Fuel system LAND ROVER DISCOVERY 2002 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 463 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-6 DESCRIPTION AND OPERATION

Description - engine management

General

The V8 engine is equipped with the Bosch Motronic M5.2.1 engine management system. This system is a sequential

multiport fuel injection system controlled by an Engine Control Module (ECM).

A single ECM is used for the control of the existing 4.0 litre engine and the new 4.6 litre engine introduced with 03

model year vehicles for the NAS market only. The ECM contains the tunes for both engines variants. When the ECM

is replaced, TestBook/T4 must be used to select the correct tune to match the engine fitment.

The ECM has On Board Diagnostic (OBD) strategies as required by various market legislative bodies. To meet these

requirements the system monitors and reports on any faults that cause excessive exhaust emissions.

In markets that mandate OBD, the ECM monitors performance of the engine for misfires, catalyst efficiency, exhaust

leaks and evaporative control loss. If a fault occurs, the ECM stores the relevant fault code and warns the driver of

component failure by illuminating the Malfunction Indicator Light in the instrument pack.

In markets where OBD is not mandatory, the ECM will still monitor performance of the engine and store the fault code,

but will not illuminate the Malfunction Indicator Light.

The ECM uses input and output information from its sensors and actuators to control the following engine conditions:

lFuel quantity.

lClosed loop fuelling.

lOpen loop fuelling.

lIgnition timing.

lKnock control.

lIdle speed control.

lEmission control.

lOn-Board Diagnostic (OBD) where applicable.

lVehicle immobilisation.

lMisfire detection (where applicable).

lVehicle speed signal.

lRough road signal (where applicable).

lLow fuel level signal (where applicable).

lCoolant temperature gauge signal.

The ECM processes sensor information from the following input sources:

lIgnition switch (position II).

lCrankshaft speed and position sensor.

lCamshaft position sensor.

lEngine coolant temperature sensor.

lMass air flow sensor.

lIntake air temperature sensor.

lKnock sensor.

lThrottle position sensor.

lHeated oxygen sensors.

lHigh/ Low ratio switch.

lFuel tank pressure sensor (where fitted)

lThermostat monitoring sensor (where fitted)

Page 464 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-7

The ECM controls the following outputs:

lFuel injectors (1 per cylinder).

lIgnition coils/ high tension leads/ spark plugs.

lFuel pump relay.

lIdle air control valve.

lHeated oxygen sensors.

lEVAP canister purge valve.

lEVAP canister vent solenoid (CVS) valve (where fitted).

lMalfunction Indicator Lamp (MIL)/ service engine soon lamp (where fitted).

lHill descent control (via SLABS interface).

lEVAP system fuel leak detection pump (where fitted)

lSecondary air injection pump (where fitted)

The ECM also interfaces with the following:

lDiagnostics via diagnostic connector with TestBook.

lController Area Network (CAN) link to EAT ECU.

lAir conditioning system.

lSelf Levelling & Anti-lock Braking System (SLABS) ECU.

lImmobilisation system via the body control unit (BCU).

lInstrument cluster.

lCruise control ECU

lActive Cornering Enhancement (ACE) ECU

Engine Control Module (ECM)

The engine control module (ECM) is located on the RH side A post below the face panel inside the vehicle. It has a

cast aluminium case and is mounted on a bracket. The ECM has 5 independent connectors totalling 134 pins.

The ECM is available in 4 variants:

lNAS.

lNAS low emission vehicles.

lUK/ Europe/ Japan/ Australia.

lROW/ Gulf.

The ECM uses a 'flash' electronic erasable programmable read only memory (EEPROM). This enables the ECM to

be externally configured, to ensure that the ECM can be updated with any new information, this also allows the ECM

to be configured with market specific data. TestBook must be used to configure replacement ECM's. The ECM can

be reconfigured up to 16 times to meet changing specifications and legislation.

The ECM memorises the positions of the crankshaft and the camshaft when the engine has stopped via the CKP and

CMP sensors. This allows immediate sequential fuel injection and ignition timing during cranking. This information is

lost if battery voltage is too low (i.e. flat battery). So the facility will be disabled for the first engine start.

Page 465 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-8 DESCRIPTION AND OPERATION

Input/Output

The ECM has various sensors fitted to the engine to allow it to monitor engine condition. The ECM processes these

signals and decides what actions to carry out to maintain optimum engine operation by comparing the information

from these signals to mapped data within its memory.

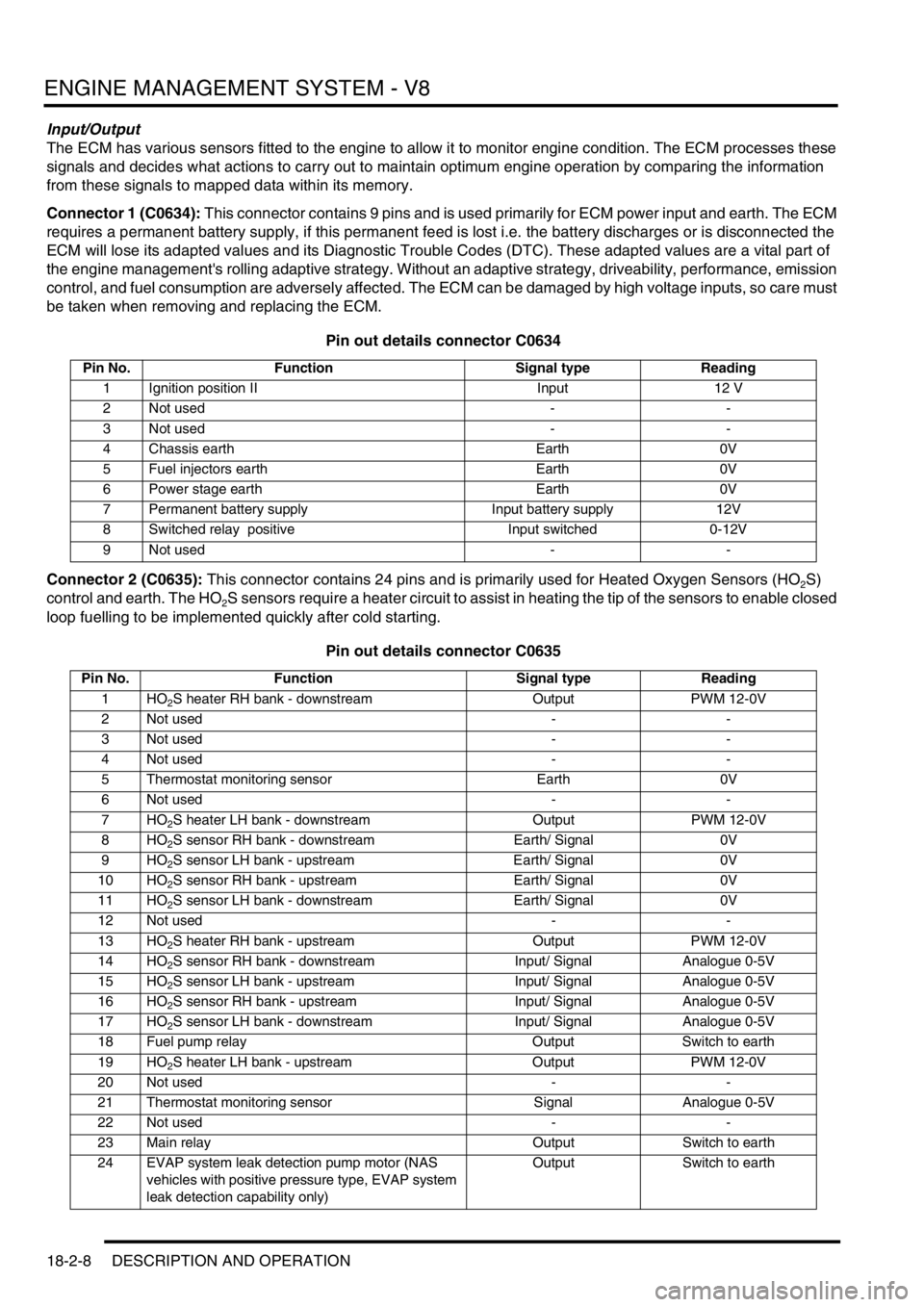

Connector 1 (C0634): This connector contains 9 pins and is used primarily for ECM power input and earth. The ECM

requires a permanent battery supply, if this permanent feed is lost i.e. the battery discharges or is disconnected the

ECM will lose its adapted values and its Diagnostic Trouble Codes (DTC). These adapted values are a vital part of

the engine management's rolling adaptive strategy. Without an adaptive strategy, driveability, performance, emission

control, and fuel consumption are adversely affected. The ECM can be damaged by high voltage inputs, so care must

be taken when removing and replacing the ECM.

Pin out details connector C0634

Connector 2 (C0635): This connector contains 24 pins and is primarily used for Heated Oxygen Sensors (HO

2S)

control and earth. The HO

2S sensors require a heater circuit to assist in heating the tip of the sensors to enable closed

loop fuelling to be implemented quickly after cold starting.

Pin out details connector C0635

Pin No. Function Signal type Reading

1 Ignition position II Input 12 V

2 Not used - -

3 Not used - -

4 Chassis earth Earth 0V

5 Fuel injectors earth Earth 0V

6 Power stage earth Earth 0V

7 Permanent battery supply Input battery supply 12V

8 Switched relay positive Input switched 0-12V

9 Not used - -

Pin No. Function Signal type Reading

1HO

2S heater RH bank - downstream Output PWM 12-0V

2 Not used - -

3 Not used - -

4 Not used - -

5 Thermostat monitoring sensor Earth 0V

6 Not used - -

7HO

2S heater LH bank - downstream Output PWM 12-0V

8HO

2S sensor RH bank - downstream Earth/ Signal 0V

9HO

2S sensor LH bank - upstream Earth/ Signal 0V

10 HO

2S sensor RH bank - upstream Earth/ Signal 0V

11 HO

2S sensor LH bank - downstream Earth/ Signal 0V

12 Not used - -

13 HO

2S heater RH bank - upstream Output PWM 12-0V

14 HO

2S sensor RH bank - downstream Input/ Signal Analogue 0-5V

15 HO

2S sensor LH bank - upstream Input/ Signal Analogue 0-5V

16 HO

2S sensor RH bank - upstream Input/ Signal Analogue 0-5V

17 HO

2S sensor LH bank - downstream Input/ Signal Analogue 0-5V

18 Fuel pump relay Output Switch to earth

19 HO

2S heater LH bank - upstream Output PWM 12-0V

20 Not used - -

21 Thermostat monitoring sensor Signal Analogue 0-5V

22 Not used - -

23 Main relay Output Switch to earth

24 EVAP system leak detection pump motor (NAS

vehicles with positive pressure type, EVAP system

leak detection capability only)Output Switch to earth

Page 466 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-9

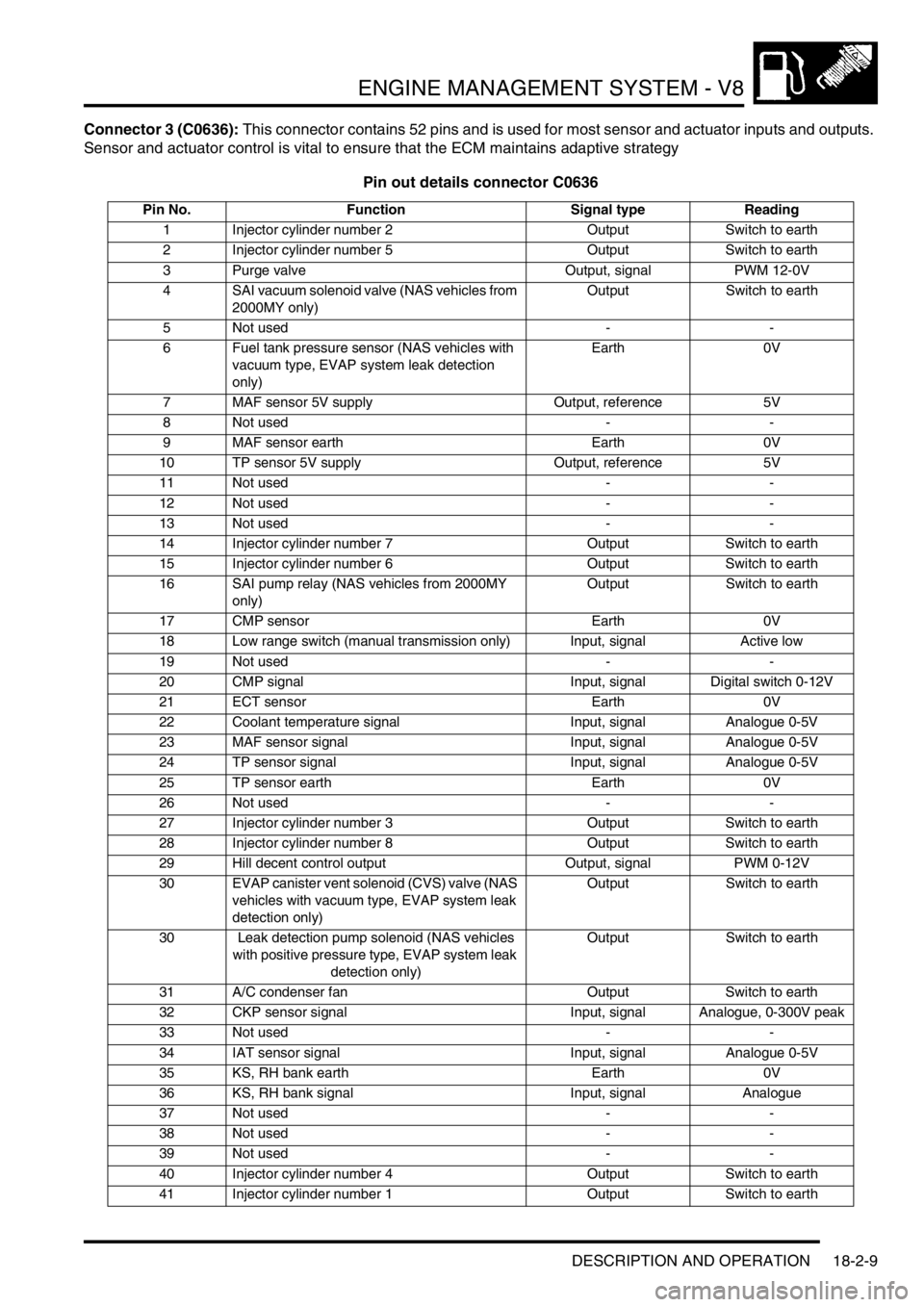

Connector 3 (C0636): This connector contains 52 pins and is used for most sensor and actuator inputs and outputs.

Sensor and actuator control is vital to ensure that the ECM maintains adaptive strategy

Pin out details connector C0636

Pin No. Function Signal type Reading

1 Injector cylinder number 2 Output Switch to earth

2 Injector cylinder number 5 Output Switch to earth

3 Purge valve Output, signal PWM 12-0V

4 SAI vacuum solenoid valve (NAS vehicles from

2000MY only)Output Switch to earth

5 Not used - -

6 Fuel tank pressure sensor (NAS vehicles with

vacuum type, EVAP system leak detection

only)Earth 0V

7 MAF sensor 5V supply Output, reference 5V

8 Not used - -

9 MAF sensor earth Earth 0V

10 TP sensor 5V supply Output, reference 5V

11 Not used - -

12 Not used - -

13 Not used - -

14 Injector cylinder number 7 Output Switch to earth

15 Injector cylinder number 6 Output Switch to earth

16 SAI pump relay (NAS vehicles from 2000MY

only)Output Switch to earth

17 CMP sensor Earth 0V

18 Low range switch (manual transmission only) Input, signal Active low

19 Not used - -

20 CMP signal Input, signal Digital switch 0-12V

21 ECT sensor Earth 0V

22 Coolant temperature signal Input, signal Analogue 0-5V

23 MAF sensor signal Input, signal Analogue 0-5V

24 TP sensor signal Input, signal Analogue 0-5V

25 TP sensor earth Earth 0V

26 Not used - -

27 Injector cylinder number 3 Output Switch to earth

28 Injector cylinder number 8 Output Switch to earth

29 Hill decent control output Output, signal PWM 0-12V

30 EVAP canister vent solenoid (CVS) valve (NAS

vehicles with vacuum type, EVAP system leak

detection only)Output Switch to earth

30 Leak detection pump solenoid (NAS vehicles

with positive pressure type, EVAP system leak

detection only)Output Switch to earth

31 A/C condenser fan Output Switch to earth

32 CKP sensor signal Input, signal Analogue, 0-300V peak

33 Not used - -

34 IAT sensor signal Input, signal Analogue 0-5V

35 KS, RH bank earth Earth 0V

36 KS, RH bank signal Input, signal Analogue

37 Not used - -

38 Not used - -

39 Not used - -

40 Injector cylinder number 4 Output Switch to earth

41 Injector cylinder number 1 Output Switch to earth

Page 467 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-10 DESCRIPTION AND OPERATION

Connector 4 (C0637): This connector contains 40 pins and facilitates use of TestBook via the Diagnostic connector.

Also contained in this connector is the Malfunction Indicator Lamp (MIL), this instrument panel lamp informs the driver

of concerns within the engine management system.

Pin out details connector C0637

42 Idle air control valve open Output, signal PWM 12-0V

43 Idle air control valve close Output, signal PWM 12-0V

44 ECT sensor signal Output, signal PWM 0-12V

45 CKP sensor earth screen Earth 0V

46 CKP sensor signal Earth reference 0V

47 Not used - -

48 KS, LH bank earth Earth 0V

49 KS, LH bank signal Input, signal Analogue

50 Not used - -

51 Not used - -

52 Not used - -

Pin No. Function Signal type Reading

1 Not used - -

2 Not used - -

3 Not used - -

4 Not used - -

5 Not used - -

6 Not used - -

7 Not used - -

8 Low fuel level Input, signal Active high

9 Fuel tank pressure sensor (NAS vehicles with

vacuum type, EVAP system leak detection

capability only)Output, reference 5V

10 Not used - -

11 Not used - -

12 Analogue fuel level (NAS vehicles with positive

pressure type, EVAP system leak detection only)Input, signal 0-5V

13 Not used - -

14 Fuel tank pressure sensor (NAS vehicles with

vacuum type, EVAP system leak detection

capability only)Input, signal Analogue 0-5V

15 Not used - -

16 ATC compressor request Input, signal Active low

17 Engine speed output Output, signal PWM 0-5V

18 Not used - -

19 Not used - -

20 Malfunction indicator lamp 'ON' Output Switched earth

21 Not used - -

22 Vehicle speed signal (VSS) Input, signal PWM 0-12V

23 Not used - -

24 Not used - -

25 Not used - -

26 Not used - -

27 Not used - -

28 Not used - -

29 ATC compressor relay Output Switched earth

30 Not used - - Pin No. Function Signal type Reading

Page 469 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-12 DESCRIPTION AND OPERATION

Connector 5 (C0638): This connector contains 9 pins and is used to control the ignition system. The ignition coils are

supplied with power and a switching earth completes the circuit.

Pin out details connector C0638

Crankshaft speed and Position (CKP) sensor (C0168)

The CKP sensor is located towards the rear of the engine below cylinder number 7, with its tip adjacent to the outer

circumference of the flywheel. The CKP sensor is the most important sensor on the vehicle and without its signal the

engine will not run. The signal produced by the CKP sensor allows the ECM to determine crankshaft angle and speed

of rotation. The ECM uses this information to calculate ignition timing and fuel injection timing.

The CKP sensor works as a variable reluctance sensor. It uses an electromagnet and a reluctor ring to generate a

signal. As the reluctor ring passes the tip of the CKP sensor the magnetic field produced by the sensor is cut and then

re-instated. The ECM measures the signal as an ac voltage.

The output voltage varies in proportion to engine speed. The reluctor ring has a set tooth pattern, 60 teeth are spaced

at 6

° intervals and are 3° wide, two teeth are removed to provide a reference mark at 60° BTDC for number 1 cylinder.

There is no back up strategy or limp home facility if this sensor fails, the engine does not run.

Pin No. Function Signal type Reading

1 Not used - -

2 Ignition , Cylinders 2 and 3 Output Switch to earth

3 Not used - -

4 Not used - -

5 Ignition coil earth Earth 0V

6 Ignition , Cylinders 1 and 6 Output Switch to earth

7 Ignition , Cylinders 4 and 7 Output Switch to earth

8 Ignition , Cylinders 5 and 8 Output Switch to earth

9 Not used - -

Page 471 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-14 DESCRIPTION AND OPERATION

In the event of a CKP sensor signal failure any of the following symptoms may be observed:

lEngine cranks but fails to start.

lMIL remains on at all times.

lEngine misfires (CKP sensor incorrectly fitted).

lEngine runs roughly or even stalls (CKP sensor incorrectly fitted).

lTachometer fails to work.

lFlywheel adaption reset – ferrous contamination

If the CKP sensor fails while the engine is running the engine will suddenly stall, this is because the CKP sensor has

no backup strategy. If this happens the ECM will produce a fault code that it can store in its memory. If the engine is

not running when the CKP sensor fails, the vehicle will crank but will be unlikely to start, and no fault code will be

generated. In this instance the MIL lamp will remain illuminated and the tachometer will fail to read.

It is vital that the CKP sensor output wires are not reversed (i.e. the connector is fitted incorrectly) as this will cause

a 3

° advance in ignition timing. This happens because the ECM uses the falling edge of the signal waveform as its

reference or timing point for each passing tooth on the reluctor.

Whenever a new crankshaft position sensor is fitted or the flywheel is removed, the adaptive values will have to be

reset, using TestBook.

Should a malfunction of the component occur, the following fault codes may be evident and can be retrieved by

TestBook:

Camshaft Position (CMP) sensor (C0176)

The CMP sensor is located on the front of the engine, above and behind the crankshaft pulley. The CMP sensor is a

Hall effect sensor producing four pulses for every two crankshaft revolutions. The sensor is positioned close to the

camshaft gear wheel, the gear wheel has four slots machined at 90

° intervals. This allows the ECM to recognise 4

individual cylinders every camshaft revolution or all 8 cylinders every crankshaft revolution.

The CMP sensor Hall effect works as a magnetic switch. It switches battery voltage on or off depending on the position

of the camshaft gear wheel in relationship to the sensor.

The ECM uses this signal for cylinder recognition to control sequential fuel injection, engine knock and diagnostic

purposes.

P Code J2012 description Land Rover description

P0335 Crankshaft position sensor a circuit malfunction Reference mark outside search window for more than

two revs, with engine speed above 500 rev/min

P0336 Crankshaft position sensor a circuit range/

performanceIncorrect number of teeth detected ±1 tooth between

reference marks with engine speed above 500 rpm

Page 472 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-15

Input/Output

Electrical input to the camshaft position sensor is from fuse 2 located in engine compartment fuse box. One output is

sensor earth, the other is the signal output to the ECM via pin 20 of connector C0636.

The CMP sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lIncorrect fitting of the sensor.

lExcessive camshaft gear wheel tolerance.

lExcessive camshaft endfloat.

lCamshaft and crankshaft misalignment.

lSpeed signal correlation with CKP sensor signal.

lCam wheel magnetised / residual magnetism

In the event of a CMP sensor signal failure any of the following symptoms may be observed:

lIgnition timing reverts to default values from ECM memory.

lLoss of cylinder correction.

lLoss of active knock control.

lLoss of active knock control diagnostics.

lLoss of cylinder identification for misfire diagnostics.

lLoss of quick synchronisation of crankshaft and camshaft for cranking/ start up.

lFuel injection could be 360

° out of phase.

lFront HO

2S sensor ageing period diagnostic disabled (NAS only)

Should a malfunction of the component occur the following fault code may be evident and can be retrieved by

TestBook:

The fault condition has to be detected for more than 100 cam pulses (25 revolutions) when the engine speed is greater

than 500 rev/min.

Engine Coolant Temperature (ECT) sensor (C0196)

The ECT sensor is located at the front of the engine adjacent to the coolant outlet pipe. The ECT sensor forms a vital

part of the ECM operating strategy, and therefore the optimum control of the running of the engine. Richer air/ fuel

ratio is required at lower coolant temperatures such as cold starting. Coolant temperature information from the ECT

sensor is also vital to enable the ECM to weaken the air/ fuel mixture as temperature rises to maintain low emissions

and optimum performance.

P code J2012 description Land Rover description

P0340 Camshaft position sensor circuit malfunction Open/short circuit to vehicle supply or earth

Page 476 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-19

Input/Output

The ECM provides the thermostat monitoring sensor with a 5 volt reference via pin 21 of connector C0635 of the ECM,

and an earth via pin 5 of connector C0635 of the ECM.

There are three types of thermostat monitoring sensor diagnostic checks:

lSensor signal is above maximum threshold. For the ECM to register this as a fault, and illuminate the MIL, the

temperature registered by the thermostat monitoring sensor must be above 140

°C (284 °F) for more than 1

second.

lSensor signal is below minimum threshold. For the ECM to register this as a fault, and illuminate the MIL, the

temperature registered by the thermostat monitoring sensor must be below -33

°C (-27 °F) for more than 1

second, while the inlet air temperature reading is greater than -32

°C (-25 °F).

lSignal difference between ECT sensor and thermostat monitoring sensor is below maximum threshold. For the

ECM to register this as a fault, and illuminate the MIL, the following conditions must exist:

lNo maximum or minimum threshold signal faults exist.

lNo faults are recorded against the thermostat monitoring sensor or vehicle speed signal.

lEngine not in idle speed control.

lFuel cut-off not active.

lEngine speed is greater than 400 rpm.

lRoad speed is greater than 0 mph.

lIntegrated mass air flow from engine start to fuel cut-off is greater than set value (between 3 kg and 10 kg

dependent upon engine coolant temperature at engine start).

lEngine coolant temperature at engine start is between 9

°C and 39 °C (48 °F and 102 °F).

lHigh range is selected.

lDelay time before thermostat monitoring is enabled is between set limits (between 50 and 500 seconds

dependent upon engine coolant temperature at engine start).

lEngine coolant temperature is greater than 90

°C (194 °F).

lThe difference between the ECT sensor reading and the thermostat monitoring sensor reading is less than

39

°C (102 °F).

Page 478 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-21

Mass Air Flow (MAF) Sensor

The MAF sensor utilises a “hot film” element contained in the air intake duct to monitor the mass of the air flow being

drawn into the engine. The MAF sensor contains two sensing elements, one element is controlled at ambient

temperature (e.g. 25

°C (77°F)), while the other is heated to 200°C (360°F) above the ambient temperature (e.g. 225°C

(437

°F)).

When the intake air passes the heated element, it cools it down, so lowering the resistance of the hot film element. In

order to maintain the same temperature, the circuit to the heated element has to supply more current. The change in

current causes a corresponding change in potential difference to be detected in the monitoring circuit. This change is

supplied to the ECM as a voltage between 0 and 5V, where it is processed by the ECM's internal mapping to interpret

the data as a measure of the mass of air flow.

The measured air mass flow is used by the ECM to determine the fuel quantity to be injected in order to maintain the

stoiciometric air:fuel mixture for optimum engine performance and low emissions.

Normal operating parameters of the MAF sensor are as follows:

MAF output

If the MAF sensor fails, the ECM implements a back up strategy which is based on throttle angle. Poor throttle

response and reduced performance will result.

The MAF sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lContaminated sensor element.

lDamaged sensor element.

lAir leak after the MAF sensor.

lInlet air restriction.

lResistance in wiring harness causing signal offset.