ECO mode LAND ROVER DISCOVERY 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 570 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-45

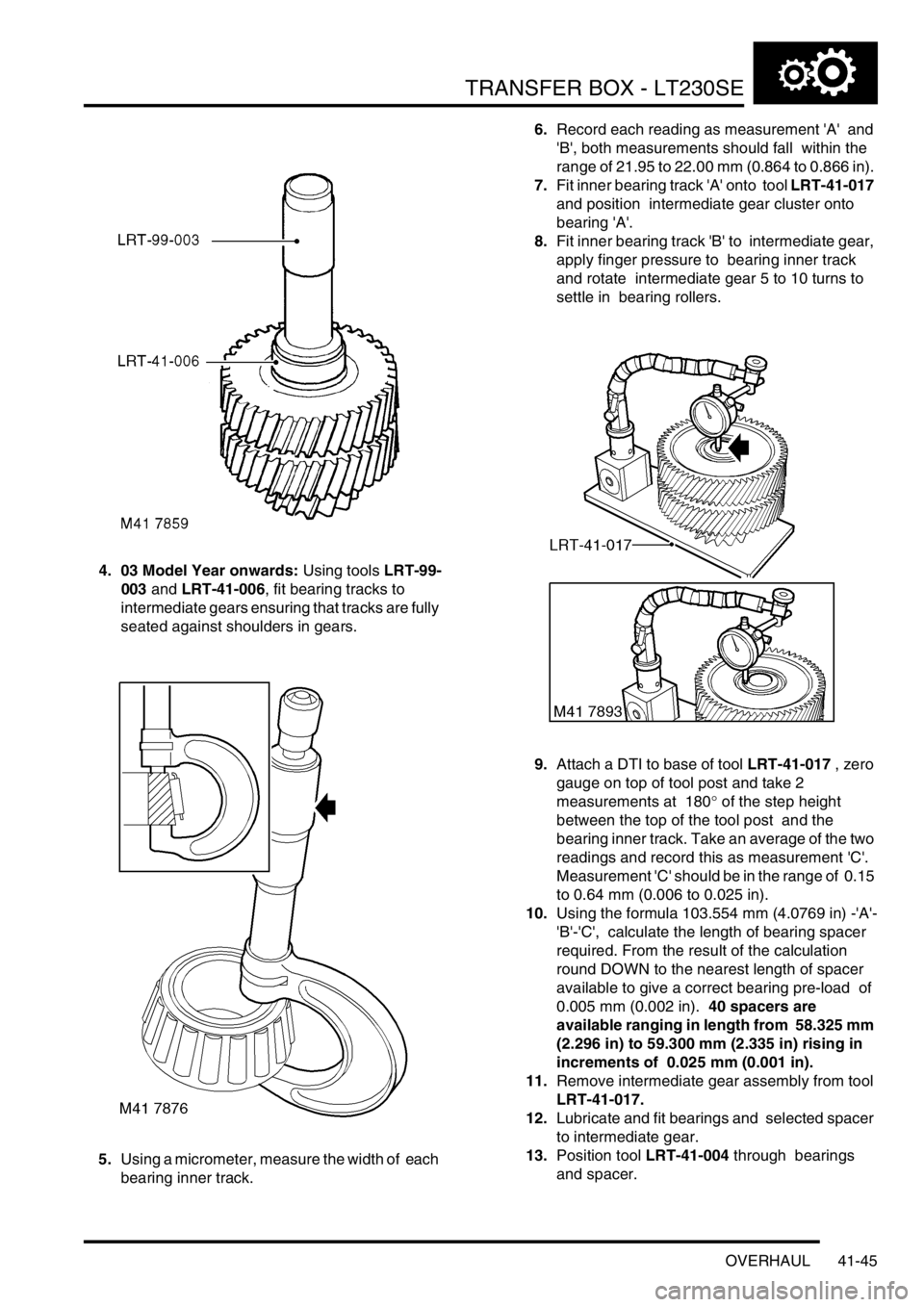

4. 03 Model Year onwards: Using tools LRT-99-

003 and LRT-41-006, fit bearing tracks to

intermediate gears ensuring that tracks are fully

seated against shoulders in gears.

5.Using a micrometer, measure the width of each

bearing inner track. 6.Record each reading as measurement 'A' and

'B', both measurements should fall within the

range of 21.95 to 22.00 mm (0.864 to 0.866 in).

7.Fit inner bearing track 'A' onto tool LRT-41-017

and position intermediate gear cluster onto

bearing 'A'.

8.Fit inner bearing track 'B' to intermediate gear,

apply finger pressure to bearing inner track

and rotate intermediate gear 5 to 10 turns to

settle in bearing rollers.

9.Attach a DTI to base of tool LRT-41-017 , zero

gauge on top of tool post and take 2

measurements at 180° of the step height

between the top of the tool post and the

bearing inner track. Take an average of the two

readings and record this as measurement 'C'.

Measurement 'C' should be in the range of 0.15

to 0.64 mm (0.006 to 0.025 in).

10.Using the formula 103.554 mm (4.0769 in) -'A'-

'B'-'C', calculate the length of bearing spacer

required. From the result of the calculation

round DOWN to the nearest length of spacer

available to give a correct bearing pre-load of

0.005 mm (0.002 in). 40 spacers are

available ranging in length from 58.325 mm

(2.296 in) to 59.300 mm (2.335 in) rising in

increments of 0.025 mm (0.001 in).

11.Remove intermediate gear assembly from tool

LRT-41-017.

12.Lubricate and fit bearings and selected spacer

to intermediate gear.

13.Position tool LRT-41-004 through bearings

and spacer.

Page 572 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-47

3.Note position of longest bolt and remove 8 bolts

securing front output shaft housing to main

casing and remove housing.

Note: Carry out the following operations if

differential lock is fitted.

4. Differential lock fitted: Remove 3 bolts

securing differential lock selector housing and

remove housing.

5. Differential lock fitted: Remove and discard

'O' rings from selector housing.

6. Up to 03 Model Year: Remove Allen plug and

remove differential lock detent spring and ball.

7. Up to 03 Model Year: Remove differential lock

warning lamp switch and locknut.

8. 03 Model Year onwards - differential lock

fitted: Remove 2 differential lock warning lamp

switches and sealing washers.9. 03 Model Year onwards - differential lock

fitted: Note position of longest bolt and remove

8 bolts securing front output housing to main

casing and remove housing.

10. 03 Model Year onwards - differential lock

fitted: Remove 3 bolts securing differential lock

selector housing and bracket, remove bracket

and housing.

11. 03 Model Year onwards - differential lock

fitted: Remove and discard 'O' rings from

selector housing.

12. 03 Model Year onwards - differential lock

fitted: Remove detent plug, recover spring and

ball.

13. All transfer boxes fitted with differential

lock: Compress differential lock selector fork

spring and remove retaining clips from each

end of spring.

14. All transfer boxes fitted with differential

lock: Withdraw differential lock selector shaft

from front output housing, recover spring and

remove selector fork.

Page 584 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-59

20.Apply sealant, Part No. STC 50552 to bolt

threads fit housing to main case, fit bolts and

tighten by diagonal selection to 45 Nm (33

lbf.ft).

21. 03 Model Year onwards: Fit high/low selector

fork and spring to high/low selector shaft, fit

retaining clips.

CAUTION: Ensure ends of spring are fully

seated in recess in clips.

22.Position high/low selector shaft and fork to

differential ensuring that fingers of selector fork

are located in selector sleeve.

23.Position differential assembly into main casing

ensuring that splines of rear output shaft are

engaged in differential.

24.Position new differential front bearing track

ensuring that track is seated squarely.

25.Position tool LRT-41-014/3 onto main casing.

26.Screw tool LRT-41-014/4 into tapped hole in

main casing and attach suitable DTI to pillar.

27.Position stylus of gauge to setting block LRT-

41-014/3 and zero gauge. 28.Position stylus onto front bearing outer track

and record reading.

29.Taking care not to disturb bearing, position

stylus on opposite side of bearing track and

record reading.

30.Obtain average of the 2 readings and record

figure.

Page 590 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-65

9. 03 Model Year onwards:Note position of

longest bolt and remove 8 bolts securing front

output shaft housing to main casing; remove

housing.

10. 03 Model Year onwards:Remove 3 bolts

securing differential lock selector housing and

bracket, remove housing.

11. 03 Model Year onwards:Remove and discard

'O' rings from selector housing.

12. 03 Model Year onwards:Remove differential

lock detent plug, recover spring and ball.

13.Compress differential lock selector fork spring

and remove retaining clips from each end of

spring.

14.Withdraw differential lock selector shaft from

front output housing, recover spring and

remove selector fork.

15.Position tool LRT-51-003 to output shaft drive

flange, remove and discard nut. 16.Remove and discard steel and felt washers.

Remove output shaft drive flange.

17.Using a copper mallet, drive output shaft from

housing.

18.Noting its fitted position, remove bearing

spacer from output shaft.

19.Noting its fitted position, remove dog clutch

from output shaft.

20.Remove and discard oil seal from housing.

Reassembly

1.Clean differential lock components. Remove all

traces of sealant from mating faces of

housings, side cover, bolt threads, detent plugs

and differential lock warning lamp switches.

2.Lubricate components with gearbox oil.

3.Using tool LRT-41-012, fit new output shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Page 602 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-5

Selector lever assembly

1Release button

2Mode switch

3Electrical connector

4Interlock solenoid (where fitted)

5Base6Gasket

7Securing bolt

8Lever

9Cover

10Position indicators

The selector lever assembly consists of a lever and a cover attached to a base. The base is located on a gasket and

secured to the transmission tunnel. The lever is hinged to the base. A latch in the lever engages with detents in the

base to provide the lever positions P, R, N, D, 3, 2, 1. The latch is disengaged by pressing a release button on the

lever knob. Except for lever movement between positions D and 3, the button must be pressed before the lever can

be moved. In some markets, vehicles incorporate an interlock solenoid at the bottom of the lever, which prevents the

lever being moved from P unless the ignition switch is in position II and the foot brake is applied. If the battery

becomes flat, the interlock system will prevent selector lever movement and removal of the ignition key.

The cover incorporates lever position indicators and the mode switch. The lever position indicators illuminate to show

the position of the selector lever. Illumination is controlled by the Body Control Unit (BCU). The mode switch is a non-

latching hinged switch that, when pressed, connects an earth to the EAT ECU to request a change of mode.

An electrical connector at the rear of the cover connects the selector lever assembly to the vehicle wiring.

Selector cable

The selector cable is a Bowden type cable that connects the selector lever assembly to a selector lever on the

gearbox. 'C' clips secure the ends of the outer cable to brackets on the selector lever assembly and the selector lever.

The inner cable is adjustable at the connection of the inner cable with the gearbox selector lever.

Page 614 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-17

Operation

Refer to illustration.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Control schematic.

When the ignition is switched on, a bulb check is performed on the transmission temperature warning lamp and the

mode warning lamps by the instrument pack and the EAT ECU respectively. The warning lamps are illuminated for

approximately 3 seconds and then extinguished.

The gear position switch outputs are monitored by the BCU and the EAT ECU. The BCU outputs gear position signals

to illuminate the position indicators each side of the gear selector lever and on the odometer LCD in the instrument

pack.

In D, 3, 2, and 1, the EAT ECU outputs control signals to the gearbox to select the required gear.

In D, all forward gears are available for selection by the EAT ECU. In 3, 2 and 1, a corresponding limit is imposed on

the highest gear available for selection. When R is selected, reverse gear only engages if the vehicle is stationary or

moving at 5 mph (8 km/h) or less. When R is deselected, reverse gear only disengages if the vehicle is moving at 4

mph (6 km/h) or less.

Selector lever interlock (where fitted)

The interlock solenoid on the selector lever is de-energised unless the foot brake is applied while the ignition is on.

While de-energised, the interlock solenoid allows the selector lever to move through the range unless P is selected.

On entering the P position, the interlock solenoid engages a latch which locks the selector lever. When the ignition is

on and the foot brake is applied, the BCU energises the interlock solenoid, which disengages the latch and allows the

selector lever to be moved out of P.

Economy, sport and manual modes

During the power-up procedure after the ignition is switched on, the EAT ECU defaults to an economy mode. Pressing

the mode switch causes the EAT ECU to change between the economy mode and the sport or the manual mode,

depending on the range selected on the transfer box:

lIf the transfer box is in high range, the EAT ECU changes to the sport mode and illuminates the sport mode

warning lamp in the instrument pack. In the sport mode the gearbox is more responsive to accelerator pedal

movement. Downshifts occur earlier and upshifts occur later.

lIf the transfer box is in low range, the EAT ECU changes to the manual mode and illuminates the manual mode

warning lamp in the instrument pack. Kickdown is disabled and the EAT ECU maintains the gearbox in the gear

selected on the selector lever (D = 4th gear) to give improved off road performance. Downshifts occur only to

prevent the engine stalling. From a standing start, the vehicle pulls away in 1st gear and, if a higher gear is

selected, upshifts almost immediately to the selected gear (shifts of more than one gear can occur).

After a second press of the mode switch the EAT ECU reverts to the economy mode, for the range selected on the

transfer box, and extinguishes the related mode warning lamp in the instrument pack.

Shift control

To provide the different driving characteristics for each mode of operation, the EAT ECU incorporates different shift

maps of throttle position/engine speed. Base shift points are derived from the appropriate shift map. When a shift is

required, the EAT ECU sends a request to the ECM for a reduction in engine torque, in order to produce a smoother

shift. The percentage of torque reduction requested varies according to the operating conditions at the time of the

request. When the EAT ECU receives confirmation of the torque reduction from the ECM, it then signals the shift

solenoid valves in the gearbox to produce the shift. To further improve shift quality, the EAT ECU also signals the

pressure regulating solenoid valve to modulate the hydraulic pressure and so control the rate of engagement and

disengagement of the brake clutches.

With time, the components in a gearbox wear and the duration of the gear shifts tends to increase, which has an

adverse effect on the brake clutches. To counteract this, the EAT ECU applies a pressure adaptation to each shift.

To calculate the adaptations, the EAT ECU monitors the pressure modulation used, and time taken, for each shift. If

a subsequent shift of the same type, in terms of throttle position and engine speed, has a longer duration, the EAT

ECU stores an adaptation for that type of shift in a volatile memory. The adaptation is then included in future pressure

calculations for that type of shift, to restore shift duration to the nominal.

Page 615 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-18 DESCRIPTION AND OPERATION

Kickdown

The EAT ECU monitors the input of the throttle position sensor to determine when kickdown is required. When it

detects a kickdown situation, the EAT ECU immediately initiates a down shift provided the target gear will not cause

the engine speed limit to be exceeded.

Torque converter lock-up

The EAT ECU energises the lock-up solenoid valve to engage the lock-up clutch. Lock-up clutch operation is

dependent on throttle position, engine speed, operating mode and the range selected on the transfer box.

High range

Unique lock-up maps, similar to the shift maps, are incorporated in the economy and sport modes for all forward gears.

Engagement and disengagement of the lock-up clutch is dependent on throttle position and engine speed.

Low range

To enhance off road control, particularly when manoeuvring at low speeds, torque converter lock-up does not occur

when there is any degree of throttle opening. When the throttle is closed above a preset engine speed, the lock-up

clutch engages to provide maximum engine braking.

Increased load/reduced torque compensation

To aid performance and driveability in the high range economy mode, the EAT ECU has three adaptive shift and lock-

up maps. These maps delay upshifts and torque converter lock-up similar to the sport mode if the inputs from the

engine indicate:

lA sustained high load on the engine, such as occurs when the vehicle is ascending a steep gradient or towing a

trailer.

lA lower than normal engine torque, such as occurs at altitude or high ambient temperatures.

The EAT ECU monitors the engine inputs and selects the most appropriate adaptive map for the prevailing conditions.

Diagnostics

While the ignition is on, the EAT ECU diagnoses the system for faults. The extent of the diagnostic capability at any

particular time depends on the prevailing operating conditions, e.g. it is not possible to check torque converter lock-

up while the vehicle is stationary, or to check for a short circuit to earth if the circuit concerned is already at a low

potential.

If a fault is detected, the EAT ECU immediately stores a fault code and the values of three operating parameters

associated with the fault. Depending on the fault, there are four possible effects:

lThe fault has little effect on gearbox operation or vehicle emissions. The driver will probably not notice any

change and the warning lamps remain extinguished.

lThe fault has little effect on gearbox operation but may effect vehicle emissions. On NAS vehicles, if the fault is

detected on a second consecutive drive cycle, the MIL illuminates.

lAll gears are available but kickdown does not function. The sport and manual warning lamps flash. The MIL

remains extinguished.

lLimp home mode is selected and vehicle performance is greatly reduced. The sport and manual warning lamps

flash. In all markets, if the fault is detected on a second consecutive drive cycle, the MIL illuminates.

After the detection of a fault, the effects remain active for the remainder of the drive cycle. In subsequent drive cycles,

as soon as the EAT ECU diagnoses the fault is no longer present, it resumes normal control of the gearbox. The

conditions required to diagnose that the fault is no longer present depend on the fault. Some faults require the engine

to be started, others require only that the ignition is switched on.

After a fault has not recurred for forty warm-up cycles, the fault is deleted from the EAT ECU memory. Only five

different faults can be stored in the memory at any one time. If a further fault occurs, the fault with the lowest priority

will be replaced by the new fault.

Mechanical limp home

In the mechanical limp home mode, gear engagement is controlled by the manual valve. The gearbox is fixed in 4th

gear if the fault occurs while the vehicle is moving, or 3rd gear if the fault occurs while the vehicle is stationary. 3rd

gear is also engaged if a vehicle is brought to a stop and the selector lever is moved out of, and back into, D. Neutral

and reverse gear are also available.

Page 617 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-20 DESCRIPTION AND OPERATION

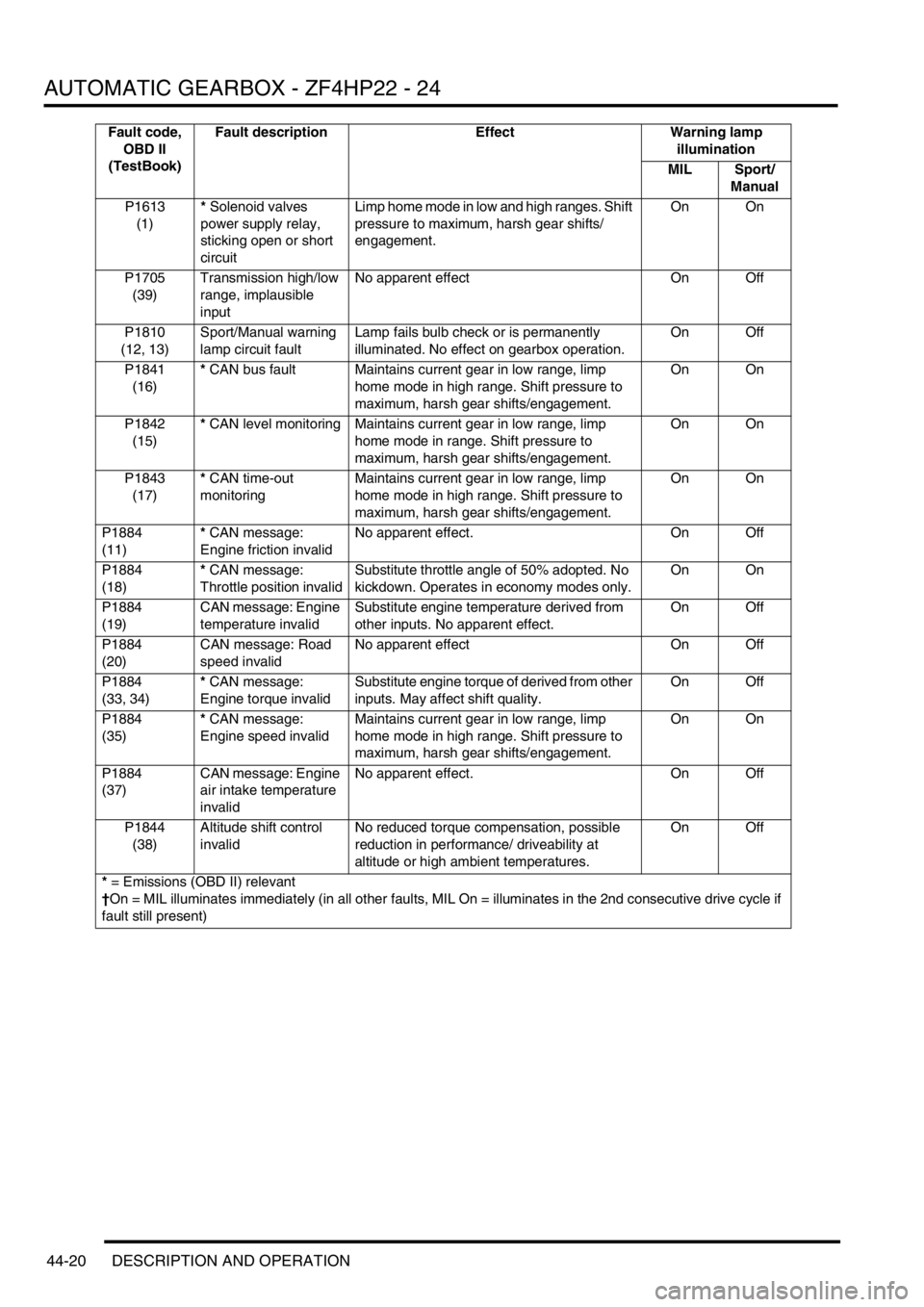

P1613

(1)* Solenoid valves

power supply relay,

sticking open or short

circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1705

(39)Transmission high/low

range, implausible

inputNo apparent effect On Off

P1810

(12, 13)Sport/Manual warning

lamp circuit faultLamp fails bulb check or is permanently

illuminated. No effect on gearbox operation.On Off

P1841

(16)* CAN bus fault Maintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1842

(15)* CAN level monitoring Maintains current gear in low range, limp

home mode in range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1843

(17)* CAN time-out

monitoringMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(11)* CAN message:

Engine friction invalidNo apparent effect. On Off

P1884

(18)* CAN message:

Throttle position invalidSubstitute throttle angle of 50% adopted. No

kickdown. Operates in economy modes only.On On

P1884

(19)CAN message: Engine

temperature invalidSubstitute engine temperature derived from

other inputs. No apparent effect.On Off

P1884

(20)CAN message: Road

speed invalidNo apparent effect On Off

P1884

(33, 34)* CAN message:

Engine torque invalidSubstitute engine torque of derived from other

inputs. May affect shift quality.On Off

P1884

(35)* CAN message:

Engine speed invalidMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(37)CAN message: Engine

air intake temperature

invalidNo apparent effect. On Off

P1844

(38)Altitude shift control

invalidNo reduced torque compensation, possible

reduction in performance/ driveability at

altitude or high ambient temperatures.On Off

* = Emissions (OBD II) relevant

†On = MIL illuminates immediately (in all other faults, MIL On = illuminates in the 2nd consecutive drive cycle if

fault still present)Fault code,

OBD II

(TestBook)Fault description Effect Warning lamp

illumination

MIL Sport/

Manual

Page 626 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-29

24. 03 Model Year onwards - If fitted: Release

and disconnect both differential lock warning

lamp switch multiplugs from main harness.

25.Remove cable tie and multiplug from bracket

on transfer box.

26.Release transfer and automatic gearbox

breather pipes from clip at rear of cylinder

block.

27.Position gearbox support jack and secure tool

LRT-99-008A to support plate on jack. 28.Position a second support jack under engine

using a block between engine sump and jack

to prevent damage to sump.

29.Remove 4 bolts and nut, remove engine LH

rear mounting.

30.Remove 4 bolts and nut, remove engine RH

rear mounting.

31.Remove 2 bolts securing gearbox oil cooler

pipe clips to engine sump and alternator

mounting bracket.

Page 704 of 1529

STEERING

DESCRIPTION AND OPERATION 57-11

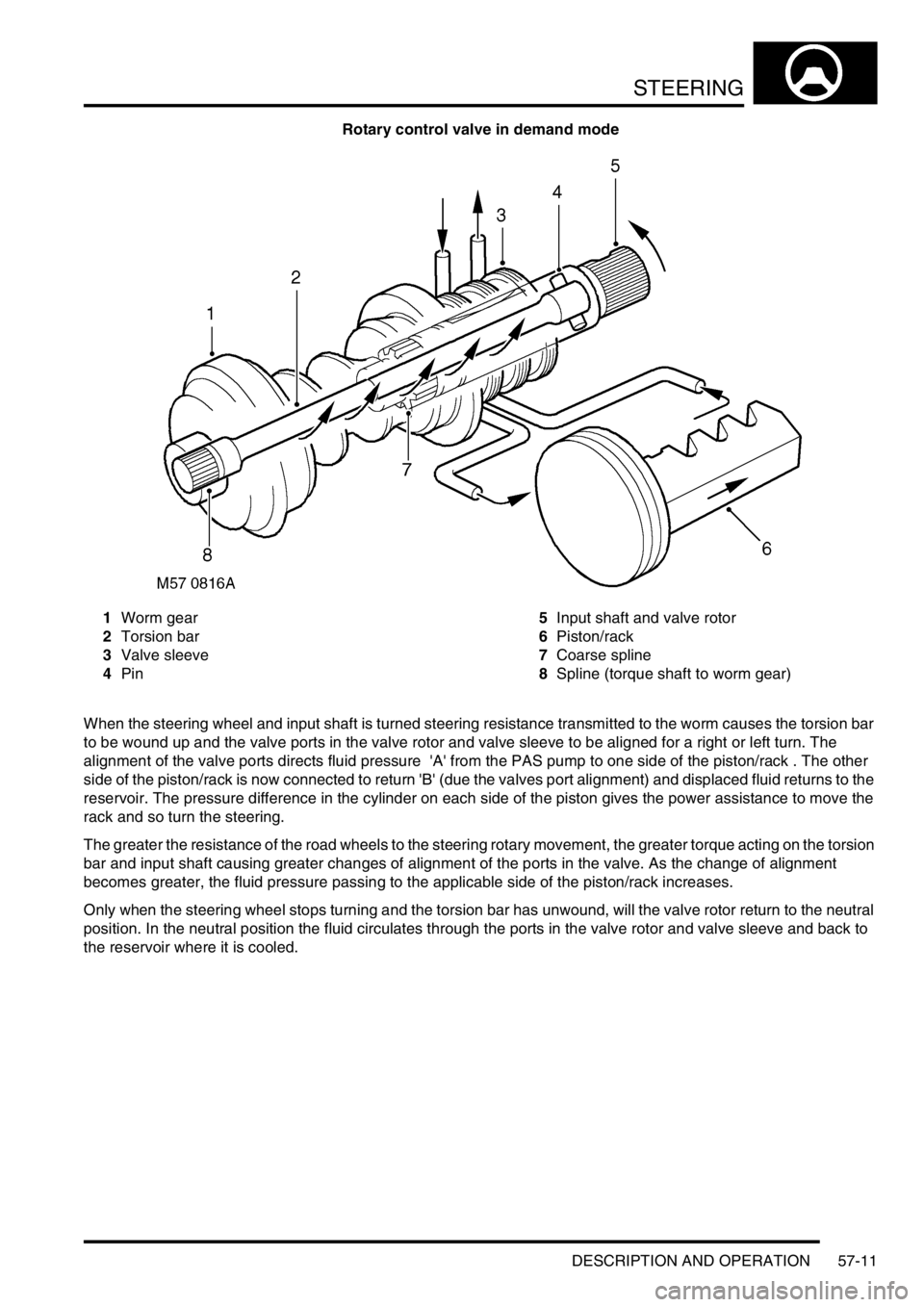

Rotary control valve in demand mode

1Worm gear

2Torsion bar

3Valve sleeve

4Pin5Input shaft and valve rotor

6Piston/rack

7Coarse spline

8Spline (torque shaft to worm gear)

When the steering wheel and input shaft is turned steering resistance transmitted to the worm causes the torsion bar

to be wound up and the valve ports in the valve rotor and valve sleeve to be aligned for a right or left turn. The

alignment of the valve ports directs fluid pressure 'A' from the PAS pump to one side of the piston/rack . The other

side of the piston/rack is now connected to return 'B' (due the valves port alignment) and displaced fluid returns to the

reservoir. The pressure difference in the cylinder on each side of the piston gives the power assistance to move the

rack and so turn the steering.

The greater the resistance of the road wheels to the steering rotary movement, the greater torque acting on the torsion

bar and input shaft causing greater changes of alignment of the ports in the valve. As the change of alignment

becomes greater, the fluid pressure passing to the applicable side of the piston/rack increases.

Only when the steering wheel stops turning and the torsion bar has unwound, will the valve rotor return to the neutral

position. In the neutral position the fluid circulates through the ports in the valve rotor and valve sleeve and back to

the reservoir where it is cooled.