reset LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1022 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-17

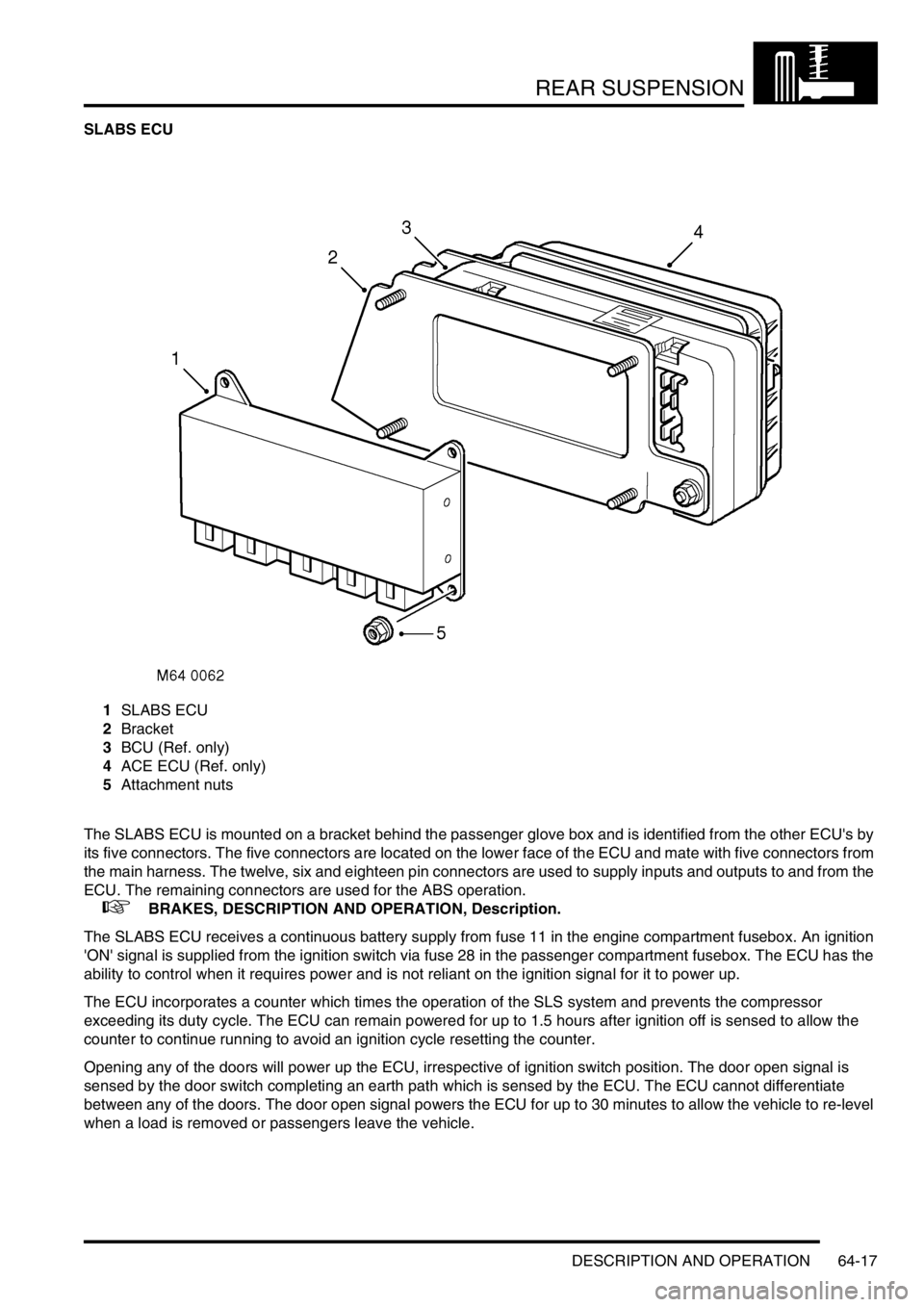

SLABS ECU

1SLABS ECU

2Bracket

3BCU (Ref. only)

4ACE ECU (Ref. only)

5Attachment nuts

The SLABS ECU is mounted on a bracket behind the passenger glove box and is identified from the other ECU's by

its five connectors. The five connectors are located on the lower face of the ECU and mate with five connectors from

the main harness. The twelve, six and eighteen pin connectors are used to supply inputs and outputs to and from the

ECU. The remaining connectors are used for the ABS operation.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

The SLABS ECU receives a continuous battery supply from fuse 11 in the engine compartment fusebox. An ignition

'ON' signal is supplied from the ignition switch via fuse 28 in the passenger compartment fusebox. The ECU has the

ability to control when it requires power and is not reliant on the ignition signal for it to power up.

The ECU incorporates a counter which times the operation of the SLS system and prevents the compressor

exceeding its duty cycle. The ECU can remain powered for up to 1.5 hours after ignition off is sensed to allow the

counter to continue running to avoid an ignition cycle resetting the counter.

Opening any of the doors will power up the ECU, irrespective of ignition switch position. The door open signal is

sensed by the door switch completing an earth path which is sensed by the ECU. The ECU cannot differentiate

between any of the doors. The door open signal powers the ECU for up to 30 minutes to allow the vehicle to re-level

when a load is removed or passengers leave the vehicle.

Page 1027 of 1672

REAR SUSPENSION

64-22 DESCRIPTION AND OPERATION

Pressing the lower button will signal the SLABS ECU, via the RF receiver and the BCU, to energise the exhaust valve

and air control valves. The SLS will lower up to 60 mm (2.36 in) below normal ride height if the button is held. If the

button is released the SLS will stop at that point.

Pressing the raise button will signal the SLABS ECU, via the RF receiver and the BCU, to start the compressor and

energise the exhaust valve and air control valves. The SLS will raise to normal ride height if the button is held. If the

button is released the SLS will stop at that point.

When raising or lowering the SLS using the remote handset, the SLS warning lamp will flash and the audible warning

will sound when the system is operating. When the SLS is fully lowered the warning lamp will stay illuminated. The

SLS will reset to normal ride height if the vehicle speed exceeds 3 mph (5 km/h) for 10 seconds when the SLS is

lowered.

Transportation mode

Transportation mode must be used when the vehicle is transported on a trailer and secured by the chassis. The

transportation mode can only be enabled and disabled with TestBook.

The transportation mode lowers the rear suspension onto the bump stops with the engine not running. When the

suspension is in transportation mode, the SLS warning lamp is continuously illuminated when the ignition is in position

II.

When the engine is started in transportation mode, the SLS system will raise the rear suspension until a gap of 25

mm (1 in.) exists between the bump stop and the axle. The SLS warning lamp will flash continuously while the SLS

system is raising the suspension. When the gap between the bump stop and the axle is achieved, the warning lamp

will illuminate continuously.

When TestBook is used to disable the transportation mode, the rear suspension will raise to normal ride height when

the engine is running.

Page 1067 of 1672

BRAKES

70-22 DESCRIPTION AND OPERATION

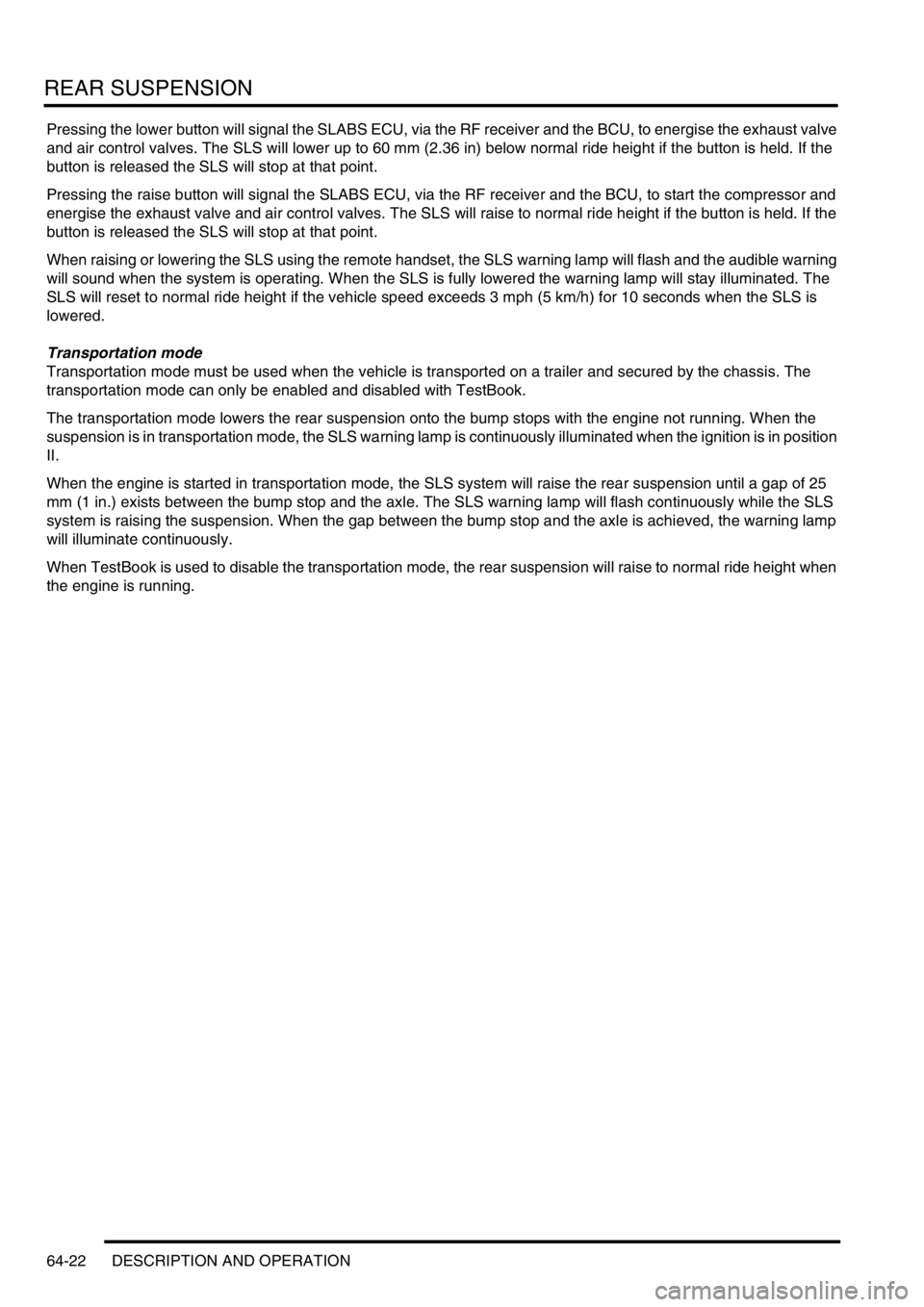

Minimum target speed

The minimum target speed depends on which gear is engaged. Reduced minimum target speeds are employed for

some gears if rough terrain or sharp bends are encountered while already travelling at the normal minimum target

speed. If loss of traction makes it impossible to maintain the minimum target speed, the SLABS ECU temporarily

increases the minimum target speed to maintain stability, then restores the normal minimum target speed when

traction improves.

HDC minimum target speeds

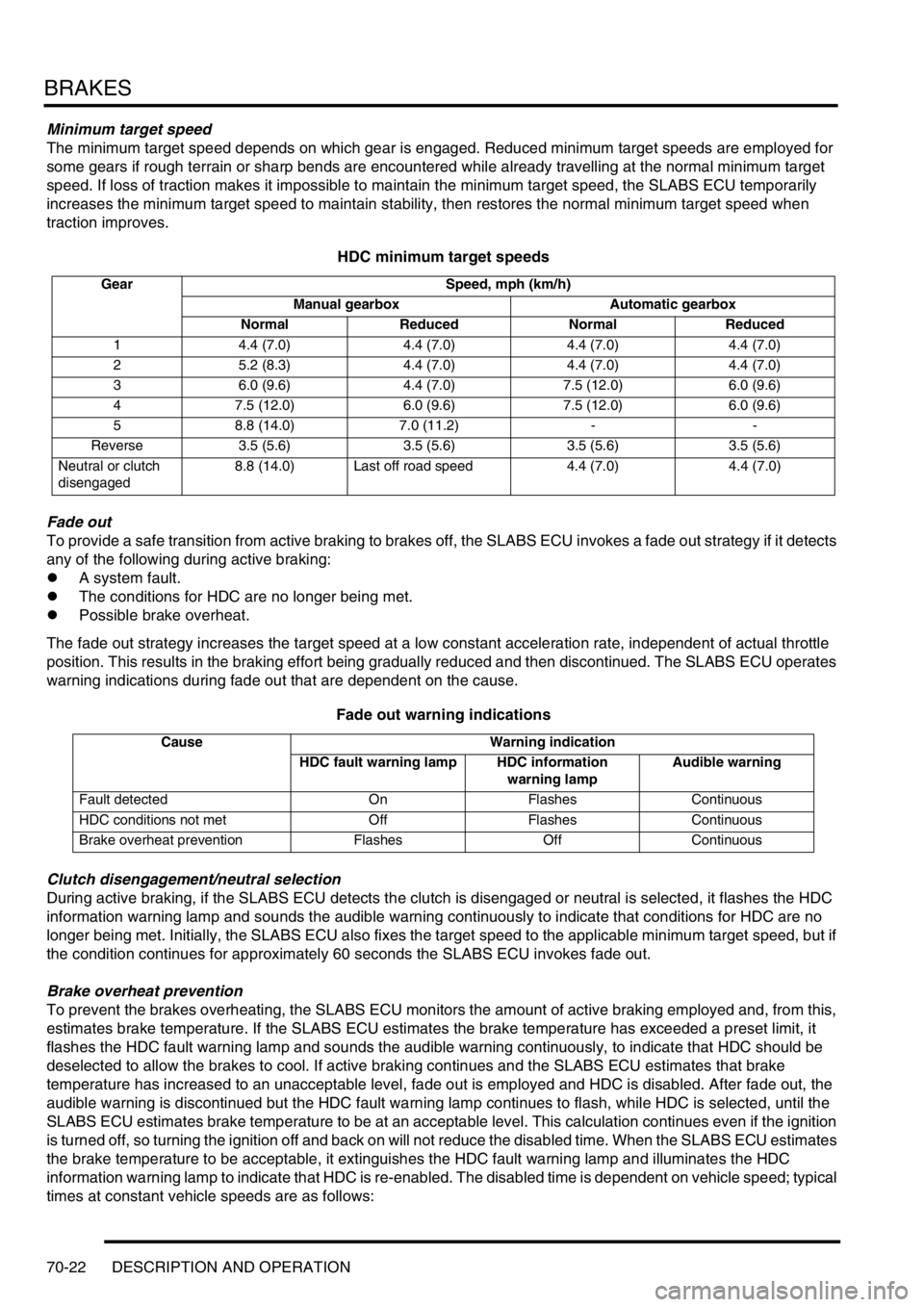

Fade out

To provide a safe transition from active braking to brakes off, the SLABS ECU invokes a fade out strategy if it detects

any of the following during active braking:

lA system fault.

lThe conditions for HDC are no longer being met.

lPossible brake overheat.

The fade out strategy increases the target speed at a low constant acceleration rate, independent of actual throttle

position. This results in the braking effort being gradually reduced and then discontinued. The SLABS ECU operates

warning indications during fade out that are dependent on the cause.

Fade out warning indications

Clutch disengagement/neutral selection

During active braking, if the SLABS ECU detects the clutch is disengaged or neutral is selected, it flashes the HDC

information warning lamp and sounds the audible warning continuously to indicate that conditions for HDC are no

longer being met. Initially, the SLABS ECU also fixes the target speed to the applicable minimum target speed, but if

the condition continues for approximately 60 seconds the SLABS ECU invokes fade out.

Brake overheat prevention

To prevent the brakes overheating, the SLABS ECU monitors the amount of active braking employed and, from this,

estimates brake temperature. If the SLABS ECU estimates the brake temperature has exceeded a preset limit, it

flashes the HDC fault warning lamp and sounds the audible warning continuously, to indicate that HDC should be

deselected to allow the brakes to cool. If active braking continues and the SLABS ECU estimates that brake

temperature has increased to an unacceptable level, fade out is employed and HDC is disabled. After fade out, the

audible warning is discontinued but the HDC fault warning lamp continues to flash, while HDC is selected, until the

SLABS ECU estimates brake temperature to be at an acceptable level. This calculation continues even if the ignition

is turned off, so turning the ignition off and back on will not reduce the disabled time. When the SLABS ECU estimates

the brake temperature to be acceptable, it extinguishes the HDC fault warning lamp and illuminates the HDC

information warning lamp to indicate that HDC is re-enabled. The disabled time is dependent on vehicle speed; typical

times at constant vehicle speeds are as follows:

Gear Speed, mph (km/h)

Manual gearbox Automatic gearbox

Normal Reduced Normal Reduced

1 4.4 (7.0) 4.4 (7.0) 4.4 (7.0) 4.4 (7.0)

2 5.2 (8.3) 4.4 (7.0) 4.4 (7.0) 4.4 (7.0)

3 6.0 (9.6) 4.4 (7.0) 7.5 (12.0) 6.0 (9.6)

4 7.5 (12.0) 6.0 (9.6) 7.5 (12.0) 6.0 (9.6)

5 8.8 (14.0) 7.0 (11.2) - -

Reverse 3.5 (5.6) 3.5 (5.6) 3.5 (5.6) 3.5 (5.6)

Neutral or clutch

disengaged8.8 (14.0) Last off road speed 4.4 (7.0) 4.4 (7.0)

Cause Warning indication

HDC fault warning lamp HDC information

warning lampAudible warning

Fault detected On Flashes Continuous

HDC conditions not met Off Flashes Continuous

Brake overheat prevention Flashes Off Continuous

Page 1082 of 1672

BRAKES

REPAIRS 70-37

Switch - brake light

$% 70.35.42

The brake switch is set automatically during fitment.

If the setting is disturbed, the switch can be reset by

depressing the brake pedal and pulling the plunger

out of the switch body, until it contacts the pedal.

Remove

1.Remove 3 fasteners and move drivers side

lower closing panel aside.

2.Disconnect multiplug from brake light switch.

3.Remove brake light switch from pedal bracket.

Refit

1.Engage switch fully into pedal bracket location

and connect multiplug.

2.Position lower closing panel and secure with

fasteners.

Brake pads - front

$% 70.40.02

WARNING: Brake pads must be renewed in axle

sets only, otherwise braking efficiency may be

impaired.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove lower guide pin bolt from caliper and

pivot caliper housing upwards.

4.Remove 2 brake pads from caliper carrier.

Shims are part of the brake pads.

Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc.

2.Scrape rust from pad locating surfaces on

caliper.

3.Clean dust from calipers using brake cleaning

fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

Page 1190 of 1672

SEATS

DESCRIPTION AND OPERATION 76-5-5

Seat switch pack

Each seat switch pack contains two switches representing the seat cushion and the seat squab. The switches provide

the following adjustments:

lSeat fore/ aft.

lCushion front up/ down.

lCushion rear up/ down.

lSquab fore/ aft.

lLumbar inflate.

lLumbar deflate.

The voltage supply to the seat switch pack is from the 40A fuse in the satellite fuse box. A pair of switches controls

the operation of each seat motor, the lumbar pump and the lumbar deflate relay.

Seat fore/ aft motor

The seat fore/ aft motor is a permanent magnet motor coupled to a rack and pinion assembly. Should the motor seize

or stick for 6 seconds or more, an internal thermal cut out switch will trip to remove voltage from the motor. Reset

time for the switch is 35 seconds.

Page 1191 of 1672

SEATS

76-5-6 DESCRIPTION AND OPERATION

Two pins within the seat switch pack control the seat fore/ aft motor. Both pins are normally earthed. Operating the

backward switch applies voltage to that pin while the other pin remains earthed. Operating the forward switch reverses

power and earth to the motor allowing the motor to run in the opposite direction.

Seat cushion front up/ down motor

The seat cushion front up/ down motor is a permanent magnet motor coupled to a rack and pinion assembly. Should

the motor seize or stick for 6 seconds or more an internal thermal cut out switch will trip to remove voltage from the

motor. Reset time for the switch is 35 seconds.

Two pins within the seat switch pack control the seat cushion front up/ down motor. Both pins are normally earthed.

Operating the up switch applies voltage to that pin while the other pin remains earthed. Operating the down switch

reverses power and earth to the motor allowing the motor to run in the opposite direction.

Seat cushion rear up/ down motor

The seat cushion rear up/ down motor is a permanent magnet motor coupled to a rack and pinion assembly. Should

the motor seize or stick for 6 seconds or more, an internal thermal cut out switch will trip to remove voltage from the

motor. Reset time for the switch is 35 seconds.

Two pins within the seat switch pack control the seat cushion rear up/ down motor. Both pins are normally earthed.

Operating the up switch applies voltage to that pin while the other pin remains earthed. Operating the down switch

reverses power and earth to the motor allowing the motor to run in the opposite direction.

Seat squab fore/ aft motor

The squab fore/ aft motor is a permanent magnet motor coupled to a rotary rack and pinion assembly. Should the

motor seize or stick for 6 seconds or more, an internal thermal cut out switch will trip to remove voltage from the motor.

Reset time for the switch is 35 seconds.

Two pins within the seat switch pack control the squab fore/ aft motor. Both pins are normally earthed. Operating the

fore switch applies voltage to that pin while the other pin remains earthed. Operating the aft switch reverses power

and earth to the motor allowing the motor to run in the opposite direction.

Lumbar pump

The lumbar pump inflates a bladder in the squab which provides extra support for the seat occupant. With no load on

the seat it takes approximately 10 seconds to completely inflate the bladder. With a load of 25 kg (55 lb) it takes

approximately 15 seconds to inflate the bladder. A pressure cut off switch in the system will operate at 0.12 to 1.93

bar (1.8 to 28 lbf.in

2). If a problem occurs with the lumbar bladder, e.g. a rupture, the whole lumbar system must be

replaced. The components are not serviceable.

Power comes from the seat switch pack through a 3A fuse in the satellite fuse box. The lumbar pump and the lumbar

deflate solenoid share an earth.

Lumbar deflate solenoid

The lumbar deflate solenoid vents the lumbar bladder to atmosphere to allow air to evacuate the bladder. The average

time to evacuate the bladder with a load of 25 kg (55 lb) is 9 seconds.

Power comes from the seat switch pack through a 3A fuse in the satellite fuse box. The lumbar deflate solenoid and

the lumbar pump share an earth.

Page 1391 of 1672

AIR CONDITIONING

82-18DESCRIPTION AND OPERATION

Operation

General

While the system is on, the ATC ECU operates the refrigerant system and the inlet air, blower speed, air temperature

and air distribution functions to produce the conditions requested on the control panel. When the system is first

switched on, the ATC ECU resumes the control outputs in use when the system was last switched off. If conditions

have changed, or a different mode is selected to switch the system on, the control outputs are then changed to

produce the required new settings.

The system operates in automatic, economy and defrost modes, with manual overrides of the inlet air source, blower

speed and air distribution. The air temperature is automatically controlled in all operating modes.

In the automatic mode, the ATC ECU operates the system to warm-up or cool down the cabin to establish and

maintain the temperature selections on the control panel, while directing the air to those outlets most comfortable for

the occupant(s). If a difference between the LH and RH temperature selections causes a conflict of the required inlet

air source, blower speed or air distribution settings, priority is given to achieving the temperature requested on the

driver's side of the control panel.

The ATC ECU enters the economy mode when the refrigerant compressor is selected off while the system is in the

automatic mode, which reduces the load on the engine. Economy mode operation is similar to the automatic mode,

but without the ability to cool the cabin if the ambient temperature is higher than the temperature selections made on

the control panel, or to dehumidify the air in the cabin.

In the defrost mode, the ATC ECU sets the inlet air source to fresh air, the blower to maximum speed, the air

distribution to windscreen and side windows, and outputs signals to the BCU to operate the rear window heater and

(where fitted) the windscreen heater. The BCU starts or, if the heaters are already on, resets the heater timers and

energises the rear window and windscreen heaters for a complete on cycle.

Air temperature control

To determine the amount of heat or cooling required by the cabin, the ATC ECU uses the sensor inputs and the

temperatures selected on the control panel to calculate target air outlet temperatures for the driver's and the front

passenger's side of the heater assembly. The ATC ECU then signals the servo motors controlling the respective blend

flaps in the heater assembly to move to the flaps to the appropriate position. The target temperatures are constantly

updated and, in the automatic mode, also used in further calculations to determine the inlet air source, the blower

speed and the air distribution.

Inlet air control

The inlet air source is automatically controlled while the system is off or on. While the system is on, the inlet air source

can also be manually controlled to give timed recirculated air or latched recirculated air.

While the system is off, the ATC ECU uses vehicle speed to determine the inlet air source. With the vehicle at rest,

the inlet air source is set to recirculated air. When vehicle speed reaches 17.5 mph (28 km/h), the inlet air source

changes to fresh air. The inlet air source then remains at fresh air until the vehicle speed decreases to 5 mph (8 km/

h), when it returns to recirculated air.

While the system is on, the ATC ECU uses the LH and RH temperature selections, vehicle speed, ambient air

temperature and coolant temperature to determine the inlet air source. In the automatic mode:

lIf one temperature selection is set to LO and one is set to a specific temperature or HI, the inlet air is set to

recirculated air.

lIf one temperature selection is set to HI and one is set to a specific temperature or HI, the inlet air is set to fresh

air.

lWhen specific LH and RH temperature selections are set, the inlet air source remains at fresh air except when

the air distribution function is set to face level only or face level and footwell outlets. If the air distribution function

is set to face level only or face level and footwell outlets, at 56 mph (90 km/h) the inlet air source changes to

recirculated air (to exclude ram effect, which becomes excessive at speed). When the vehicle speed decreases

to 37.5 mph (60 km/h), the inlet air source returns to fresh air.

Page 1437 of 1672

WIPERS AND WASHERS

84-16 DESCRIPTION AND OPERATION

Operation

Front intermittent wipe variable delay

The front intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Front variable delay operation activates when the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch is in the intermittent position.

The BCU receives the front intermittent wipe signal from the front wash/ wipe switch. The BCU receives a separate

signal from the variable delay switch, determines the delay interval from the front wash/ wipe switch position and

passes it on to the IDM. The IDM energises the front wiper relay to activate the front wiper motor.

If the delay duration is decreased during front variable delay operation, the wipers immediately operate once and then

the delay cycle is reset to the new duration.

If the delay duration is increased during front variable delay operation, the delay cycle is automatically increased by

the BCU.

Front low speed

Front low-speed operation activates when the following conditions are met:

lIgnition switch is in position I or II.

lFront wipe/ wash switch is in low speed position.

Selecting low-speed on the front wash/ wipe switch signals the IDM to energises the front wiper relay, which provides

power to the front wiper motor assembly.

Front high speed

Front high-speed operation activates when the following conditions are met:

lIgnition switch is in position I or II.

lFront wipe/ wash switch is in high speed position.

Selecting high speed on the front wash/ wipe switch allows power to flow from the switch directly to the wiper motor.

The high-speed input goes to a set of brushes in the wiper motor that are closer together than the low speed brushes.

These brushes allow the motor to run at a faster speed but with less torque.

Front washer

Front washer operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront washer switch operated.

Flicking the front washer switch energises the front washer pump motor for 0.4 second. Holding the front washer

switch for longer than 0.4 second allows the front washer pump motor to run as long as the switch is held.

There are two front washer configurations. If the vehicle is fitted with programme wash/ wipe, and the front washer

pump motor is active for more than 0.5 second, the front wipers operate at low speed. The wipers continue to operate

for 4 seconds after the washer switch is released. In some markets, the driver must activate the front wipers after a

front washer operation.

The front washer operation has a higher priority than the variable delay operation. This means that if intermittent wipe

is active when a front washer operation is initiated, the wash cycle executes and the intermittent wipe is re-instated

at the end of the wash operation.

Page 1438 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-17

Front flick wipe

Flick wipe operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront flick switch is operated.

Pressing the flick wipe switch operates the front wiper motor at high speed. The front wiper motor operates as long

as the flick switch is activated. Releasing the flick switch causes the front wiper motor to run through the park switch

circuitry. The park switch only permits low speed operation. Thus if the flick switch is pressed and immediately

released, the wipers operate at low speed.

Rear intermittent wipe variable delay

The rear intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Rear variable delay operation only activates if the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch on intermittent.

lRear wipe switch is operated.

The BCU determines the desired delay interval based on the setting of the variable delay switch. The rear wash/ wipe

delay is nominally twice as long as that of the front. This information passes from the IDM to the rear wiper relay and

activates the rear wiper motor.

If the delay duration is decreased during operation of the rear wiper, the wipers immediately operate once and the

delay cycle is reset.

If the delay duration is increased during operation of the rear wiper, the delay cycle is automatically increased by the

BCU.

Reverse wiping

Reverse wiping operates the rear wiper motor when reverse gear is selected. The transmission must be in reverse

for longer then 0.5 seconds before reversing wipe activates. Reversing wipe activates if the following conditions are

met:

lIgnition switch is in position II.

lReverse gear is selected.

lRear wiper or front wipers operating.

If the rear wiper is active in any mode when reverse gear is selected, the rear wiper activates for 4 second. After 4

seconds the rear wiper operates in a delay operation at the same delay interval set by the variable delay switch until

reverse gear is deselected.

If the front wipers are operating on either low or high speed when reverse gear is selected, the rear wiper activates

continuously until reverse gear is deselected.

In order to enable reversing wipe functions, the BCU utilises the reversing light switch located within the transmission

to determine when reverse gear has been selected.

If the front intermittent wipe is active when reverse gear is selected, the rear wiper completes 2 cycles before operating

at the same intermittent delay as the front wipers.

Page 1439 of 1672

WIPERS AND WASHERS

84-18 DESCRIPTION AND OPERATION

Rear wipe

Rear wipe operation will only activate when the following conditions are met:

lIgnition switch is in position II.

lRear wipe switch is operated.

Operating the rear wiper switch provides an earth input to the BCU. The BCU tells the IDM to activate the rear wiper

relay, which provides battery voltage to the wiper motor through the normally closed contacts of the park switch.

Rear wash

Rear wash will only operate when the following conditions are met:

lIgnition switch is in position II.

lRear wash switch operated.

Operating the rear washer switch for longer than 0.4 second allows the rear washer pump motor and rear wipers to

run as long as the switch is held. The wipers run for 4 seconds after the rear washer switch is released. Flicking the

rear washer switch energises the rear washer pump motor for 0.4 second.

The rear washer operation has a higher priority than the intermittent wipe operation. If the intermittent wipe is active

when a rear washer operation is initiated, the wash cycle executes and the intermittent wipe is re-instated at the end

of the washer operation.

Wiper park switch

The park switch allows the wipers to come to rest in the park position when the wipe switch is turned off in mid-wipe.

The park switch consists of a positive and a negative contact. These two contacts are described as closed at park

and closed when operating. When the wipers first start, the park switch is in the closed at park position. A relay

controls battery voltage to the motor. Battery voltage passes through this relay contact to move the wiper motor from

the park position.

When the motor moves, the park switch moves to the closed when operating position. Battery voltage to this relay

contact is direct from fuse 19. Battery voltage passes through this contact to keep the wiper motor running. The wiper

motor operates for one complete revolution until the park switch moves to the closed at park position again.

Switching off the wipers removes battery voltage from the closed at park contact. When the wipers reach the closed

at park switch an earth is applied and the motor stops abruptly.

Headlamp power wash

Headlamp power wash activates when the following conditions are met:

lIgnition switch in position II.

lHeadlamps switched on.

lFront wash switch operated.

lBCU counter allows headlamp power wash.

Operating the front washer switch with the headlamps switched on energises the IDM, supplying a voltage to the

headlamp powerwash relay, which operates the headlamp powerwash pump and increments a counter within the

BCU. This counter prevents the headlamp powerwash pump from operating every time the front washer switch is

activated. Headlamp powerwash is only operational every third front wash cycle, providing the headlamps are on.

The counter resets when the ignition switch is turned off.

When the BCU permits headlamp power wash operation, the pump motor operates only for 0.5 second.