check transmission fluid LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 62 of 1529

GENERAL INFORMATION

03-27

Body Repairs

General

Body shells are of welded construction and bolted to

a chassis frame. Front and rear sections of the shell

are designed as 'energy absorbing' zones. This

means they are designed to deform progressively

when subjected to impact in order to minimise the

likelihood of injury to vehicle occupants.

It is essential that design dimensions and strength

are restored in accident rectification. It is important

that neither structural weakness nor excessive local

stiffness are introduced into the vehicle during body

repair.

Repairs usually involve a combination of operations

ranging from straightening procedures to renewal of

individual panels or panel assemblies. The repairer

will determine the repair method and this decision will

take into account a balance of economics between

labour and material costs and the availability of repair

facilities in both equipment and skills. It may also

involve considerations of the vehicles' downtime,

replacement vehicle availability and repair turn-

around time.

It is expected that a repairer will select the best and

most economic repair method possible, making use

of the facilities available. The instructions given are

intended to assist a skilled body repairer by

expanding approved procedures for panel

replacement. The objective is to restore the vehicle

to a safe running condition by carrying out a repair

which is as close as is feasible to original standard.

The results should not advertise to the experienced

eye that the vehicle has been damaged, although the

repair might not be identical in all respects to the

original factory build. Commercial bodyshop repair

facilities cannot always duplicate methods of

construction used during production.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and suspension

geometry checked after completion. Where

necessary a road test of the vehicle should be carried

out, particularly where safety-related items are

concerned.

Where major units have been disconnected or

removed it is necessary to ensure that fluid levels are

checked and topped up where necessary. It is also

necessary to ensure that the repaired vehicle is in a

roadworthy condition in respect of tyre pressures,

lights, washer fluid etc. Body repairs often involve the removal of mechanical

and electrical units and associated wiring. Where

necessary, refer to the relevant section of the

Workshop Manual for removal and refitting

instructions.

Taking into consideration the differences in body

styles, suspension systems and engine and

transmission layouts, the location of the following

components as applicable to a particular vehicle is

critical:

lFront suspension upper damper mountings on

RH and LH chassis longitudinals.

lFront suspension or sub frame mountings.

lEngine mountings on RH and LH chassis

longitudinals.

lRear suspension upper damper mountings on

RH and LH chassis longitudinals.

lRear suspension mountings or lower pivots.

Additional points which can be used to check

alignment and assembly are:

lInner holes in cross member - side - main floor.

lHoles in front bulkhead.

lHoles in rear longitudinals.

lHoles in rear lower panels.

Apertures for windscreen, rear screen, bonnet and

doors can be measured and checked using the

dimensional information provided and also by

offering up an undamaged component as a gauge.

Straightening

Whenever possible, structural members should be

cold straightened under tension. Do not attempt to

straighten with a single pull but rework the damaged

area using a series of pulls, releasing tension

between each stage and using the opportunity to

check alignment.

Body jig

Unless damage is limited to cosmetic panels, all

repair work to body members must be carried out on

a body jig, to ensure that impact damage has not

spread into more remote parts of the structure.

Mounting on a jig will also ensure that the

straightening and panel replacement procedures do

not cause further distortion.

If original dimensions cannot be satisfactorily

restored by these methods, damaged structural

members should be replaced. Damaged areas

should be cut away using a high speed saw, NOT an

oxy-acetylene torch.

As a rule, body dimensions are symmetrical about

the centre line. A good initial check for distortion is

therefore to measure diagonally and to investigate

apparent differences in dimensions.

Page 639 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-42 REPAIRS

Refit

1.Clean intermediate plate and mating faces with

a lint free cloth.

2.Position intermediate plate to converter

housing, fit bolts and tighten evenly to 46 Nm

(34 lbf.ft)

3.Fit new sealing washers to M14 Allen plugs, fit

plugs and tighten to 40 Nm (30 lbf.ft).

4.Fit new sealing washers to M20 plugs, fit plugs

and tighten to 50 Nm (37 lbf.ft).

5.Fit oil cooler adaptors and tighten to 42 Nm (30

lbf.ft)

6.Clean pump housing and mating face on

intermediate plate with lint free cloth.

7.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

8.Position pump locating dowel into intermediate

plate.

9.Align pump to dowel and position in

intermediate plate.

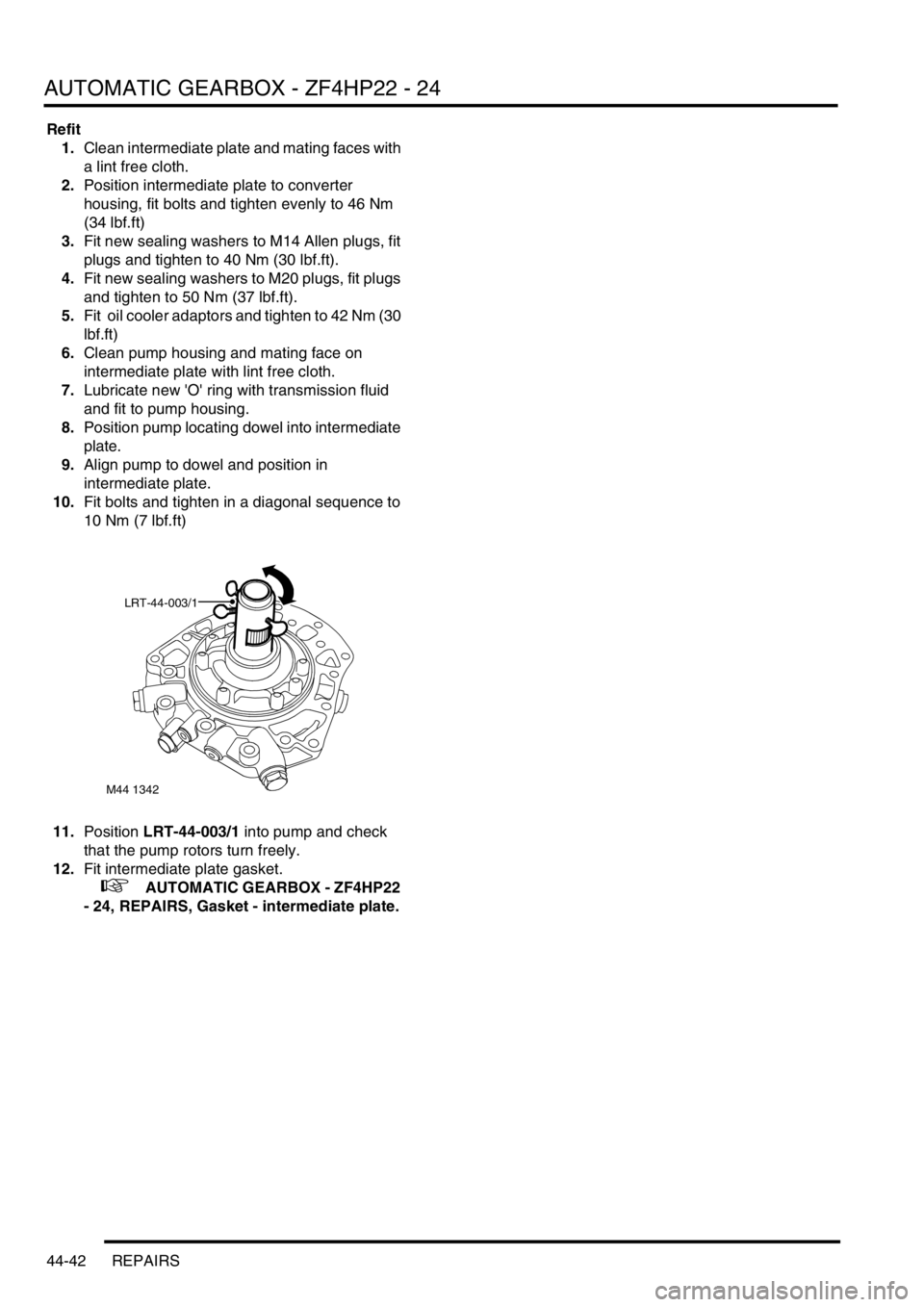

10.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

11.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

12.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1342

LRT-44-003/1

Page 640 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-43

Pump - fluid

$% 44.32.01

Remove

1.Remove intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

2.Remove 8 bolts securing fluid pump to

intermediate plate and carefully remove pump

from intermediate plate.

3.Note position and remove pump locating dowel.

4.Remove and discard 'O' ring from pump

housing.Refit

1.Clean pump housing and mating face on

intermediate plate with lint free cloth.

2.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

3.Position pump locating dowel into intermediate

plate.

4.Align fluid pump to dowel and position in

intermediate plate.

5.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

6.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

7.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1336

M44 1341

M44 1342

LRT-44-003/1

Page 1489 of 1529

INSTRUMENTS

88-6 DESCRIPTION AND OPERATION

The third warning lamp pack is located in the top right-hand side of the instrument pack and contains the following

warning lamps:

lSRS warning lamp.

lSLS off road mode warning lamp.

lTrailer warning lamp.

lGlow plug warning lamp.

lWater in fuel filter warning lamp.

lSeat belt warning lamp.

lTransmission high temperature warning lamp.

The fourth warning lamp pack is located underneath the tachometer of the instrument pack contains the following

warning lamps:

lOil pressure warning lamp.

lAlternator charge warning lamp.

lHDC fault warning lamp.

lSelf Levelling Suspension (SLS) warning lamp.

lActive Cornering Enhancement (ACE) warning lamp.

lGearbox manual/sport mode warning lamps.

The serial communication link is used to allow information to travel to and from the instrument pack, and it provides

the ability to configure the instrument pack to a specific market. It also allows the instrument pack to be controlled by

TestBook for diagnostics.

There are five market specific variants of the instrument pack:

lUnited Kingdom (UK).

lNorth American Specification (NAS).

lCanada.

lAustralia.

lRest Of the World (ROW), Gulf and Japan.

The main difference between the five markets is that the speedometer will indicate road speed in mph as major figures

and km/h as minor figures, km/h as major figures and mph as minor figures or km/h only.

When TestBook is used to diagnose the instrument pack it demands each of the dials and warning lamps to operate

in-turn so a visual check of their operation can be made.

CAUTION: The instrument pack must not be stored on its face side at any time. This is because the dials have

damping fluid within them to ensure smooth operation of the dials' indicator needles. This fluid will leak out.

Speedometer

The speedometer informs the driver of the current vehicle road speed. It has a Liquid Crystal Display (LCD) to show

odometer, trip meter and, on automatic gearbox models, the selected gear. The speedometer will not show speeds

of less than 1.5 mph (2.5 km/h).

There are three different market configurations:

lNAS and UK = mph as major figures km/h as minor figures.

lCanada = km/h as major figures mph as minor figures.

lROW and Australia = km/h only.

The Self Levelling and Anti-Lock Brake System (SLABS) ECU provides the signal input for the road speed. The signal

is at 8000 pulses per mile (1.6 kilometres).