LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 501 of 1529

MANUAL GEARBOX - R380

37-30 OVERHAUL

4.Using tools LRT-37-043, LRT-37-043/2 and

LRT-99-002, press new bearing onto input

shaft.

5.Using tool LRT-99-002 and a suitable mandrel,

fit input shaft outer bearing track to front cover.

6.Fit layshaft bearing track to front cover.

7.Using tool LRT-99-002 and a suitable mandrel,

fit pilot bearing outer track to input shaft.

8.Clean synchroniser hubs, gears and bearings.

9.Position output shaft in protected vice jaws,

output end upwards.

10.Fit 2nd gear bearing, 2nd gear and

synchromesh baulk rings onto output shaft.

11.Position 1st / 2nd synchroniser hub onto output

shaft. Ensure that baulk rings are correctly

located in hub.

12.Position 1st gear synchromesh baulk rings,

needle roller bearing, 1st gear and bearing

collar onto output shaft. Ensure baulk rings are

correctly located in hub.

13.Remove output shaft from vice. 14.Using tool LRT-37-001, LRT-37-044 and

LRT-99-002, press taper bearing onto output

shaft.

15.Using a feeler gauge, check end float of 1st

gear between gear and collar flange:

lNew = 0.05 - 0.20 mm (0.002 - 0.008 in)

lService limit = 0.327 mm (0.012 in)

16.Using a feeler gauge, check end float of 2nd

gear between gear and output shaft flange:

lNew = = 0.04 - 0.21 mm (0.0016 - 0.0083

in)

lService limit = 0.337 mm (0.013 in)

Page 502 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-31

17.Invert output shaft in vise and fit 3rd gear,

bearing, baulk rings, 3rd / 4th synchroniser and

spacer.

18.Remove output shaft from vice.

19.Using tool LRT-99-002 and a suitable mandrel,

press pilot bearing onto output shaft.

20.Check end float of 3rd gear between gear and

flange on output shaft:

lNew = 0.11 - 0.21 mm (0.004 - 0.0083 in)

lService limit = 0.337 mm (0.013 in)

21.Check output shaft and layshaft end float as

follows.

22.The end float setting for both shafts is:

lNew = 0.00 to 0.05 mm (0.0 to - 0.002 in)

lService limit = 0.05 mm (0.002 in) 23.Fit front cover to gearbox case without the oil

seal and tighten bolts by diagonal selection to

25 Nm (18 lbf.ft).

24.Position in vice with front cover facing

downwards.

25.Fit input shaft to gearbox case less 4th gear

baulk ring.

26.Fit output shaft assembly to input shaft.

27.Fit output shaft bearing track and shim to centre

plate.

28.Fit centre plate to gearbox case and secure

using 8 slave bolts.

29.Rotate output shaft to settle bearings.

30.Fit a suitably large ball bearing into end of

output shaft.

31.Position a suitable DTI and zero probe on ball

bearing.

32.Lift output shaft and note DTI reading.

33.If reading is incorrect, dismantle and fit shim to

give correct end float.

34.Repeat above procedure.

35.Repeat procedure for layshaft end float.

36.Remove and discard 6 bolts and remove

gearbox front cover.

37.Fit gearbox selector fork - set.

+ MANUAL GEARBOX - R380,

OVERHAUL, Fork - set - selector shaft.

38.Fit gearbox front cover.

+ MANUAL GEARBOX - R380,

OVERHAUL, Cover - front.

Page 503 of 1529

MANUAL GEARBOX - R380

37-32 OVERHAUL

Synchroniser - gearbox - set

$% 37.20.07

Disassembly

1.Remove gearbox selector fork set.

+ MANUAL GEARBOX - R380,

OVERHAUL, Fork - set - selector shaft.

2.Using tool LRT-99-002 and support bars

under 1st gear, press output shaft bearing from

output shaft.

3.Remove 1st gear, bearing collar, needle roller

bearing and synchromesh rings.

4.Noting its fitted position, remove 1st / 2nd gear

synchroniser hub, 2nd gear synchromesh

rings, 2nd gear and needle roller bearing. 5.Using tool LRT-99-002 and support bars under

3rd gear, press off output shaft pilot bearing.

6.Remove spacer, 3rd / 4th gear synchroniser

hub, synchromesh baulk rings, 3rd gear and

needle roller bearing.

7.Remove output shaft.

Reassembly

1.Clean output shaft, synchroniser hubs, gears

and bearings.

2.Position output shaft in protected vice jaws,

output end upwards.

3.Fit 2nd gear bearing, 2nd gear and

synchromesh baulk rings onto output shaft.

4.Position 1st / 2nd synchroniser hub onto output

shaft. Ensure that baulk rings are correctly

located in hub.

5.Position 1st gear synchromesh baulk rings,

needle roller bearing, 1st gear and bearing

collar onto output shaft. Ensure baulk rings are

correctly located in hub.

6.Remove output shaft from vice.

Page 504 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-33

7.Using tool LRT-37-001, LRT-37-044 and

LRT-99-002, press taper bearing onto output

shaft.

8.Check end float of 1st gear using a feeler gauge

between gear and collar flange:

lNew = 0.05 - 0.20 mm (0.002 - 0.008 in)

lService limit = 0.327 mm (0.012 in)

9.Check end float of 2nd gear using a feeler

gauge between gear and output shaft flange:

lNew = 0.04 - 0.21 mm (0.0016 - 0.0083 in)

lService limit = 0.337 mm (0.013 in)10.Invert output shaft in vice and fit 3rd gear,

bearing, baulk rings, 3rd / 4th synchroniser and

spacer.

11.Remove output shaft from vice.

12.Using tool LRT-99-002 and a suitable mandrel

press pilot bearing onto output shaft.

13. Check end float of 3rd gear between gear and

flange on output shaft.

lNew = 0.11 - 0.21 mm (0.004 - 0.0083 in)

lService limit = 0.337 mm (0.013 in)

14.Fit gearbox selector fork set.

+ MANUAL GEARBOX - R380,

OVERHAUL, Fork - set - selector shaft.

Page 505 of 1529

MANUAL GEARBOX - R380

37-34 OVERHAUL

Fork - set - selector shaft

$% 37.16.45

Disassembly

1.Remove reverse idler gear shaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, Shaft - reverse idler.

2.With assistance, remove output shaft, selector

shaft and layshaft assemblies.

3.Remove selector shaft and fork assembly from

output shaft synchronisers.

4.Inspect the selector fork pads for wear, the

wear limit is 6.5 mm (2.559 in).Reassembly

1.Clean selector shaft, forks and locations on

synchronisers.

2.Lubricate forks and shaft with clean gear oil.

3.Position selector shaft assembly to output shaft

synchronisers.

4.With assistance, fit output shaft and layshaft

assembly into gearbox case.

5.Fit reverse idler gear shaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, Shaft - reverse idler.

Page 506 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-35

Shaft - gearbox - input

$% 37.20.16

Disassembly

1.Remove gearbox front cover.

+ MANUAL GEARBOX - R380,

OVERHAUL, Cover - front.

2.Remove reverse idler gear shaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, Shaft - reverse idler.

3.With assistance, remove output shaft, selector

shaft and layshaft as an assembly. Remove

selector shaft and fork. 4.Remove input shaft from gearbox case.

5.Using tool LRT-37-004, and LRT-99-004,

remove pilot bearing track from input shaft.

Page 507 of 1529

MANUAL GEARBOX - R380

37-36 OVERHAUL

6.Invert output shaft and using tool LRT- 99-002

and support bars under 3rd gear, press off pilot

bearing.7.Using tool LRT-37-043 and LRT-99-002,

remove taper roller bearing from input shaft.

8.Using a suitable soft metal drift, remove

bearing outer track from front cover.

9.Remove and discard input shaft oil seal from

front cover.

Page 508 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-37

Reassembly

1.Clean input shaft and bearing/oil seal recess in

front cover.

2.Lubricate a new input shaft oil seal with

gearbox oil.

3.Fit oil seal using a suitable mandrel.

4.Using a press and a suitable mandrel, fit

bearing outer track in front cover.

5.Using a press and a suitable mandrel, fit pilot

bearing outer track to input shaft.

6.Using tool LRT-37-043, LRT-37–043/2 and

LRT-99-002, fit new taper bearing to input

shaft.7.Using tool LRT-99-002 and a suitable mandrel,

press new pilot bearing onto output shaft.

8.Position input shaft to gearbox case.

9.With assistance, fit output shaft and layshaft

assembly into gearbox case.

10.Fit reverse idler gear shaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, Shaft - reverse idler.

11.Fit gearbox front cover.

+ MANUAL GEARBOX - R380,

OVERHAUL, Cover - front.

Page 509 of 1529

MANUAL GEARBOX - R380

37-38 OVERHAUL

Extension - gearbox rear

$% 37.12.01

Disassembly

1.Remove 4 bolts and remove gear selector

housing.

2.Using tools LRT-37-009, LRT-37-001/2 and

LRT-37-010 , remove output shaft oil seal

collar.3.Remove bolt securing interlock spool retainer

and discard 'O' ring.

4.Noting fitted position of 2 longest bolts, remove

10 bolts securing extension housing to

gearbox.

5.Remove extension housing from gearbox

centre plate.

Page 510 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-39

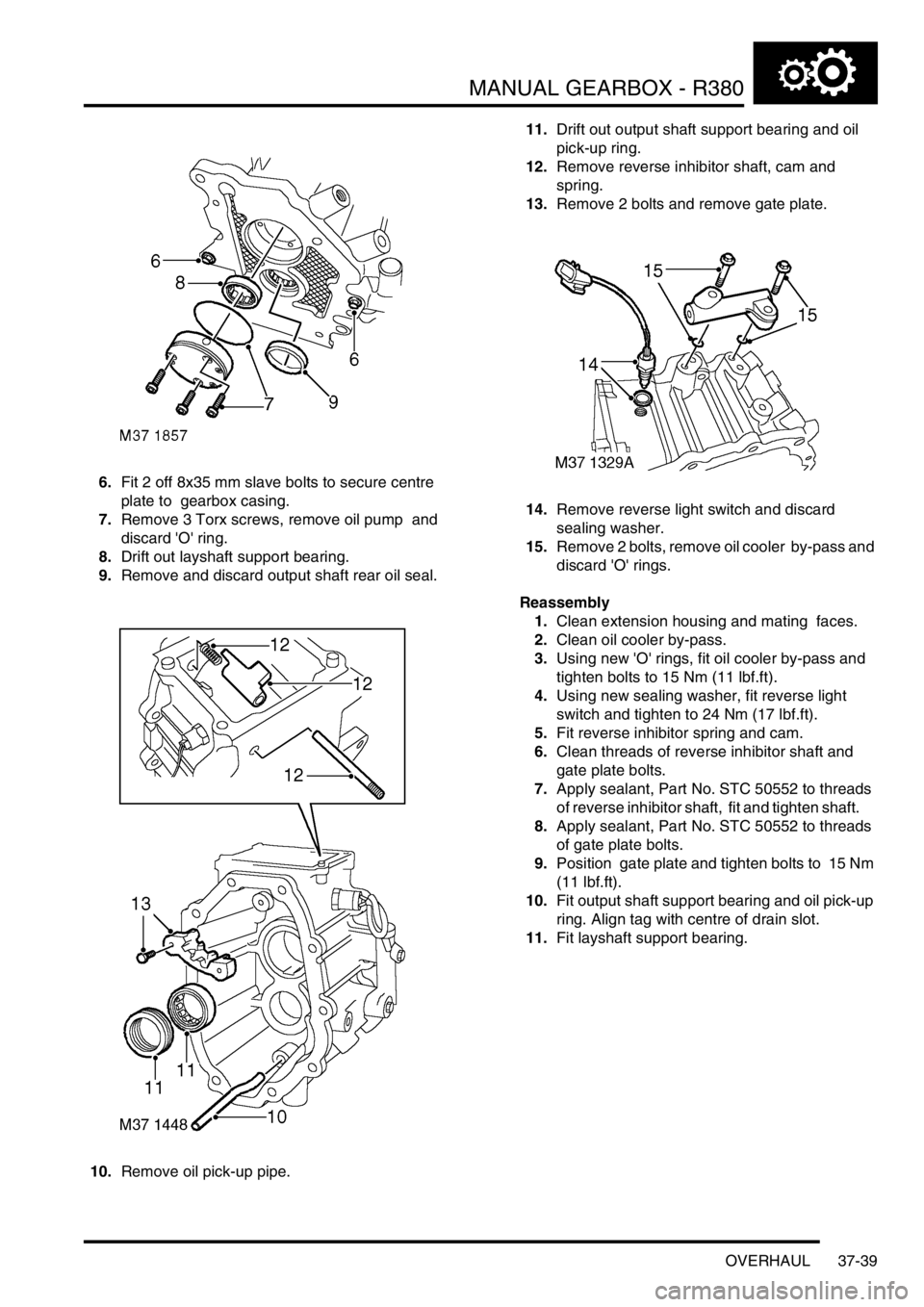

6.Fit 2 off 8x35 mm slave bolts to secure centre

plate to gearbox casing.

7.Remove 3 Torx screws, remove oil pump and

discard 'O' ring.

8.Drift out layshaft support bearing.

9.Remove and discard output shaft rear oil seal.

10.Remove oil pick-up pipe. 11.Drift out output shaft support bearing and oil

pick-up ring.

12.Remove reverse inhibitor shaft, cam and

spring.

13.Remove 2 bolts and remove gate plate.

14.Remove reverse light switch and discard

sealing washer.

15.Remove 2 bolts, remove oil cooler by-pass and

discard 'O' rings.

Reassembly

1.Clean extension housing and mating faces.

2.Clean oil cooler by-pass.

3.Using new 'O' rings, fit oil cooler by-pass and

tighten bolts to 15 Nm (11 lbf.ft).

4.Using new sealing washer, fit reverse light

switch and tighten to 24 Nm (17 lbf.ft).

5.Fit reverse inhibitor spring and cam.

6.Clean threads of reverse inhibitor shaft and

gate plate bolts.

7.Apply sealant, Part No. STC 50552 to threads

of reverse inhibitor shaft, fit and tighten shaft.

8.Apply sealant, Part No. STC 50552 to threads

of gate plate bolts.

9.Position gate plate and tighten bolts to 15 Nm

(11 lbf.ft).

10.Fit output shaft support bearing and oil pick-up

ring. Align tag with centre of drain slot.

11.Fit layshaft support bearing.