LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 511 of 1529

MANUAL GEARBOX - R380

37-40 OVERHAUL

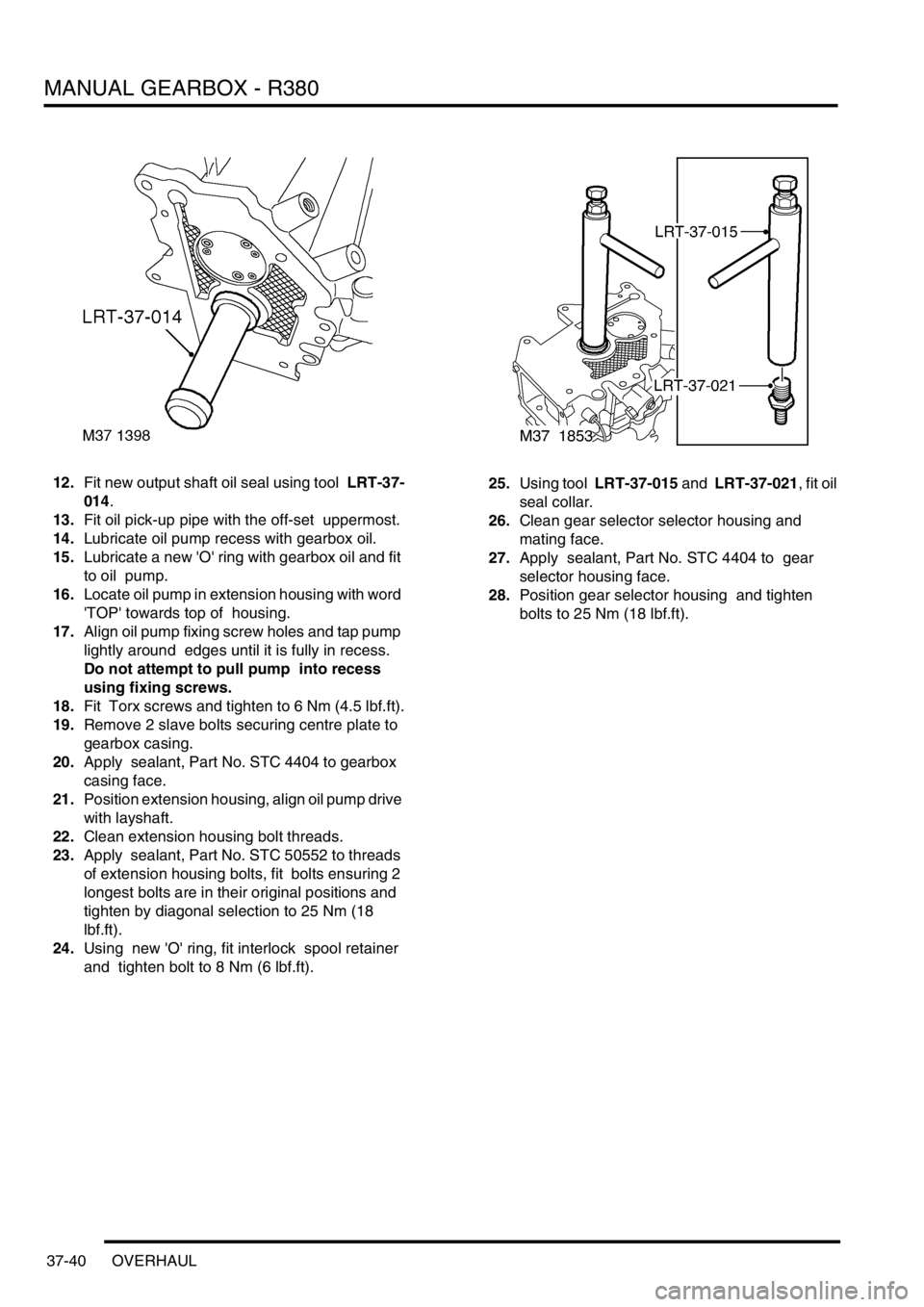

12.Fit new output shaft oil seal using tool LRT-37-

014.

13.Fit oil pick-up pipe with the off-set uppermost.

14.Lubricate oil pump recess with gearbox oil.

15.Lubricate a new 'O' ring with gearbox oil and fit

to oil pump.

16.Locate oil pump in extension housing with word

'TOP' towards top of housing.

17.Align oil pump fixing screw holes and tap pump

lightly around edges until it is fully in recess.

Do not attempt to pull pump into recess

using fixing screws.

18.Fit Torx screws and tighten to 6 Nm (4.5 lbf.ft).

19.Remove 2 slave bolts securing centre plate to

gearbox casing.

20.Apply sealant, Part No. STC 4404 to gearbox

casing face.

21.Position extension housing, align oil pump drive

with layshaft.

22.Clean extension housing bolt threads.

23.Apply sealant, Part No. STC 50552 to threads

of extension housing bolts, fit bolts ensuring 2

longest bolts are in their original positions and

tighten by diagonal selection to 25 Nm (18

lbf.ft).

24.Using new 'O' ring, fit interlock spool retainer

and tighten bolt to 8 Nm (6 lbf.ft). 25.Using tool LRT-37-015 and LRT-37-021, fit oil

seal collar.

26.Clean gear selector selector housing and

mating face.

27.Apply sealant, Part No. STC 4404 to gear

selector housing face.

28.Position gear selector housing and tighten

bolts to 25 Nm (18 lbf.ft).

Page 512 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-41

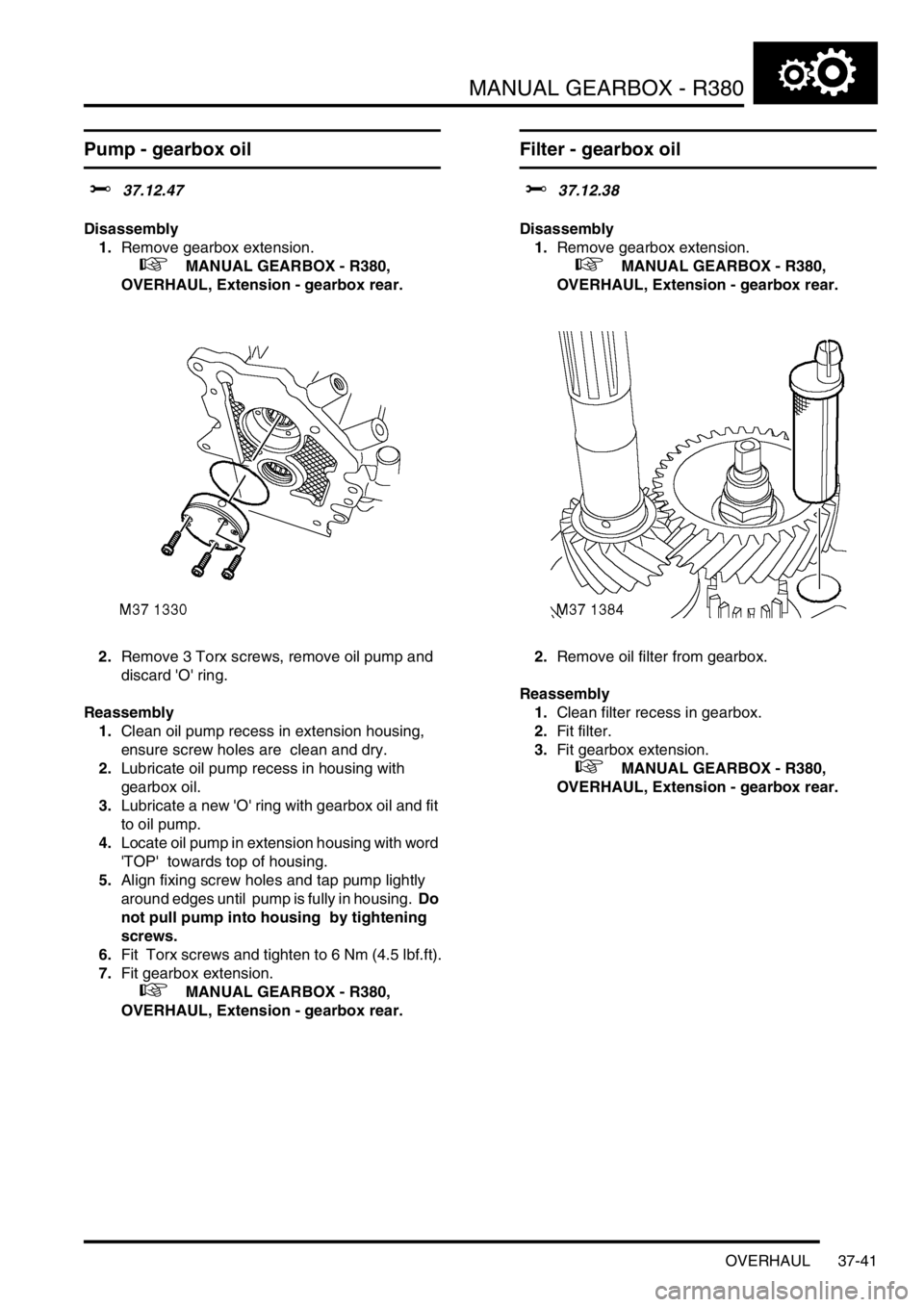

Pump - gearbox oil

$% 37.12.47

Disassembly

1.Remove gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove 3 Torx screws, remove oil pump and

discard 'O' ring.

Reassembly

1.Clean oil pump recess in extension housing,

ensure screw holes are clean and dry.

2.Lubricate oil pump recess in housing with

gearbox oil.

3.Lubricate a new 'O' ring with gearbox oil and fit

to oil pump.

4.Locate oil pump in extension housing with word

'TOP' towards top of housing.

5.Align fixing screw holes and tap pump lightly

around edges until pump is fully in housing. Do

not pull pump into housing by tightening

screws.

6.Fit Torx screws and tighten to 6 Nm (4.5 lbf.ft).

7.Fit gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Filter - gearbox oil

$% 37.12.38

Disassembly

1.Remove gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove oil filter from gearbox.

Reassembly

1.Clean filter recess in gearbox.

2.Fit filter.

3.Fit gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Page 513 of 1529

MANUAL GEARBOX - R380

37-42 OVERHAUL

Gear - 5th gear set

$% 37.20.36

Disassembly

1.Remove 5th gear - layshaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, 5th gear - layshaft.

2.Using tool LRT-37-001/2, LRT-37-009 and

LRT-37-010, remove output shaft support

bearing track.

3.Remove 5th gear and baulk ring from output

shaft. Reassembly

1.Clean gears and shafts.

2.Position 5th gear and baulk ring to output shaft.

3.Using tool LRT-37-015 and LRT-37-021, fit

support bearing track to output shaft.

4.Fit 5th gear - layshaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, 5th gear - layshaft.

Page 514 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-43

Synchronizer assembly - 5th/reverse

$% 37.20.38

Disassembly

1.Remove gearbox rear extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove 5th gear set.

+ MANUAL GEARBOX - R380,

OVERHAUL, Gear - 5th gear set.

3.Remove split needle roller bearing from output

shaft.

4.Remove and discard Allen screw and remove

gear change yoke.

5.Remove and discard circlip securing 5th/

reverse synchronizer hub to output shaft.

6.Remove synchronizer hub and selector fork

assembly. Reassembly

1.Clean gears, shafts, bearings and selector

fork.

2.Position selector fork to synchronizer, fit

assembly to output shaft and selector shaft. Fit

new hub retaining circlip.The fit of the circlip

is controlled by the selective washer behind

the reverse gear bearing collar on the

output shaft.

3. Adjust to give a reverse gear end-float of

0.005 - 0.055mm (0.0002 - 0.0021in).

4.Apply sealant, Part No. STC 50552 to threads

of new gear change lever yoke Allen screw.

5.Position gear change lever yoke and tighten

Allen screw to 25 Nm (18 lbf.ft).

6.Position split needle roller bearing to output

shaft.

7.Fit 5th gear set.

+ MANUAL GEARBOX - R380,

OVERHAUL, Gear - 5th gear set.

8.Fit gearbox rear extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Page 515 of 1529

MANUAL GEARBOX - R380

37-44 OVERHAUL

5th gear - layshaft

$% 37.20.43

Disassembly

1.Remove gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Using a suitable two legged puller and remove

5th gear layshaft support bearing track from

end of layshaft.

3.Release staking from 5th gear retaining nut. 4.Using tool LRT-37-023 to hold 5th gear,

remove and discard stake nut.

5.Remove retaining ring and split collars

securing 5th gear to output shaft.

Page 516 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-45

6.Remove split collar and 5th gear from layshaft. Reassembly

1.Clean gear and layshaft.

2.Position 5th gear and split collar to layshaft

ensuring that bevelled side of collar is towards

5th gear.

3.Position split collars and retaining ring securing

5th gear to output shaft.

4.Position tool LRT-37-023 to hold 5th gear and

tighten new stake nut to 220 Nm (162 lbf.ft) and

stake nut.

5.Apply a small amount of heat and fit support

bearing track to layshaft.

6.Fit gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Page 517 of 1529

MANUAL GEARBOX - R380

37-46 OVERHAUL

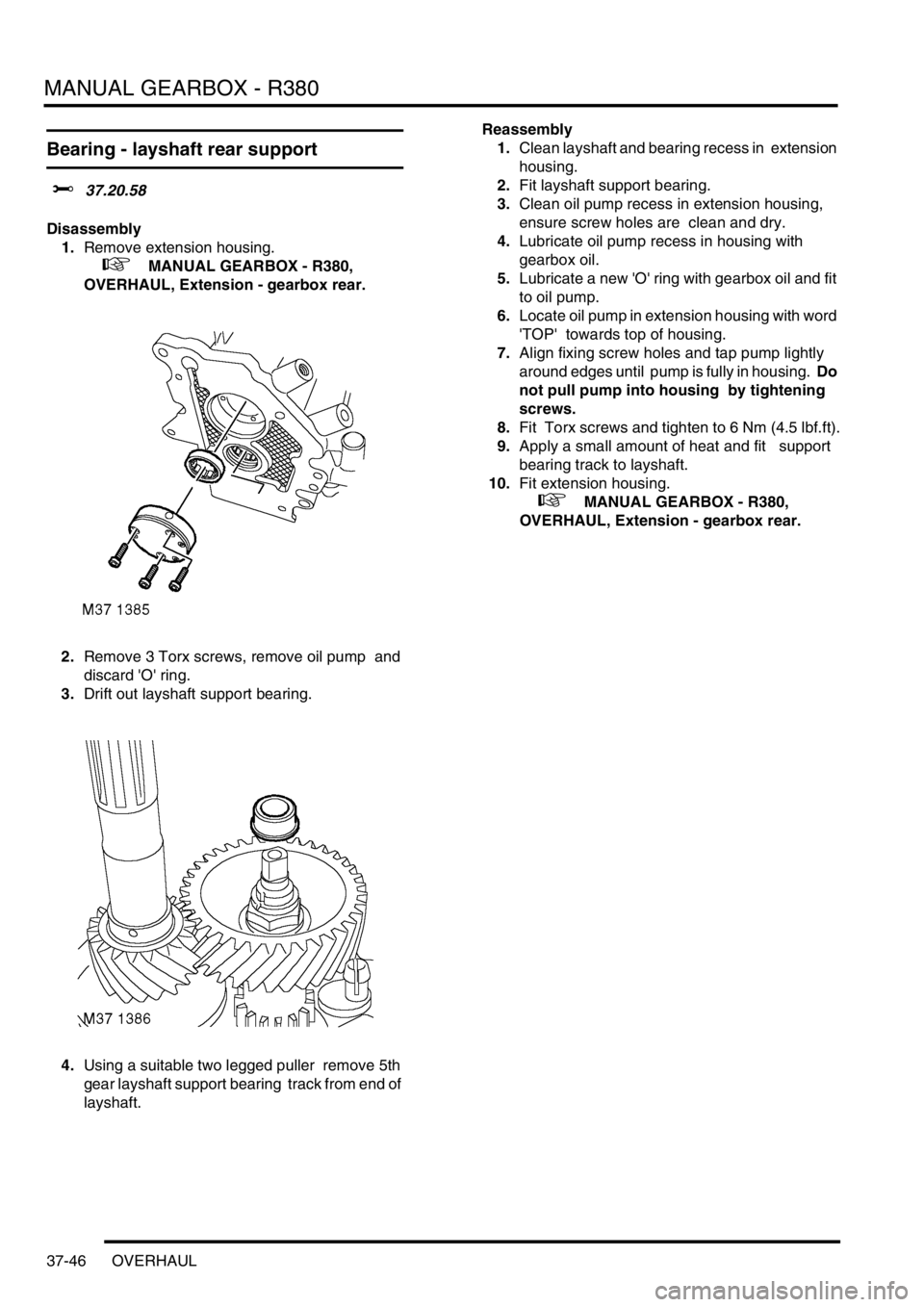

Bearing - layshaft rear support

$% 37.20.58

Disassembly

1.Remove extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove 3 Torx screws, remove oil pump and

discard 'O' ring.

3.Drift out layshaft support bearing.

4.Using a suitable two legged puller remove 5th

gear layshaft support bearing track from end of

layshaft. Reassembly

1.Clean layshaft and bearing recess in extension

housing.

2.Fit layshaft support bearing.

3.Clean oil pump recess in extension housing,

ensure screw holes are clean and dry.

4.Lubricate oil pump recess in housing with

gearbox oil.

5.Lubricate a new 'O' ring with gearbox oil and fit

to oil pump.

6.Locate oil pump in extension housing with word

'TOP' towards top of housing.

7.Align fixing screw holes and tap pump lightly

around edges until pump is fully in housing. Do

not pull pump into housing by tightening

screws.

8.Fit Torx screws and tighten to 6 Nm (4.5 lbf.ft).

9.Apply a small amount of heat and fit support

bearing track to layshaft.

10.Fit extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Page 518 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-47

Bearing - output shaft rear support

$% 37.20.55

Disassembly

1.Remove extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Using tool LRT-37-001/2, LRT-37-009 and

LRT-37-010, remove output shaft support

bearing track.

3.Remove output shaft rear oil seal. 4.Remove output shaft support bearing and oil

pick-up ring.

Reassembly

1.Clean output shaft and bearing recess in

extension housing.

2.Fit output shaft support bearing and oil pick-up

ring. (Align tag with centre of drain slot).

3.Fit new output shaft oil seal using LRT-37-014.

Page 519 of 1529

MANUAL GEARBOX - R380

37-48 OVERHAUL

4.Using tool LRT-37-015 and LRT-37-021, fit

support bearing track to output shaft.

5.Fit extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Shaft - reverse idler

$% 37.20.13

Disassembly

1.Remove 5th / reverse gear synchroniser.

+ MANUAL GEARBOX - R380,

OVERHAUL, Synchronizer assembly - 5th/

reverse.

2.Remove reverse gear complete with needle

roller bearing and collar noting selective spacer

between collar and centre plate bearing.

3.Remove layshaft reverse gear noting oil groove

faces centre plate bearing.

4.Remove detent screw from centre plate and

collect upper detent ball and spring.

Page 520 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-49

5.Remove 2 bolts securing spool retainer to

gearbox case. Remove retainer, remove and

discard 'O' ring - if fitted.

6.Remove interlock spool from selector shaft.

7.Remove filter from gearbox case.

8.Align selector shaft pin with slot in centre plate

and using wooden blocks and hide mallet,

release centre plate and collect lower detent

ball and spring. 9.Press out reverse idler shaft using a suitable

press.

10.Remove idler gear, needle roller bearing and

spacer.