LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 481 of 1529

Page 482 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-11

REPAIRS

Housing - gear selector

$% 37.16.37

Remove

1.Remove centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

2.Loosen pinch bolt and remove gear lever

extension.

3.Drill out 9 pop rivets and remove gear lever

cover plate and seal.

4.Remove retaining strap and remove gear lever

housing rubber boot.5.Remove 4 bolts securing gear selector

housing.

6.Remove gear selector housing.

Refit

1.Clean mating faces on selector housing and

gearbox.

2.Apply sealant, Part No. STC 4404 to selector

housing.

3.Clean selector housing bolt threads and apply

sealant, Part No. STC 50552 to threads.

4.Position selector housing and tighten bolts to

25 Nm (18 lbf.ft).

5.Loosen bias adjustment plate bolts.

6.Select 4th gear, move lever fully to the right

and tighten bias adjustment plate bolts to 25

Nm (18 lbf.ft)

7.Check adjustment is correct by selecting 3rd

and 4th gears.

8.Fit gear lever housing rubber and secure with

retaining strap.

9.Fit seal and cover plate and secure with pop

rivets.

10.Fit gear lever extension and tighten pinch bolt

to 25 Nm (18 lbf.ft).

11.Fit centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

Page 483 of 1529

MANUAL GEARBOX - R380

37-12 REPAIRS

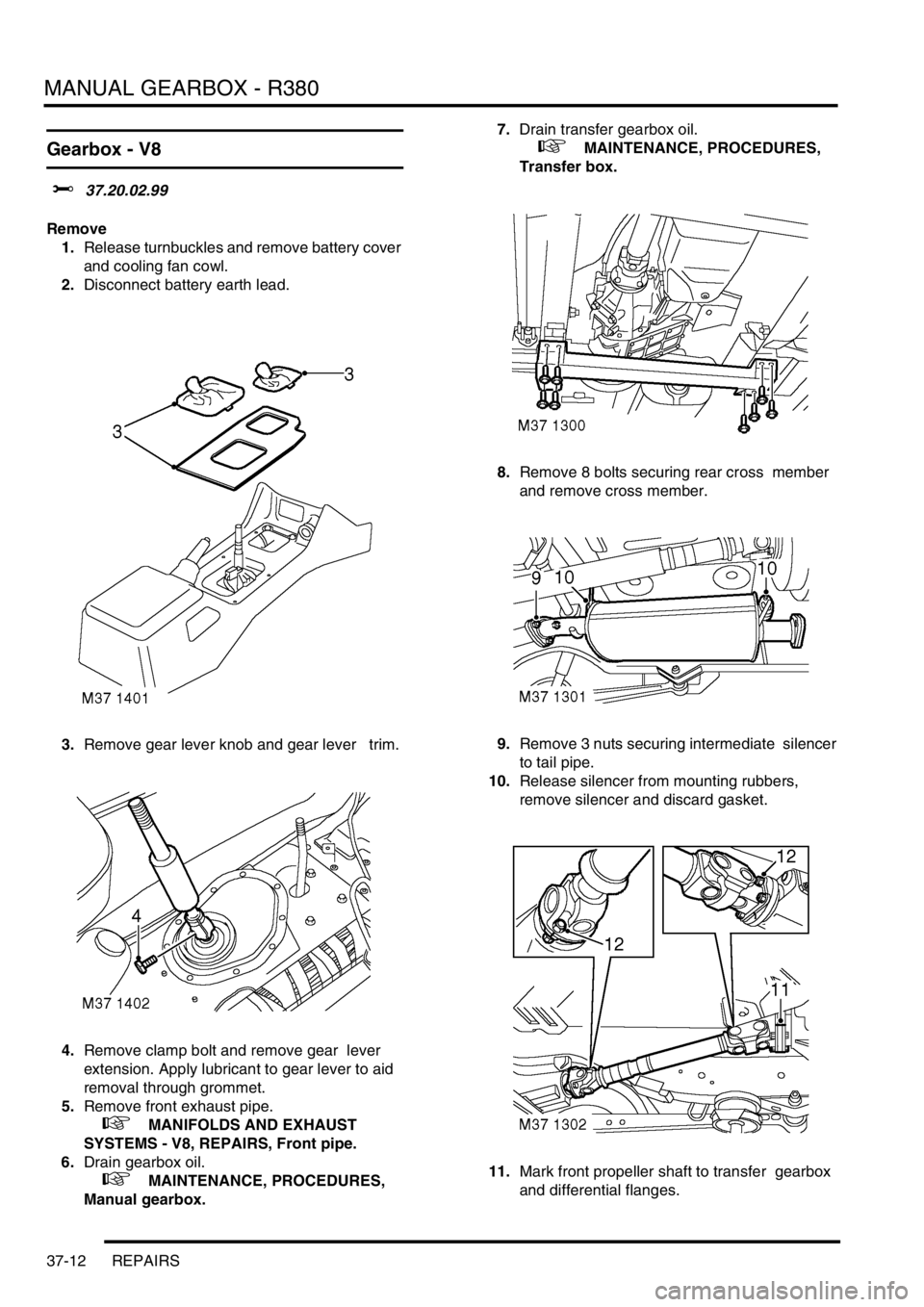

Gearbox - V8

$% 37.20.02.99

Remove

1.Release turnbuckles and remove battery cover

and cooling fan cowl.

2.Disconnect battery earth lead.

3.Remove gear lever knob and gear lever trim.

4.Remove clamp bolt and remove gear lever

extension. Apply lubricant to gear lever to aid

removal through grommet.

5.Remove front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

6.Drain gearbox oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.7.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

8.Remove 8 bolts securing rear cross member

and remove cross member.

9.Remove 3 nuts securing intermediate silencer

to tail pipe.

10.Release silencer from mounting rubbers,

remove silencer and discard gasket.

11.Mark front propeller shaft to transfer gearbox

and differential flanges.

Page 484 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-13

12.Remove 8 nuts securing front propeller shaft to

transfer gearbox and differential.

13.Remove propeller shaft.

14.Repeat above operation for rear propeller

shaft.

15.Remove handbrake drum retaining screw and

remove handbrake drum.

16.Remove 4 bolts from handbrake back plate,

release back plate and tie aside. 17.Remove 2 bolts securing clutch slave cylinder,

collect heat shield, release slave cylinder and

position aside.

18.Fit support plate LRT-99-007 to gearbox jack.

19.Position gearbox jack and support plate to

gearbox and secure with 3 bolts.

20.Support the weight of gearbox, remove nuts

securing gearbox mountings to body.

21.Remove 8 bolts securing mountings to

gearbox, raise gearbox and remove both

mountings.

Page 485 of 1529

MANUAL GEARBOX - R380

37-14 REPAIRS

22.Lower gearbox sufficiently to access top of

gearbox.

23.Ensure gear lever is released from grommet

and no wires or pipes are trapped when

gearbox is lowered.

24.Remove clevis pin and 'C' washer securing low

ratio selector cable to lever and release cable

from lever housing.

25.Remove 2 cable ties securing cable to fuel

pipes. 26.Disconnect 2 Lucars from oil temperature

sensor and disconnect reverse lamp switch

multiplug.

27.Remove banjo bolts securing breather pipes

and discard sealing washers.

28.Remove bolt securing breather pipe 'P' clip and

release breather pipes.

29. If fitted: Disconnect 2 Lucars from differential

lock switch, release and disconnect transfer

box neutral sensor multiplug.

30. If fitted: Release harness from 2 retaining

clips.

31.Position container to catch oil spillage

Page 486 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-15

32.Remove 3 bolts securing oil cooling pipe

housing to gearbox, release housing and

discard 'O' rings.

33.Using a second jack support the weight of the

engine.

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing. 5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 487 of 1529

MANUAL GEARBOX - R380

37-16 REPAIRS

Gearbox - Diesel

$% 37.20.02.99

Remove

1.Release turn buckles and remove battery cover

and cooling fan cowl.

2.Disconnect battery earth lead.

3.Remove gear lever knob and gear lever trim.

4.Remove clamp bolt and remove gear lever

extension.

5.Apply a little lubricant to gear lever to aid

removal through grommet.

6.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.7.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

8.Drain gearbox oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

9.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

10.Remove 3 nuts securing intermediate silencer

to tail pipe.

11.Release silencer from mounting rubbers,

remove silencer and discard gasket.

12.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

13.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

Page 488 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-17

14.Remove handbrake drum retaining screw and

remove handbrake drum.

15.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

16.Remove 2 bolts securing clutch slave cylinder,

collect heat shield, release slave cylinder and

position aside. 17.Fit support plate LRT-99-007 to gearbox jack.

18.Position gearbox jack and support plate to

gearbox and secure with 3 bolts.

19.Support the weight of gearbox, remove nuts

securing gearbox mountings to body.

20.Remove 4 bolts securing both mountings to

gearbox, raise gearbox and remove both

mountings.

21.Lower gearbox sufficiently to access top of

gearbox.

Page 489 of 1529

MANUAL GEARBOX - R380

37-18 REPAIRS

22.Ensure gear lever is released from grommet

and no wires or pipes are trapped when

gearbox is lowered.

23.Remove clevis pin and 'C' washer securing low

ratio selector cable to lever and release cable

from lever housing.

24.Remove 2 cable ties securing cable to fuel

pipes. 25.Disconnect 2 Lucars from oil temperature

sensor and disconnect reverse lamp switch

multiplug.

26.Remove banjo bolts securing breather pipes

and discard sealing washers.

27.Remove bolt securing breather pipe 'P' clip and

release breather pipes.

28. If fitted: Disconnect 2 Lucars from differential

lock switch, release and disconnect transfer

box neutral sensor multiplug. Release harness

from 2 retaining clips.

29.Position container to catch oil spillage

30.Remove 2 bolts securing oil cooling pipe

housing to gearbox, release housing and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

31.Using a second jack support the weight of the

engine.

Page 490 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties.

13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox. 17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.