brake LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1502 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-33

Cruise control

The Neutral/ Reverse/ Park/ Brake selected output is used by the cruise control system. The BCU checks for the

following inputs:

lIgnition on.

lGearbox state.

lBrake switch activated.

For vehicles with manual transmission, Neutral/ Reverse/ Park/ Brake selected output is on if the ignition is on and

brake switch activated is on. Otherwise, the Neutral/ Reverse/ Park/ Brake selected output is off.

For vehicles with automatic transmission, the Neutral/ Reverse/ Park/ Brake selected output is on if the ignition is on

and brake switch activated is on, or if the ignition is on and 'gearbox state' is in Neutral, Park or Reverse. Otherwise

Neutral/ Reverse/ Park/ Brake selected output is off.

Shift interlock (where fitted)

On automatic gearbox models, the BCU and IDM combine to operate a shift interlock solenoid, so that the gear

selector lever can only be moved when certain logical conditions have been satisfied. Operation of the interlock may

be affected, if the battery becomes discharged.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

When the gear selector lever is in the Park position and the ignition is off, an interlock solenoid is de-energised, locking

the gear selector lever in the Park position.

The gear selector lever can only be moved from the Park position when the ignition is switched on and the brake pedal

is depressed. When these conditions are satisfied, the brake pedal switch signal is received by the BCU which then

signals the IDM to energise the interlock relay. When the interlock relay is energised, the interlock solenoid is

operated, unlocking the gear selector lever.

When the brake pedal is released, the feed to the BCU is removed and the shift interlock solenoid is de-energised.

The locking mechanism controlled by the solenoid will lock the gear selector lever once it is returned to the Park

position.

The shift interlock option can be programmed in one of three states dependent on market/ customer requirements,

these are:

lOption 1– not fitted.

lOption 2 – normal operation.

lOption 3 – inhibit transfer box.

The BCU checks the status of the following inputs to determine the logic action for employing the shift interlock

solenoid:

lBrake switch activated.

lIgnition state.

lGearbox state.

In the event of a communications link failure, the shift interlock solenoid enable is switched on for 1 minute every time

the ignition is switched on and switched off when the ignition is turned off.

Ignition interlock (where fitted)

On automatic gearbox models, when the ignition key is inserted in the ignition switch, the ignition key-in switch

contacts close to supply a signal to the BCU to indicate the presence of the key in the switch and provide a supply

feed to the ignition interlock solenoid. If the gear selector lever is in a position other than Park, or the 'transfer box

neutral selected' is on, the BCU will supply an earth path to complete the ignition interlock circuit and cause the

interlock solenoid to be engaged. With the interlock solenoid engaged, removal of the ignition key is prevented. The

BCU will open the circuit, to allow removal of the ignition key, only when the gear selector lever is in the Park position

and the transfer box is in either high or low range.

Page 1564 of 1672

IN CAR ENTERTAINMENT

DESCRIPTION AND OPERATION 86-6-11

If one headphone amplifier unit has control of the tape player, CD or radio, the other headphone amplifier will be able

to listen and be able to change tape tracks or radio bands. Other buttons allow a search seek function of radio band

or compact disk track, reversal of the tape, radio station and volume adjustment depending on the current operating

mode. If one radio headphone amplifier has control of the radio, tape or CD autochanger the other radio headphone

amplifier is able to change the track or radio band selected. A headphone socket with a glow ring is located on the

control panel. When a headphone is turned on , a 'headphone-module active' signal is sent to the radio cassette

player. The design incorporates panel illumination and a glow-ring to locate the socket in low light conditions. To

control the audio output from the radio headphone amplifiers, signals are sent to and received from the radio cassette

player.

Automatic volume control (High line system only)

An automatic base and treble volume control feature compensates for increases in interior road/transmission noise.

A road speed signal is monitored by the power amplifier, the signal is supplied by the SLABS ECU.

+ BRAKES, DESCRIPTION AND OPERATION, Description.The power amplifier boosts the levels of base

and treble as road speed increases. This system ensures that the apparent volume of sound remains constant and is

not affected by increases in the background noise in the vehicle.

Speakers

Some vehicles will not have all the speakers, the type and location of speakers fitted depends on the trim level and

ICE options specified for the vehicle.

A-post speakers LH/RH (if fitted)

The A-post speakers are located in the A-post trim on each side of the windscreen, and are each protected by a metal

grille. The speakers are held from the rear by a bayonet clip that clamps the speaker on to the A-post trim. The A-post

speakers are a high range type and have a power rating of:

lMid line system A-post speakers have a power rating of 15 watts and an impedance of 4

Ω.

lHigh line system A-post speakers have a power rating of 30 watts and an impedance of 4

Ω.

Upper front and rear door speakers LH/RH (high line system only)

The upper door speakers are located in the upper door trim, the speaker is protected by an integral metal grille. The

speaker is held in by a threaded ring that clamps the speaker from the rear onto the door trim. The upper door speaker

is a mid-range type and has a power rating of 30 watts and an impedance of 4

Ω.

Lower front door speakers LH/RH

The lower front door speaker is located in the front end of the lower (pocket) trim and is secured by three self tapping

screws. The speaker is protected by a clip on circular metal grille. The type of lower front door speakers fitted depends

on trim level and market:

lThe base and mid line systems are fitted with full-range door speakers with a power rating of 15 watts and an

impedance of 4

Ω

lThe high line system is fitted with a low-range door speaker with a power rating of 30 watts and an impedance

of 4

Ω.

Lower rear door speaker LH/RH

The lower rear door speaker is located in the lower door trim and is secured by three self tapping screws. The speaker

is protected by a clip on metal grille. The type of lower rear door speaker fitted depends on trim level and market:

lThe base and mid line systems are fitted with full-range door speakers with a power rating of 15 watts and an

impedance of 4

Ω

lThe high line system is fitted with a low-range door speaker with a power rating of 30 watts and an impedance

of 4

Ω.

Low range tail door speakers (high line system only)

The low range tail door speaker are located in a plastic casing in the lower door trim. Each of the two speakers is

secured to the casing with four self tapping screws. The casing is secured to the lower door structure with eight bolts.

The tail door trim surrounds the casing, the front of the casing is covered by a metal grill that is secured with six

screws. The low range tail door speakers have a power rating of 30 watts and has an impedance of 4

Ω.

Page 1590 of 1672

HARNESSES

REPAIRS 86-7-19

24.Disconnect 3 multiplugs from chassis harness.

25.Remove RH front indicator repeater lamp from

wing.

26.Disconnect multiplug from repeater lamp.

27.Remove repeater lamp.

28.Attach draw string to indicator lamp harness.

29.Withdraw harness to fuse box.

30.Remove draw string and secure.31.Disconnect main harness multiplug from

engine harness and ABS sensor.

32.Disconnect multiplugs from cruise control

actuator and brake fluid level switch.

33.Withdraw harness to bulkhead.

Page 1596 of 1672

HARNESSES

REPAIRS 86-7-25

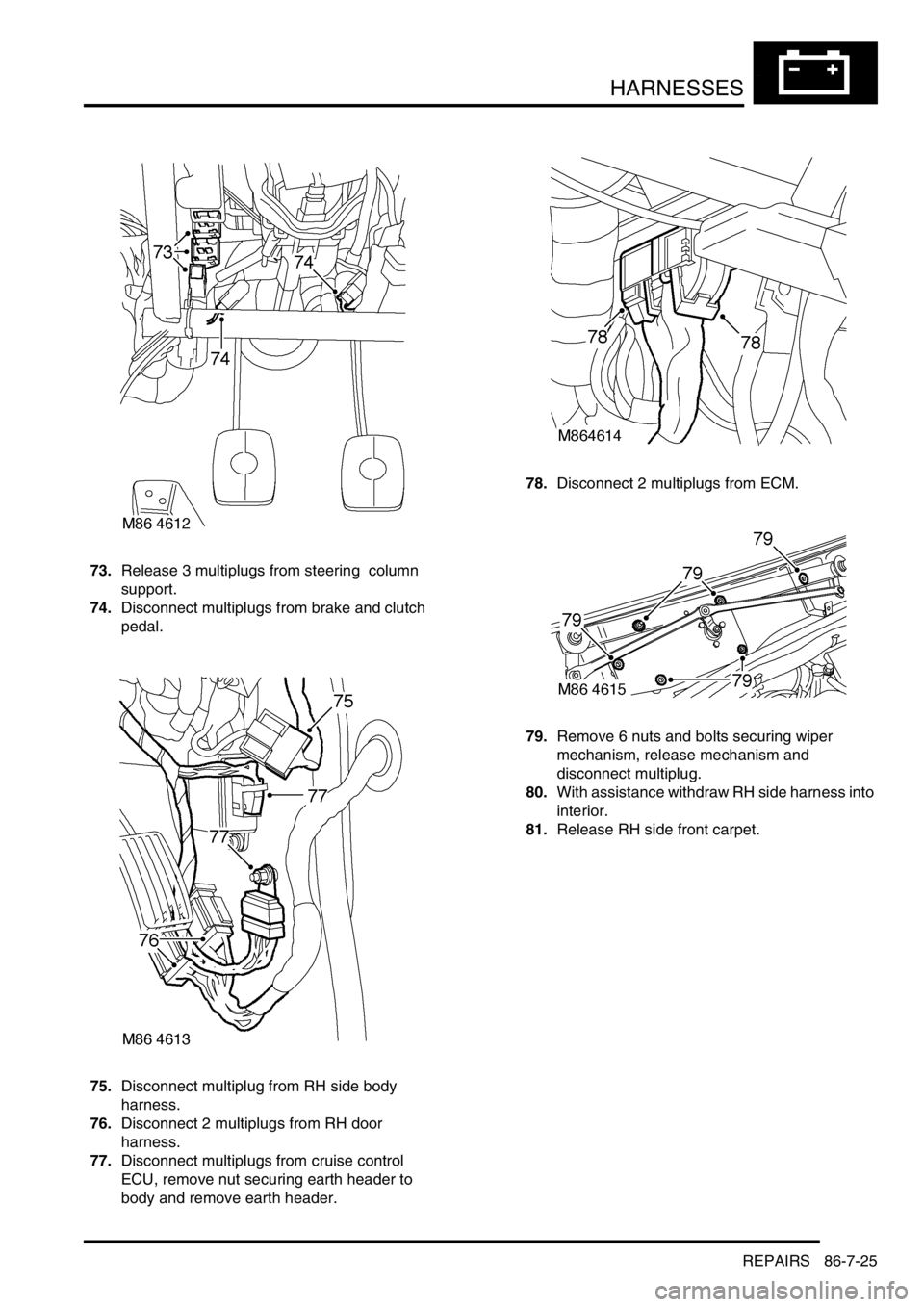

73.Release 3 multiplugs from steering column

support.

74.Disconnect multiplugs from brake and clutch

pedal.

75.Disconnect multiplug from RH side body

harness.

76.Disconnect 2 multiplugs from RH door

harness.

77.Disconnect multiplugs from cruise control

ECU, remove nut securing earth header to

body and remove earth header. 78.Disconnect 2 multiplugs from ECM.

79.Remove 6 nuts and bolts securing wiper

mechanism, release mechanism and

disconnect multiplug.

80.With assistance withdraw RH side harness into

interior.

81.Release RH side front carpet.

Page 1597 of 1672

HARNESSES

86-7-26 REPAIRS

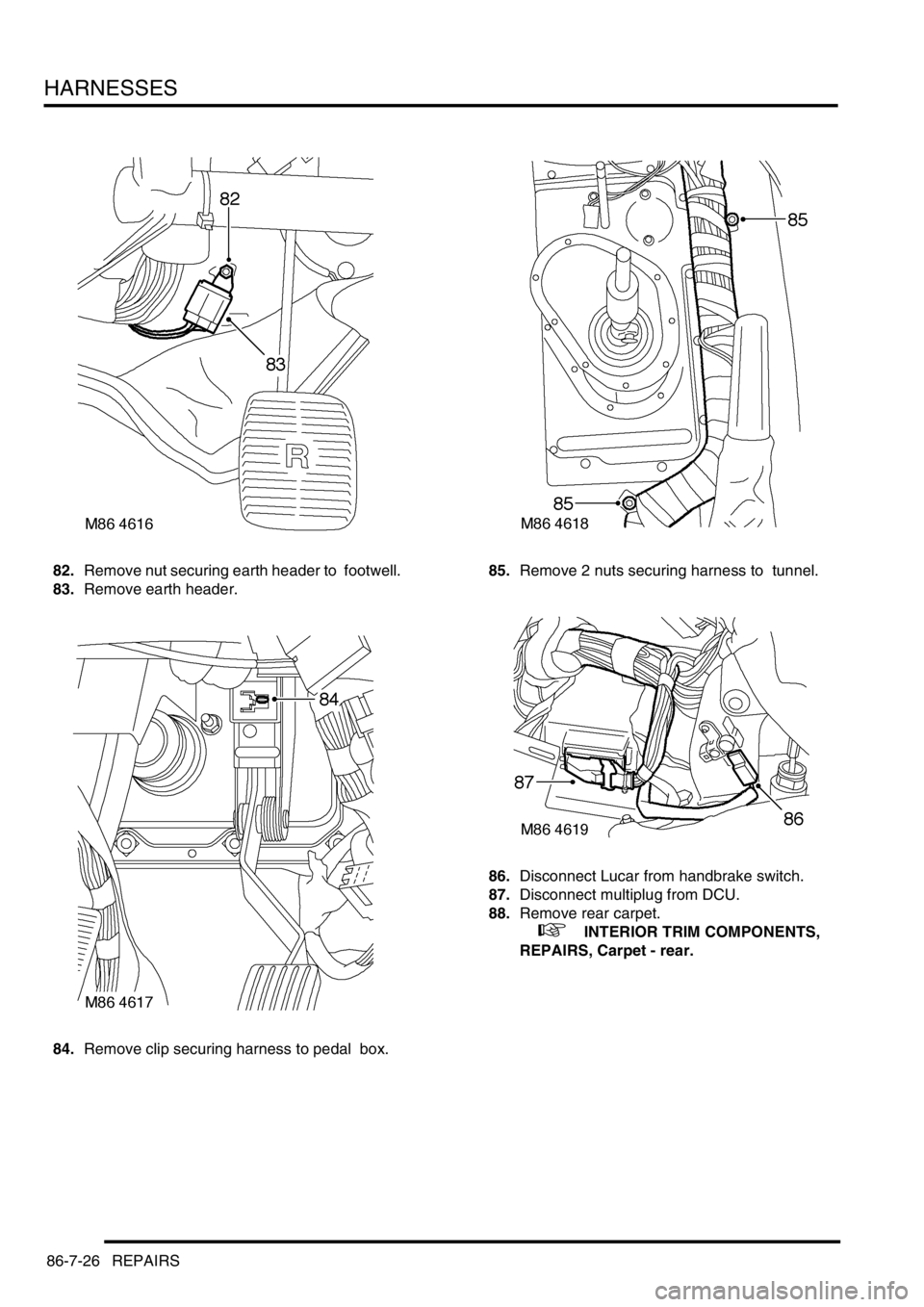

82.Remove nut securing earth header to footwell.

83.Remove earth header.

84.Remove clip securing harness to pedal box. 85.Remove 2 nuts securing harness to tunnel.

86.Disconnect Lucar from handbrake switch.

87.Disconnect multiplug from DCU.

88.Remove rear carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - rear.

Page 1598 of 1672

HARNESSES

REPAIRS 86-7-27

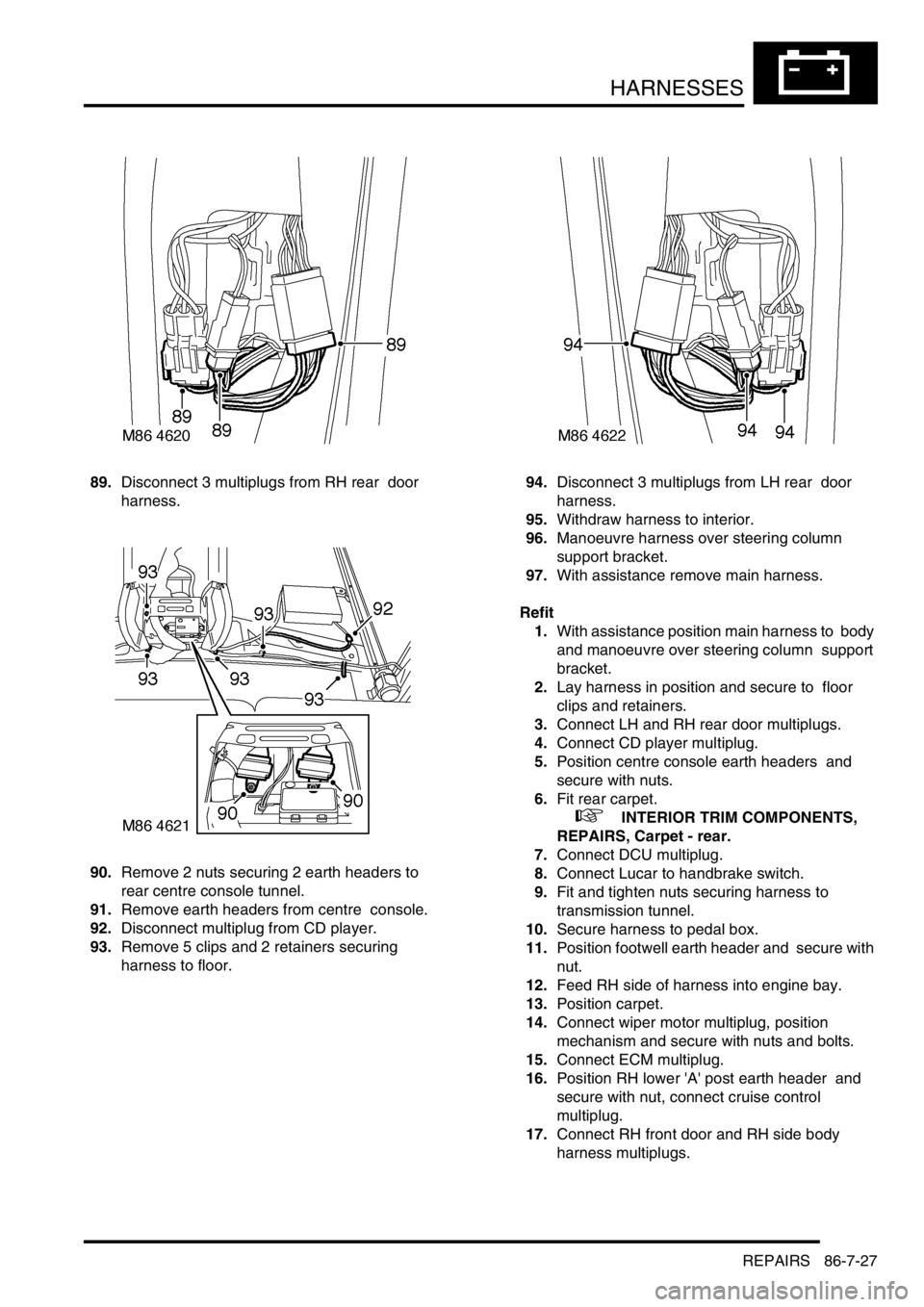

89.Disconnect 3 multiplugs from RH rear door

harness.

90.Remove 2 nuts securing 2 earth headers to

rear centre console tunnel.

91.Remove earth headers from centre console.

92.Disconnect multiplug from CD player.

93.Remove 5 clips and 2 retainers securing

harness to floor. 94.Disconnect 3 multiplugs from LH rear door

harness.

95.Withdraw harness to interior.

96.Manoeuvre harness over steering column

support bracket.

97.With assistance remove main harness.

Refit

1.With assistance position main harness to body

and manoeuvre over steering column support

bracket.

2.Lay harness in position and secure to floor

clips and retainers.

3.Connect LH and RH rear door multiplugs.

4.Connect CD player multiplug.

5.Position centre console earth headers and

secure with nuts.

6.Fit rear carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - rear.

7.Connect DCU multiplug.

8.Connect Lucar to handbrake switch.

9.Fit and tighten nuts securing harness to

transmission tunnel.

10.Secure harness to pedal box.

11.Position footwell earth header and secure with

nut.

12.Feed RH side of harness into engine bay.

13.Position carpet.

14.Connect wiper motor multiplug, position

mechanism and secure with nuts and bolts.

15.Connect ECM multiplug.

16.Position RH lower 'A' post earth header and

secure with nut, connect cruise control

multiplug.

17.Connect RH front door and RH side body

harness multiplugs.

Page 1599 of 1672

HARNESSES

86-7-28 REPAIRS

18.Secure multiplugs to steering column support

bracket and connect brake and clutch pedal

multiplugs.

19.Connect multiplugs to column switch and

passive coil.

20.Position passenger compartment fusebox,

connect multiplugs, fit fusebox to fascia and

secure with nut.

21.Connect ignition switch multiplug to fuse box.

22.With assistance feed LH side of harness into

engine bay.

23.Connect multiplugs to front door harness and

body harness.

24.Position earth headers to LH lower 'A' post and

secure with nuts.

25.Connect multiplugs to ECU pack.

26.Position harness in engine bay.

27.Connect and secure heated front screen

multiplugs.

28.Fit plenum molding.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

29.Connect multiplugs to ABS sensor and fuel

cut-off switch.

30.Using draw string feed harness through inner

wing, remove draw string, connect repeater

lamp multiplug and fit lamp.

31.Connect multiplugs to ABS modulator.

32.Feed harness through to front panel.

33.Position body earth leads and secure with

bolts.

34.Connect washer reservoir multiplugs and

pipes, secure pipes with clips.

35.Secure fog lamp multiplug.

36.Secure earth header behind headlamp.

37.Connect multiplugs to headlamp level motor,

headlamp and side lamp.

38.Fit indicator lamp

+ LIGHTING, REPAIRS, Lamp - front

repeater.

39.Connect multiplug to LH horn.

40.Feed harness to ACE accelerometer, connect

multiplug and secure with cable ties.

41.Connect cruise control, ABS sensor and brake

fluid level switch multiplugs.

42.Connect engine harness multiplug and feed

harness along RH wing to fuse box.

43.Using draw string pull harness through inner

wing, remove draw string, connect repeater

lamp multiplug and fit lamp. 44.Connect chassis harness multiplugs.

45.Position engine bay fuse box and connect

multiplugs, fit fuse box and secure with screws.

46.Connect multiplugs to front of fuse box.

47.Position battery and starter cables and secure

with screws.

48.Fit fuse box cover.

49.Position earth lead and secure with nut.

50.Feed harness through to front panel.

51.Secure fog lamp multiplug.

52.Connect headlamp level motor, headlamp and

side lamp multiplugs.

53.Fit indicator lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

54.Secure harness to RH front panel.

55.Connect cooling fan and horn multiplug.

56.Secure harness to lower support rail.

57.Connect receiver drier and air temperature

sensor multiplugs.

58.Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

59.Fit battery tray.

60.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

61.Position both lower 'A' post trims and secure

with studs.

62.Fit heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models

without air conditioning.

Page 1628 of 1672

INSTRUMENTS

DESCRIPTION AND OPERATION 88-1

INS TRUMENTS DESCRIPTION AND OPERAT ION

Instrument pack

1Hill descent control information warning lamp

2Overspeed warning lamp

3Brake system warning lamp

4Malfunction Indicator Lamp (MIL)

5Tachometer

6Direction indicator warning lamp

7Main beam warning lamp

8Direction indicator warning lamp

9Speedometer

10SRS warning lamp

11Off road mode warning lamp

12Glow plug warning lamp

13Trailer warning lamp

14Water in fuel filter warning lamp

15Transmission high temperature warning lamp

16Seat belt warning lamp17Fuel tank level gauge

18Low fuel level warning lamp

19LCD odometer/trip meter

20Anti-theft status warning lamp

21ABS warning lamp

22Gearbox manual/sport mode warning lamp

23Alternator charge warning lamp

24ACE warning lamp

25Oil pressure warning lamp

26SLS warning lamp

27Hill descent control warning lamp

28Engine coolant temperature gauge

29High coolant temperature warning lamp

30Traction control warning lamp

31Differential lock warning lamp

32Transfer box neutral warning lamp

Page 1629 of 1672

INSTRUMENTS

88-2 DESCRIPTION AND OPERATION

Instrument component location - Engine

compartment / underneath vehicle

1ECM (diesel models)

2Alternator

3Glow plugs

4Transmission temperature sensor

5Water in fuel filter sensor

6Fuel tank sender unit

7Differential lock switch – vehicles up to 03

model year8Differential lock switches – vehicles from 03

model year (where fitted)

9Parking brake switch

10Brake fluid level switch

11Oil pressure switch

Page 1631 of 1672

INSTRUMENTS

88-4 DESCRIPTION AND OPERATION

Instrument block diagram

1Instrument pack

2ECM

3Brake fluid level switch

4Parking brake switch

5Oil pressure switch

6Alternator

7Fuel tank sender unit

8Water in fuel filter sensor

9Transmission temperature sensor

10Differential lock switch - vehicles up to 03

model year or Differential lock switches -

vehicles from 03 model year11Audible warning speaker

12SRS DCU

13SLABS ECU

14BCU

15ACE ECU

16EAT ECU

17Diagnostic connector

18Serial communications link