oil type LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 681 of 1529

FRONT AXLE

54-2 DESCRIPTION AND OPERATION

Description

General

The front axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in a steering knuckle at each end of the axle casing and connected to the differential unit by a drive

shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the front suspension.

Yokes at each end of the casing incorporate upper and lower ball joints for attachment of the steering knuckles.

A differential cover on the front of the axle casing contains an oil level plug for checking and replenishment of the

differential lubricating oil. A magnetic drain plug is installed on the underside of the casing. An oil seal is installed in

each end of the axle casing to prevent leakage past the drive shafts.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located in the left rear corner of the engine compartment.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a drive flange which is secured with a bolt

and washer. An oil seal prevents leakage past the drive flange.

Steering knuckle

The steering knuckles are mounted on upper and lower ball joints in the yokes at the end of the axle casing. A tension

collet, in the lower mounting point of each steering knuckle, accommodates manufacturing tolerances to enable the

correct tightening of both ball joints. Lugs are incorporated on the steering knuckles for attachment of the steering

system drag link and track rod.

Page 682 of 1529

FRONT AXLE

DESCRIPTION AND OPERATION 54-3

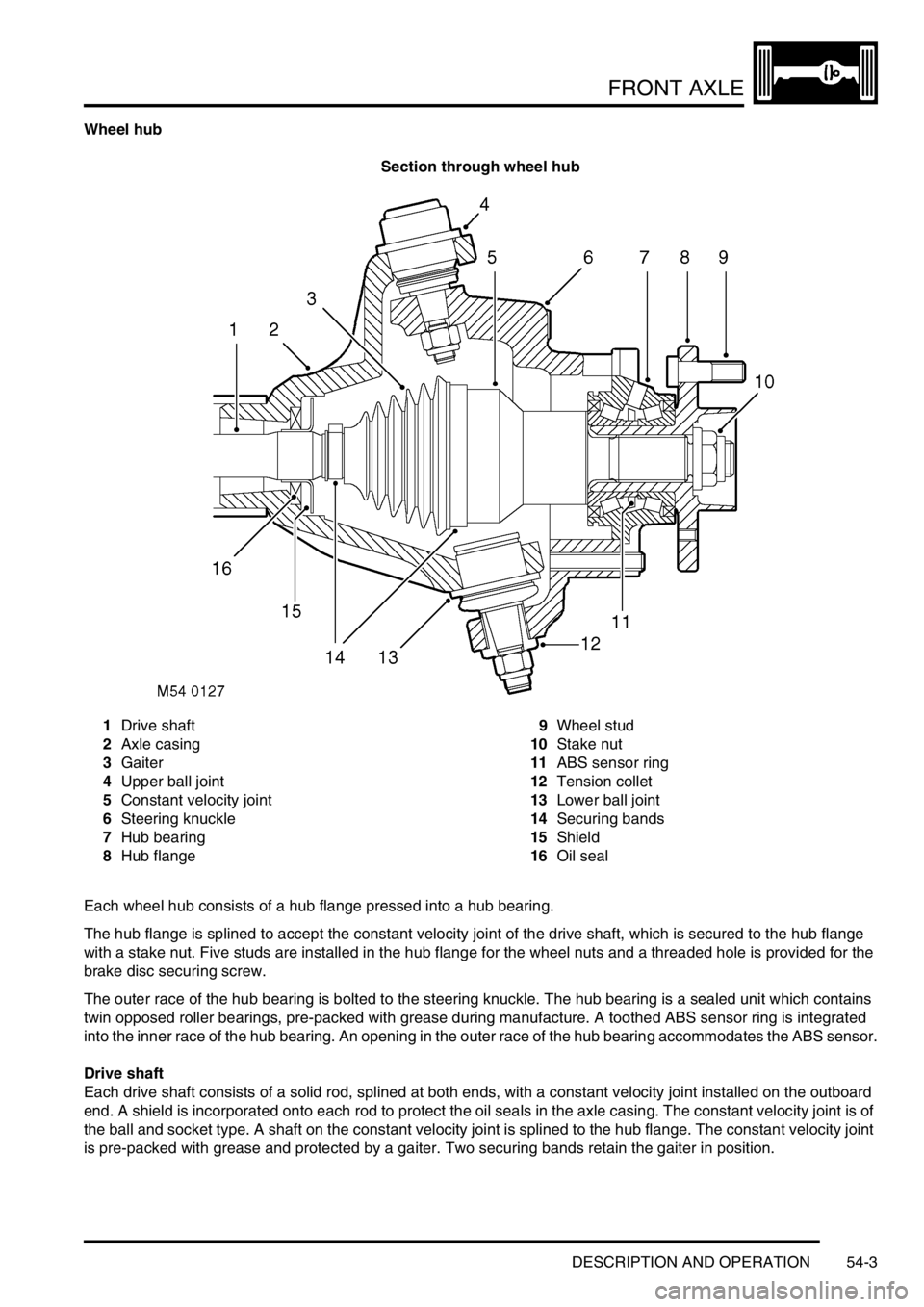

Wheel hub

Section through wheel hub

1Drive shaft

2Axle casing

3Gaiter

4Upper ball joint

5Constant velocity joint

6Steering knuckle

7Hub bearing

8Hub flange9Wheel stud

10Stake nut

11ABS sensor ring

12Tension collet

13Lower ball joint

14Securing bands

15Shield

16Oil seal

Each wheel hub consists of a hub flange pressed into a hub bearing.

The hub flange is splined to accept the constant velocity joint of the drive shaft, which is secured to the hub flange

with a stake nut. Five studs are installed in the hub flange for the wheel nuts and a threaded hole is provided for the

brake disc securing screw.

The outer race of the hub bearing is bolted to the steering knuckle. The hub bearing is a sealed unit which contains

twin opposed roller bearings, pre-packed with grease during manufacture. A toothed ABS sensor ring is integrated

into the inner race of the hub bearing. An opening in the outer race of the hub bearing accommodates the ABS sensor.

Drive shaft

Each drive shaft consists of a solid rod, splined at both ends, with a constant velocity joint installed on the outboard

end. A shield is incorporated onto each rod to protect the oil seals in the axle casing. The constant velocity joint is of

the ball and socket type. A shaft on the constant velocity joint is splined to the hub flange. The constant velocity joint

is pre-packed with grease and protected by a gaiter. Two securing bands retain the gaiter in position.

Page 816 of 1529

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-7

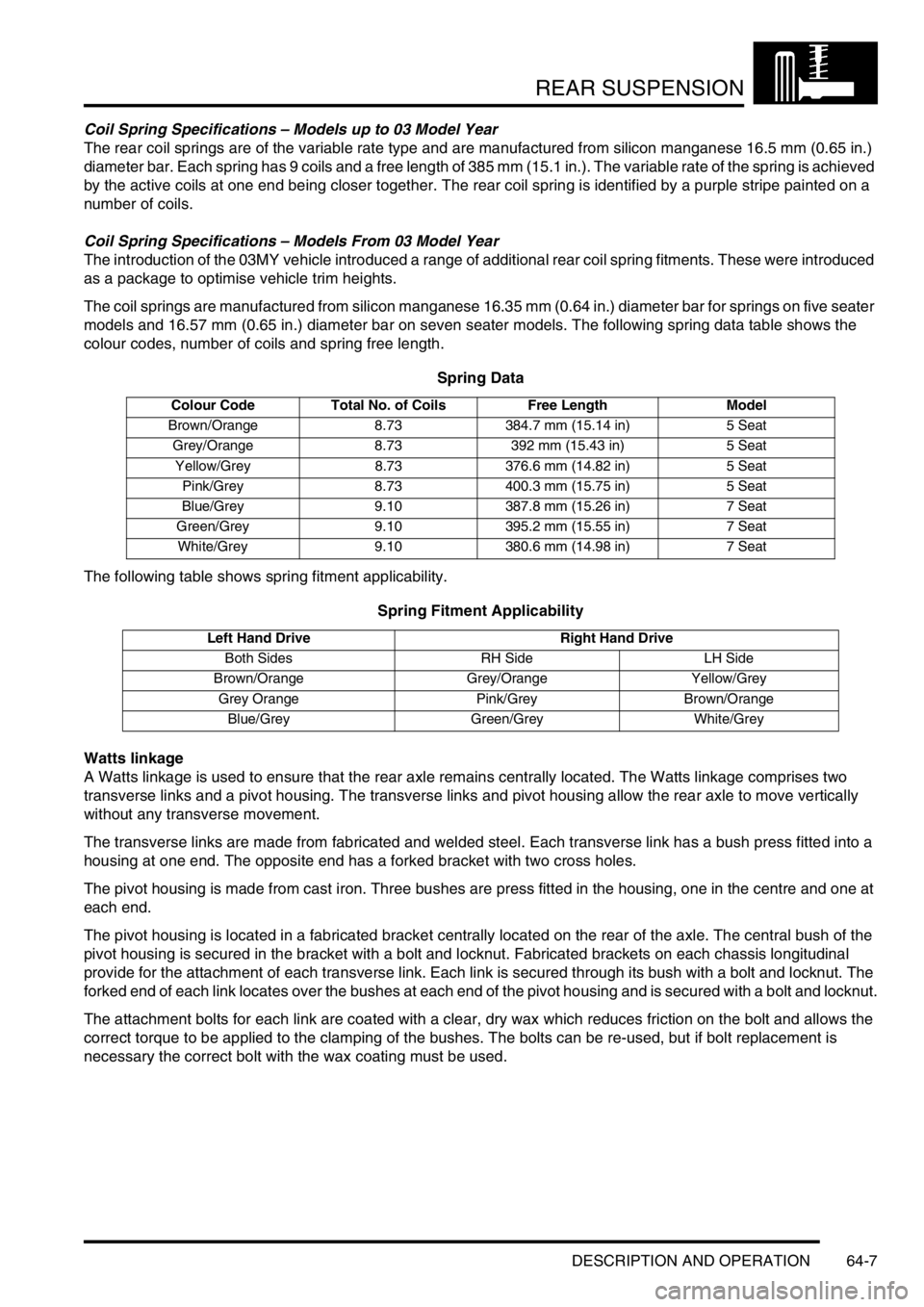

Coil Spring Specifications – Models up to 03 Model Year

The rear coil springs are of the variable rate type and are manufactured from silicon manganese 16.5 mm (0.65 in.)

diameter bar. Each spring has 9 coils and a free length of 385 mm (15.1 in.). The variable rate of the spring is achieved

by the active coils at one end being closer together. The rear coil spring is identified by a purple stripe painted on a

number of coils.

Coil Spring Specifications – Models From 03 Model Year

The introduction of the 03MY vehicle introduced a range of additional rear coil spring fitments. These were introduced

as a package to optimise vehicle trim heights.

The coil springs are manufactured from silicon manganese 16.35 mm (0.64 in.) diameter bar for springs on five seater

models and 16.57 mm (0.65 in.) diameter bar on seven seater models. The following spring data table shows the

colour codes, number of coils and spring free length.

Spring Data

The following table shows spring fitment applicability.

Spring Fitment Applicability

Watts linkage

A Watts linkage is used to ensure that the rear axle remains centrally located. The Watts linkage comprises two

transverse links and a pivot housing. The transverse links and pivot housing allow the rear axle to move vertically

without any transverse movement.

The transverse links are made from fabricated and welded steel. Each transverse link has a bush press fitted into a

housing at one end. The opposite end has a forked bracket with two cross holes.

The pivot housing is made from cast iron. Three bushes are press fitted in the housing, one in the centre and one at

each end.

The pivot housing is located in a fabricated bracket centrally located on the rear of the axle. The central bush of the

pivot housing is secured in the bracket with a bolt and locknut. Fabricated brackets on each chassis longitudinal

provide for the attachment of each transverse link. Each link is secured through its bush with a bolt and locknut. The

forked end of each link locates over the bushes at each end of the pivot housing and is secured with a bolt and locknut.

The attachment bolts for each link are coated with a clear, dry wax which reduces friction on the bolt and allows the

correct torque to be applied to the clamping of the bushes. The bolts can be re-used, but if bolt replacement is

necessary the correct bolt with the wax coating must be used.

Colour Code Total No. of Coils Free Length Model

Brown/Orange 8.73 384.7 mm (15.14 in) 5 Seat

Grey/Orange 8.73 392 mm (15.43 in) 5 Seat

Yellow/Grey 8.73 376.6 mm (14.82 in) 5 Seat

Pink/Grey 8.73 400.3 mm (15.75 in) 5 Seat

Blue/Grey 9.10 387.8 mm (15.26 in) 7 Seat

Green/Grey 9.10 395.2 mm (15.55 in) 7 Seat

White/Grey 9.10 380.6 mm (14.98 in) 7 Seat

Left Hand Drive Right Hand Drive

Both Sides RH Side LH Side

Brown/Orange Grey/Orange Yellow/Grey

Grey Orange Pink/Grey Brown/Orange

Blue/Grey Green/Grey White/Grey

Page 817 of 1529

REAR SUSPENSION

64-8 DESCRIPTION AND OPERATION

Anti-roll bar

The anti-roll bars fitted differ between ACE and non-ACE vehicles. On non-ACE vehicles a conventional 'passive' anti-

roll bar is used. On ACE vehicles an 'active' torsion bar is used. Both types are attached to the tubular cross-member

at the rear of the chassis with mounting rubbers and clamp plates. The clamp plates locate in fabricated brackets

attached to the tubular cross-member and secured with bolts.

Each end of the anti-roll bar is attached to an anti-roll bar link. Each link has a spherical bearing attached at each end.

One end is attached to a bracket on the axle and secured with a locknut. The opposite end attaches through a hole

in the anti-roll bar and is also secured with a locknut. On 'active' torsion bars, the RH anti-roll bar link is attached to a

long arm which in turn is attached to the anti-roll bar.

Passive anti-roll bar

The passive anti-roll bar is a conventional anti-roll bar which opposes axle movement, reducing the effects of lateral

forces on the vehicle body.

With the conventional passive anti-roll bar, axle movement is opposed by the anti-roll bar through links attached to

the axle casing and each end of the anti-roll bar.

On vehicles with coil springs (no SLS fitted) the anti-roll bar is manufactured from 19 mm (0.74 in.) diameter spring

steel bar.

On vehicles with air springs (SLS fitted) the anti-roll bar is manufactured from 29 mm (1.14 in.) diameter spring steel

bar.

Active torsion bar

+ FRONT SUSPENSION, DESCRIPTION AND OPERATION, Description - ACE.The 'active' torsion bar is

used in conjunction with the ACE system to control body roll and directional stability giving a reduction of the effects

of lateral forces on the vehicle body over a conventional 'passive' anti-roll bar.

The torsion bar opposes axle movement by the application of a hydraulic force to oppose the lateral forces through

links attached to the axle casing and each end of the bar. The torsion bar is made from 35 mm (1.4 in.) diameter spring

steel. One end is fitted with an arm which is operated by a hydraulic actuator to oppose corning forces.

Page 863 of 1529

BRAKES

70-10 DESCRIPTION AND OPERATION

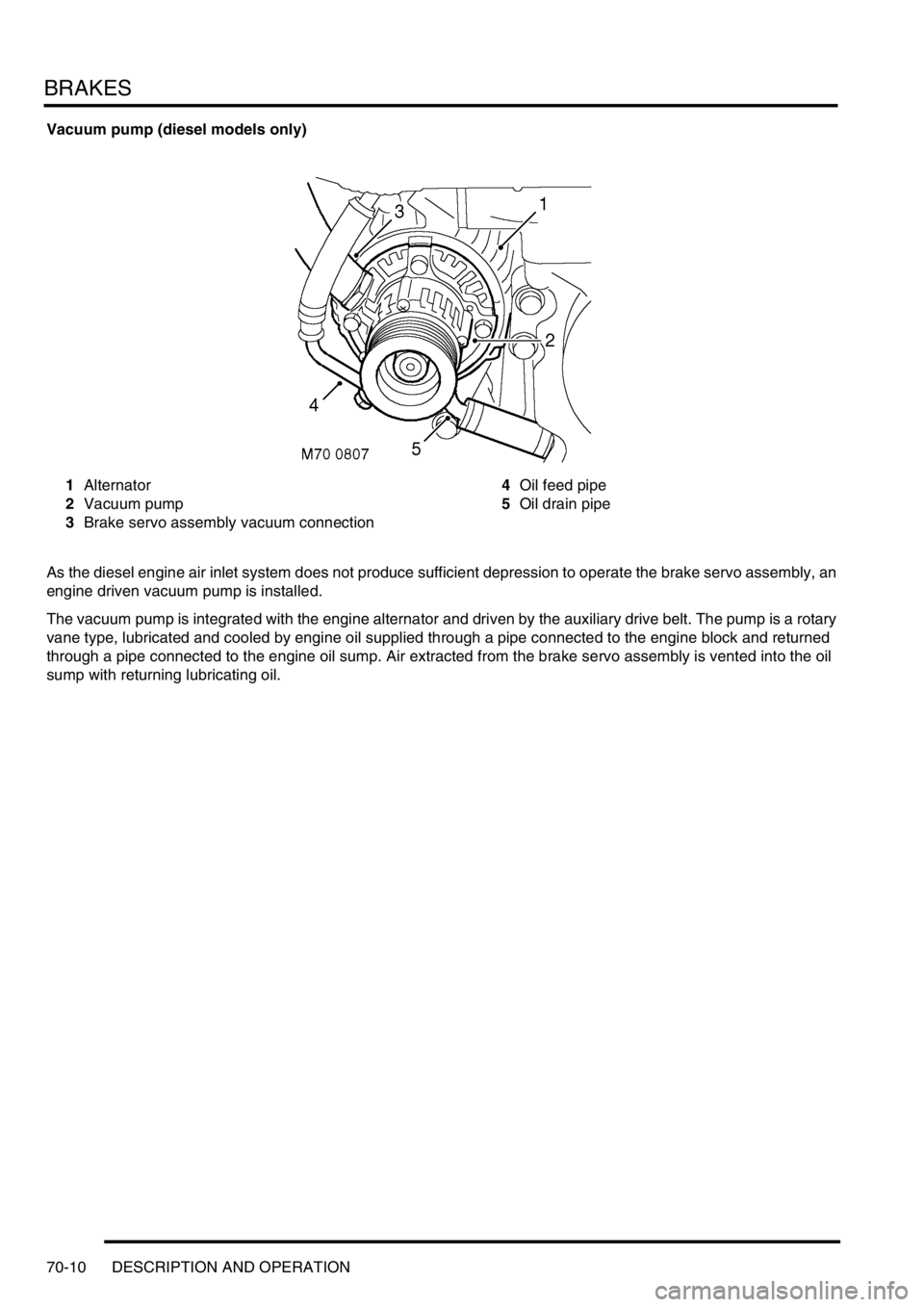

Vacuum pump (diesel models only)

1Alternator

2Vacuum pump

3Brake servo assembly vacuum connection4Oil feed pipe

5Oil drain pipe

As the diesel engine air inlet system does not produce sufficient depression to operate the brake servo assembly, an

engine driven vacuum pump is installed.

The vacuum pump is integrated with the engine alternator and driven by the auxiliary drive belt. The pump is a rotary

vane type, lubricated and cooled by engine oil supplied through a pipe connected to the engine block and returned

through a pipe connected to the engine oil sump. Air extracted from the brake servo assembly is vented into the oil

sump with returning lubricating oil.

Page 1216 of 1529

AIR CONDITIONING

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING 82-27

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

Refrigerant recovery, recycling and

recharging

$% 82.30.02

Recovery

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

Operate the refrigerant station in accordance

with the manufacturers instructions.

5.Turn Process switch to correct position.

6.Turn Main switch to 'ON'.

7.Allow station to recover refrigerant from

system.

WARNING: Refrigerant must always be

recycled before re-use to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance

with SAE J1991. Other equipment may not

recycle refrigerant to the required level of

purity.

A R134a Refrigerant Recovery Recycling

Recharging Station must not be used with

any other type of refrigerant.

Refrigerant R134a from domestic and

commercial sources must not be used in

motor vehicle air conditioning systems.

8.Close valves on refrigerant station.

9.Turn Main switch to 'OFF'.

10.Close valves on connectors.

11.Disconnect connectors high and low pressure

hoses from connectors.

12.Fit dust caps to connectors. 13.Open tap at rear of station to drain refrigerant

oil.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

WARNING: Servicing must only be carried

out by personnel familiar with both the

vehicle system and the charging and testing

equipment. All operations must be carried

out in a well ventilated area away from open

flame and heat sources.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn Main switch to 'ON'.

7.Allow station to evacuate system.

Page 1516 of 1529

INSTRUMENTS

DESCRIPTION AND OPERATION 88-33

Engine oil pressure warning lamp

The engine oil pressure warning lamp within the instrument pack utilises a red LED and a clear legend. The LED

illuminates when the engine oil pressure is below the specified pressure (see table), providing the driver with a visible

warning that the engine oil pressure has fallen below the specified minimum reading.

There is no self-test performed at ignition on for this warning lamp.

The power input for the LED is supplied by the instrument pack via fuse 27. The oil pressure switch located on the

engine provides the earth path to illuminate the warning lamp, it will remain illuminated until the engine is started and

the oil pressure exceeds the appropriate threshold and opens the switch contacts.

Low oil pressure switch operating pressures

The response to the voltage signal at the instrument pack is as follows:

l< 1.8 volts = warning lamp on.

l> 7.7 volts = warning lamp off.

Engine type Switch opening pressure, bar (lbf.in2)

V8 0.22 to 0.59 (3.0 to 8.5)

Diesel 0.25 to 0.42 (3.5 to 6.0)