LAND ROVER DISCOVERY 2002 Workshop Manual

DISCOVERY 2002

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57246/w960_57246-0.png

LAND ROVER DISCOVERY 2002 Workshop Manual

Trending: transmission, engine, fuse, navigation system, Road wheel speed sensor, wheel bolt torque, turn signal

Page 1421 of 1672

AIR CONDITIONING

82-48REPAIRS

Page 1422 of 1672

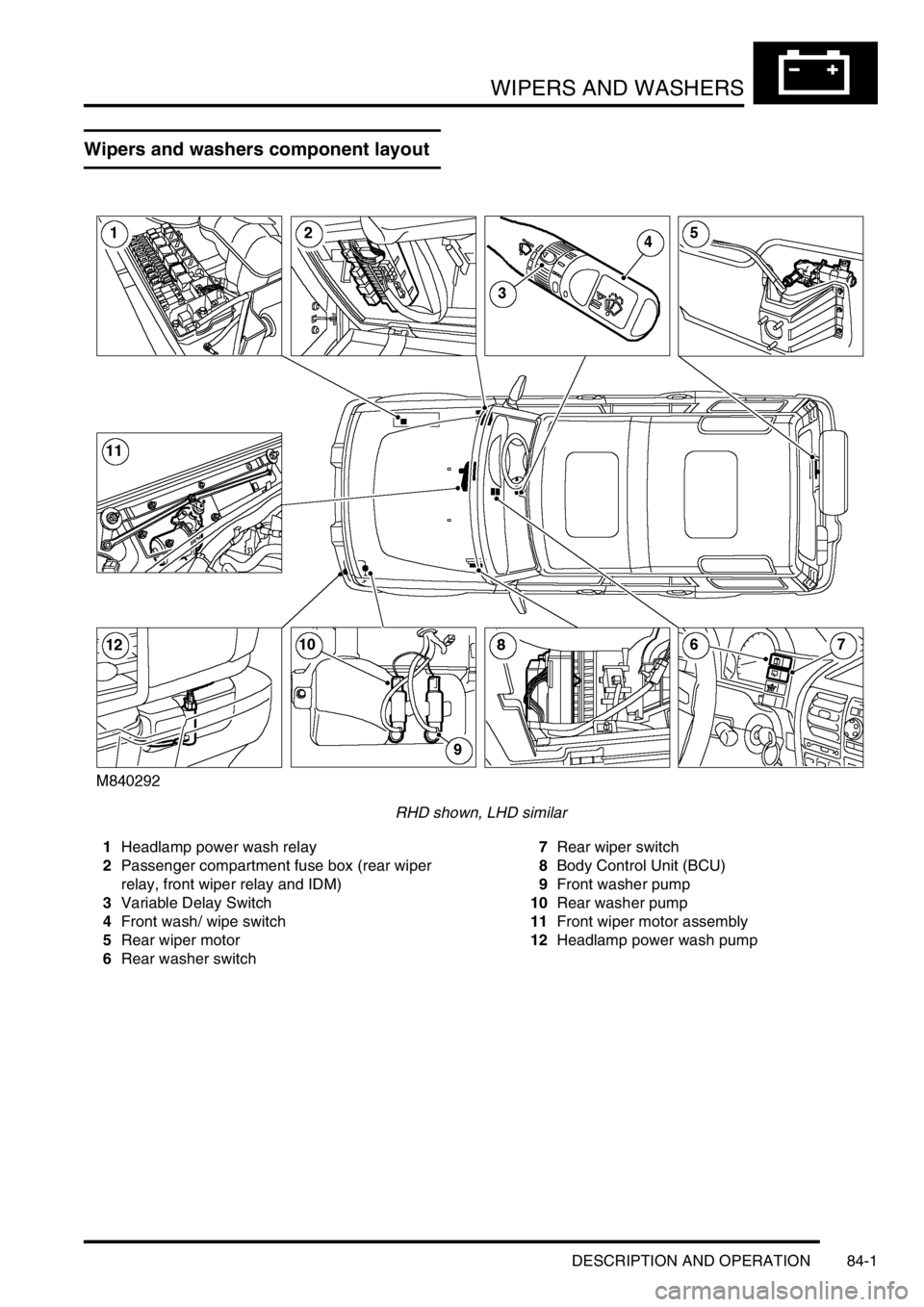

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-1

WIPERS AND WASHERS DESCRIPTION AND OPERAT ION

Wipers and washers component layout

RHD shown, LHD similar

1Headlamp power wash relay

2Passenger compartment fuse box (rear wiper

relay, front wiper relay and IDM)

3Variable Delay Switch

4Front wash/ wipe switch

5Rear wiper motor

6Rear washer switch7Rear wiper switch

8Body Control Unit (BCU)

9Front washer pump

10Rear washer pump

11Front wiper motor assembly

12Headlamp power wash pump

Page 1423 of 1672

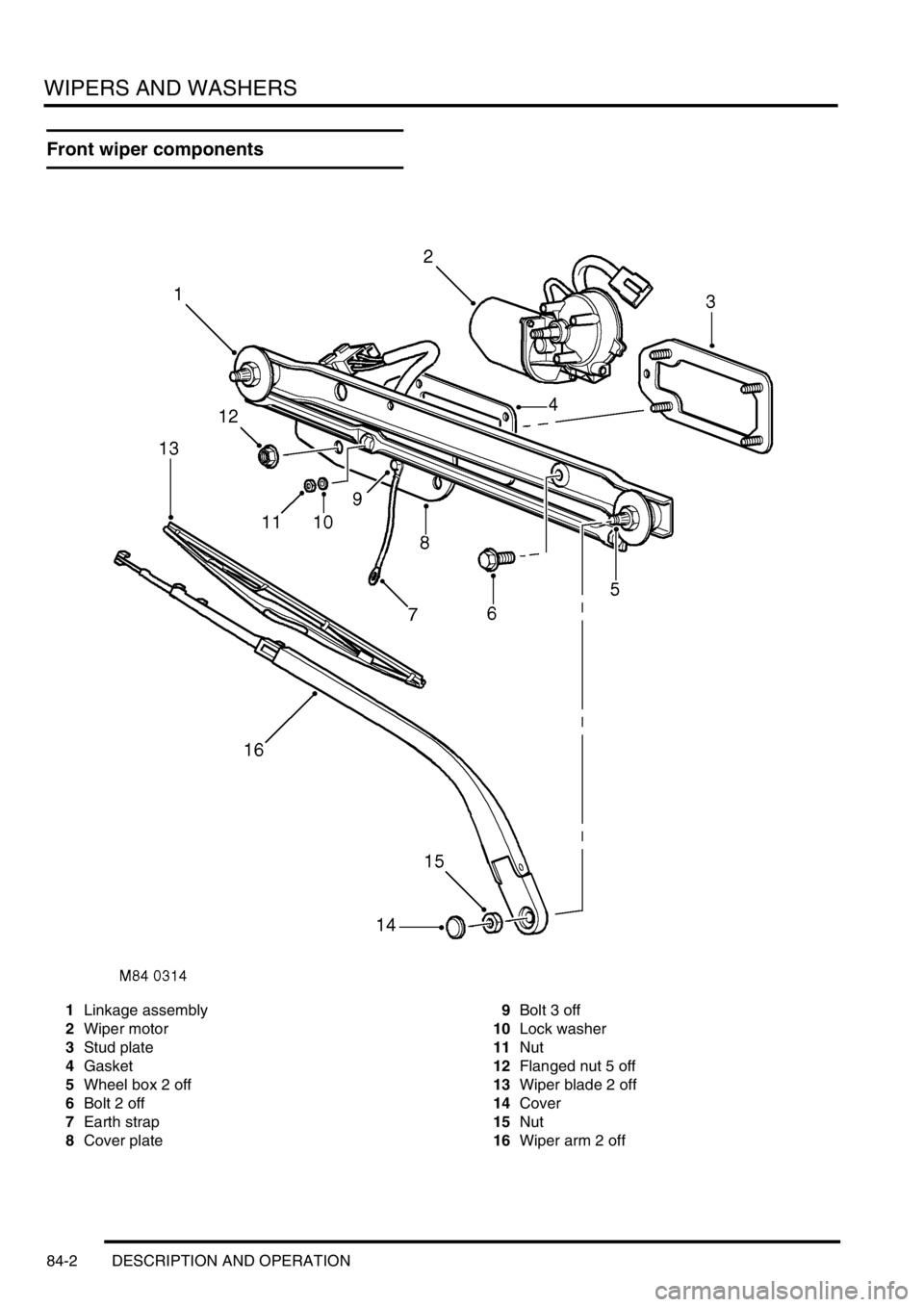

WIPERS AND WASHERS

84-2 DESCRIPTION AND OPERATION

Front wiper components

1Linkage assembly

2Wiper motor

3Stud plate

4Gasket

5Wheel box 2 off

6Bolt 2 off

7Earth strap

8Cover plate9Bolt 3 off

10Lock washer

11Nut

12Flanged nut 5 off

13Wiper blade 2 off

14Cover

15Nut

16Wiper arm 2 off

Page 1424 of 1672

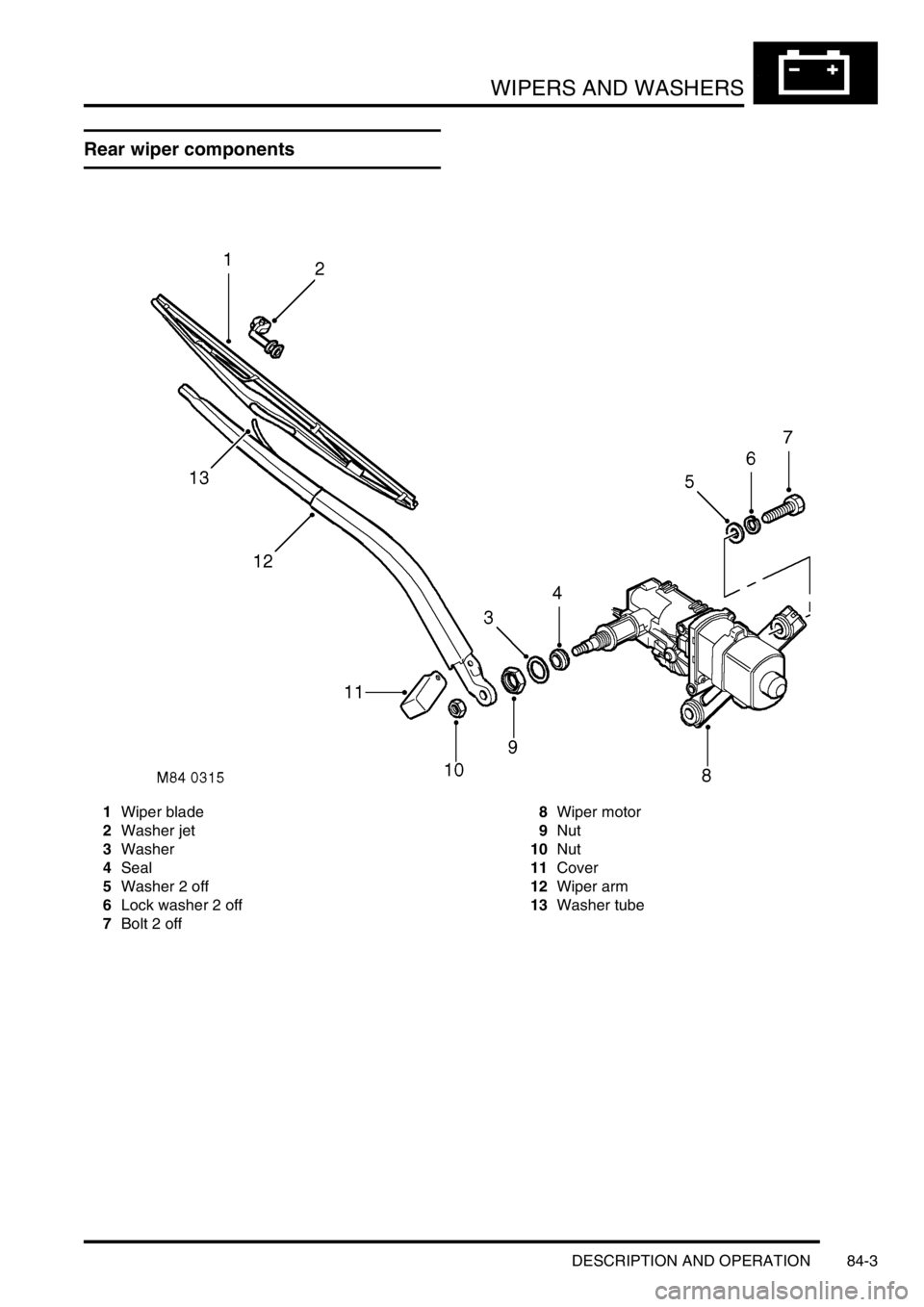

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-3

Rear wiper components

1Wiper blade

2Washer jet

3Washer

4Seal

5Washer 2 off

6Lock washer 2 off

7Bolt 2 off8Wiper motor

9Nut

10Nut

11Cover

12Wiper arm

13Washer tube

Page 1425 of 1672

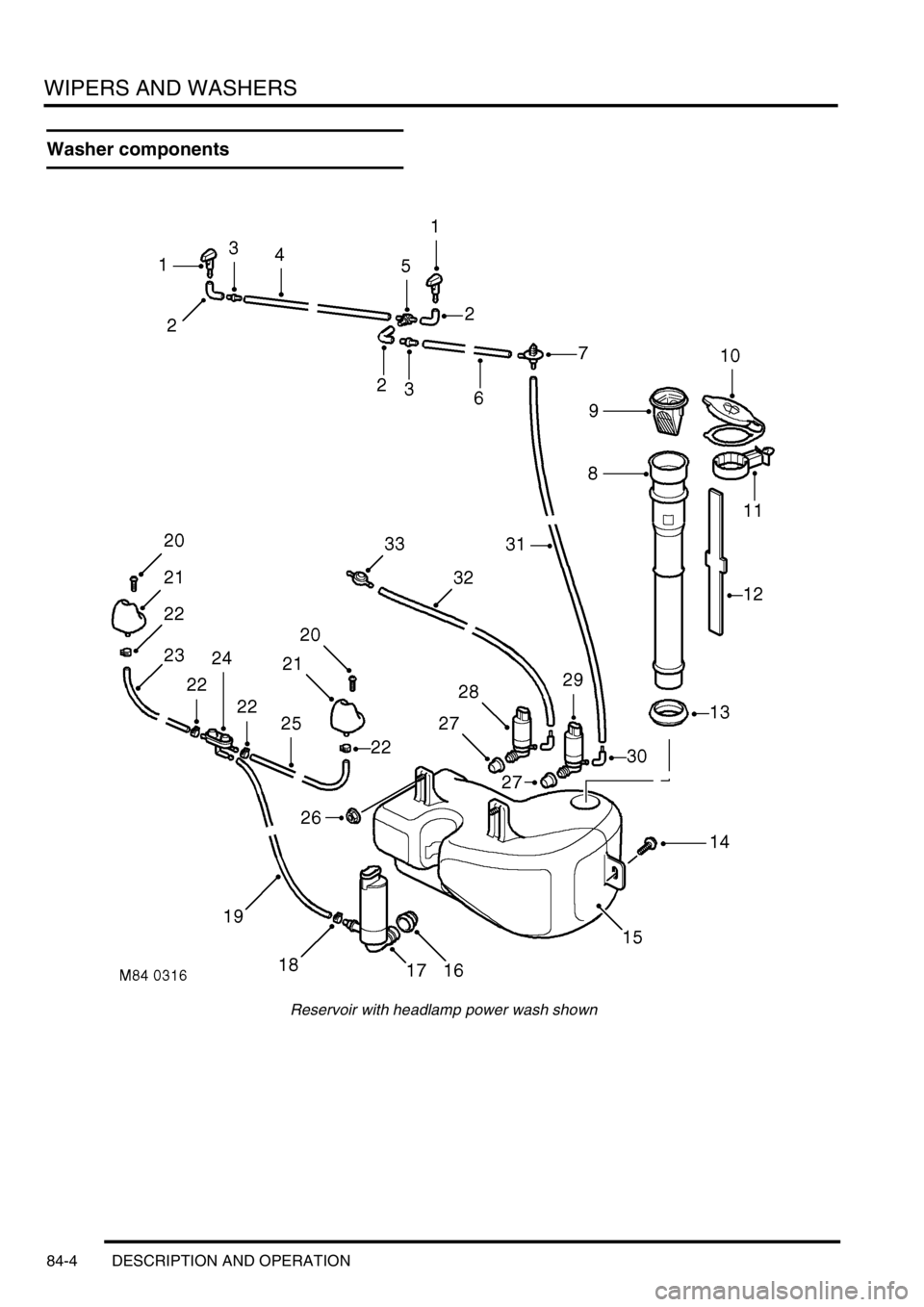

WIPERS AND WASHERS

84-4 DESCRIPTION AND OPERATION

Washer components

Reservoir with headlamp power wash shown

Page 1426 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-5

1Windscreen washer jet 2 off

2Elbow 3 off

3In-line non-return valve

4Tube

5'T' connector

6Tube

7Connector

8Filler neck tube

9Filter

10Cap

11Bracket

12Level float

13Filler neck seal

14Bolt

15Reservoir

16Pump sealing grommet (if fitted)

17Powerwash pump (if fitted)18Clip

19Tube

20Screw 2 off

21Powerwash jet 2 off

22Clip 4 off

23Tube

24'T' connector

25Tube

26Nut 2 off

27Pump sealing grommet 2 off

28Rear washer pump

29Front windscreen washer pump

30Elbow 2 off

31Tube - front windscreen

32Tube - rear tail door window

33Non-return valve

Page 1427 of 1672

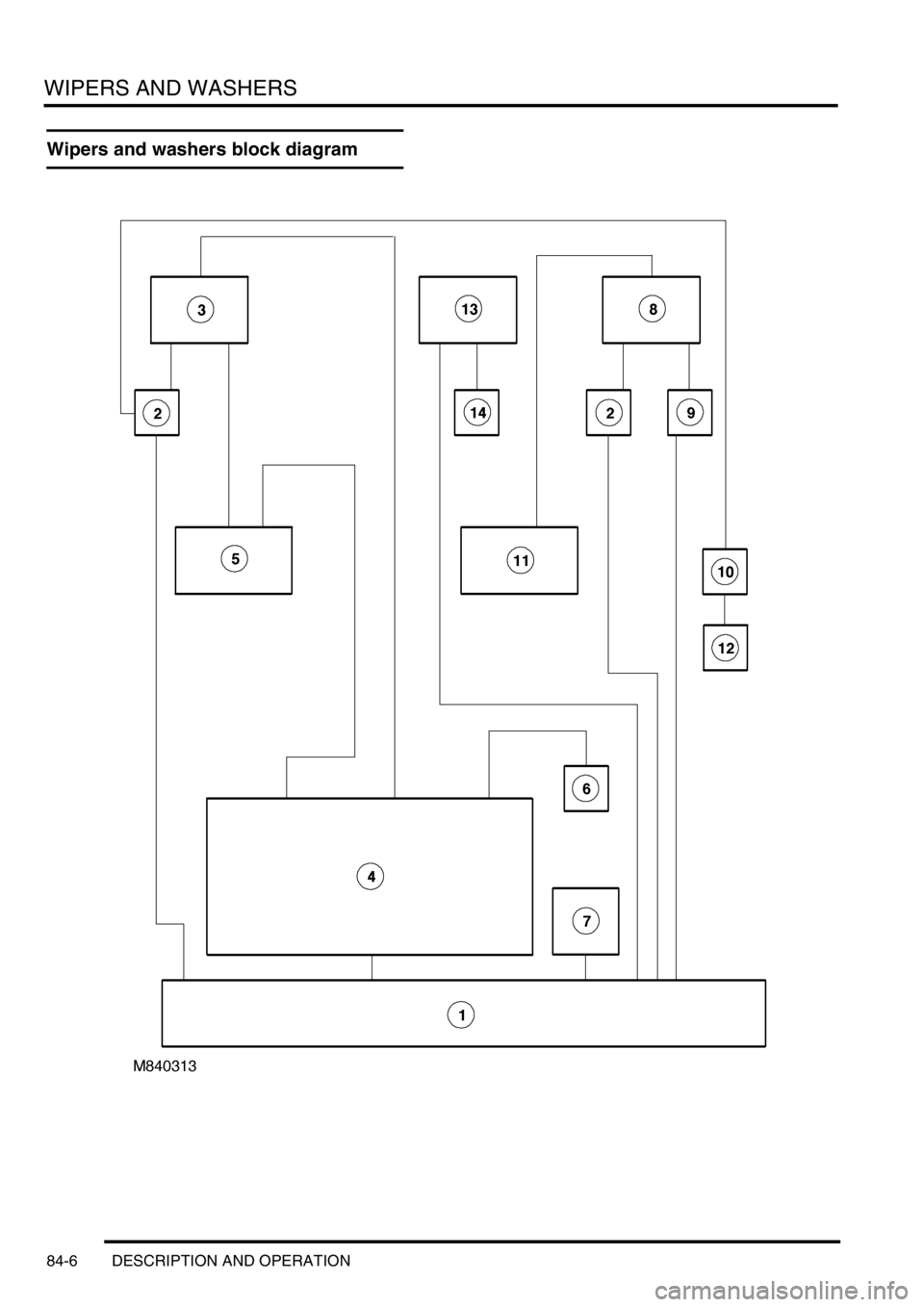

WIPERS AND WASHERS

84-6 DESCRIPTION AND OPERATION

Wipers and washers block diagram

Page 1428 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-7

1BCU

2IDM

3Front wiper relay

4Front wash / wipe switch

5Front wiper motor assembly

6Front washer pump motor

7Variable delay switch

8Rear wiper relay

9Rear wiper switch

10Rear washer switch

11Rear wiper motor

12Rear washer pump motor

13Headlamp power wash relay

14Headlamp power wash pump motor

Page 1429 of 1672

WIPERS AND WASHERS

84-8 DESCRIPTION AND OPERATION

Description

General

All markets have a common wiper system with headlamp powerwash as an option.

The wipers system comprises two front wipers and one rear wiper which are powered by electric motors. A washer

reservoir is located in the front left hand wheel arch and is fitted with two electric pumps. Each pump supplies washer

fluid to either the front or rear screens. On certain models, a third pump can be fitted to operate a headlamp power

wash function. Operation of the front and rear wipers and washers is controlled by the driver using switches located

on a steering column stalk and push button switches on the fascia.

Control of the wipers and washers is achieved by the following components:

lBCU.

lIDM.

lFront wiper relay.

lFront wash/ wipe switch.

lVariable delay switch.

lFront wiper motor assembly.

lFront washer pump motor.

lRear wiper relay.

lRear wiper switch.

lRear washer switch.

lRear wiper motor.

lRear washer pump motor.

Both the Body Control Unit (BCU) and the Intelligent Driver Module (IDM) control the wiper system. The BCU controls

the time delay function of the wiper system and is located below and behind the passenger glovebox. During engine

cranking the BCU prevents wiper functions. Two relays are located in the passenger compartment fusebox. The

relays control the delay operation of the front and rear wipers. The relays are an integral part of the fusebox and

cannot be renewed separately.

Power for the wiper system is supplied by the IDM, which is integral with the passenger fusebox and cannot be

renewed as a component. A serial communication link allows communication between the IDM and the BCU.

The system has diagnostic capabilities through TestBook.

Front wipers

The two front windscreen wipers are operated by a linkage assembly and an electric motor located under the plenum

grill below the windscreen. The linkage and motor assembly is handed for left and right hand drive vehicles. The motor

is an integral part of the linkage and cannot be replaced separately.

The linkage comprises a pressed steel mounting plate which provides for the attachment of a wheel box at each end.

The mounting plate is secured to the bulkhead with flanged nuts which attach to a stud plate located behind the

bulkhead. A link arm is attached to each wheel box by a short link and secured with circlips. The link arm has an

attachment hole centrally located along its length for the electric motor drive link.

The electric motor is mounted in a recess in the bulkhead below a sealed cover plate. The drive spindle of the motor

protrudes through the cover plate and is fitted with a link. The link is attached to a tapered spline on the motor spindle

and is secured with a lock washer and nut. The opposite end of the link is attached to the central attachment point on

the link arm and secured with a circlip.

Each wheel box has a taper splined shaft which allows for the attachment of the wiper arm which is secured with a

washer and nut. The shaft of each wheel box is passed through a rubber sealed aperture in the plenum. The wiper

arm attachment to the splined shaft has a pivot to which the remainder of the arm is attached. The two parts of the

arm are connected by a spring which controls the pressure of the blade on the screen to a predetermined amount.

Page 1430 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-9

The wiper blades are attached to the wiper arms with a clips that allow the blade to pivot. Each wiper blade comprises

a number of levers and yokes to which the rubber wiper is attached. The levers and yokes ensure that the pressure

applied by the arm spring is distributed evenly along the full length of the blade. The rubber wiper is held in the yokes

by a pair of stainless steel strips which also contribute to the even distribution of spring pressure along the blade. The

driver's side wiper blade is fitted with an aerofoil which presses the blade onto the screen at high speed. This prevents

the blade from lifting off the screen and maintains the wiping performance.

Front wash/ wipe switch

The front wash/ wipe switch is located on a stalk on the RH side of the steering column and allows the driver to control

the operation of the front wipers and the front washer pump.

Operating the washer switch provides battery voltage from fuse 19 in the passenger compartment fusebox to the

washer pump motor.

Operating the flick wipe function provides battery voltage from fuse 19 in the passenger compartment fuse box to the

high-speed brushes of the wiper motor.

Operating the intermittent function provides a battery voltage signal to the BCU. The BCU determines the wipe

interval from the variable delay switch and signals the IDM to activate the front wiper relay, which provides battery

voltage to the wiper motor.

Operating the low-speed function provides battery voltage from fuse 19 in the passenger compartment fuse box to

the low-speed brushes of the wiper motor.

Operating the high-speed function provides battery voltage from fuse 19 in the passenger compartment fuse box to

the high-speed brushes of the wiper motor

Trending: ABS, Working on brakes, Telephone, brake fluid, bolt pattern, washer fluid, length