brake light LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1031 of 1672

REAR SUSPENSION

64-26 REPAIRS

10.Position the wheel hub and drive shaft on a

press, place supports beneath the wheel studs

and press the drive shaft from the wheel hub.Refit

1.Clean drive shaft splines, wheel hub and axle

mating faces, ABS sensor and sensor recess.

2.Fit drive shaft to axle casing.

3.Lubricate new bearing hub 'O' ring with clean

differential oil.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

4.Fit 'O' ring to wheel hub.

5.Apply a 3 mm (0.125 in) wide bead of Loctite

640 around drive shaft circumference as

illustrated.

6.Fit wheel hub to drive shaft and align to axle.

The Loctite will smear along the length of the

splines as the wheel hub is fitted to the drive

shaft.

7.Fit bolts securing wheel hub to axle and tighten

to 100 Nm (74 lbf.ft).

8.Fit new drive shaft nut and lightly tighten.

9.Fit rear brake disc.

+ BRAKES, REPAIRS, Brake disc -

rear.

10.With an assistant depressing the brake pedal,

tighten drive shaft nut to 490 Nm (360 lbf.ft).

Stake drive shaft nut. The drive shaft nut

must be tightened before the Loctite has

cured.

11.Connect ABS sensor multiplug and secure

harness to harness bracket and brake hose.

12.Fit road wheel and tighten nuts to 140 Nm (103

lbf.ft).

13.Remove stand(s) and lower vehicle.

M51 0057

M51 0058

Page 1065 of 1672

BRAKES

70-20 DESCRIPTION AND OPERATION

Operation

Refer to illustration.

+ BRAKES, DESCRIPTION AND OPERATION, Brake system control diagram.

When the ignition is switched on, the SLABS ECU performs a check of the brake related warning lamps as part of the

power up procedure. The warning lamps are illuminated for approximately 3 seconds and then extinguished. If a fault

warning lamp remains illuminated after the lamp check, a fault has been detected and repair action is required.

ABS

The ABS function prevents the road wheels locking during brake application, thus maintaining vehicle stability even

under emergency conditions.

WARNING: ABS is an aid to retaining steering control and stability while braking:

lABS cannot defy the natural laws of physics acting on the vehicle.

lABS will not prevent accidents resulting from excessive cornering speeds, following another vehicle too

closely, aquaplaning, etc.

lThe additional control provided by ABS must never be exploited in a dangerous or reckless manner

which could jeopardise the safety of driver or other road users.

lThe fitting of ABS does not imply that the vehicle will always stop in a shorter distance.

NOTE: During normal braking the feel of the brake pedal on vehicles equipped with ABS will be the same as that on

non ABS vehicles. During anti-lock braking operation the driver will experience feedback in the form of a pulsating

brake pedal and solenoid/pump motor noise from the ABS modulator.

The anti-lock braking function is automatically enabled whenever the ABS modulator is in the normal braking mode.

While the anti-lock braking function is enabled, if the SLABS ECU detects a wheel decelerating faster than the

average and at the calibrated wheel slip limit for ABS operation, it operates the ABS modulator in the ABS braking

mode for the affected wheel.

EBD

The EBD function optimises the distribution of hydraulic pressure between the front and rear axles, under all vehicle

load configurations and road conditions, to maintain vehicle stability during braking. EBD operates in forward and

reverse and is automatically enabled whenever the ABS modulator is in the normal braking mode at vehicle

deceleration rates of 0.3 g and above (i.e. medium to high brake pedal loads). EBD operation is similar to that of ABS,

but is calibrated to intervene at lower wheel slip limits and operates the brakes in axle pairs instead of individually.

During braking, if the SLABS ECU detects the wheels of one axle going slower than those of the other axle, i.e. a

potential wheel slip situation, it signals the ABS modulator to close the inlet solenoid valve for the brakes of the slower

wheels. This prevents any further increase in hydraulic pressure to those brakes, while allowing the hydraulic pressure

to the brakes on the other axle to increase and so maximise the overall braking effort. If the wheel speeds of the axle

being subjected to EBD control return within the calibrated wheel slip limits, the SLABS ECU signals a stepped

opening of the inlet solenoid valves, which allows a progressive increase of hydraulic pressure to the related brakes.

Operation of EBD is detectable from a stiffening of brake pedal movement as the inlet solenoid valves close and a

slight pulsing of the brake pedal as the inlet solenoid valves open. EBD operation ceases immediately the brake pedal

is released.

The wheel slip limit for EBD operation varies with vehicle speed. During normal operation, the inlet solenoid valves

always operate in axle pairs, with only one axle pair closed at any one time. Since the most lightly loaded wheel during

a braking manoeuvre will usually be the first to reach the slip limit, under most vehicle load configurations and road

conditions EBD control occurs on the trailing axle. However, EBD control can occur on the leading axle or switch

between axles during the braking manoeuvre.

Page 1082 of 1672

BRAKES

REPAIRS 70-37

Switch - brake light

$% 70.35.42

The brake switch is set automatically during fitment.

If the setting is disturbed, the switch can be reset by

depressing the brake pedal and pulling the plunger

out of the switch body, until it contacts the pedal.

Remove

1.Remove 3 fasteners and move drivers side

lower closing panel aside.

2.Disconnect multiplug from brake light switch.

3.Remove brake light switch from pedal bracket.

Refit

1.Engage switch fully into pedal bracket location

and connect multiplug.

2.Position lower closing panel and secure with

fasteners.

Brake pads - front

$% 70.40.02

WARNING: Brake pads must be renewed in axle

sets only, otherwise braking efficiency may be

impaired.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove lower guide pin bolt from caliper and

pivot caliper housing upwards.

4.Remove 2 brake pads from caliper carrier.

Shims are part of the brake pads.

Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc.

2.Scrape rust from pad locating surfaces on

caliper.

3.Clean dust from calipers using brake cleaning

fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

Page 1159 of 1672

INTERIOR TRIM COMPONENTS

76-3-6 REPAIRS

9.Release handbrake gaiter from console.

10.Remove clip and clevis pin securing cable to

handbrake lever.

11.Move handbrake to fully upward position.

12.Release electric seat switches from console.

13.Disconnect multiplugs from switches and

remove.

14.Remove 2 bolts securing rear of console to

transmission tunnel.

15.Release centre console from fascia.

16.Disconnect multiplug and bulb from cigar

lighter. 17.Remove console.

NOTE: Do not carry out further dismantling if

component is removed for access only.

18.Remove 4 screws securing storage bin lid to

console and remove lid.

19.Release cigar lighter body from console and

remove.

Refit

1.Fit and secure cigar lighter body to console.

2.Fit lid to console and secure with screws.

3.Fit console.

4.Connect multiplug and bulb to cigar lighter.

5.Fit centre console to fascia.

6.Fit 2 bolts securing rear of console to

transmission tunnel.

7.Connect multiplugs to seat switches.

8.Fit switches to console.

9.Move handbrake to lowered position.

10.Fit cable to handbrake and secure with clevis

pin and clip.

11.Fit handbrake gaiter to console.

12.Fit bolts securing forward edge of console to

transmission tunnel.

13. Models with veneer trim: Position veneered

console cover and connect multiplugs to switch

pack. Fit cigar lighter element and secure

veneered console cover to console.

14. Models with base trim: Connect multiplugs to

switch pack, fit switch pack to console and

secure with screws.

15. Models with base trim: Fit cover plate to

switch pack, and rubber mat to console.

16.Fit transfer box gaiter and knob to lever.

17.Secure transfer box gaiter to console.

18.Connect multiplug to selector panel, fit and

secure panel to centre console.

19.Fit spacer and knob to gear selector lever.

20. Models from 03MY:Fit both centre console

cup holders.

Page 1161 of 1672

INTERIOR TRIM COMPONENTS

76-3-8 REPAIRS

6. Models with veneer trim: Release veneered

console cover from console and remove cigar

lighter element. Disconnect multiplugs from

switch pack and remove veneered console

cover.

7.Remove 2 bolts securing forward edge of

console to transmission tunnel. 8.Release handbrake gaiter from console.

9.Remove clip and clevis pin securing cable to

handbrake.

10.Move handbrake to fully upward position.

11.Release electric seat switches from console.

12.Disconnect multiplugs from switches and

remove.

13.Remove 2 bolts securing rear of console to

transmission tunnel.

14.Release centre console from fascia.

15.Disconnect multiplug and bulb from cigar

lighter.

Page 1162 of 1672

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-9

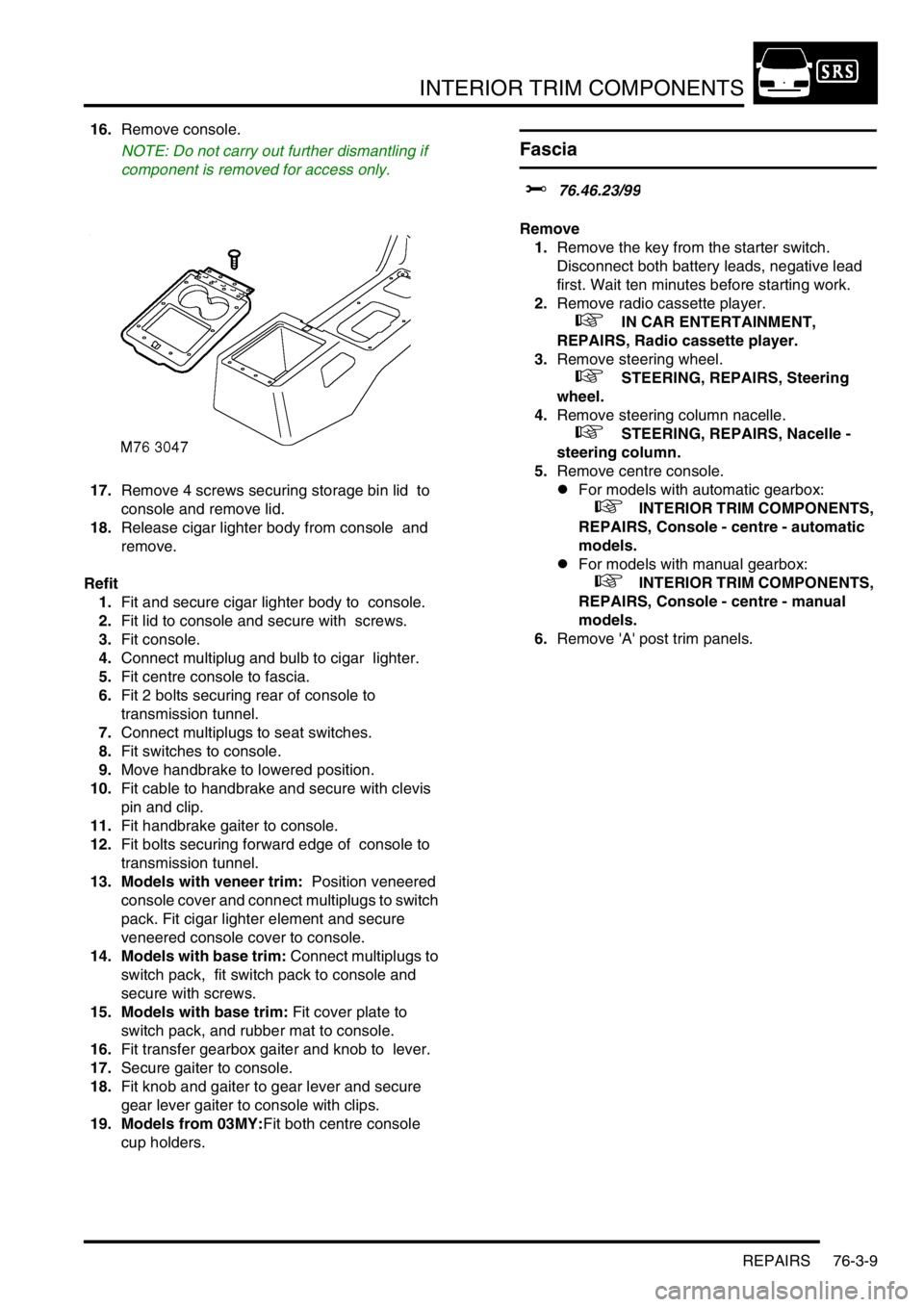

16.Remove console.

NOTE: Do not carry out further dismantling if

component is removed for access only.

17.Remove 4 screws securing storage bin lid to

console and remove lid.

18.Release cigar lighter body from console and

remove.

Refit

1.Fit and secure cigar lighter body to console.

2.Fit lid to console and secure with screws.

3.Fit console.

4.Connect multiplug and bulb to cigar lighter.

5.Fit centre console to fascia.

6.Fit 2 bolts securing rear of console to

transmission tunnel.

7.Connect multiplugs to seat switches.

8.Fit switches to console.

9.Move handbrake to lowered position.

10.Fit cable to handbrake and secure with clevis

pin and clip.

11.Fit handbrake gaiter to console.

12.Fit bolts securing forward edge of console to

transmission tunnel.

13. Models with veneer trim: Position veneered

console cover and connect multiplugs to switch

pack. Fit cigar lighter element and secure

veneered console cover to console.

14. Models with base trim: Connect multiplugs to

switch pack, fit switch pack to console and

secure with screws.

15. Models with base trim: Fit cover plate to

switch pack, and rubber mat to console.

16.Fit transfer gearbox gaiter and knob to lever.

17.Secure gaiter to console.

18.Fit knob and gaiter to gear lever and secure

gear lever gaiter to console with clips.

19. Models from 03MY:Fit both centre console

cup holders.

Fascia

$% 76.46.23/99

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove radio cassette player.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio cassette player.

3.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

4.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

5.Remove centre console.

lFor models with automatic gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

lFor models with manual gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

6.Remove 'A' post trim panels.

Page 1276 of 1672

PANEL REPAIRS

REPAIRS 77-2-27

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Valance upper assembly - LH

In this procedure, the front wing, the valance outer

reinforcement and the bonnet alarm switch mounting

bracket are replaced in conjunction with the LH

valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Remove brake pipes from valance.

8.Release harness from valance and position

aside.

9. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1485 of 1672

BODY CONTROL UNIT

86-3-16 DESCRIPTION AND OPERATION

Headlamps

The BCU contains a feature which allow the vehicle headlamps to be turned on when the remote transmitter is

pressed (courtesy headlamps).

For markets with daylight running lamps, the BCU controls the logical operation of the daylight running lamps. Options

are daylight running lamps are on if the main beam headlamps are off, or the daylight running lamps are on with main

and dipped beam off and the gearbox not in Park.

Front fog lamps

For markets with front fog lamps fitted, the BCU controls the operation of the front fog lamps. Options can be selected

so that the fog lamps will operate with or without the headlamps on main beam.

Instrument pack

The BCU communicates with the instrument pack via a serial data bus.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

lThe instrument pack provides the BCU and IDM with details of vehicle speed.

lSignals are provided from the IDM to the instrument pack and BCU when the direction indicator lamps are active.

lFor certain markets, the BCU provides a signal to the instrument pack for indicating when the transfer box is in

neutral.

lThe IDM can signal the instrument pack to illuminate a trailer warning lamp. This operates when the IDM senses

that the current drawn by the indicator circuit exceeds a preset threshold.

lThe odometer reading displayed on the instrument pack LCD screen is also stored in non volatile memory in the

BCU. Whenever the ignition is turned from position I to position II, the instrument pack and the BCU compare

their stored values.

lThe gear selector position is displayed on the instrument pack LCD screen under the direction of the BCU.

Starting

The starting system comprises a starter motor and solenoid located at the rear right hand side of the engine. A starter

relay controlled by the BCU is used to supply battery power for starter solenoid operation. The starter motor receives

its feed directly from the battery.

Cruise control

The BCU processes several signals used for cruise control:

lWhen the brake pedal is pressed, a low voltage brake lamp signal is sent via the BCU to the cruise control ECU.

lThe gear position switch sends an input via the BCU to the cruise control ECU if the selector lever is in Park,

Neutral or Reverse.

lA voltage supply is fed from the BCU to the cruise control SET+ switch.

lA voltage supply is fed from the BCU to the cruise control RES switch.

On vehicles with automatic transmission, if the BCU receives an input from the gear position switch or the brake pedal

switch, the BCU sends a signal to the cruise control ECU to cancel or inhibit cruise control operation.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - cruise control.

Shift interlock (where fitted)

On automatic gearbox models, the BCU and IDM combine with an interlock relay located in the passenger

compartment fuse box to operate a shift interlock solenoid, so that the gear selector lever cannot be moved out of

Park until certain logical conditions have been satisfied. Operation of the interlock may be affected, if the battery

becomes discharged.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

Page 1487 of 1672

BODY CONTROL UNIT

86-3-18 DESCRIPTION AND OPERATION

Self levelling suspension and ABS

The BCU communicates with the SLABS ECU for several functions:

lAn output is provided from the SLABS ECU to the BCU to provide the logic conditions for issuing the SLS audible

warning.

lThe BCU receives an input from the SLABS ECU relating to the raise/ lower command from the remote handset.

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description - SLS.

Hill descent control

The BCU provides an output signal to the SLABS ECU for automatic transmission in neutral for HDC control. The

BCU checks the status of the ignition and 'gearbox state' inputs and provides a 'Neutral selected' output. If the ignition

is on and 'gearbox state' is Neutral, the 'Neutral selected' output is on, otherwise 'Neutral selected' is off.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

Heated screens

The Heated Front Screen (HFS) is fitted for some market destinations and is operated from a non-latching switch

located on the instrument pack cowl. The BCU will only allow the heated front screen to operate when the engine is

running and controls the time-out period for switching the circuit off.

The heated front screen operation can also be controlled from the Automatic Temperature Control (ATC) ECU on

vehicles fitted with air conditioning.

The heated rear window will only function when the engine is running, and is operated by a non-latching switch on the

instrument pack cowl. The heated rear window can also be operated by the ATC ECU on vehicles fitted with air

conditioning.

Interior courtesy lamps

The BCU controls the operation of the interior courtesy lamps. The courtesy lamps are situated in the front, mid and

rear areas of the headlining.

Fuel flap actuator

The BCU provides an earth path to the fuel flap release solenoid to allow the fuel filler flap to be opened. This is only

allowed if the alarm system is not set and all other conditions have been satisfied. The fuel flap release switch is

located in the fascia switch pack and it receives a voltage supply from the passenger compartment fuse box.

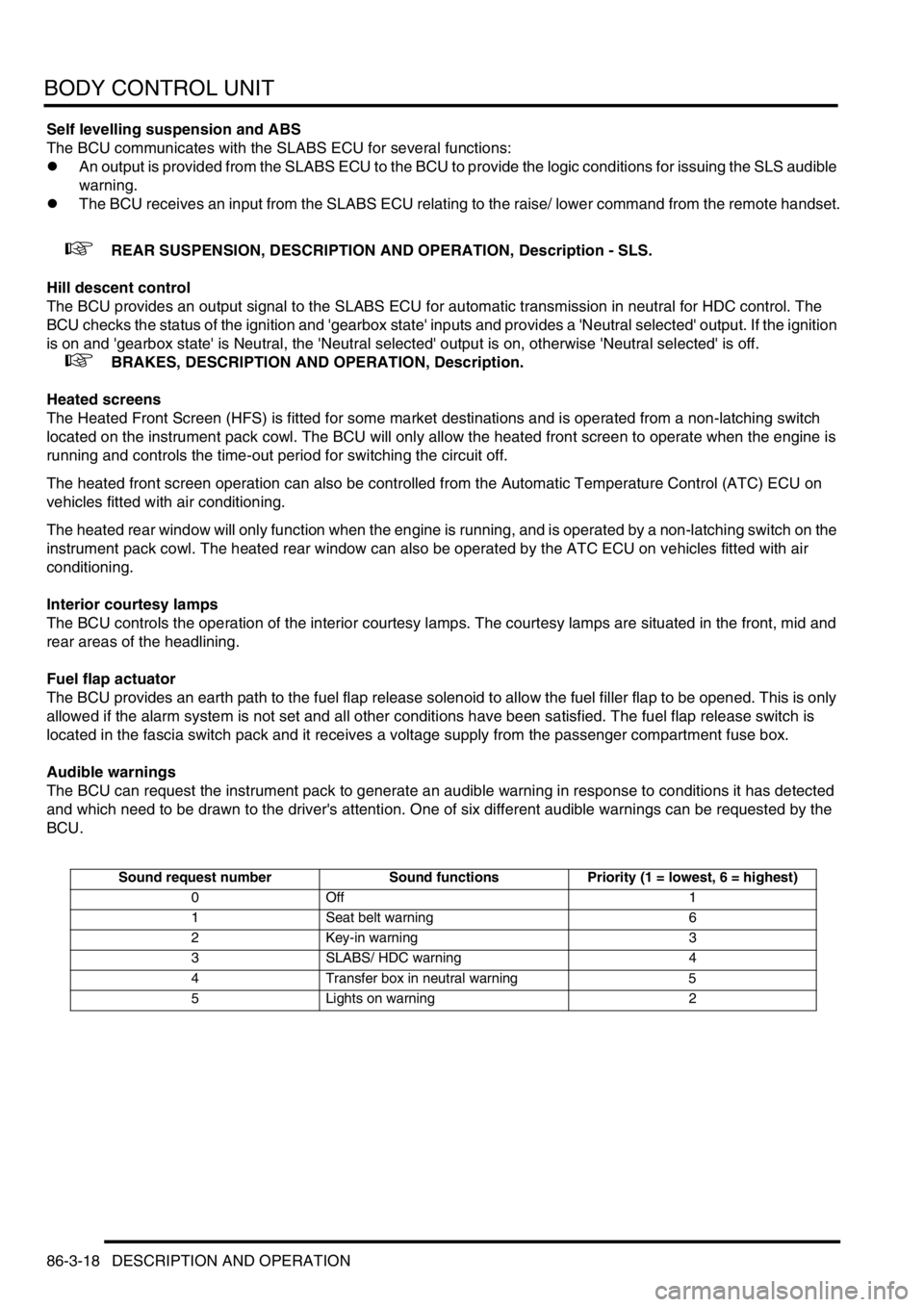

Audible warnings

The BCU can request the instrument pack to generate an audible warning in response to conditions it has detected

and which need to be drawn to the driver's attention. One of six different audible warnings can be requested by the

BCU.

Sound request number Sound functions Priority (1 = lowest, 6 = highest)

0Off 1

1 Seat belt warning 6

2 Key-in warning 3

3 SLABS/ HDC warning 4

4 Transfer box in neutral warning 5

5 Lights on warning 2

Page 1564 of 1672

IN CAR ENTERTAINMENT

DESCRIPTION AND OPERATION 86-6-11

If one headphone amplifier unit has control of the tape player, CD or radio, the other headphone amplifier will be able

to listen and be able to change tape tracks or radio bands. Other buttons allow a search seek function of radio band

or compact disk track, reversal of the tape, radio station and volume adjustment depending on the current operating

mode. If one radio headphone amplifier has control of the radio, tape or CD autochanger the other radio headphone

amplifier is able to change the track or radio band selected. A headphone socket with a glow ring is located on the

control panel. When a headphone is turned on , a 'headphone-module active' signal is sent to the radio cassette

player. The design incorporates panel illumination and a glow-ring to locate the socket in low light conditions. To

control the audio output from the radio headphone amplifiers, signals are sent to and received from the radio cassette

player.

Automatic volume control (High line system only)

An automatic base and treble volume control feature compensates for increases in interior road/transmission noise.

A road speed signal is monitored by the power amplifier, the signal is supplied by the SLABS ECU.

+ BRAKES, DESCRIPTION AND OPERATION, Description.The power amplifier boosts the levels of base

and treble as road speed increases. This system ensures that the apparent volume of sound remains constant and is

not affected by increases in the background noise in the vehicle.

Speakers

Some vehicles will not have all the speakers, the type and location of speakers fitted depends on the trim level and

ICE options specified for the vehicle.

A-post speakers LH/RH (if fitted)

The A-post speakers are located in the A-post trim on each side of the windscreen, and are each protected by a metal

grille. The speakers are held from the rear by a bayonet clip that clamps the speaker on to the A-post trim. The A-post

speakers are a high range type and have a power rating of:

lMid line system A-post speakers have a power rating of 15 watts and an impedance of 4

Ω.

lHigh line system A-post speakers have a power rating of 30 watts and an impedance of 4

Ω.

Upper front and rear door speakers LH/RH (high line system only)

The upper door speakers are located in the upper door trim, the speaker is protected by an integral metal grille. The

speaker is held in by a threaded ring that clamps the speaker from the rear onto the door trim. The upper door speaker

is a mid-range type and has a power rating of 30 watts and an impedance of 4

Ω.

Lower front door speakers LH/RH

The lower front door speaker is located in the front end of the lower (pocket) trim and is secured by three self tapping

screws. The speaker is protected by a clip on circular metal grille. The type of lower front door speakers fitted depends

on trim level and market:

lThe base and mid line systems are fitted with full-range door speakers with a power rating of 15 watts and an

impedance of 4

Ω

lThe high line system is fitted with a low-range door speaker with a power rating of 30 watts and an impedance

of 4

Ω.

Lower rear door speaker LH/RH

The lower rear door speaker is located in the lower door trim and is secured by three self tapping screws. The speaker

is protected by a clip on metal grille. The type of lower rear door speaker fitted depends on trim level and market:

lThe base and mid line systems are fitted with full-range door speakers with a power rating of 15 watts and an

impedance of 4

Ω

lThe high line system is fitted with a low-range door speaker with a power rating of 30 watts and an impedance

of 4

Ω.

Low range tail door speakers (high line system only)

The low range tail door speaker are located in a plastic casing in the lower door trim. Each of the two speakers is

secured to the casing with four self tapping screws. The casing is secured to the lower door structure with eight bolts.

The tail door trim surrounds the casing, the front of the casing is covered by a metal grill that is secured with six

screws. The low range tail door speakers have a power rating of 30 watts and has an impedance of 4

Ω.