mirror LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1166 of 1672

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-13

Panel - auxiliary switch

$% 76.46.38

Remove

1.Carefully remove electric exterior mirror switch

from auxiliary switch panel and disconnect

multiplug.

2. Models with headlamp levelling: Release

knob and remove nut securing headlamp

levelling switch to auxiliary switch panel.

3.Release 2 fasteners and open fascia access

panel.

4. Models with headlamp levelling: Remove

headlamp levelling switch from auxiliary switch

panel and disconnect multiplug.

5. Models with A/C: Remove 2 screws securing

in-car temperature sensor to auxiliary switch

panel.

6. Models with A/C: Disconnect multiplug from

in-car temperature sensor and remove from

auxiliary switch panel.

7.Release 2 clips securing auxiliary switch panel

to fascia and remove panel.

Refit

1.Position auxiliary switch panel to fascia and clip

into position.

2. Models with A/C: Connect multiplug to in-car

temperature sensor.

3. Models with A/C: Position in-car temperature

sensor to auxiliary switch panel and secure with

screws.

4. Models with headlamp levelling: Position

headlamp levelling switch to auxiliary switch

panel and secure with nut.5. Models with headlamp levelling: Replace

cap and connect multiplug to headlamp

levelling switch.

6.Connect multiplug to exterior mirror switch and

fit switch to auxiliary switch panel.

Page 1179 of 1672

SCREENS

76-4-2 REPAIRS

Windscreen

$% 76.81.01

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

WARNING: If glass has splintered, protect eyes

and operate demister blower to remove glass

from heater ducts. Use a vacuum cleaner to

remove glass from fascia, carpet and seats.

Remove

1.Remove air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

2.If fitted, disconnect screen heater multiplugs.

3.Remove top corner trim finishers from body.

4.Remove windscreen top finisher and discard.

5.Release interior mirror from slug and tie aside.

6.Fit protection to exterior body work adjacent to

screen.

7.Cover body panels adjacent to glass.

8.Cover heater ducts with masking tape.

9.Cover interior of vehicle with protective sheet.

Page 1181 of 1672

SCREENS

76-4-4 REPAIRS

15.Apply a continuous bead of sealant to sealant

face on screen as shown.

16.With assistance, lift screen into place and align

to screen supports and tape. Ensure top

finisher is located into correct position. Lightly

press glass to fully seat sealer.

CAUTION: Do not apply heavy pressure to

the sides of the windscreen. Lightly press

windscreen from centre outwards until

edges are to required gap. Pushing sides

into position can bend windscreen and lead

to cracking in service.

17.Remove protective covers and tape.

18.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

19.Fit interior mirror to slug.

20.If applicable, connect screen heater multiplugs.

21.Fit air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

CAUTION: A curing time of 6 hours is

desirable. During this time leave a window

open to ventilate the vehicle interior. If the

vehicle must be used before the curing time

has elapsed, do not drive at speed or slam

the doors with the windows closed.

CAUTION: Vehicles fitted with a passenger

airbag should not be driven for 24 hours.

Glass - body side - rear

$% 76.81.18

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

Remove

1.If fitted, disconnect coaxial cable from terminal

on glass.

2.Fit protection to exterior body work adjacent to

glass.

3.Cover body panels adjacent to glass.

4.Fit protection to internal trim adjacent to glass.

5.Cover interior of vehicle with protective sheet.

Page 1226 of 1672

SUNROOF

DESCRIPTION AND OPERATION 76-6-11

Sunroof ECU

The sunroof ECU is located behind the head lining above the rear view mirror. Most functions of the sunroof ECU are

covered under other components.

Sunroof ECU connector pin details - C0784

Sunroof ECU connector pin details - C0785

Pin No. Description Input/Output

1 Rear sunroof microswitch Input

2 Front sunroof switch - open Input

3 Not used -

4 Sunroof microswitches - common Input

5 Not used -

6 Rear sunroof, rear switch - open Input

7 Rear sunroof, front switch - open Input

8 Front sunroof microswitch Input

Pin No. Description Input/Output

1 Front sunroof motor forward Output

2 ECU earth Input

3 Battery power supply Input

4 Rear sunroof motor backwards Output

5 Front sunroof motor backwards Output

6 Rear sunroof motor forwards Output

7 Front sunroof switch - close Input

8 Rear sunroof, front switch - close Input

9 Rear sunroof, rear switch - close Input

10 Sunroof enable Input

Page 1339 of 1672

CORROSION PREVENTION AND SEALING

77-4-24 SEALING

Water leaks

Where water leakage is involved, always adopt a logical approach to the problem using a combination of skill,

experience and intuition. Do not reach a conclusion based only on visual evidence, such as assuming that a wet

footwell is caused by a leak emanating from the windscreen. It will often be found that the source of the leak is

elsewhere. Use of the correct procedure will increase the chance of locating a leak, however obscure it may seem.

Tools and equipment

The following tools and equipment are recommended for the purpose of detection and rectification of water leaks:

1Garden sprayer (hand-operated)

2Wet/dry vacuum cleaner

3Dry, absorbent cloths

4Battery torch

5Small mirror

6Weatherstrip locating tool

7Trim panel remover

8Small wooden or plastic wedges

9Dry compressed air supply

10Hot air blower

11Sealer applicators

12Ultrasonic leak detector

During leak detection, the vehicle should be considered in three basic sections:

lThe front interior space;

lThe rear passenger space;

lThe loadspace or boot.

Testing

From the information supplied by the customer it should be possible for the bodyshop operator to locate the starting

point from which the leak may be detected. After the area of the leak has been identified, find the actual point of entry

into the vehicle.

A simple and effective means in the first instance is an ordinary garden spray with provision for pressure and jet

adjustment, which will allow water to be directed in a jet or turned into a fine spray. Use a mirror and a battery-powered

torch (NOT a mains voltage inspection lamp) to see into dark corners.

The sequence of testing is particularly important. Start at the lowest point and work slowly upwards, to avoid testing

in one area while masking the leak in another. For example, if testing started at the level of the windscreen, any water

cascading into the plenum chamber could leak through a bulkhead grommet and into the footwells. Even at this point

it could still be wrongly assumed that the windscreen seal was at fault.

Another important part of identifying a water leak is by visual examination of door aperture seals, grommets and

weatherstrips for damage, deterioration or misalignment, together with the fit of the door itself against the seals.

Sealing

When the point of the leak has been detected, it will then be necessary to rectify it using the following procedure:

1Renew all door aperture seals and weatherstrips which have suffered damage, misalignment or deterioration

2Check all body seals to ensure that they are correctly located on their mounting flanges/faces using a lipping

tool if necessary

3Dry out body seams to be treated using compressed air and/or a hot air blower as necessary

4Apply sealant on the outside of the joint wherever possible to ensure the exclusion of water

5When rectifying leaks between a screen glass and it's weatherstrip (or in the case of direct glazing, between the

glass and bodywork), avoid removing the glass if possible. Apply the approved material at the appropriate

location (i.e. glass to weatherstrip or glass to body)

Page 1573 of 1672

HARNESSES

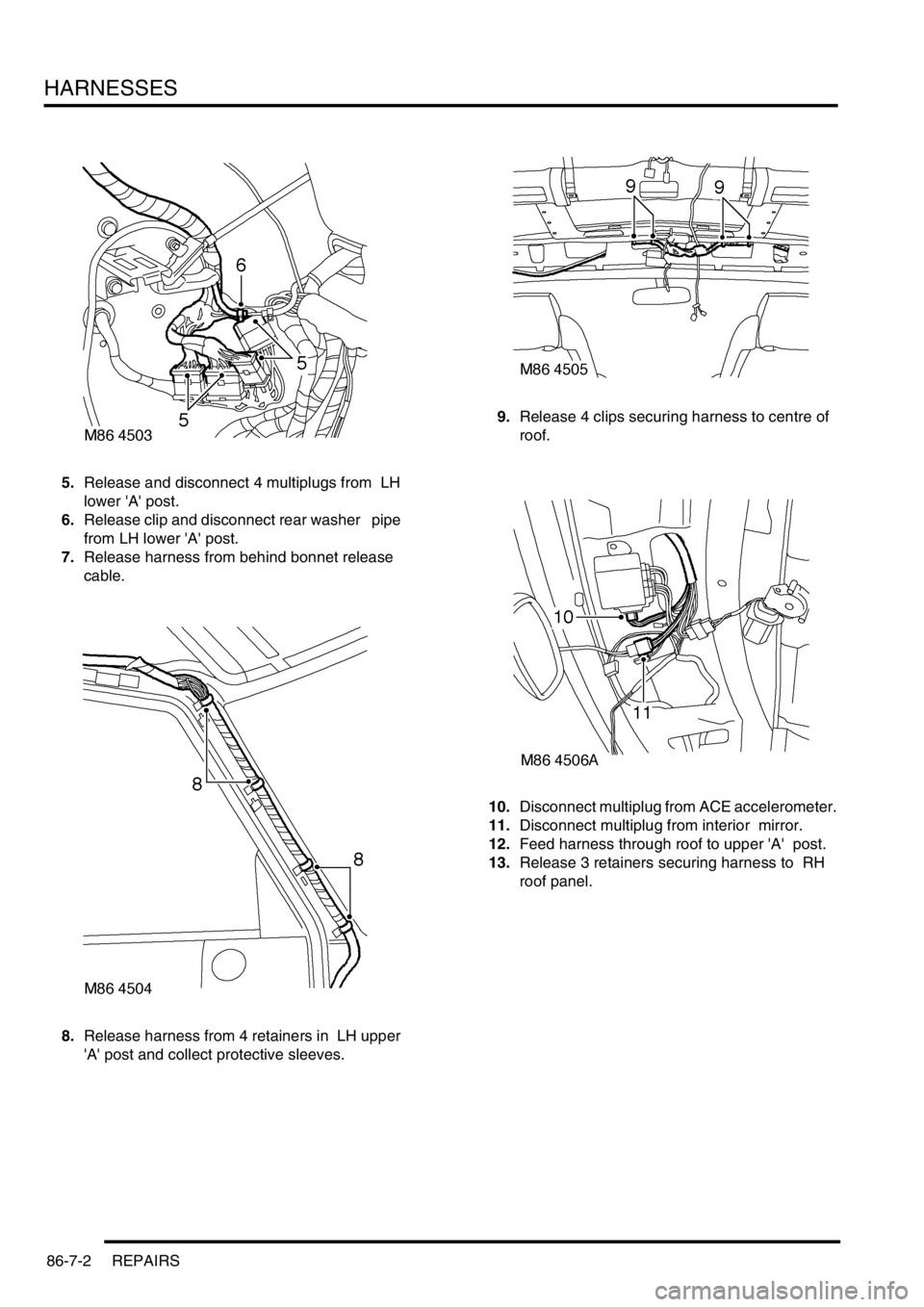

86-7-2 REPAIRS

5.Release and disconnect 4 multiplugs from LH

lower 'A' post.

6.Release clip and disconnect rear washer pipe

from LH lower 'A' post.

7.Release harness from behind bonnet release

cable.

8.Release harness from 4 retainers in LH upper

'A' post and collect protective sleeves. 9.Release 4 clips securing harness to centre of

roof.

10.Disconnect multiplug from ACE accelerometer.

11.Disconnect multiplug from interior mirror.

12.Feed harness through roof to upper 'A' post.

13.Release 3 retainers securing harness to RH

roof panel.

Page 1579 of 1672

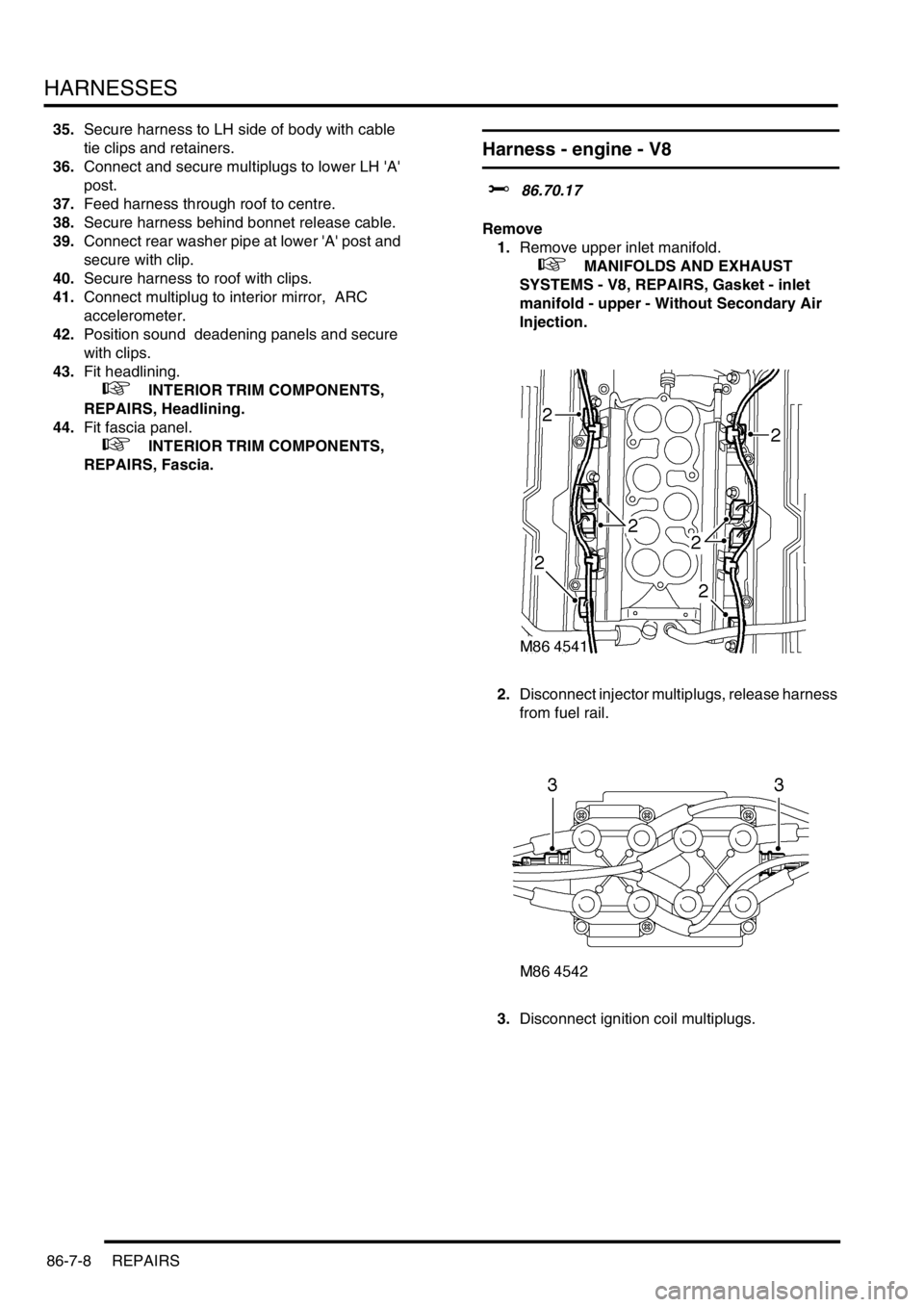

HARNESSES

86-7-8 REPAIRS

35.Secure harness to LH side of body with cable

tie clips and retainers.

36.Connect and secure multiplugs to lower LH 'A'

post.

37.Feed harness through roof to centre.

38.Secure harness behind bonnet release cable.

39.Connect rear washer pipe at lower 'A' post and

secure with clip.

40.Secure harness to roof with clips.

41.Connect multiplug to interior mirror, ARC

accelerometer.

42.Position sound deadening panels and secure

with clips.

43.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

44.Fit fascia panel.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.

Harness - engine - V8

$% 86.70.17

Remove

1.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

2.Disconnect injector multiplugs, release harness

from fuel rail.

3.Disconnect ignition coil multiplugs.

Page 1669 of 1672

INSTRUMENTS

88-42 DESCRIPTION AND OPERATION

Interior rear view mirror with compass

(where fitted)

1Cover

2Electrical connector

3Mounting bracket

4Light sensor

5Compass LED display

6Compass calibration switch

7Compass printed circuit board

Certain vehicles have an interior rear view mirror that features an automatic photochromatic dimming function and an

electronic compass with LED display.

The compass mirror is a self-contained unit and does not interface with any other vehicle system or electronic control

unit. The mirror is fixed to a metal bracket attached to the windscreen.

A three pin connector provides the electrical connection to the mirror's internal circuit board. Pin-1 of the connector

provides the 12V power supply to the board via the auxiliary relay located in the engine compartment fusebox. When

the ignition switch is turned to the 'II' position, a 12V supply is provided to energise the coil of the auxiliary relay via

fuse 26 in the passenger compartment fusebox. The auxiliary relay's contact supply voltage is provided from the

vehicle battery through fusible links 1 & 7. When the relay's contacts close, a 12V supply is fed to the compass mirror

circuit board via fuse 15 in the passenger compartment fusebox. This is the supply voltage feed for the mirror's internal

compass.

Pin-2 of the electrical connector provides the path to earth.

Pin-3 of the electrical connector is a 12V ignition switched supply voltage (position 'II' of the ignition switch). The

supply voltage is provided to the mirror's circuit board via fuse 25 in the passenger compartment fusebox, and the

reverse lamp switch (normally closed) for vehicles with manual transmission or the starter inhibitor / reverse light

switch (normally closed) for vehicles with automatic transmission. This is the supply voltage feed for the mirror's

photochromatic dimming function.

M88 0297

3

2

7

616

45

Page 1670 of 1672

INSTRUMENTS

DESCRIPTION AND OPERATION 88-43

Compass

The mirror's compass display is activated when the ignition switch is turned to position 'II'. If the compass has been

previously calibrated, the current direction of the vehicle will be shown in the LED display at the upper RH side of the

mirror's reflective surface. The display is able to indicate one of eight compass points (i.e. N, NE, E, SE, S, SW, W or

NW).

The compass mirror circuit board contains a microchip which is able to determine changes in vehicle direction due to

the changes in the earth's magnetic field. The circuit board is located in the stem of the mirror so that it follows the

changes in the vehicles direction and is not affected by adjustment of the mirror itself.

Because of changes in the lines of magnetic influence, the compass is set for operation in one of fifteen different zones

depending on the current location of the vehicle. If the vehicle is to be driven in a different zone, the compass will have

to be reset for operation in that zone. To determine the correct zone for a particular location on the planet, refer

to the maps provided in the Owner's Handbook. The mirror's default setting is zone 8 which is suitable for central

European countries (Germany, Austria, Italy etc.).

The compass should be set to the correct zone using the following procedure:

1Switch the ignition to position 'II'.

aIf the compass displays one of the eight compass point directions, proceed to step '3'.

bIf the compass displays 'C' then proceed to step '2'.

cIf the display does not show either of the above, then the calibration button on the underside of the mirror

should be pressed and held for approximately 6 seconds, using a small probe (e.g. paper clip or ballpoint

pen). The compass should now enter the set mode and 'C' should be shown in the display.

2To calibrate the compass, the vehicle must be driven slowly (5 mph (8 km/h) or less) in a circle until the display

shows a direction (usually 1 or 2 revolutions). The mirror can calibrate itself during normal driving, but this will

take considerably longer.

3Set the compass to the relevant zone of magnetic influence by pressing the calibration button on the underside

of the mirror for approximately 3 seconds, using a small probe, until a number is shown in the display. If the zone

is being entered for the first time, the default zone setting '8' should be displayed. If the zone is being reset from

a previous entry, the previous zone setting number will be displayed.

The calibration button should now be pressed and released with single presses, using a small probe, until the

desired zone number appears in the display.

After approximately 10 seconds, the compass display should return correctly set to the required zone.

Note the degree of magnetic variation from one zone to another is only very slight. Recalibration of the compass is

not normally necessary unless several zone changes are undertaken.

Automatic dimming

The mirror's automatic dimming function operates when the ignition switch is turned to the 'II' position.

A light sensor is contained at the upper centre of the mirror which detects the intensity of light from the headlights of

following vehicles in dark or low light conditions. When the light intensity is sufficiently high, the mirror automatically

adjusts the brightness of the reflected light by photochromatically changing the mirror's reflective properties and so

preventing glare affecting the driver.

When reverse gear is selected, the power supply for the mirror's photochromatic function is opened so that the mirror

defaults to its normal reflective properties while the reversing operation is in progress.

Another light sensor is located on the rear of the mirror so that the unit can detect the difference between strong

ambient light and that attributable to following vehicle headlights. To check operation of the light dimming function of

the mirror, use the following procedure:

1Turn ignition switch to position 'II', and ensure reverse gear is not selected.

2Cover the sensor on the back of the mirror.

3Shine a bright light on the front (reflective side) of the mirror; the mirror should darken.