air suspension LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 975 of 1672

FRONT SUSPENSION

60-36 REPAIRS

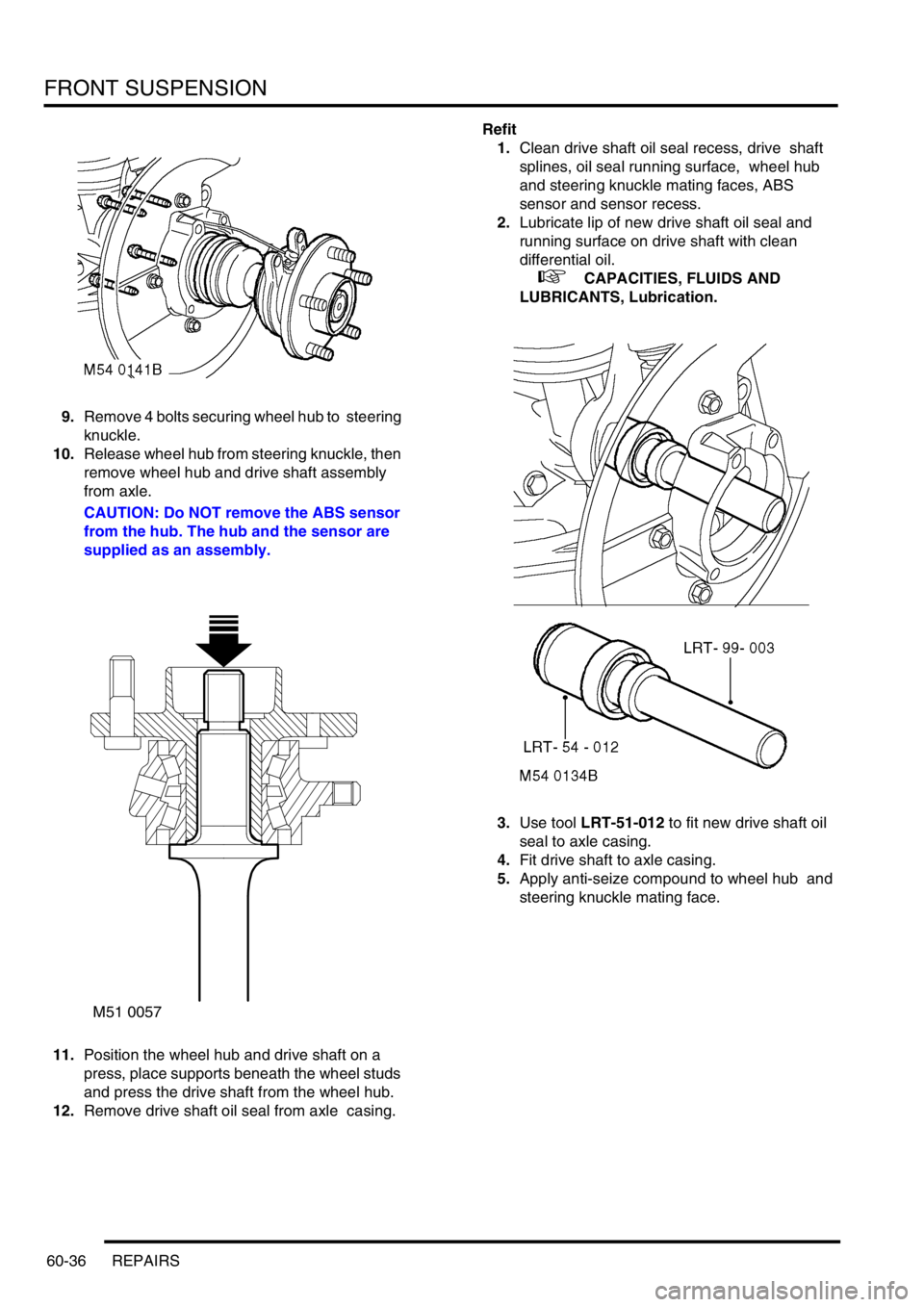

9.Remove 4 bolts securing wheel hub to steering

knuckle.

10.Release wheel hub from steering knuckle, then

remove wheel hub and drive shaft assembly

from axle.

CAUTION: Do NOT remove the ABS sensor

from the hub. The hub and the sensor are

supplied as an assembly.

11.Position the wheel hub and drive shaft on a

press, place supports beneath the wheel studs

and press the drive shaft from the wheel hub.

12.Remove drive shaft oil seal from axle casing. Refit

1.Clean drive shaft oil seal recess, drive shaft

splines, oil seal running surface, wheel hub

and steering knuckle mating faces, ABS

sensor and sensor recess.

2.Lubricate lip of new drive shaft oil seal and

running surface on drive shaft with clean

differential oil.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

3.Use tool LRT-51-012 to fit new drive shaft oil

seal to axle casing.

4.Fit drive shaft to axle casing.

5.Apply anti-seize compound to wheel hub and

steering knuckle mating face.

M51 0057

Page 976 of 1672

FRONT SUSPENSION

REPAIRS 60-37

6.Apply a 3 mm (0.125 in) wide bead of Loctite

640 around drive shaft circumference, as

illustrated.

7.Ensure ABS harness is located in cut out in

steering knuckle.

8.Fit wheel hub to drive shaft and align steering

knuckle. The Loctite will smear along the length

of the splines as the wheel hub is fitted to the

drive shaft.

9.Fit wheel hub bolts and tighten to 100 Nm (74

lbf.ft).

10.Fit new drive shaft nut and lightly tighten.

11.Fit front brake disc.

+ BRAKES, REPAIRS, Brake disc -

front.

12.With assistance, final tighten drive shaft nut to

490 Nm (360 lbf.ft). Stake drive shaft nut. The

drive shaft nut must be tightened before

Loctite has cured.

13.Secure ABS sensor harness to brackets and

secure grommet to inner wing.

14.Fit road wheel and tighten nuts to 140 Nm (103

lbf.ft).

15.Remove stand(s) and lower vehicle.

16.Connect ABS sensor multiplug.

Damper - front

$% 60.30.02

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3. RH damper: Release coolant reservoir and

position aside.

4.Loosen through bolt securing damper to turret.

WARNING: Make sure the axle cannot move

when the damper is disconnected. The

damper limits the downward movement of

the axle. If the axle is not restrained,

disconnecting the damper will allow

unrestricted movement which may cause

personal injury or damage to equipment.

M51 0058

Page 977 of 1672

FRONT SUSPENSION

60-38 REPAIRS

5.Remove 4 nuts securing turret base to chassis.

6.Remove 2 bolts securing damper to axle.

7. ACE models: Remove bolt securing ACE pipe

clamp to chassis.

8. ACE models: Remove bolt securing ACE pipe

clamp to turret.

9.Release harness clip from turret.

10.Raise turret and remove through bolt.

11.Compress damper and manoeuvre turret from

engine bay.

12.Remove damper. Refit

1.Position damper and manoeuvre turret into

position. Raise damper and align to turret. Fit

through bolt but do not tighten at this stage.

2.Align damper assembly to spring seat.

3.Fit bolts securing damper to axle and tighten to

45 Nm (33 lbf.ft).

4.Fit nuts securing turret to chassis and tighten

to 23 Nm (17 lbf.ft).

5.Tighten through bolt to 125 Nm (92 lbf.ft).

6. ACE models: Position ACE pipe clamp to

chassis and secure with bolt.

7. ACE models: Position ACE pipe clamp to

turret and secure with bolt.

8.Secure harness to turret.

9. RH damper: Reposition coolant reservoir.

10.Fit road wheel and tighten nuts to 140 Nm (103

lbf.ft).

11.Remove stand(s) and lower vehicle.

Page 978 of 1672

FRONT SUSPENSION

REPAIRS 60-39

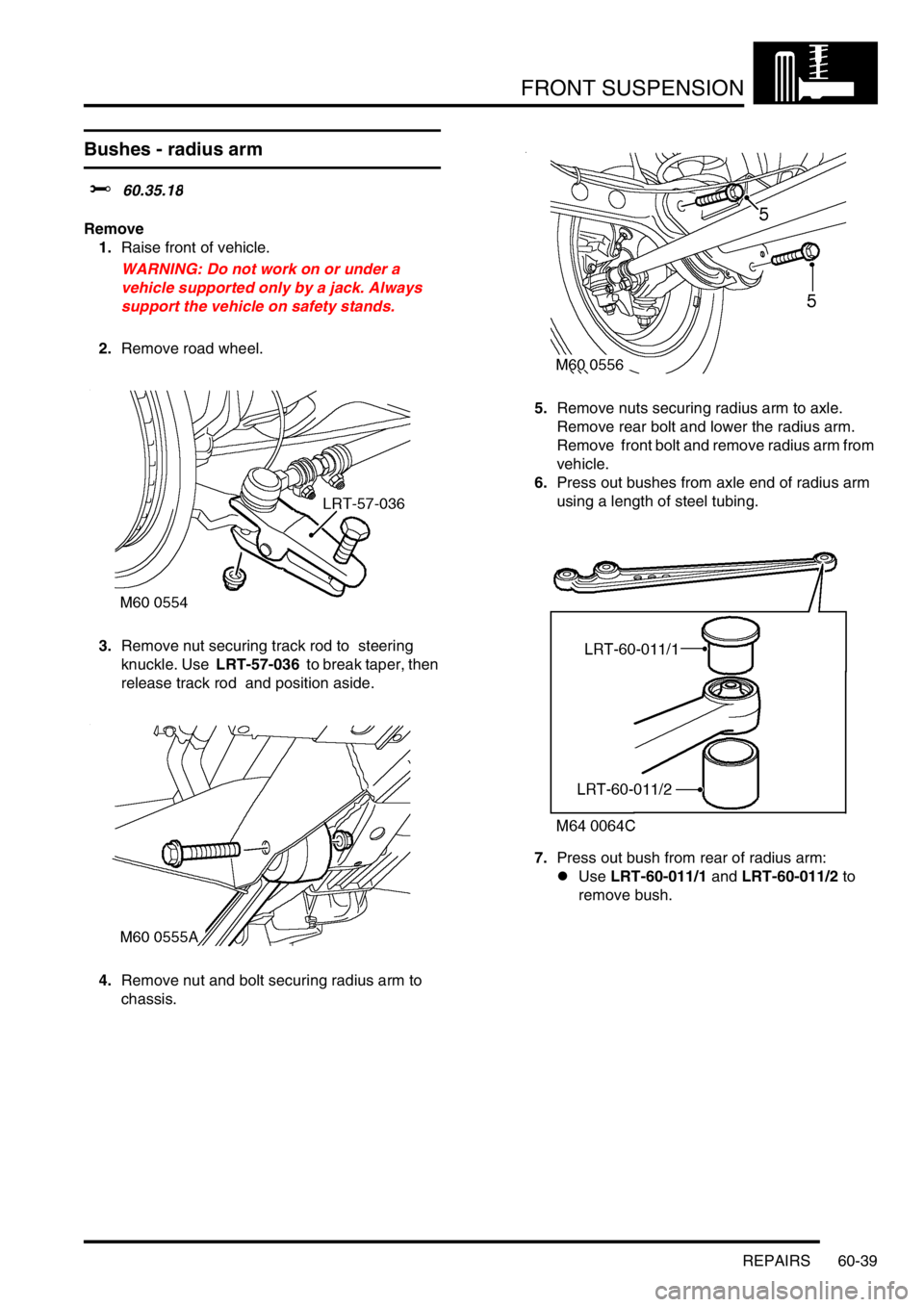

Bushes - radius arm

$% 60.35.18

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove nut securing track rod to steering

knuckle. Use LRT-57-036 to break taper, then

release track rod and position aside.

4.Remove nut and bolt securing radius arm to

chassis. 5.Remove nuts securing radius arm to axle.

Remove rear bolt and lower the radius arm.

Remove front bolt and remove radius arm from

vehicle.

6.Press out bushes from axle end of radius arm

using a length of steel tubing.

7.Press out bush from rear of radius arm:

lUse LRT-60-011/1 and LRT-60-011/2 to

remove bush.

Page 979 of 1672

FRONT SUSPENSION

60-40 REPAIRS

Refit

1.Clean bush locations in radius arm.

2.Press bushes into radius arm:

lUse LRT-60-011/1, LRT-60-011/2 and

LRT-60-011/3 to fit bush at rear of radius

arm.

3.Position radius arm to vehicle. Fit securing

bolts and nuts but do not tighten at this stage.

4.Fit track rod to steering knuckle. Fit and tighten

nut to 125 Nm (92 lbf.ft).

5.Fit road wheel and tighten nuts to 140 Nm (103

lbf.ft).

6.Remove stand(s) and lower vehicle.

7.Tighten radius arm nuts and bolts to 230 Nm

(170 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

ECU - ACE

$% 60.60.01

Remove

1.Remove BCU.

+ BODY CONTROL UNIT, REPAIRS,

Body control unit (BCU).

2.Remove 5 multiplugs from SLABS ECU.

3.Remove multiplug from ACE ECU.

4.Remove lower nut and loosen upper nut

securing SLABS and ACE ECU bracket to

body.

5.Remove ECU's and bracket assembly.

Page 980 of 1672

FRONT SUSPENSION

REPAIRS 60-41

6.Remove 3 nuts securing ACE ECU and remove

ACE ECU.

Refit

1.Fit ACE ECU to bracket and secure with nuts.

2.Fit ECU's and bracket assembly to body and

secure with nuts.

3.Connect multiplugs to ACE ECU and SLABS

ECU.

4.Fit BCU.

+ BODY CONTROL UNIT, REPAIRS,

Body control unit (BCU).

5.If a replacement ACE ECU has been fitted, use

TestBook to calibrate ACE system.

Accelerometer - ACE - upper

$% 60.60.02

CAUTION: The accelerometer is an extremely

delicate component and can easily be rendered

unserviceable. Never use an accelerometer

which has been dropped or subjected to

mistreatment of any type.

Remove

1.Remove front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

2.Disconnect multiplug from accelerometer.

3.Use LRT-60-014A to release clip and remove

accelerometer.

Refit

1.Using LRT-60-014A, fit accelerometer fully into

clip.

2.Connect accelerometer multiplug.

3.Fit front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

4.If a replacement accelerometer has been fitted,

use TestBook to calibrate ACE system.

Page 981 of 1672

FRONT SUSPENSION

60-42 REPAIRS

Accelerometer - ACE - lower

$% 60.60.03

CAUTION: The accelerometer is an extremely

delicate component and can easily be rendered

unserviceable. Never use an accelerometer

which has been dropped or subjected to

mistreatment of any type.

Remove

1.Raise vehicle on a ramp.

2.Disconnect multiplug from accelerometer.

3.Use LRT-60-014A to release clip and remove

accelerometer.

Refit

1.Use LRT-60-014A, fit accelerometer fully into

clip.

2.Connect accelerometer multiplug.

3.Lower vehicle.

4.If a replacement accelerometer has been fitted,

use TestBook to calibrate ACE system.

Pump - ACE - V8

$% 60.60.10

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Loosen 3 clips securing air intake hose.

Release air intake hose and position aside.

Note: Pre 03 MY air intake hose illustrated.

Page 982 of 1672

FRONT SUSPENSION

REPAIRS 60-43

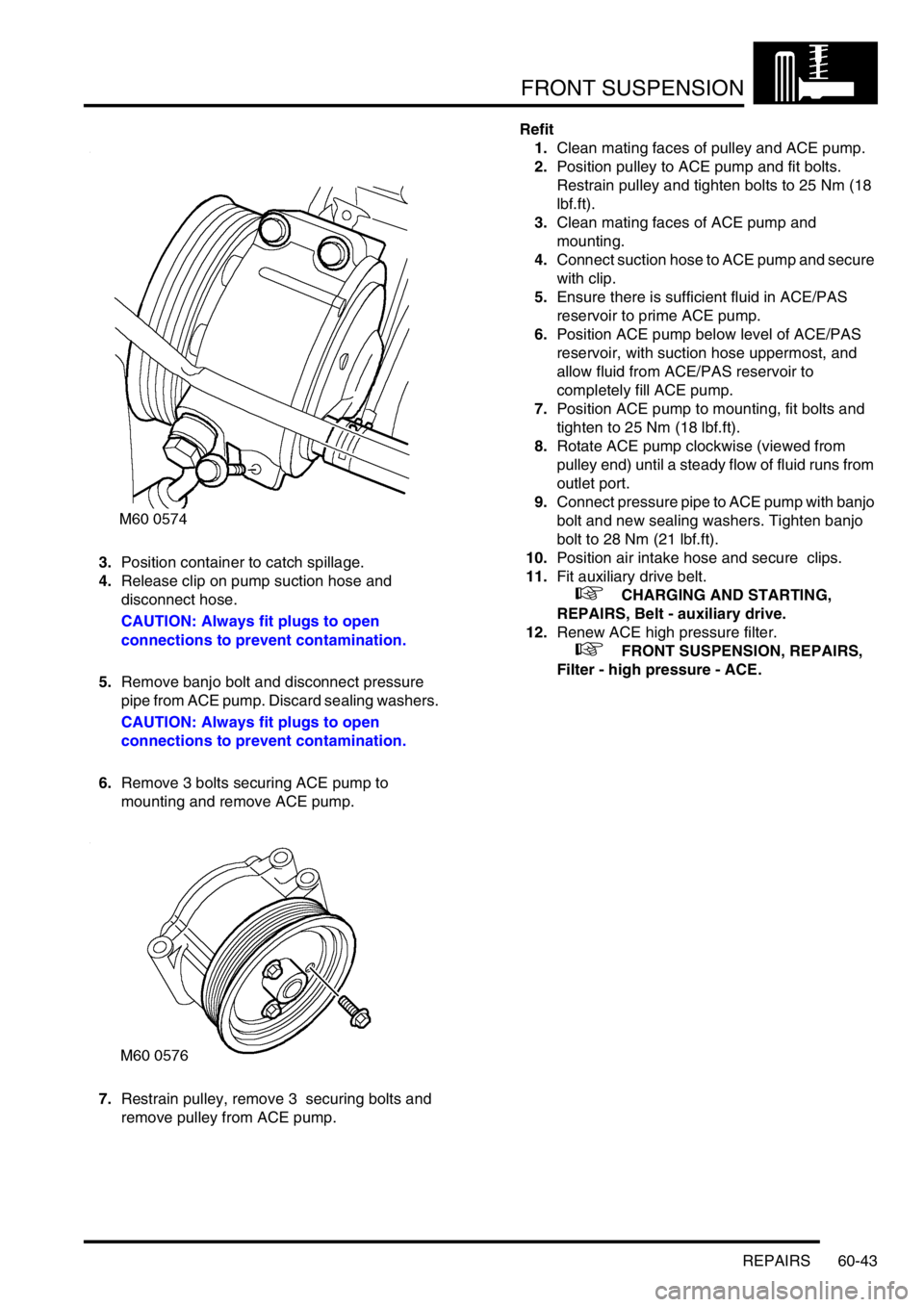

3.Position container to catch spillage.

4.Release clip on pump suction hose and

disconnect hose.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove banjo bolt and disconnect pressure

pipe from ACE pump. Discard sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 3 bolts securing ACE pump to

mounting and remove ACE pump.

7.Restrain pulley, remove 3 securing bolts and

remove pulley from ACE pump. Refit

1.Clean mating faces of pulley and ACE pump.

2.Position pulley to ACE pump and fit bolts.

Restrain pulley and tighten bolts to 25 Nm (18

lbf.ft).

3.Clean mating faces of ACE pump and

mounting.

4.Connect suction hose to ACE pump and secure

with clip.

5.Ensure there is sufficient fluid in ACE/PAS

reservoir to prime ACE pump.

6.Position ACE pump below level of ACE/PAS

reservoir, with suction hose uppermost, and

allow fluid from ACE/PAS reservoir to

completely fill ACE pump.

7.Position ACE pump to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

8.Rotate ACE pump clockwise (viewed from

pulley end) until a steady flow of fluid runs from

outlet port.

9.Connect pressure pipe to ACE pump with banjo

bolt and new sealing washers. Tighten banjo

bolt to 28 Nm (21 lbf.ft).

10.Position air intake hose and secure clips.

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

12.Renew ACE high pressure filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

Page 983 of 1672

FRONT SUSPENSION

60-44 REPAIRS

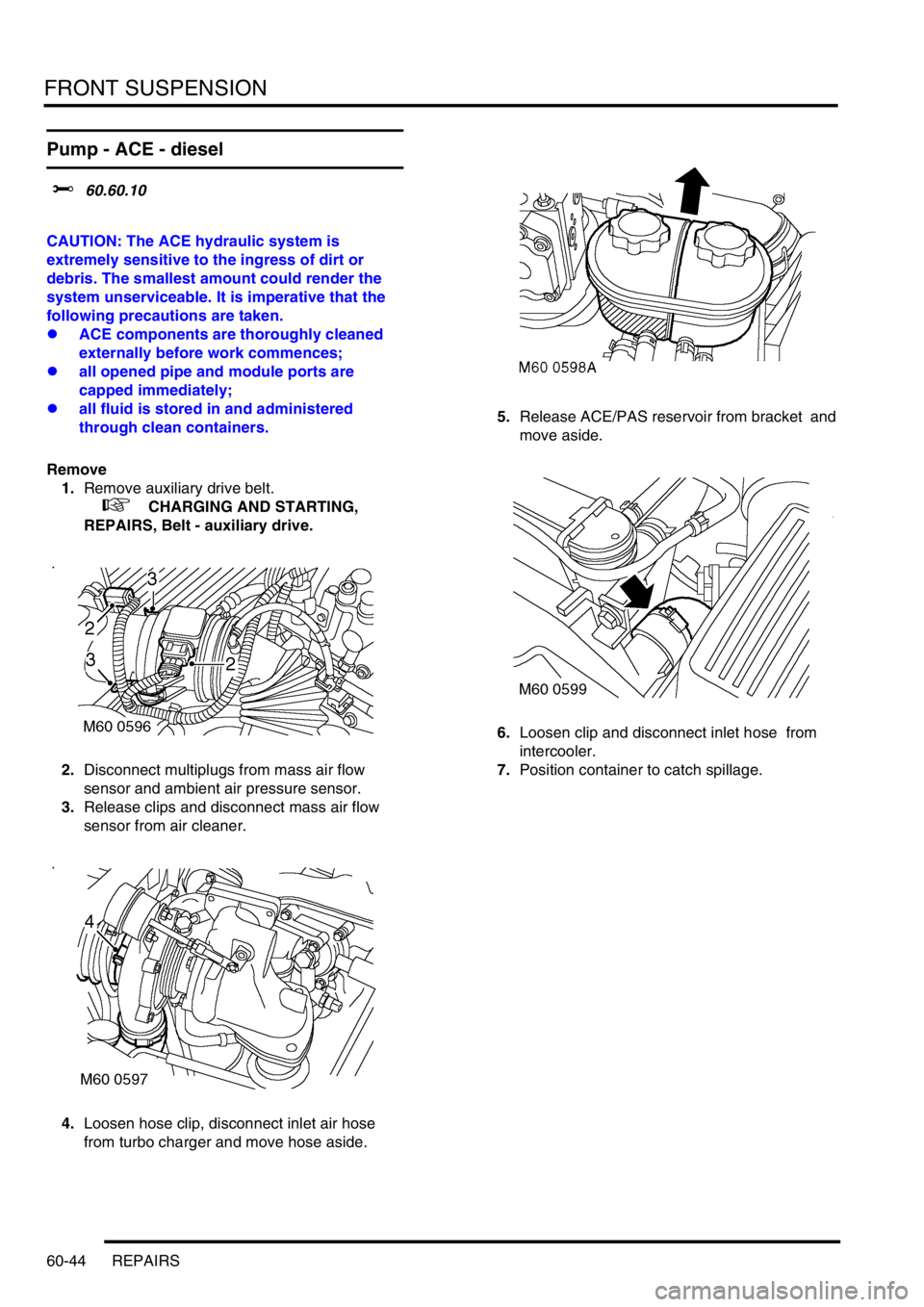

Pump - ACE - diesel

$% 60.60.10

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Disconnect multiplugs from mass air flow

sensor and ambient air pressure sensor.

3.Release clips and disconnect mass air flow

sensor from air cleaner.

4.Loosen hose clip, disconnect inlet air hose

from turbo charger and move hose aside. 5.Release ACE/PAS reservoir from bracket and

move aside.

6.Loosen clip and disconnect inlet hose from

intercooler.

7.Position container to catch spillage.

Page 984 of 1672

FRONT SUSPENSION

REPAIRS 60-45

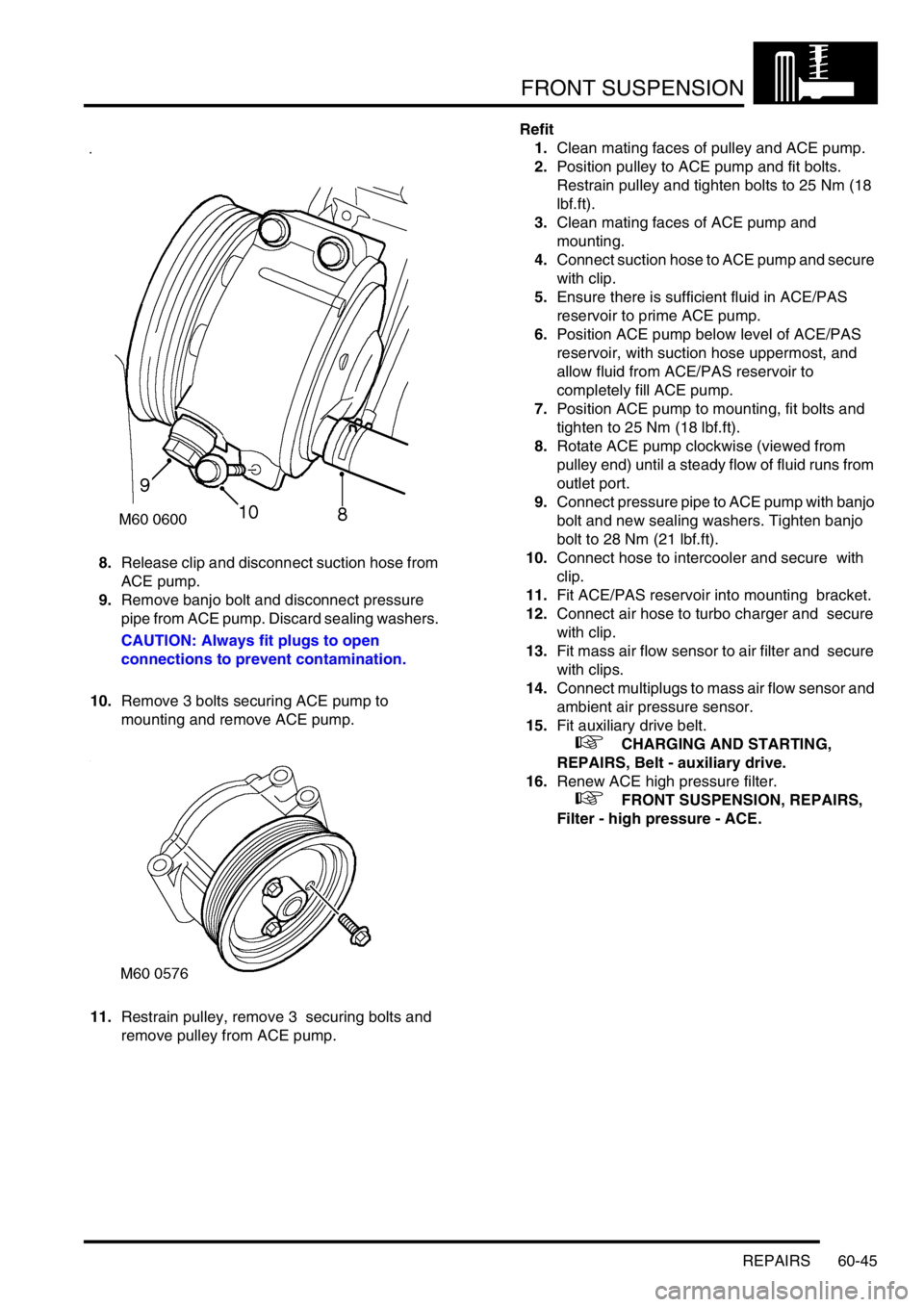

8.Release clip and disconnect suction hose from

ACE pump.

9.Remove banjo bolt and disconnect pressure

pipe from ACE pump. Discard sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

10.Remove 3 bolts securing ACE pump to

mounting and remove ACE pump.

11.Restrain pulley, remove 3 securing bolts and

remove pulley from ACE pump.Refit

1.Clean mating faces of pulley and ACE pump.

2.Position pulley to ACE pump and fit bolts.

Restrain pulley and tighten bolts to 25 Nm (18

lbf.ft).

3.Clean mating faces of ACE pump and

mounting.

4.Connect suction hose to ACE pump and secure

with clip.

5.Ensure there is sufficient fluid in ACE/PAS

reservoir to prime ACE pump.

6.Position ACE pump below level of ACE/PAS

reservoir, with suction hose uppermost, and

allow fluid from ACE/PAS reservoir to

completely fill ACE pump.

7.Position ACE pump to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

8.Rotate ACE pump clockwise (viewed from

pulley end) until a steady flow of fluid runs from

outlet port.

9.Connect pressure pipe to ACE pump with banjo

bolt and new sealing washers. Tighten banjo

bolt to 28 Nm (21 lbf.ft).

10.Connect hose to intercooler and secure with

clip.

11.Fit ACE/PAS reservoir into mounting bracket.

12.Connect air hose to turbo charger and secure

with clip.

13.Fit mass air flow sensor to air filter and secure

with clips.

14.Connect multiplugs to mass air flow sensor and

ambient air pressure sensor.

15.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

16.Renew ACE high pressure filter.

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.