brakes LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 117 of 1672

MAINTENANCE

10-8 PROCEDURES

Brake fluid

Replace

1.Replace brake fluid.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Fuel filter - diesel engine

Replace

1.Replace filter element.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Element - fuel filter.

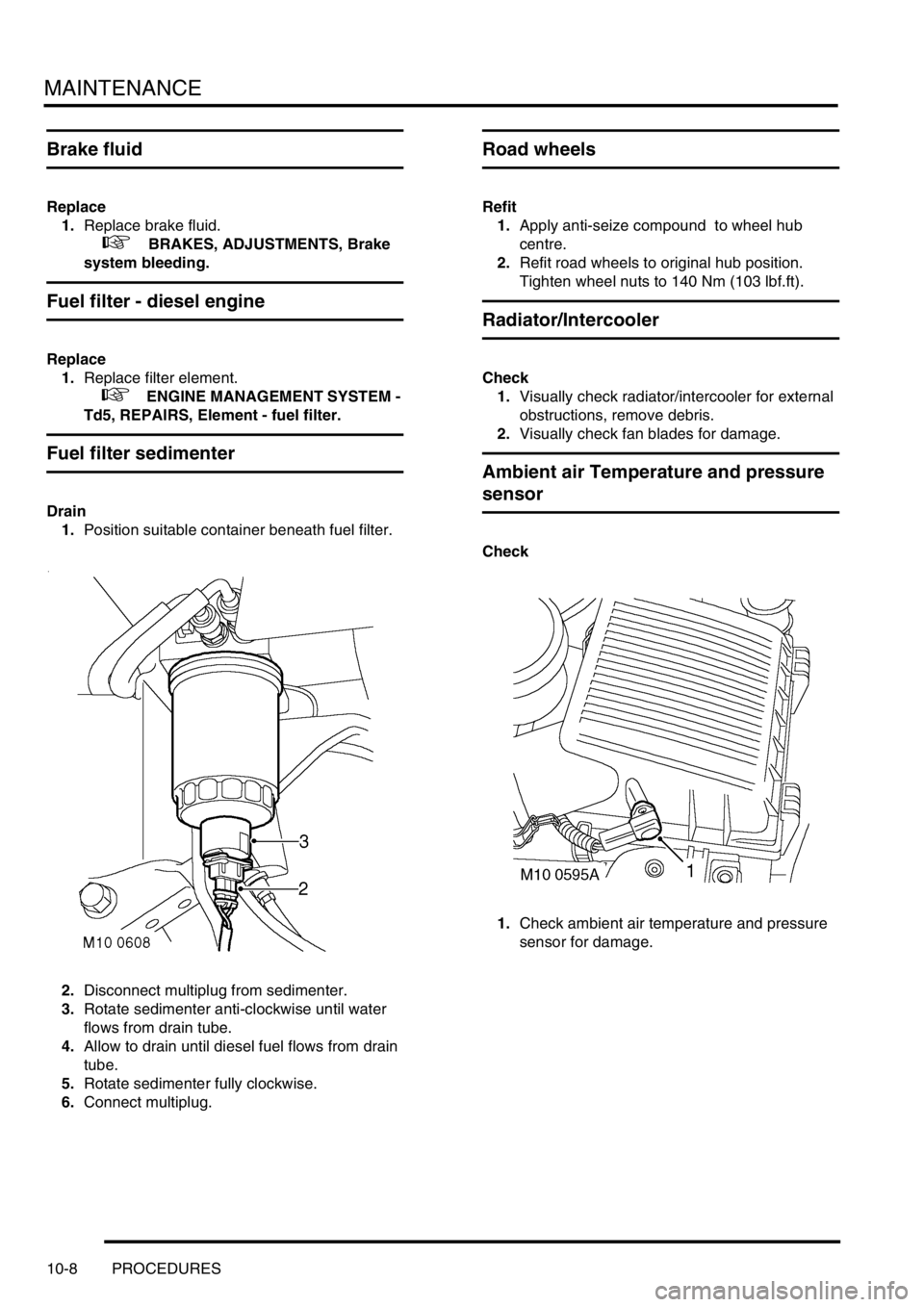

Fuel filter sedimenter

Drain

1.Position suitable container beneath fuel filter.

2.Disconnect multiplug from sedimenter.

3.Rotate sedimenter anti-clockwise until water

flows from drain tube.

4.Allow to drain until diesel fuel flows from drain

tube.

5.Rotate sedimenter fully clockwise.

6.Connect multiplug.

Road wheels

Refit

1.Apply anti-seize compound to wheel hub

centre.

2.Refit road wheels to original hub position.

Tighten wheel nuts to 140 Nm (103 lbf.ft).

Radiator/Intercooler

Check

1.Visually check radiator/intercooler for external

obstructions, remove debris.

2.Visually check fan blades for damage.

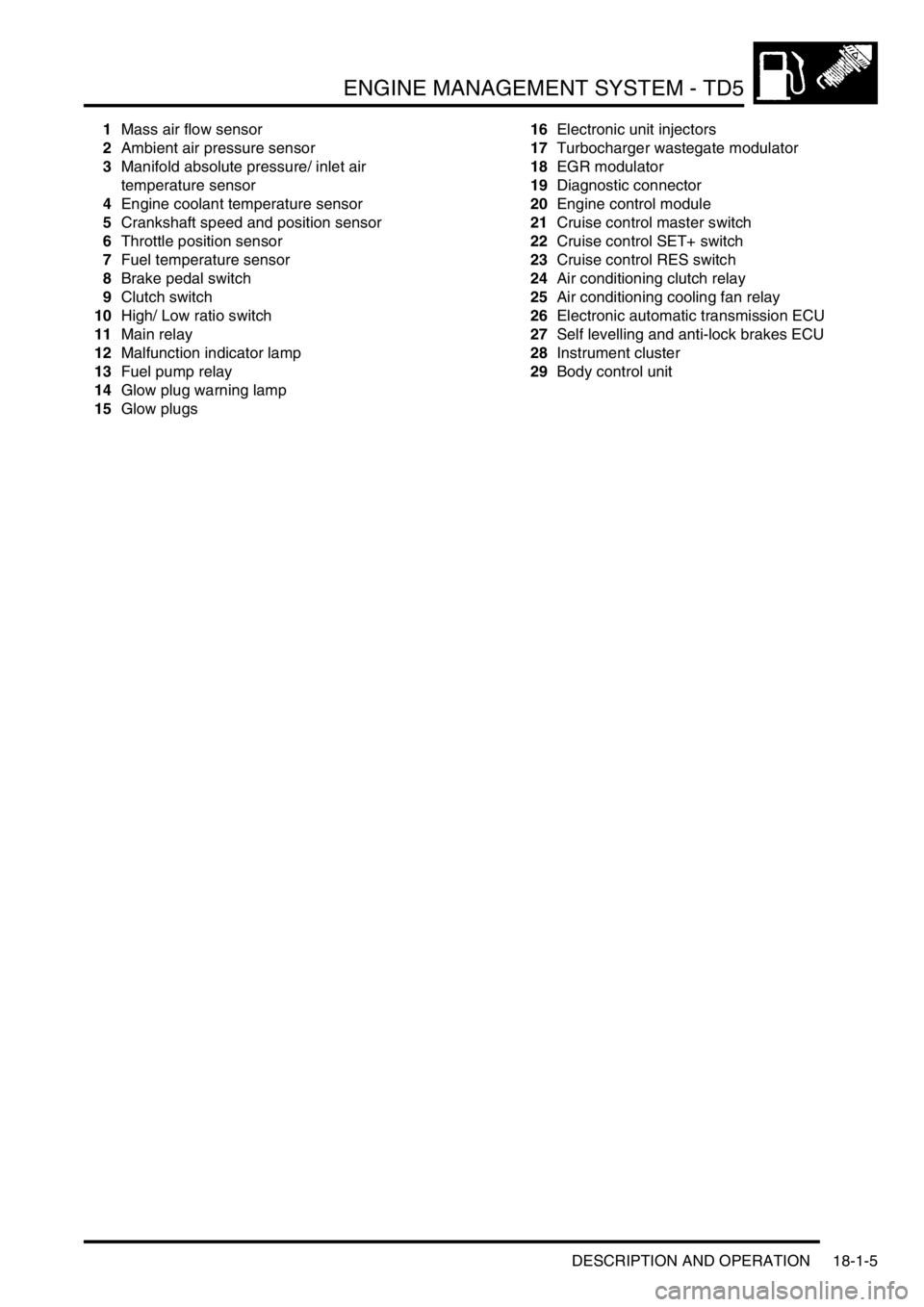

Ambient air Temperature and pressure

sensor

Check

1.Check ambient air temperature and pressure

sensor for damage.

Page 398 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-5

1Mass air flow sensor

2Ambient air pressure sensor

3Manifold absolute pressure/ inlet air

temperature sensor

4Engine coolant temperature sensor

5Crankshaft speed and position sensor

6Throttle position sensor

7Fuel temperature sensor

8Brake pedal switch

9Clutch switch

10High/ Low ratio switch

11Main relay

12Malfunction indicator lamp

13Fuel pump relay

14Glow plug warning lamp

15Glow plugs16Electronic unit injectors

17Turbocharger wastegate modulator

18EGR modulator

19Diagnostic connector

20Engine control module

21Cruise control master switch

22Cruise control SET+ switch

23Cruise control RES switch

24Air conditioning clutch relay

25Air conditioning cooling fan relay

26Electronic automatic transmission ECU

27Self levelling and anti-lock brakes ECU

28Instrument cluster

29Body control unit

Page 399 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-6 DESCRIPTION AND OPERATION

Description

General

An engine control module (ECM) controls the five-cylinder direct injection diesel engine, and works on the drive by

wire principle. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the Throttle

Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for cruise control and air

conditioning control. In addition, the ECM supplies output control for the exhaust gas recirculation and turbocharger

boost pressure. The ECM has a self-diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

lMass air flow sensor.

lAmbient air pressure sensor.

lManifold absolute pressure/inlet air temperature sensor.

lEngine coolant temperature sensor.

lCrankshaft speed and position sensor.

lThrottle position sensor.

lFuel temperature sensor.

lAir conditioning request.

lAir conditioning fan request.

lBrake pedal switch.

lClutch switch.

lCruise control master switch.

lCruise control SET+ switch.

lCruise control RES switch.

lHigh/low ratio switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once the

ECM has compared current information with stored information within its memory, it can make any adjustment it

requires to the operation of the engine via the following:

lAir conditioning clutch relay.

lAir conditioning cooling fan relay.

lElectronic vacuum regulator solenoid.

lMalfunction indicator lamp.

lFuel pump relay.

lGlow plug warning lamp.

lGlow plugs.

lFuel injectors.

lMain relay.

lTurbocharger wastegate modulator.

lTemperature gauge.

The ECM interfaces with the following:

lElectronic Automatic Transmission (EAT).

lSelf Levelling and Anti-lock Brakes System (SLABS).

lSerial communication link.

lInstrument cluster.

lBody Control Unit (BCU).

Page 496 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-39

Hill Decent Control (HDC)

Refer to Brakes for description of the hill descent control.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

High/Low ratio switch

Refer to Transfer Box for description of the high/ low ratio switch transfer box components.

+ TRANSFER BOX - LT230SE, DESCRIPTION AND OPERATION, Description.

Malfunction Indicator Lamp (MIL)/ service engine soon warning lamp

The MIL/ service engine soon warning lamp is located in the instrument cluster. It illuminates to alert the driver to

system malfunctions. Service engine soon warning lamp is the name for this warning lamp in NAS only, it is called

MIL in all other markets.

During ignition a self-test function of the lamp is carried out. The lamp will illuminate for 3 seconds then it will

extinguish if no faults exist.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Input/Output

The MIL is supplied with battery voltage from the instrument cluster. When the ECM detects a fault, it provides an

earth path to illuminate the MIL. Output to the MIL is via pin 20 of connector C0637 of the ECM.

Page 521 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-64 DESCRIPTION AND OPERATION

Vacuum pump assembly

The vacuum pump assembly contains three components:

lThe vacuum pump.

lThe vacuum control valve.

lThe vacuum dump valve.

The vacuum pump provides the vacuum for the system while the two valves work in conjunction to allow the pump to

increase the vacuum to the pneumatic actuator (increase vehicle speed) or release vacuum from the pneumatic

actuator (decrease vehicle speed). On vehicles from 03 model year, the cruise control vacuum pump and pneumatic

actuator assembly is fitted with a heat shield to protect the components from heat from the exhaust manifold.

The vacuum control valve opens to allow the vacuum pump to increase the vacuum in the pneumatic actuator to

increase vehicle speed. When the vehicle reaches the set speed, the vacuum pump control valve closes to hold

vacuum in the pneumatic actuator and the vacuum pump is turned off by the cruise control ECU.

The vacuum dump valve is normally open. When cruise control is active, the cruise control ECU provides voltage to

close the vacuum dump valve. If power is lost, (e.g. when the brakes or clutch are applied or cruise control is turned

off at the cruise control master switch) the vacuum dump valve will immediately open and cruise control will be

deactivated.

The cruise control ECU provides power for all three components within the vacuum pump assembly. The cruise

control ECU provides earth control circuits for the vacuum pump and the vacuum control valve. The vacuum dump

valve is permanently grounded.

Input/Output

The cruise control ECU provides both power and earth to the components within the vacuum pump assembly. Current

draw at the vacuum pump assembly varies depending on components operating.

Vacuum pump current draw

Component State of components

Vacuum dump valve Off On On On

Vacuum control valve Off Off On On

Vacuum pump Off Off Off On

Current draw, amperes 0 0.23 0.37 2.14

Page 864 of 1672

REAR AXLE

REPAIRS 51-5

REPAIRS

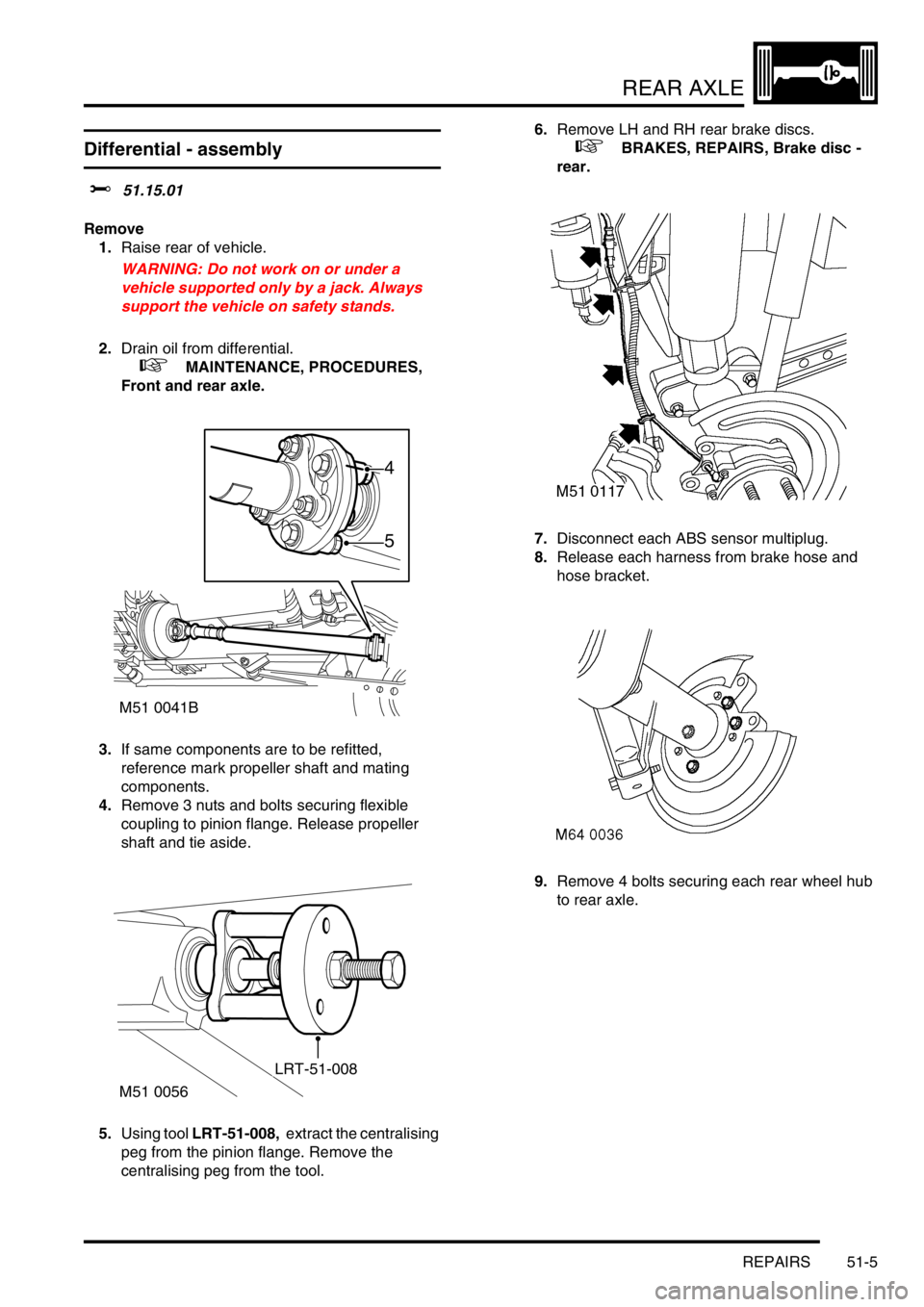

Differential - assembly

$% 51.15.01

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Drain oil from differential.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

3.If same components are to be refitted,

reference mark propeller shaft and mating

components.

4.Remove 3 nuts and bolts securing flexible

coupling to pinion flange. Release propeller

shaft and tie aside.

5.Using tool LRT-51-008, extract the centralising

peg from the pinion flange. Remove the

centralising peg from the tool.6.Remove LH and RH rear brake discs.

+ BRAKES, REPAIRS, Brake disc -

rear.

7.Disconnect each ABS sensor multiplug.

8.Release each harness from brake hose and

hose bracket.

9.Remove 4 bolts securing each rear wheel hub

to rear axle.

M51 0041B

5

4

M51 0056

LRT-51-008

Page 865 of 1672

REAR AXLE

51-6 REPAIRS

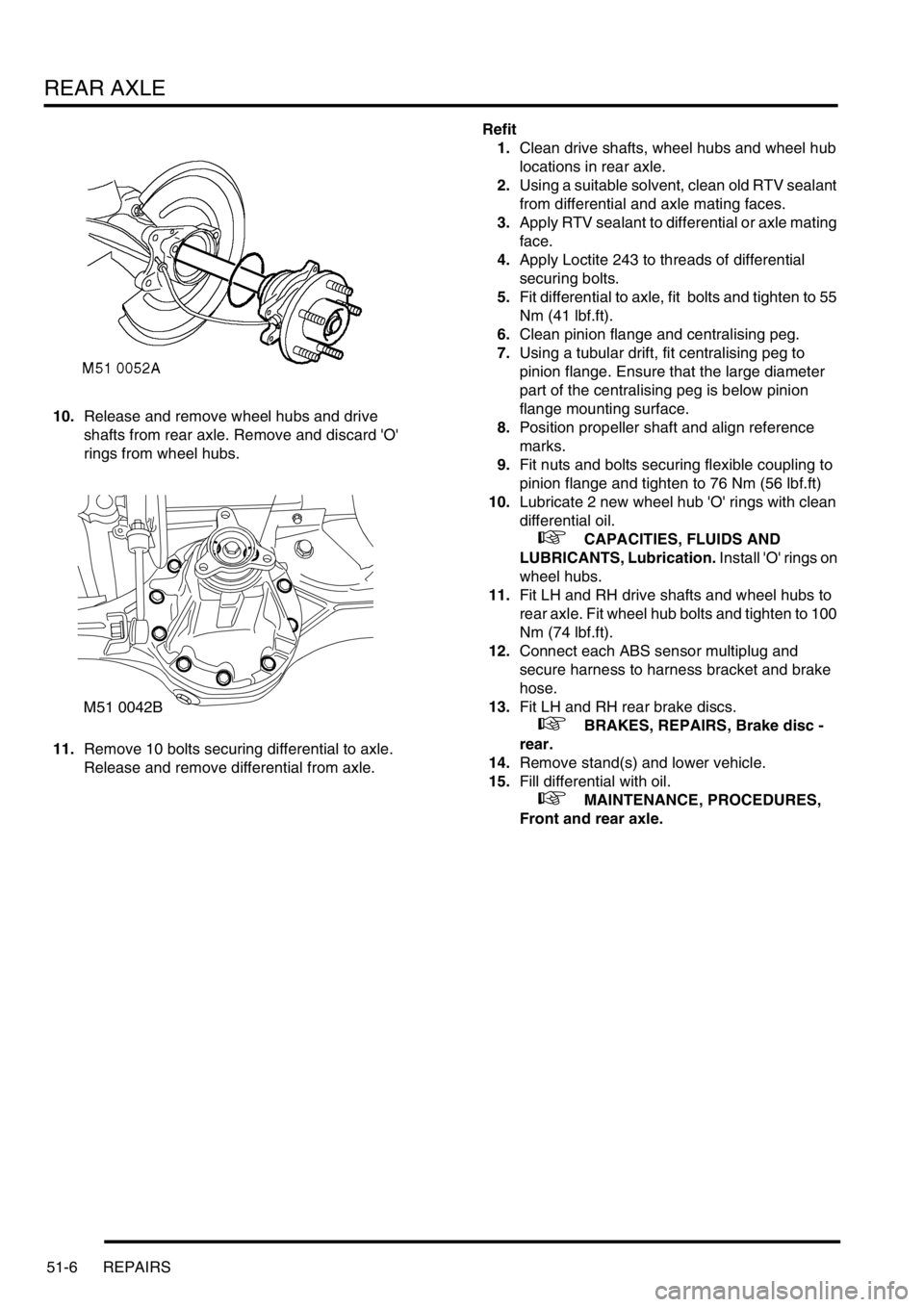

10.Release and remove wheel hubs and drive

shafts from rear axle. Remove and discard 'O'

rings from wheel hubs.

11.Remove 10 bolts securing differential to axle.

Release and remove differential from axle. Refit

1.Clean drive shafts, wheel hubs and wheel hub

locations in rear axle.

2.Using a suitable solvent, clean old RTV sealant

from differential and axle mating faces.

3.Apply RTV sealant to differential or axle mating

face.

4.Apply Loctite 243 to threads of differential

securing bolts.

5.Fit differential to axle, fit bolts and tighten to 55

Nm (41 lbf.ft).

6.Clean pinion flange and centralising peg.

7.Using a tubular drift, fit centralising peg to

pinion flange. Ensure that the large diameter

part of the centralising peg is below pinion

flange mounting surface.

8.Position propeller shaft and align reference

marks.

9.Fit nuts and bolts securing flexible coupling to

pinion flange and tighten to 76 Nm (56 lbf.ft)

10.Lubricate 2 new wheel hub 'O' rings with clean

differential oil.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication. Install 'O' rings on

wheel hubs.

11.Fit LH and RH drive shafts and wheel hubs to

rear axle. Fit wheel hub bolts and tighten to 100

Nm (74 lbf.ft).

12.Connect each ABS sensor multiplug and

secure harness to harness bracket and brake

hose.

13.Fit LH and RH rear brake discs.

+ BRAKES, REPAIRS, Brake disc -

rear.

14.Remove stand(s) and lower vehicle.

15.Fill differential with oil.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

M51 0042B

Page 878 of 1672

FRONT AXLE

REPAIRS 54-5

REPAIRS

Differential - assembly

$% 54.10.01

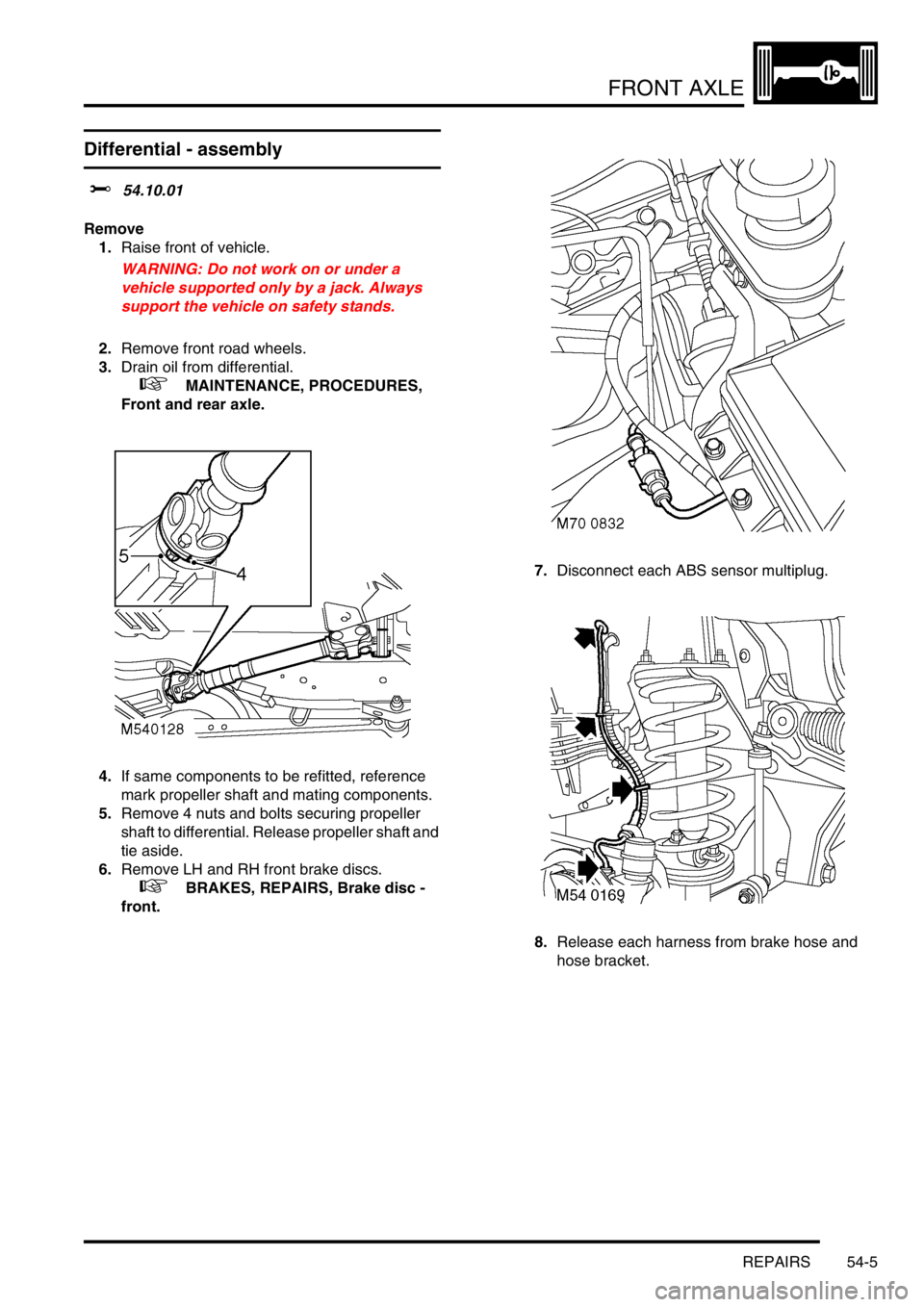

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheels.

3.Drain oil from differential.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

4.If same components to be refitted, reference

mark propeller shaft and mating components.

5.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

6.Remove LH and RH front brake discs.

+ BRAKES, REPAIRS, Brake disc -

front.7.Disconnect each ABS sensor multiplug.

8.Release each harness from brake hose and

hose bracket.

Page 880 of 1672

FRONT AXLE

REPAIRS 54-7

13.Fit front brake discs.

+ BRAKES, REPAIRS, Brake disc -

front.

14.Fit front road wheels and tighten nuts to 140

Nm (103 lbf.ft).

15.Remove stand(s) and lower vehicle.

16.Fill differential with oil.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

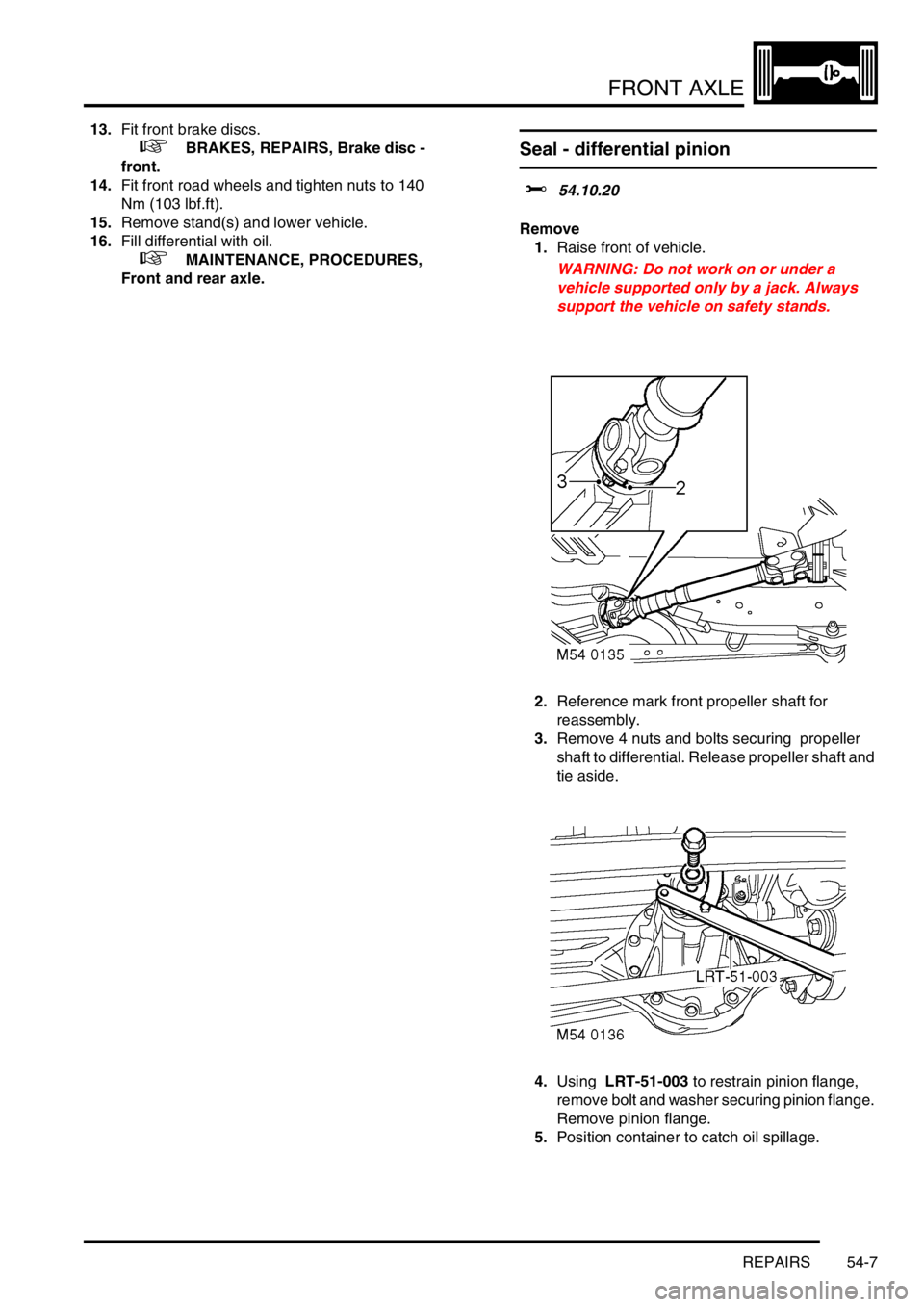

Seal - differential pinion

$% 54.10.20

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Reference mark front propeller shaft for

reassembly.

3.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

4.Using LRT-51-003 to restrain pinion flange,

remove bolt and washer securing pinion flange.

Remove pinion flange.

5.Position container to catch oil spillage.

Page 882 of 1672

FRONT AXLE

REPAIRS 54-9

Seal - oil - front axle casing

$% 54.15.04

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove front brake disc.

+ BRAKES, REPAIRS, Brake disc -

front.

4.Disconnect ABS sensor multiplug.5.Release harness from brake hose and hose

bracket.

6.Remove 4 bolts securing wheel hub to steering

knuckle.

7.Release wheel hub from steering knuckle.

8.Remove wheel hub and drive shaft from axle.