alternator belt LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 531 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-74 REPAIRS

5.Disconnect multiplug from ECT sensor.

6.Remove sensor from inlet manifold and discard

sealing washer.

Refit

1.Clean sealant from threads in manifold.

2.Apply Loctite 577 to sensor threads.

3.Fit new sealing washer to ECT sensor and

tighten sensor to 10 Nm (7 lbf.ft).

4.Connect multiplug to ECT sensor.

5.Position alternator, fit bolts and tighten to 45

Nm (33 lbf.ft).

6.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

7.Top up cooling system.

8.Connect battery earth lead.

9.Fit battery cover and secure with fixings.

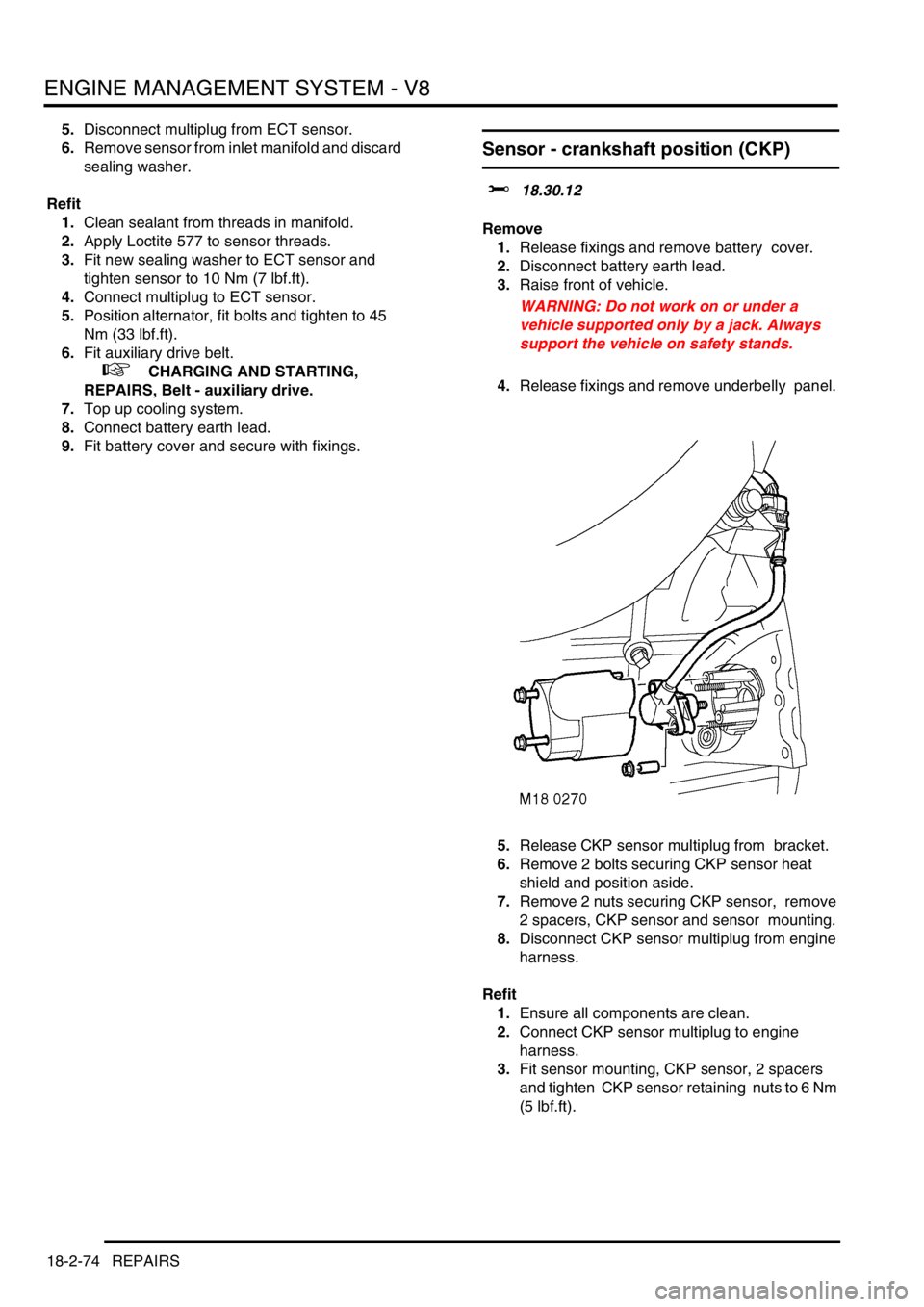

Sensor - crankshaft position (CKP)

$% 18.30.12

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Release fixings and remove underbelly panel.

5.Release CKP sensor multiplug from bracket.

6.Remove 2 bolts securing CKP sensor heat

shield and position aside.

7.Remove 2 nuts securing CKP sensor, remove

2 spacers, CKP sensor and sensor mounting.

8.Disconnect CKP sensor multiplug from engine

harness.

Refit

1.Ensure all components are clean.

2.Connect CKP sensor multiplug to engine

harness.

3.Fit sensor mounting, CKP sensor, 2 spacers

and tighten CKP sensor retaining nuts to 6 Nm

(5 lbf.ft).

Page 644 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

REPAIRS 30-2-15

Refit

1.Clean old RTV sealant from cylinder head and

cylinder block notches.

2.Clean mating faces of cylinder block, cylinder

head and inlet manifold.

3.Apply RTV sealant to cylinder head and

cylinder block notches.

4.Fit new gasket seals, ensuring ends engage

correctly in notches.

5.Fit new inlet manifold gasket.

6.Position gasket clamps and fit bolts, but do not

tighten at this stage.

7.Position inlet manifold to engine. Fit manifold

bolts and, working in the sequence shown,

tighten bolts initially to 10 Nm (7 lbf.ft) then to

51 Nm (38 lbf.ft).

8.Tighten gasket clamp bolts to 18 Nm (13 lbf.ft).

9.Connect fuel pipe.

10.Clean top hose outlet pipe mating faces.

11.Fit new 'O' ring to outlet pipe.

12.Position outlet pipe, fit bolts and tighten to 22

Nm (16 lbf.ft).

13.Position alternator, fit bolts and tighten to 45

Nm (33 lbf.ft).

14.Position PAS pump to auxiliary housing and

locate housing on engine. Fit bolts and tighten

to 40 Nm (30 lbf.ft).

15.Fit and tighten auxiliary housing nut to 10 Nm (7

lbf.ft).

16.Fit bolts securing PAS pump and tighten to 22

Nm (16 lbf.ft). 17.Position oil cooling pipe bracket fit bolt and

tighten to 22 Nm (16 lbf.ft).

18.Fit and tighten PAS pump high pressure pipe.

19.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

20.Clean PAS pump pulley mating faces.

21.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (16 lbf.ft).

22.Clean ACE pump dowels and dowel holes.

23.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

24.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

25.Secure injector harness and connect injector

multiplugs.

26.Position top hose and secure clips.

27.Fit rocker covers.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - LH.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - RH.

28.Check and top up PAS fluid

Page 1055 of 1672

BRAKES

70-10 DESCRIPTION AND OPERATION

Vacuum pump (diesel models only)

1Alternator

2Vacuum pump

3Brake servo assembly vacuum connection

4Oil feed pipe

5Oil drain pipe

As the diesel engine air inlet system does not produce sufficient depression to operate the brake servo assembly, an

engine driven vacuum pump is installed.

The vacuum pump is integrated with the engine alternator and driven by the auxiliary drive belt. The pump is a rotary

vane type, lubricated and cooled by engine oil supplied through a pipe connected to the engine block and returned

through a pipe connected to the engine oil sump. Air extracted from the brake servo assembly is vented into the oil

sump with returning lubricating oil.

Page 1087 of 1672

BRAKES

70-42 REPAIRS

Vacuum pump - servo

$% 70.50.19

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Release cover and remove nut securing lead

to alternator.

3.Disconnect alternator multiplug.

4.Remove bolt (LH thread) and remove auxiliary

drive belt tensioner. 5.Remove bolt securing support stay to

alternator.

6.Release clip and disconnect oil drain hose from

vacuum pump.

7.Disconnect vacuum pump oil supply pipe from

cylinder head and discard 'O' ring.

8.Remove bolt securing alternator and release

from mounting bracket.

9.Disconnect vacuum hose from vacuum pump.

10.Remove alternator. Take care not to damage

radiator cooling fins.

11.Remove 4 bolts, and remove vacuum pump

from alternator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 1088 of 1672

BRAKES

REPAIRS 70-43

Refit

1.Clean mating faces of alternator and vacuum

pump.

2.Fit vacuum pump to alternator and tighten

bolts to 8 Nm (6 lbf.ft).

3.Position alternator to engine and connect

multiplug.

4.Connect vacuum hose and oil drain hose to

vacuum pump and secure clips.

5.With assistance align alternator to mounting

bracket and fit but do not tighten bolt.

6.Fit bolt securing support stay to alternator and

tighten to 25 Nm (18 lbf.ft) .

7.Tighten bolt securing alternator to mounting

bracket to 45 Nm (33 lbf.ft).

8.Using new 'O' ring, connect oil supply pipe to

cylinder head and tighten to 10 Nm (7 lbf.ft).

9.Connect lead to alternator and tighten nut to 6

Nm (4.4 lbf.ft).

10.Fit auxiliary drive belt tensioner and tighten bolt

to 50 Nm (37 lbf.ft).

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Housing - caliper - front

$% 70.55.24

Remove

1.Raise front of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Clamp brake hose to prevent fluid loss.

4.Remove brake hose banjo bolt and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 guide pin bolts and remove caliper

housing from carrier.

6.Remove 2 brake pads from caliper carrier.

Page 1286 of 1672

PANEL REPAIRS

REPAIRS 77-2-37

Sill outer assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove RH or LH front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove RH or LH front door.

+ DOORS, REPAIRS, Door - front.

5.Remove RH or LH rear door.

+ DOORS, REPAIRS, Door - rear.

6.Remove RH or LH sill finisher.

7.Remove RH or LH 'A' post inner lower

finishers.

8.Remove RH or LH front seat.

+ SEATS, REPAIRS, Seat - front.

9. LH side: Remove power amplifier and EAT

ECU.

+ IN CAR ENTERTAINMENT,

REPAIRS, Amplifier - power.

10. RH side: Remove CD autochanger.

+ IN CAR ENTERTAINMENT,

REPAIRS, CD autochanger.

11.Remove rear seats.

+ SEATS, REPAIRS, Seat - rear.

12.Remove RH or LH front seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - front.

13.Remove tread plates from front and rear door

apertures.

14.Release carpet and position aside.

15.Remove front and rear door aperture seals.

16.Release relevant wiring from 'A' post, 'B/C' post

and sill areas, and position aside.

17.Remove loadspace lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

18. RH side: Remove lower ACE accelerometer.

+ FRONT SUSPENSION, REPAIRS,

Accelerometer - ACE - lower.

19. LH side: Remove SLS air compressor unit.

+ REAR SUSPENSION, REPAIRS,

Compressor unit - air - SLS.

20. Models with rear A/C: Recover refrigerant

from A/C system and remove A/C pipes from

LH sill.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

21.Remove 2 bolts securing body to chassis.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit 2 bolts securing body to chassis and tighten

to 45 Nm (33 lbf.ft).

2. Models with rear A/C: Fit A/C pipes to sill and

recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

3. LH side: Fit SLS air compressor unit.

+ REAR SUSPENSION, REPAIRS,

Compressor unit - air - SLS.

4. RH side: Fit lower ACE accelerometer.

+ FRONT SUSPENSION, REPAIRS,

Accelerometer - ACE - lower.

5.Fit loadspace lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

6.Fit relevant wiring to 'A' post, 'B/C' post and sill

areas.

7.Fit front and rear door door aperture seals.

8.Fit carpet and secure into position.

9.Fit tread plates to front and rear door apertures.

10.Fit front seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - front.

11.Fit rear seats.

+ SEATS, REPAIRS, Seat - rear.

12. LH side: Fit CD autochanger.

+ IN CAR ENTERTAINMENT,

REPAIRS, CD autochanger.

13. RH side: Fit power amplifier and EAT ECU.

+ IN CAR ENTERTAINMENT,

REPAIRS, Amplifier - power.

14.Fit front seat.

+ SEATS, REPAIRS, Seat - front.

15.Fit 'A' post inner lower finishers.

M77 1716A

Page 1288 of 1672

PANEL REPAIRS

REPAIRS 77-2-39

'B/C' post assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove RH or LH rear door.

+ DOORS, REPAIRS, Door - rear.

4.Remove front door striker from 'B/C' post.

5.Remove RH or LH sill finisher.

6.Remove RH or LH front seat.

+ SEATS, REPAIRS, Seat - front.

7. RH side: Remove power amplifier.

+ IN CAR ENTERTAINMENT,

REPAIRS, Amplifier - power.

8. LH side: Remove CD autochanger.

+ IN CAR ENTERTAINMENT,

REPAIRS, CD autochanger.

9.Remove RH or LH front seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - front.

10.Remove RH or LH rear seat.

+ SEATS, REPAIRS, Seat - rear.

11.Remove head lining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

12.Remove tread plate from front and rear door

apertures.

13.Release carpet from fixings and position aside.

14.Remove front and rear door door aperture

seals.

15.Release relevant wiring from 'B/C' post and sill

areas and position aside.

16.Remove side drip rail finisher.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

2. Before welding 'B/C' post to roof, apply

'Heat shrink paste' to roof area to avoid heat

damage to paintwork.

Refit

1.Fit side drip rail finisher.

2.Fit wiring to 'B/C' post and sill areas.

3.Fit front and rear door door aperture seal.

4.Position carpet and secure with fixings.

5.Fit tread plates to front and rear door apertures.

6.Fit head lining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

7.Fit rear seat.

+ SEATS, REPAIRS, Seat - rear.

8.Fit front seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - front.

9. LH side: Fit CD autochanger.

+ IN CAR ENTERTAINMENT,

REPAIRS, CD autochanger.

10. RH side: Fit power amplifier.

+ IN CAR ENTERTAINMENT,

REPAIRS, Amplifier - power.

11.Fit RH or LH front seat.

+ SEATS, REPAIRS, Seat - front.

12.Fit sill finisher.

Page 1291 of 1672

PANEL REPAIRS

77-2-42 REPAIRS

Body side inner rear assembly

In this procedure, the panel body side assembly is

replaced in conjunction with the body side inner rear

assembly.

Remove

1.Disconnect battery eath lead.

2.Disconnect leads/multiplug from alternator.

3.Remove panel body side assembly.

+ PANEL REPAIRS, REPAIRS, Panel

body side assembly.

4.Remove RH or LH rear seat.

+ SEATS, REPAIRS, Seat - rear.

5.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

6.Remove rear side seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - rear - side.

7.Remove third row seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belts - third row.

8.Remove fuel tank.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Tank - fuel.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Tank - fuel.

9.Remove fuel filler tube.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Filler tube - fuel.

10. RH side: Remove fuel flap release solenoid.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Solenoid - fuel filler flap release.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Solenoid - fuel filler flap release.

11. RH side: Remove air extractor vent.

12.Remove relevant wiring.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit and secure wiring.

2. RH side: Fit air extractor vent.

3. RH side: Fit fuel flap release solenoid.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Solenoid - fuel filler flap release.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Solenoid - fuel filler flap release.

4.Fit fuel filler tube.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Filler tube - fuel.

5.Fit fuel tank.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Tank - fuel.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Tank - fuel.

6.Fit third row seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belts - third row.

7.Fit rear side seat belt.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belt - rear - side.

8.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

9.Fit rear seat.

+ SEATS, REPAIRS, Seat - rear.

10.Fit panel body side assembly.

+ PANEL REPAIRS, REPAIRS, Panel

body side assembly.

11.Connect leads/multiplug to alternator.

12.Connect battery leads, negative lead last.

M77 1698A

Page 1294 of 1672

PANEL REPAIRS

REPAIRS 77-2-45

'E' post assembly

In this procedure, the panel body side assembly and

tail door are replaced in conjunction with the 'E' post

assembly. If required the 'E' post closing assembly

can also be replaced.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove panel body side assembly.

+ PANEL REPAIRS, REPAIRS, Panel

body side assembly.

4.Remove rear seats.

+ SEATS, REPAIRS, Seat - rear.

5.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

6.Remove third row seat belts.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belts - third row.

7.Remove relevant wiring.

8.Remove rear drip rail finisher.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.Refit

1.Fit rear drip rail finisher.

2.Fit and secure wiring.

3.Fit third row seat belts.

+ RESTRAINT SYSTEMS, REPAIRS,

Seat belts - third row.

4.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

5.Fit rear seats.

+ SEATS, REPAIRS, Seat - rear.

6.Fit panel body side assembly.

+ PANEL REPAIRS, REPAIRS, Panel

body side assembly.

7.Connect leads/multiplug to alternator.

8.Connect battery leads, negative lead last.

M77 1701A

Page 1450 of 1672

CHARGING AND STARTING

REPAIRS 86-1-1

CHARGING AND STARTING REPAIRS

Alternator - diesel

$% 86.10.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Release cover and remove nut securing lead

to alternator.

3.Disconnect alternator multiplug.

4.Remove bolt (LH thread) and remove auxiliary

drive belt tensioner. 5.Remove bolt securing support stay to

alternator.

6.Release clip and disconnect oil drain hose from

vacuum pump.

7.Disconnect vacuum pump oil supply pipe from

cylinder head and discard 'O' ring.

8.Remove bolt securing alternator and release

from mounting bracket.

9.Disconnect vacuum hose from vacuum pump.

10.Remove alternator. Take care not to damage

radiator cooling fins.

11.Remove 4 bolts, and remove vacuum pump

from alternator.

CAUTION: Always fit plugs to open

connections to prevent contamination.