differential LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 589 of 1529

TRANSFER BOX - LT230SE

41-64 OVERHAUL

Dog clutch - differential lock

$% 41.20.23

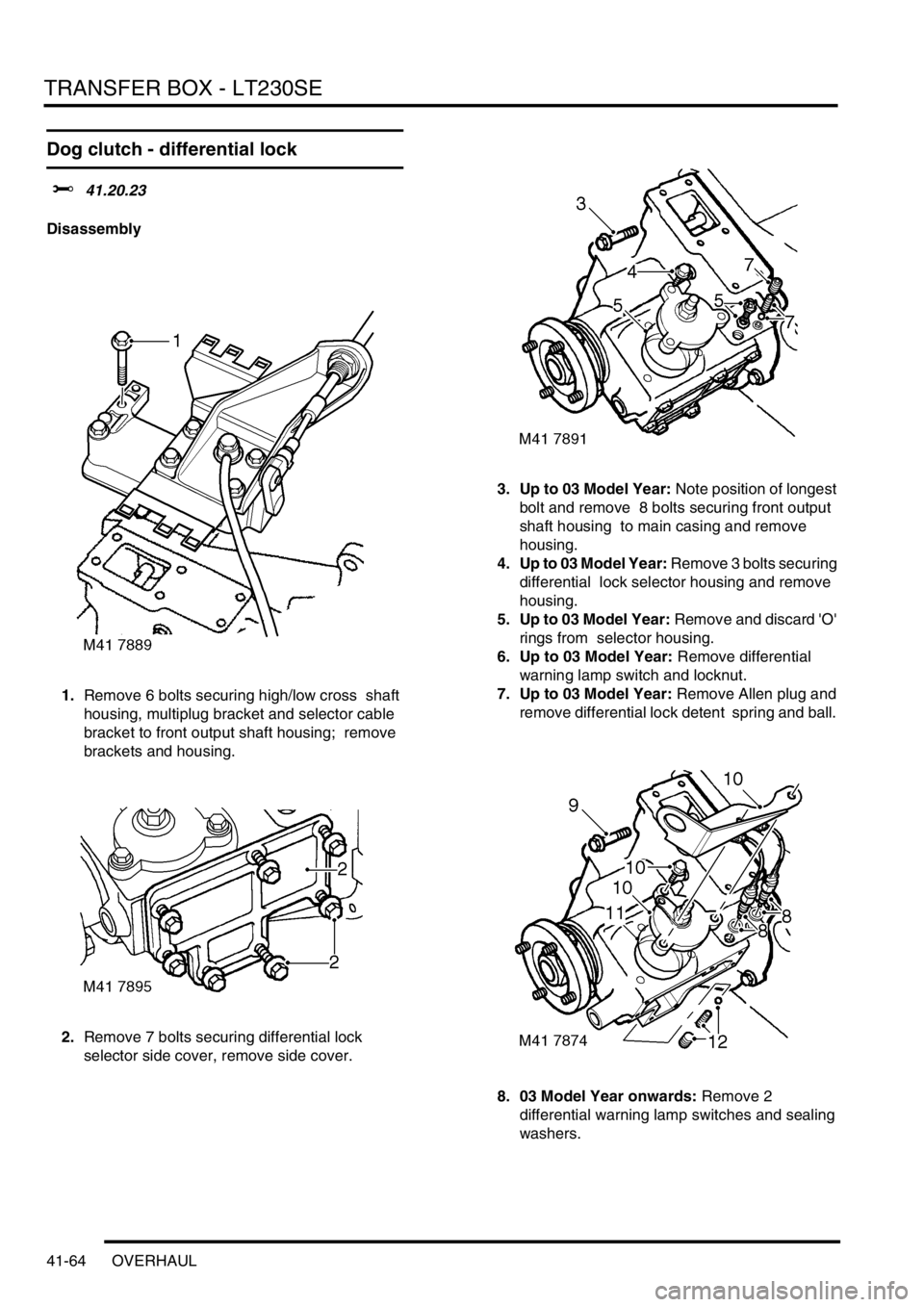

Disassembly

1.Remove 6 bolts securing high/low cross shaft

housing, multiplug bracket and selector cable

bracket to front output shaft housing; remove

brackets and housing.

2.Remove 7 bolts securing differential lock

selector side cover, remove side cover.3. Up to 03 Model Year: Note position of longest

bolt and remove 8 bolts securing front output

shaft housing to main casing and remove

housing.

4. Up to 03 Model Year: Remove 3 bolts securing

differential lock selector housing and remove

housing.

5. Up to 03 Model Year: Remove and discard 'O'

rings from selector housing.

6. Up to 03 Model Year: Remove differential

warning lamp switch and locknut.

7. Up to 03 Model Year: Remove Allen plug and

remove differential lock detent spring and ball.

8. 03 Model Year onwards: Remove 2

differential warning lamp switches and sealing

washers.

Page 590 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-65

9. 03 Model Year onwards:Note position of

longest bolt and remove 8 bolts securing front

output shaft housing to main casing; remove

housing.

10. 03 Model Year onwards:Remove 3 bolts

securing differential lock selector housing and

bracket, remove housing.

11. 03 Model Year onwards:Remove and discard

'O' rings from selector housing.

12. 03 Model Year onwards:Remove differential

lock detent plug, recover spring and ball.

13.Compress differential lock selector fork spring

and remove retaining clips from each end of

spring.

14.Withdraw differential lock selector shaft from

front output housing, recover spring and

remove selector fork.

15.Position tool LRT-51-003 to output shaft drive

flange, remove and discard nut. 16.Remove and discard steel and felt washers.

Remove output shaft drive flange.

17.Using a copper mallet, drive output shaft from

housing.

18.Noting its fitted position, remove bearing

spacer from output shaft.

19.Noting its fitted position, remove dog clutch

from output shaft.

20.Remove and discard oil seal from housing.

Reassembly

1.Clean differential lock components. Remove all

traces of sealant from mating faces of

housings, side cover, bolt threads, detent plugs

and differential lock warning lamp switches.

2.Lubricate components with gearbox oil.

3.Using tool LRT-41-012, fit new output shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Page 591 of 1529

TRANSFER BOX - LT230SE

41-66 OVERHAUL

4.Fit bearing spacer to output shaft with chamfer

on spacer towards threaded end.

5.Fit dog clutch with flange on clutch facing

towards splined end.

6.Using a copper mallet, drive output shaft into

bearing.

7.Compress differential lock selector spring and

fit selector fork.

8.Position selector fork to groove in dog clutch.

9.Fit differential lock selector shaft and locate in

housing recess, rotate shaft until the two flats

for retaining clips are at right angles to the

cover plate mating face.

10.Compress differential lock selector spring and

fit retaining clips at each end of spring.

CAUTION: Ensure ends of spring are fully

seated in recess in clips.

11.Apply sealant, Part No. STC 4600 to front

output shaft housing.

12.Position housing ensuring that output shaft and

dog clutch splines are correctly engaged.

13.Apply sealant, Part No. STC 50552 to threads

of bolts.

14.Fit front output shaft housing bolts and tighten

in a diagonal sequence to 45 Nm (33 lbf.ft).

15.Apply sealant, Part No. STC 4600 to mating

face of high/low selector housing.

16.Position high/low selector housing to front

output housing ensuring that high/low selector

finger is located in groove in selector shaft.

17. Position multiplug and selector cable brackets

to high/low selector housing

18.Apply sealant, Part No. STC 50552 to threads

of high/low selector housing bolts.

19.Fit bolts and tighten to 25 Nm (18 lbf.ft).20.Fit differential lock detent ball and spring.

21. Up to 03 Model Year: Apply sealant, Part No.

STC 50552 to threads of detent plug.

22. Up to 03 Model Year: Fit and tighten detent

plug, then unscrew 2 complete turns.

23. 03 Model Year onwards: Apply sealant, Part

No. STC 50552 to threads of differential lock

detent plug.

24.Fit differential lock detent ball and spring.

25.Fit detent plug and tighten until head of plug is

level with face of housing.

26.Using a suitable straight edge, check that head

of plug is correctly positioned, screw plug in or

out as necessary.

27.Lubricate and fit new 'O' rings to differential lock

selector housing.

28.Fit selector housing, ensure selector finger is

located in shaft recess.

29.Position bracket to selector housing.

30.Apply sealant, Part No. STC 50552 to threads

of selector housing bolts, fit bolts and tighten to

25 Nm (18 lbf.ft).

M41 7886

Page 592 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-67

31.Clean threads of differential lock warning lamp

switch(es).

32. Uo to 03 Model year: Fit nut to switch head

with counterbore positioned towards switch

head. The nut acts as a spacer to ensure

that switch setting is correct. Always

ensure that nut is fully tightened to switch

head (no gap).

33. Uo to 03 Model year: Apply sealant, Part No.

STC 50552 to threads of differential warning

lamp switch.

34. Uo to 03 Model year: Position switch into front

output housing until nut bottoms out on

housing, tighten nut to 11 Nm (8 lbf.ft).

35. 03 Model Year onwards: Fit new aluminium

sealing washers to differential lock warning

lamp switches.

CAUTION: Ensure that replacement

washers are the same thickness as the

originals.

36. 03 Model Year onwards: Apply sealant, Part

No. STC 50552 to threads of both switches.

37. 03 Model Year onwards: Fit switches and

tighten to 25 Nm (18 lbf.ft).

38. If fitted: Operate differential lock selector lever

and check that detent ball can be felt to

positively engage/disengage with grooves in

shaft.

39. Up to 03 Model Year: Screw plug in or out until

setting is correct

40.Apply sealant, Part No. STC 4600 to mating

face of differential lock selector side cover.

41.Apply sealant, Part No. STC 50552 to threads

of side cover bolts.

42.Position differential lock selector side cover to

front output shaft housing, fit bolts and tighten

25 Nm (18 lbf.ft).43.Fit output flange, new felt and steel washers

and new retaining nut.

44.Using tool LRT-51-003 to restrain flange,

tighten output flange nut to 162 Nm (119 lbf.ft).

Page 595 of 1529

TRANSFER BOX - LT230SE

41-70 OVERHAUL

7.Position dial gauge with stylus contacting input

gear, push input gear rearwards and zero

gauge.

8.Push input gear forwards and note gauge

reading.

9.Calculate thickness of shim required using the

formula - A+B+C=D where:

lA= Thickness of installed shim - 3.15 mm

(0.12 in)

lB= Recorded end-float.

lC= Required pre-load - 0.05 mm (0.002 in).

lD= Thickness of shim required.

10.If an alternative shim is required to establish

correct pre-load, fit an alternative shim. Shims

are available from 3.15 to 4.00 mm (0.12 to

0.16 in) thickness, in increments of 0.05 mm

(0.002 in).

11.Remove 2 bolts, remove bearing housing and

input gear.

12.Lubricate input gear and bearings with

recommended oil.

13.Position input gear into main casing.

14.Apply sealant, Part No. STC 4600to bearing

housing and cover.

15.Apply sealant, Part No. STC 50552 to threads

of cover bolts and stud nut.

16.Position bearing housing/cover, align reference

marks and tighten bolts and stud nut by

diagonal selection to 45 Nm (33 lbf.ft).

17.Using tool LRT-37-014 fit new input shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Low gear - differential

$% 41.20.62

Disassembly

1.Remove differential.

+ TRANSFER BOX - LT230SE,

OVERHAUL, Dog clutch - differential lock.

2.Secure differential in a soft jawed vice.

3.Release staking from bearing retaining nut.

4.Using tool LRT-41-007 remove and discard

bearing retaining nut.

5.Position tool LRT-99-002. to a vice.

6.Position tool LRT-41-001 around rear

differential bearing, position differential to tool

LRT-99-002 and press off bearing.

Page 596 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-71

7.Remove high range gear and bush.

8.Make suitable alignment marks between high/

low selector sleeve and hub, remove selector

sleeve. 9.Using a suitable press and thrust button LRT-

41-001remove high/low hub and low range

gear.

Reassembly

1.Clean differential components.

2.Lubricate components with gearbox oil.

3.Fit differential in soft jawed vice, and fit low

range gear with dog teeth facing uppermost.

4.Fit high/low hub ensuring that machined

groove on hub teeth faces towards low range

gear.

5.Fit high/low selector sleeve ensuring that

alignment marks on hub and sleeve are

together.

6.Fit bush to high range gear ensuring collar is

uppermost.

7.Fit high range gear and bush onto shaft.

Page 597 of 1529

TRANSFER BOX - LT230SE

41-72 OVERHAUL

8.Fit rear bearing using tool LRT-41-008.

9.Fit new bearing retaining nut and using tool

LRT-41-007, tighten to 72 Nm (53 lbf.ft).

CAUTION: Ensure that threads of nut are

'Patched.'

10.Using a suitable drift, stake collar of nut into

differential shaft recess.

11.Fit differential.

+ TRANSFER BOX - LT230SE,

OVERHAUL, Differential assembly.

Page 625 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-28 REPAIRS

15.Remove handbrake drum retaining screw and

remove brake drum.

16.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

17. Models fitted with high/low shift interlock

solenoid: Release interlock solenoid multiplug

and disconnect multiplug from main harness.

18. Models fitted with high/low shift interlock

solenoid: Remove sleeve retaining rings and

remove sleeve from high/low selector cable.

19. If fitted Remove and discard clevis pin

securing differential lock selector cable to

transfer gearbox.20. If fitted Loosen locknuts securing differential

lock selector cable to differential lock selector

cable abutment bracket.

21. If fitted Release and remove differential lock

selector cable from differential lock selector

cable abutment bracket.

22.Remove clevis pin securing high/low ratio

selector cable to selector lever, remove 'C' clip

and remove outer cable from abutment

bracket.

23. Up to 03 Model Year - If fitted: Disconnect

from differential lock warning lamp switch and

multiplugs from high/low ratio switch and

neutral sensor.

Page 626 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-29

24. 03 Model Year onwards - If fitted: Release

and disconnect both differential lock warning

lamp switch multiplugs from main harness.

25.Remove cable tie and multiplug from bracket

on transfer box.

26.Release transfer and automatic gearbox

breather pipes from clip at rear of cylinder

block.

27.Position gearbox support jack and secure tool

LRT-99-008A to support plate on jack. 28.Position a second support jack under engine

using a block between engine sump and jack

to prevent damage to sump.

29.Remove 4 bolts and nut, remove engine LH

rear mounting.

30.Remove 4 bolts and nut, remove engine RH

rear mounting.

31.Remove 2 bolts securing gearbox oil cooler

pipe clips to engine sump and alternator

mounting bracket.

Page 628 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-31

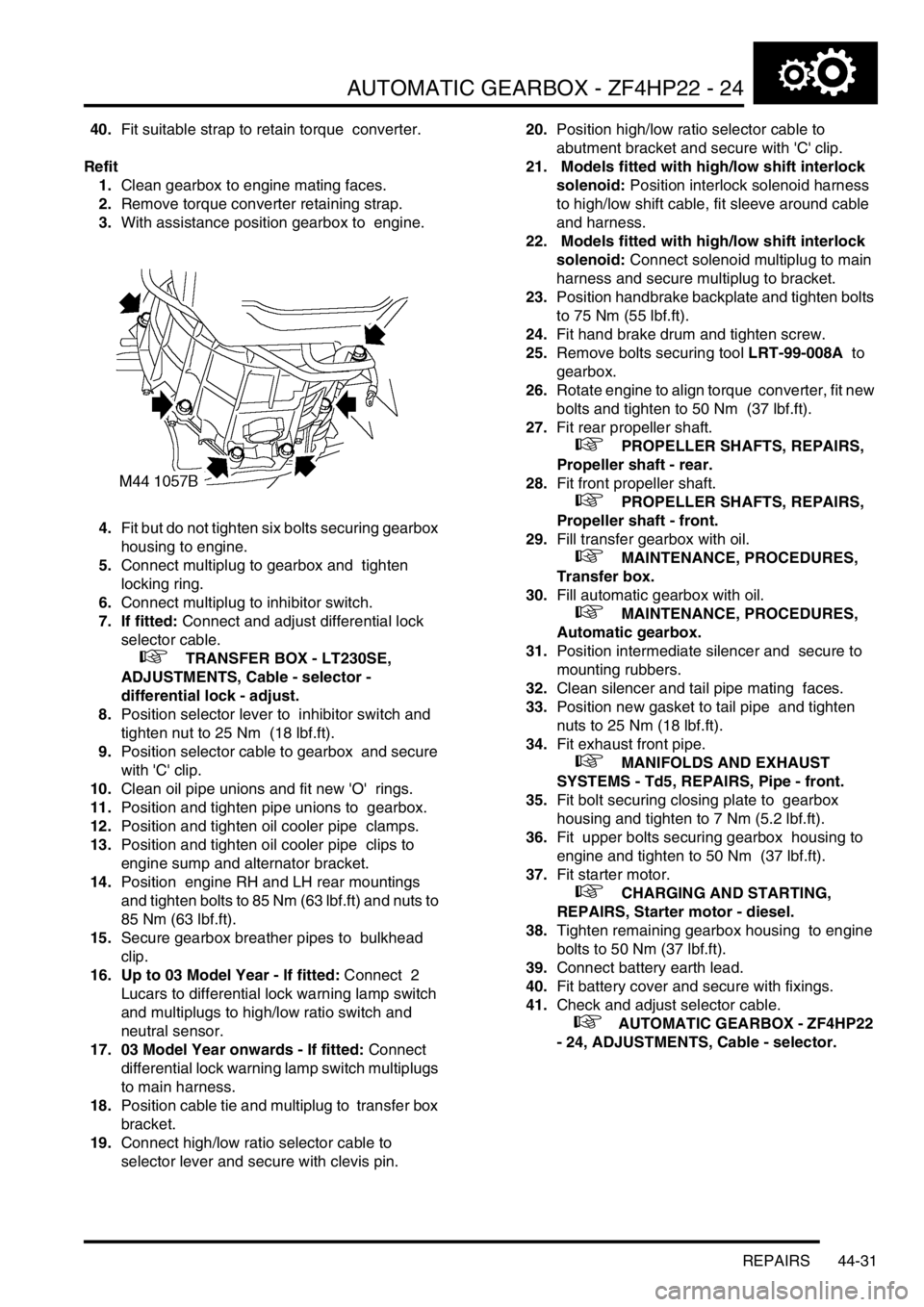

40.Fit suitable strap to retain torque converter.

Refit

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit but do not tighten six bolts securing gearbox

housing to engine.

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect multiplug to inhibitor switch.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clips to

engine sump and alternator bracket.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer box

bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin. 20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

21. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness.

22. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

23.Position handbrake backplate and tighten bolts

to 75 Nm (55 lbf.ft).

24.Fit hand brake drum and tighten screw.

25.Remove bolts securing tool LRT-99-008A to

gearbox.

26.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

27.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

28.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

29.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

31.Position intermediate silencer and secure to

mounting rubbers.

32.Clean silencer and tail pipe mating faces.

33.Position new gasket to tail pipe and tighten

nuts to 25 Nm (18 lbf.ft).

34.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

35.Fit bolt securing closing plate to gearbox

housing and tighten to 7 Nm (5.2 lbf.ft).

36.Fit upper bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

37.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

38.Tighten remaining gearbox housing to engine

bolts to 50 Nm (37 lbf.ft).

39.Connect battery earth lead.

40.Fit battery cover and secure with fixings.

41.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.