ECO mode LAND ROVER DISCOVERY 1999 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1253 of 1529

WIPERS AND WASHERS

84-18 DESCRIPTION AND OPERATION

Front flick wipe

Flick wipe operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront flick switch is operated.

Pressing the flick wipe switch operates the front wiper motor at high speed. The front wiper motor operates as long

as the flick switch is activated. Releasing the flick switch causes the front wiper motor to run through the park switch

circuitry. The park switch only permits low speed operation. Thus if the flick switch is pressed and immediately

released, the wipers operate at low speed.

Rear intermittent wipe variable delay

The rear intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Rear variable delay operation only activates if the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch on intermittent.

lRear wipe switch is operated.

The BCU determines the desired delay interval based on the setting of the variable delay switch. The rear wash/ wipe

delay is nominally twice as long as that of the front. This information passes from the IDM to the rear wiper relay and

activates the rear wiper motor.

If the delay duration is decreased during operation of the rear wiper, the wipers immediately operate once and the

delay cycle is reset.

If the delay duration is increased during operation of the rear wiper, the delay cycle is automatically increased by the

BCU.

Reverse wiping

Reverse wiping operates the rear wiper motor when reverse gear is selected. The transmission must be in reverse

for longer then 0.5 seconds before reversing wipe activates. Reversing wipe activates if the following conditions are

met:

lIgnition switch is in position II.

lReverse gear is selected.

lRear wiper or front wipers operating.

If the rear wiper is active in any mode when reverse gear is selected, the rear wiper activates for 4 second. After 4

seconds the rear wiper operates in a delay operation at the same delay interval set by the variable delay switch until

reverse gear is deselected.

If the front wipers are operating on either low or high speed when reverse gear is selected, the rear wiper activates

continuously until reverse gear is deselected.

In order to enable reversing wipe functions, the BCU utilises the reversing light switch located within the transmission

to determine when reverse gear has been selected.

If the front intermittent wipe is active when reverse gear is selected, the rear wiper completes 2 cycles before operating

at the same intermittent delay as the front wipers.

Rear wipe

Rear wipe operation will only activate when the following conditions are met:

lIgnition switch is in position II.

lRear wipe switch is operated.

Operating the rear wiper switch provides an earth input to the BCU. The BCU tells the IDM to activate the rear wiper

relay, which provides battery voltage to the wiper motor through the normally closed contacts of the park switch.

Page 1275 of 1529

LIGHTING

86-2-2 ADJUSTMENTS

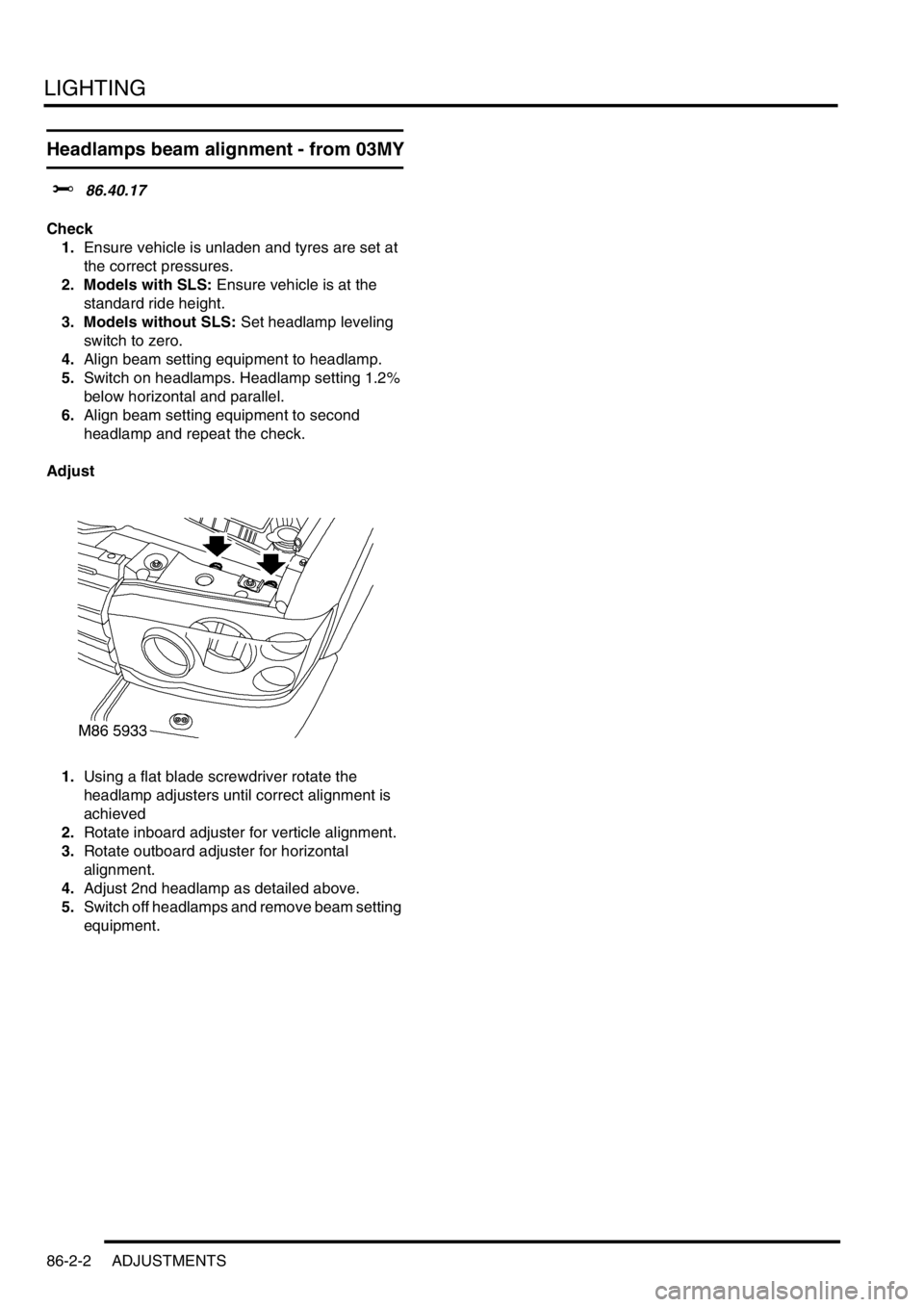

Headlamps beam alignment - from 03MY

$% 86.40.17

Check

1.Ensure vehicle is unladen and tyres are set at

the correct pressures.

2. Models with SLS: Ensure vehicle is at the

standard ride height.

3. Models without SLS: Set headlamp leveling

switch to zero.

4.Align beam setting equipment to headlamp.

5.Switch on headlamps. Headlamp setting 1.2%

below horizontal and parallel.

6.Align beam setting equipment to second

headlamp and repeat the check.

Adjust

1.Using a flat blade screwdriver rotate the

headlamp adjusters until correct alignment is

achieved

2.Rotate inboard adjuster for verticle alignment.

3.Rotate outboard adjuster for horizontal

alignment.

4.Adjust 2nd headlamp as detailed above.

5.Switch off headlamps and remove beam setting

equipment.

Page 1288 of 1529

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-1

BODY CONTROL UNIT DESCRIPTION AND OPERAT ION

Description

General

The Body Control Unit (BCU) is located behind the passenger glovebox and is connected to the main harness by four

connectors on its bottom edge and an additional connector located on the side of the BCU casing. Mounting the BCU

behind the fascia makes it reasonably inaccessible for intruders to disable the anti-theft system.

The BCU uses solid-state microprocessor control to perform logical operations and timing functions for a variety of

the vehicle's electrically operated systems, these include:

lDoor locking.

lAnti-theft alarm and immobilisation system.

lExterior lighting including direction indicators and hazard warning lamps.

lCourtesy lighting.

lWipers and washers.

lElectric windows and sunroof.

lHeated windows.

The BCU also communicates with several other electronically controlled systems such as the EAT ECU and SLABS

ECU and also has a datalink between the Intelligent Driver Module (IDM) and the instrument pack. The datalink is a

low speed bus capable of transmitting and receiving messages at a data rate of 10,400 bits per second. Additional

inputs and outputs to peripheral devices are included which are necessary for determining vehicle status for particular

logical operations e.g. crank, ignition key inserted, fuel flap enable etc.

The BCU receives its power supply from the engine compartment fuse box, and is protected by a 10 A fuse.

The BCU communicates with the IDM to provide the control signals to perform power switching operations in

conjunction with dedicated relays.

IDM

The IDM is integrated into the passenger compartment fuse box, which is mounted behind the fascia below the

steering column. There are no harnesses between the fuse box and the IDM. The IDM performs the power switching

operations for several of the vehicle's electrical systems.

The IDM communicates with the BCU and the instrument pack via a serial interface. If the BCU or the IDM is replaced,

the communications link between the two units has to be re-established. This can be done either by switching on the

ignition and leaving it on for five minutes, or by using TestBook. The vehicle immobilisation will remain active until the

communications link between the BCU and IDM has been re-established.

Transit mode

To prevent excessive battery drain during transit to overseas markets, the vehicle is placed in a transit mode. The

following functions are disabled when the vehicle is in transit mode:

lVolumetric sensors.

lPassive immobilisation.

lImmobilisation of the vehicle by use of door lock.

lIgnition key interlock.

lElectric seat enable time-out with driver's door open.

Page 1301 of 1529

BODY CONTROL UNIT

86-3-14 DESCRIPTION AND OPERATION

Central Door Locking (CDL)

The BCU carries out the logic control operation for CDL. A CDL switch is mounted on the fascia panel and has two

inputs to the BCU, one for lock and one for unlock.

Door locking and unlocking can be performed using the remote transmitter in the keys and the receiver unit located

above the vehicle's headlining, behind the rear sunroof aperture. The receiver detects the signals sent from the

remote transmitter and sends a decoded signal to the BCU for processing.

Four methods of door locking are available:

lRemote handset locking.

lVehicle key locking.

lCDL switch locking.

lSpeed related locking.

Two security levels of door locking are available, CDL and Superlocking. The anti-theft alarm system works in

conjunction with the CDL system.

Electric windows and sunroof

The BCU controls the logical operations and the timing periods for the electric front windows. The rear windows are

hard-wired and the two electric sunroofs are controlled by a dedicated ECU which is enabled by the BCU.

The front windows are electrically operated using two rocker switches located in the centre console. Electric motors

are located in each of the front doors.

The rear windows are enabled by the IDM controlling the operation of the rear window relay located in the passenger

compartment fuse box.

Wipers and washers

The wiper and washer functions are controlled by the BCU and the IDM.

The front wipers and washers are operated from the switch stalk located on the right hand side of the steering column

and only operate when the ignition switch is in position I or II. The front wipers are operated by a motor located below

the windscreen plenum.

+ WIPERS AND WASHERS, DESCRIPTION AND OPERATION, Description.

The BCU controls the wiper motor frequency of operation via the IDM when intermittent wipe or wash is selected. The

front intermittent wipe option features five different intermittent delay periods. The shortest delay period is 3 seconds

and this is increased by 2 second increments up to a maximum delay of 11 seconds. The desired delay period for the

front wipers is set by the position of the rotary switch located on the wiper column stalk.

The rear wiper switch is located on the instrument pack cowl and is latched when pressed. The rear wiper electric

motor is located in the tail door. The rear wiper operation is controlled according to a programmed strategy via the

BCU and the IDM. The BCU also checks for a signal from either the reverse lamp switch located in the vehicle gearbox

(manual gearbox models) or the gear position switch (automatic gearbox models) for operating the rear wipers when

the vehicle is in reverse. The rear wiper and washer only operate when the ignition switch is in position II.

The front and rear washer pumps and the headlamp powerwash (where fitted) are also controlled through the BCU.

The washers are operated from electric pumps attached to the washer reservoir located in the left hand wheel arch.

The front wash switch is located on the wiper column stalk and is pulled towards the steering wheel to select the

washer function. When the front washers are operated, the wipers are also activated for three full cycles. The rear

wash switch is located on the instrument pack cowl. The BCU programme can be configured in one of two modes of

operation:

lNo wiper operation when the wash switch is pressed.

lWiper action after an initial delay of 400 ms.

Headlamp wash is activated by the BCU via the IDM and operates when the headlamps are on and the front washers

function is selected.

Page 1303 of 1529

BODY CONTROL UNIT

86-3-16 DESCRIPTION AND OPERATION

Cruise control

The BCU processes several signals used for cruise control:

lWhen the brake pedal is pressed, a low voltage brake lamp signal is sent via the BCU to the cruise control ECU.

lThe gear position switch sends an input via the BCU to the cruise control ECU if the selector lever is in Park,

Neutral or Reverse.

lA voltage supply is fed from the BCU to the cruise control SET+ switch.

lA voltage supply is fed from the BCU to the cruise control RES switch.

On vehicles with automatic transmission, if the BCU receives an input from the gear position switch or the brake pedal

switch, the BCU sends a signal to the cruise control ECU to cancel or inhibit cruise control operation.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - cruise control.

Shift interlock (where fitted)

On automatic gearbox models, the BCU and IDM combine with an interlock relay located in the passenger

compartment fuse box to operate a shift interlock solenoid, so that the gear selector lever cannot be moved out of

Park until certain logical conditions have been satisfied. Operation of the interlock may be affected, if the battery

becomes discharged.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

Ignition key interlock (where fitted)

On automatic gearbox models, the ignition key interlock solenoid prevents removal of the ignition key from the ignition

switch when the transmission gear selector is not in the Park position. The logic control operation for this is performed

by the BCU.

Transfer box interlock (where fitted)

On automatic gearbox models, a transfer box interlock solenoid is controlled by the IDM to prevent transfer box shift

lever being moved out of high or low range unless certain conditions have been satisfied. The IDM controls the

operation of the transfer box relay which is located in the passenger compartment fuse box.

+ TRANSFER BOX - LT230SE, DESCRIPTION AND OPERATION, Description.

Gear position switch

A gear position switch is located on the automatic gearbox and is used to inform the BCU of the gear selector lever

position. The BCU has four sensing inputs from the gear position switch contacts W, X, Y, Z, which are used to

determine the gearbox drive status at any particular instance. The BCU gives an output corresponding to the gearbox

status derived from the gear position switch inputs. The logic states defining the gear selector positions are listed in

the table below, where Z1, Z2, Z3 and Z4 represent intermediate states which exist as the selector lever position is

changed:

Gear position Switch contacts

WX Y Z

P (Park) 1 0 0 0

Z11100

R (Reverse) 0 1 0 0

Z11100

N (Neutral) 1 1 1 0

Z21010

D (Drive) 1 0 1 1

Z31111

30111

Z40011

20001

Z40011

10010

Page 1306 of 1529

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-19

Operation

For IDM inputs which are also inputs for BCU functions, the delay before the BCU recognises the change in input

status is less than 250 ms. The BCU uses a debounce algorithm to ignore changes in input having a duration less

than 100 ms with the exception of automatic gearbox W, X, Y, Z inputs, which have a debounce period of 33 ms.

Transit mode

To prevent excessive battery drain during transit to overseas markets, the vehicle is placed in a transit mode.

To exit the transit mode, simultaneously hold down the heated rear window switch and the rear fog lamp switch, turn

the ignition switch from 0 to II and, after a minimum of 2 seconds, release the switches.

Transit mode can be entered using TestBook. When TestBook communicates with the BCU for diagnostics related to

BCU operation, it first checks that the vehicle is not in transit mode.

Anti-theft system

The BCU uses the driver's door key lock and unlock switches to activate and deactivate the security system. The

driver's door lock is also used for entering the EKA.

+ ALARM SYSTEM AND HORN, DESCRIPTION AND OPERATION, Description.

Immobilisation

For immobilisation, the BCU disables the starter motor relay. When the engine is cranking, the ECM looks for a coded

signal from the BCU. If the signal is not received within one second of cranking, the fuel supply to the engine is

stopped and the injectors are disabled. This also prevents unburnt fuel from entering the catalyst.

If the BCU is disconnected, the engine starter motor will remain isolated by the starter motor relay and the ECM will

remain immobilised. The main wiring for the system is contained within the main harness which is relatively

inaccessible, so preventing intruders from disabling the system by cutting the wires for the immobilisation system.

Once the immobiliser has been activated, destruction of the trigger device or the wiring to it will not disarm the system.

The RF transmitter communicates to the BCU via the RF receiver using a 70 bit code. Pressing the unlock button on

the transmitter will re-mobilise the vehicle. The RF transponder is integrated into the metal key assembly, inserting

the key into the ignition switch will induce a signal in the exciter coil to re-mobilise the vehicle.

Anti-theft alarm

The alarm system provides a warning of unauthorised access to the vehicle and includes perimetric and volumetric

monitoring under the control of the BCU.

The perimetric protection system detects opening of all doors, tail door and bonnet and will also detect the operation

of the ignition key switch. The following conditions must be satisfied before the BCU will operate all of the functions

of perimetric protection:

lAll doors and hinged panels are in the closed position.

lIgnition key out of the ignition switch.

lInertia switch is not tripped.

If all conditions are not satisfied the BCU will enter a mislock condition.

The volumetric sensor uses two ultrasonic sensors mounted in the headlining to detect movement within the vehicle.

The alarm will trigger when the sensor signals the BCU for 200 ms or greater. Within a single setting period the alarm

system will allow a maximum of 10 triggers as a result of any combination of sensor inputs. It is possible to lock the

vehicle without enabling the volumetric alarm by using the key. The same conditions needed to satisfy enabling of the

perimetric protection system is also needed to enable volumetric protection.

When the alarm system is set the BCU checks the status of all the inputs from the door and bonnet switches to ensure

the integrity of the vehicle before setting the alarm system into operational mode. In some markets, when the alarm

is set the BCU sends a signal to the IDM which will cause the direction indicators to flash three times for a duration of

3 seconds.

If the sensors are triggered the BCU will activate an alarm sounder to provide an audible warning of a theft attempt.

The activation period of the alarm sounder is 25 to 30 seconds. The duty cycle of the alarm sounder is 50:50 ± 10%.

Page 1309 of 1529

BODY CONTROL UNIT

86-3-22 DESCRIPTION AND OPERATION

Electric windows and sunroof

Three modes of operation are available:

lDriver cancel – the front windows, rear windows and sunroof will be disabled 44 seconds after the driver's door

is opened.

lAll cancel – The front windows, rear windows and sunroof will be disabled 44 seconds after any door is opened.

lNo cancel – the front windows, rear windows and sunroof will be disabled when the ignition is turned off.

The BCU will allow window and sunroof operation when the ignition key is in position II. The BCU provides a voltage

to the window control switches. When the switches are pressed, they provide a path to earth to complete the circuit

and initiate window operation. Window and sunroof operation is suspended when the ignition switch is in the crank

position.

For front window operation, the BCU checks the status of the following inputs:

lIgnition state.

lDriver's door open.

lPassenger or rear door open.

lFront right window down.

lFront right window up.

lFront left window down.

lFront left window up.

lRight window stall detect.

lLeft window stall detect.

The front window motors are directly connected to the BCU by two wires. Each wire can be used as a feed or return,

dependent on the required direction for motor operation (open or close). The BCU provides the following outputs:

lRight window up.

lRight window down.

lLeft window up.

lLeft window down.

The electric front windows are enabled when the ignition switch is in position II and is disabled if the ignition switch is

moved to the crank position.

The BCU checks the status of the following inputs to determine when to provide the rear window enable and sunroof

enable output signals:

lIgnition state.

lDriver's door open.

lPassenger or rear door open.

The rear window enable and sunroof enable lines are on when the ignition switch is in position II, and are switched

off if the ignition switch is moved to the crank position.

The BCU monitors the circuit current draw when the windows are operating to detect the occurrence of a stall

condition. If the BCU determines that the window has stalled, it will cut the power supply to stop the operation of the

window motor. The BCU only starts to check for a stall condition after the window has been operating for 500 ms. This

delay period enables the initial current surge to pass and eliminates false detections of window stall. A stall condition

is activated when a nominal current value is exceeded for a period greater than 300 ms.

If the BCU detects that it has been operating the same window motor in one direction for more than 10 ± 0.2 seconds,

without the BCU detecting a stall condition or the control switch being released, it will automatically stop operation of

the window motor (timed out). Window operation can resume when the window switch is released and pressed again.

If the window was operating in one touch mode, the window operation will resume on the next press of the window

switch.

One touch mode automatically lowers the window to its fully open position, without the need for the window switch to

be kept pressed for the duration of the window travel. One touch mode is initialised if the window switch is pressed

for a period of less than 0.4 ± 0.2 second. One touch mode continues to lower the window until the BCU detects:

lA stall condition exists (window has reached bottom of travel).

lWindow switch is repressed in either direction for more than 0.4 ± 0.2 second.

lThe BCU has operated the motor for a period greater than 10 ± 0.2 seconds.

Page 1311 of 1529

BODY CONTROL UNIT

86-3-24 DESCRIPTION AND OPERATION

The heated rear window operation period and voltage supply is controlled by the BCU. The BCU receives a voltage

supply feed from the engine compartment fuse box and an ignition switched supply through a fuse in the passenger

compartment fuse box. When the heated rear window switch is operated, it completes a path to earth, signalling a

request for heated rear window operation to the BCU. The BCU then supplies a feed to the heated rear window switch

to light the switch indicator, and earths the supply from the coil of the heated rear window relay via the IDM to turn the

heated rear window elements on. The BCU maintains a supply for a predetermined time (15 minutes), then opens the

earth path after the time-out period to turn the heated rear window operation off. If the heated rear window switch is

pressed a second time, the circuit is also interrupted to turn off the supply to the heated front screen.

On vehicles fitted with air conditioning, the heated rear window is also operated by the ATC ECU when DEF (defrost)

is selected. In this case the ATC ECU provides the trigger signal to the BCU to turn the heated rear window circuit on

or, if it is already on, to re-start the time out period.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

In the event of a communications link failure occurring while the heated rear window enable is on, the relay and lamp

will be de-activated.

Wipers and washers

Front and rear wash/ wipe operations are controlled by the BCU via the IDM.

Front wipers and washers

When front intermittent wipe is selected using the wiper switch on the column stalk, the BCU signals the IDM to

operate the wiper motor. The IDM then supplies a voltage to the normal speed winding of the wiper motor for a period

of no longer than 500 ms. The timed feed ensures the wiper motor operates, but does not complete more than a single

wipe of the screen. The BCU checks the position of the delay switch to determine the delay period which should be

utilised for the intermittent wipe operation. The delay period of the front intermittent wipe is maintained until the wiper

switch is moved to the off, normal or fast speed position, or the delay period is changed.

When front intermittent wipe is selected, a delay period of 500 ms will be incurred before the wipers operate. This

delay prevents the occurrence of a wipe action when the wiper switch is changed to the off position from the normal

or fast modes of operation.

To enable the front intermittent wipe facility, the BCU checks the state of the following inputs:

lIgnition state.

lFront intermittent wiper switch.

lFront intermittent wiper rate.

If the ignition switch is in the off or crank position, the front wipers are not active and the front wiper enable output is

switched off.

If the option to initiate a wipe action in addition to a front screen wash action has been configured in the BCU, the

wipers will operate 400 ms after the washer pump becomes active. If the washer switch is released within 400 ms,

the wipers will not be activated. If a washer switch is pressed for longer than 400 ms, the BCU will operate the wipers

after an initial delay of 400 ms, and will continue to operate for as long as the washer switch is depressed plus an

additional 4 seconds.

The front wash/ wipe programme can be configured to operate in one of two ways:

lOption 1 – normal.

lOption 2 – no wipe.

The BCU checks for the following inputs:

lIgnition state.

lFront washer pump switch.

The BCU can provide the following wash / wipe outputs depending on the logic states prevailing:

lFront wiper enable.

lFront wash/ wipe in progress flag.

In the event of a communications link failure occurring while the front wash/ wipe programme is in operation, the front

wiper enable output is switched off.

Page 1312 of 1529

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-25

Rear wipers and washers

The rear wiper is initially operated for a period of 4 seconds when the rear wiper switch is pressed, to complete two

full cycles. After this, the rear wiper will operate every other time the front wiper completes a wipe operation. During

the wipe operation, the front and rear wipers are synchronised, and changes to the delay period during intermittent

wipe will change the delay period for both front and rear wipers.

Operation of the rear washer switch causes the washer motor to operate for as long as the switch is operated. The

wiper also operates while the switch is depressed and for a further 4 seconds after the switch is released.

The BCU checks for the following inputs to determine when to provide the rear wiper enable signal:

lIgnition state.

lRear wiper switch.

lFront intermittent wiper rate.

lFront intermittent wiper switch.

If the ignition switch is in the off or crank position, the rear wipers are not active and the rear wiper enable output is

switched off.

In the event of a communications link failure occurring while the rear intermittent wipe programme is in operation, the

rear wiper enable output is switched off.

Reverse gear wipe

The BCU changes the operation of the rear wiper when the front wiper is active and reverse gear is selected. The rear

wiper operation rate used when the preconditions have been satisfied depend on the prevailing front wiper operating

mode and the position of the rear wiper switch. If the rear wiper is on or the front wiper is operating at an intermittent

rate when reverse gear is selected, the BCU will operate the rear wiper continuously for 4 seconds via the IDM. After

the initial period, the rear wiper will operate at the same rate as the front wiper.

The BCU checks for the following inputs to determine when to provide the rear wiper enable signal if the vehicle is in

reverse gear:

lIgnition state.

lRear wiper switch.

lFront intermittent wiper rate.

lReverse gear selected.

lFront intermittent wiper switch.

lFront wiper switch state.

lFront wash/ wipe in progress flag.

In the event of a communications link failure occurring while the reversing wipe is in operation, the rear wiper enable

output is switched off.

Headlamp wash

The headlamp wash will only operate when the headlamps are on, and then only every third time the front windscreen

wash button is pressed. When the BCU operates the headlamp washers, it activates the washer pump relay for a

period of 500 ms. The BCU supplies an earth path for the coil of the power wash relay located in the engine

compartment fuse box when the washer function is selected.

The BCU checks for the following inputs to determine when to provide power to the headlamp power wash relay:

lIgnition state.

lFront washer pump switch.

lDipped beam.

lMain beam state.

If the ignition switch is in the off position, the headlamp power wash relay is also held off. if the ignition state is crank,

the headlamp power wash relay is switched off and the headlamp power wash counter is reset to 0.

In the event of a communications link failure occurring while the headlamp power wash relay in on , the relay remains

on until the 500 ms timer has completed, then the relay is switched off.

Page 1313 of 1529

BODY CONTROL UNIT

86-3-26 DESCRIPTION AND OPERATION

Electric seats

The BCU can be programmed to operate the electric seats according to one of three options:

lOption 1 – no electric seats.

lOption 2 – normal.

lOption 3 – operates with ignition only.

To determine when to provide an output to the passenger and drivers seat enable relay, the BCU checks the condition

of the following inputs:

lIgnition state.

lTransit mode.

lDriver's door open.

The electrically controlled seats are operated when the ignition switch is in position I or II or for a predetermined period

when the driver's door is open. If the ignition state is in crank, the seat enable relay is off. If the ignition state is off and

the driver's door open input is off, the seat enable relay is off. If the ignition state is off and the driver's door open input

is on and transit mode is on, the seat enable relay output is off.

The power supply to each seat switch pack is powered from a power seat relay located on the underside of each seat

frame. The feed from the relay is protected by a fuse located in a satellite fuse block located adjacent to the power

seat relay. The fuse block also contains two additional fuses which are used to protect the feeds to the lumbar pump

and solenoid.

With the ignition switch in position I or II or the driver's door open, the BCU provides an earth path for the coils of the

LH and RH power seat relays, energising the relays and closing the contacts. If the driver's door input signal is on for

longer than 45 seconds with the ignition switched off, the seat enable relay is switched off.

Direction indicators and hazard warning lamps

The BCU supplies reference voltages for the LH and RH indicators. When the direction indicator switch is used to

select the LH or RH indicator position, an earth path is completed which signals the BCU that a request for direction

indicator operation has been made. The BCU then communicates this request to the IDM which supplies an earth

path for the coil of the relevant relay (LH or RH indicator relay). When the relay coil is energised, the relay contacts

close and a voltage supply is provided via a resistor to the relevant direction indicators. The IDM controls the timing

of the flash operations by continually removing and restoring the earth path to the direction indicator relay coil.

The BCU checks for the following inputs for performing the logic operations associated with the direction indicator

lamps:

lIgnition state.

lRH indicators selected.

lLH indicators selected.

lHazards selected.

lInertia switch hazard request.

lOne short indicator flash request (anti-theft system arming).

lTwo short indicator flash request (superlocking).

lOne long indicator flash request (anti-theft system disarming).

lAlarm flashing indicators (anti-theft alarm triggered).

The following outputs are provided by the BCU as a result of the inputs received and the logical operations performed:

lRH indicators enable.

lLH indicators enable.

lDirection indicator left message (link to IDM).

lDirection indicator right message (link to IDM).

Direction indicator lamp failure detection

The BCU uses the following logic inputs to determine if there is a direction indicator bulb failure or if the presence of

a trailer is detected. The BCU uses the information to decide which output to enable at any particular instance:

lRight direction indicators requested.

lLeft direction indicators requested.

lRH indicators current sense.

lLH indicators current sense.