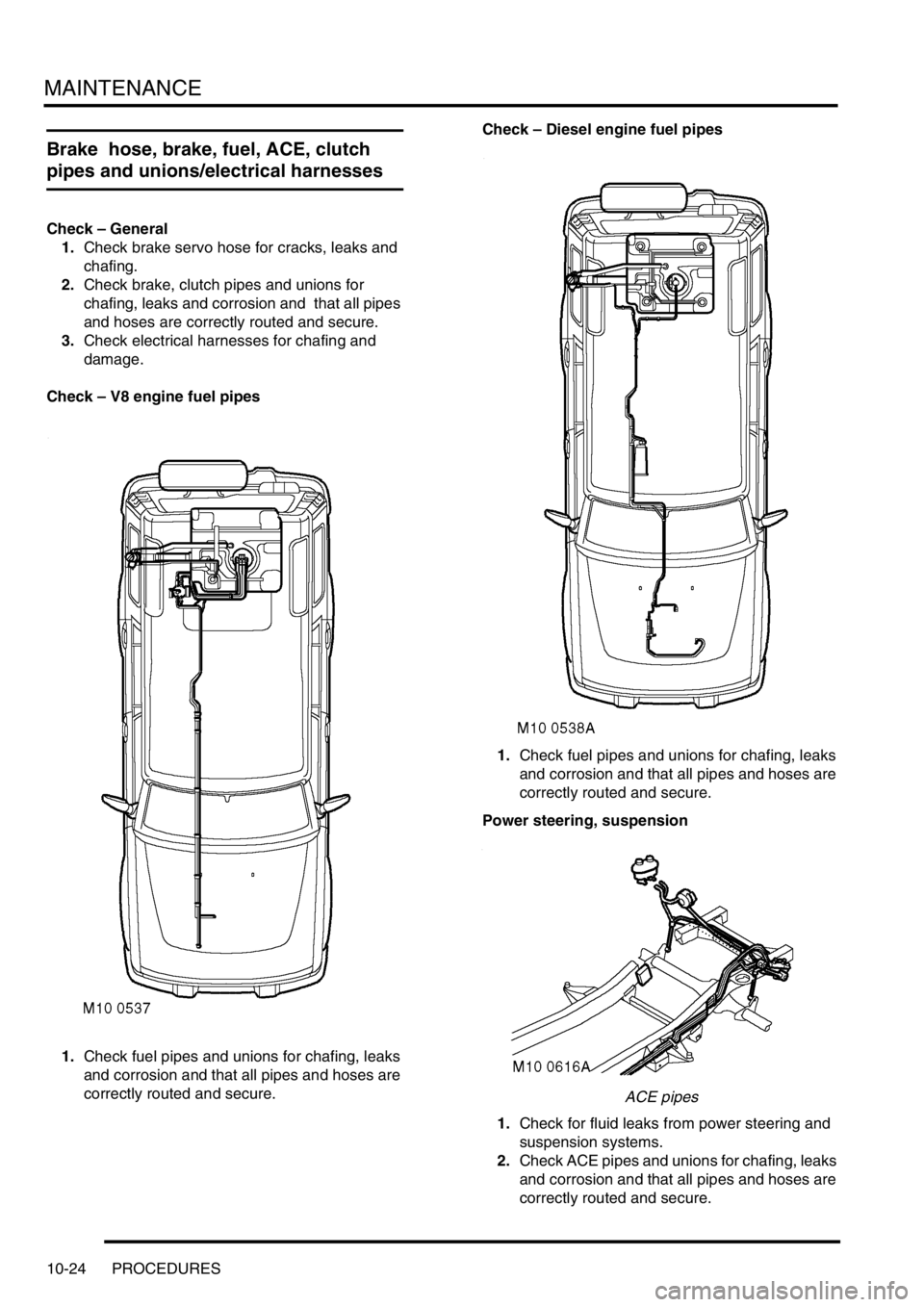

Check – V8 engine fuel pipes

1.Check fuel pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure. Check – Diesel engine fuel pipes

1.Check fuel pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure.

Power steering, suspension

ACE pipes

1.Check for fluid leaks from power steering and

suspension systems.

2.Check ACE pipes and unions for chafing, leaks

and corrosion and that all pipes and hoses are

correctly routed and secure.

Page 154 of 1529

MAINTENANCE

PROCEDURES 10-31

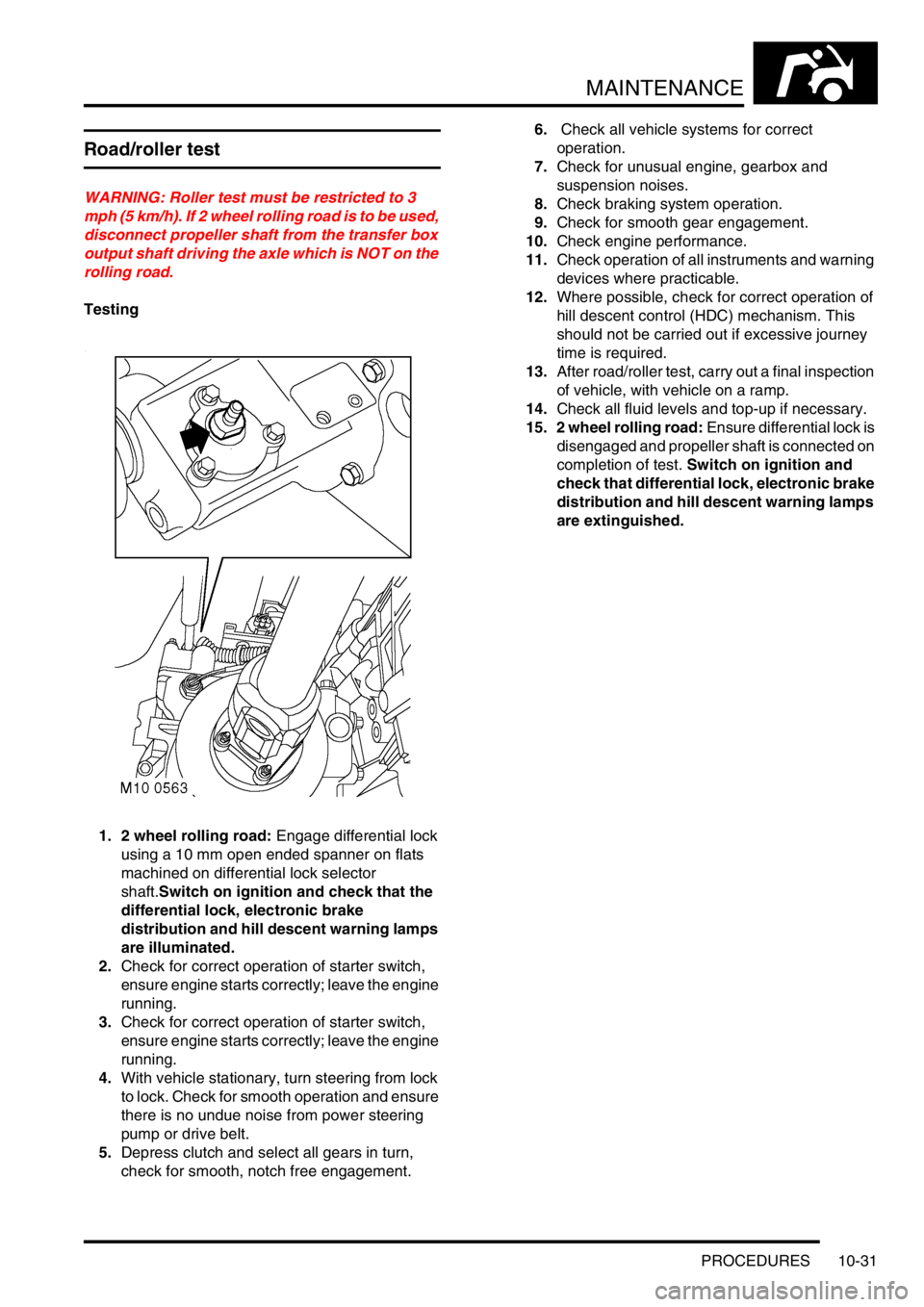

Road/roller test

WARNING: Roller test must be restricted to 3

mph (5 km/h). If 2 wheel rolling road is to be used,

disconnect propeller shaft from the transfer box

output shaft driving the axle which is NOT on the

rolling road.

Testing

1. 2 wheel rolling road: Engage differential lock

using a 10 mm open ended spanner on flats

machined on differential lock selector

shaft.Switch on ignition and check that the

differential lock, electronic brake

distribution and hill descent warning lamps

are illuminated.

2.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

3.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

4.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from power steering

pump or drive belt.

5.Depress clutch and select all gears in turn,

check for smooth, notch free engagement.6. Check all vehicle systems for correct

operation.

7.Check for unusual engine, gearbox and

suspension noises.

8.Check braking system operation.

9.Check for smooth gear engagement.

10.Check engine performance.

11.Check operation of all instruments and warning

devices where practicable.

12.Where possible, check for correct operation of

hill descent control (HDC) mechanism. This

should not be carried out if excessive journey

time is required.

13.After road/roller test, carry out a final inspection

of vehicle, with vehicle on a ramp.

14.Check all fluid levels and top-up if necessary.

15. 2 wheel rolling road: Ensure differential lock is

disengaged and propeller shaft is connected on

completion of test. Switch on ignition and

check that differential lock, electronic brake

distribution and hill descent warning lamps

are extinguished.

Page 186 of 1529

ENGINE - V8

REPAIRS 12-2-31

Flywheel

$% 12.53.07

Remove

1.Remove gearbox

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Restrain flywheel.

3.Working in sequence, progressively slacken 6

bolts securing clutch cover to flywheel.

Remove bolts.

4.Remove clutch cover.

5.Remove clutch plate.

6.Release crankshaft sensor multiplug from

bracket.

7.Remove 2 bolts securing crankshaft sensor

cover. 8.Remove crankshaft sensor cover.

9.Remove 2 nuts securing crankshaft sensor.

10.Remove crankshaft sensor.

11.Remove 6 bolts securing flywheel.

12.Remove flywheel.

On early engines, balance weights are on

engine side of flywheel; replacement flywheels

will have balance weights on clutch side of

flywheel.

Refit

1.Clean mating faces of flywheel and crankshaft,

dowel and dowel hole. Ensure bolt holes in

crankshaft are clean and dry.

2.Fit flywheel to crankshaft and tighten bolts to

78 Nm (58 lbf.ft).

3.Clean crankshaft sensor and mating face.

4.Fit crankshaft sensor and tighten nuts to 6 Nm

(4.4 lbf.ft).

5.Fit crankshaft sensor cover and tighten bolts to

6 Nm (5 lbf.ft).

6.Fit crankshaft sensor multiplug to bracket.

7.Clean clutch cover, drive plate and spigot bush

in end of crankshaft. Renew worn components

as necessary.

8.If refitting existing drive plate, apply 'Molycote

FB 180' to splines.