oil filter LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 154 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-15

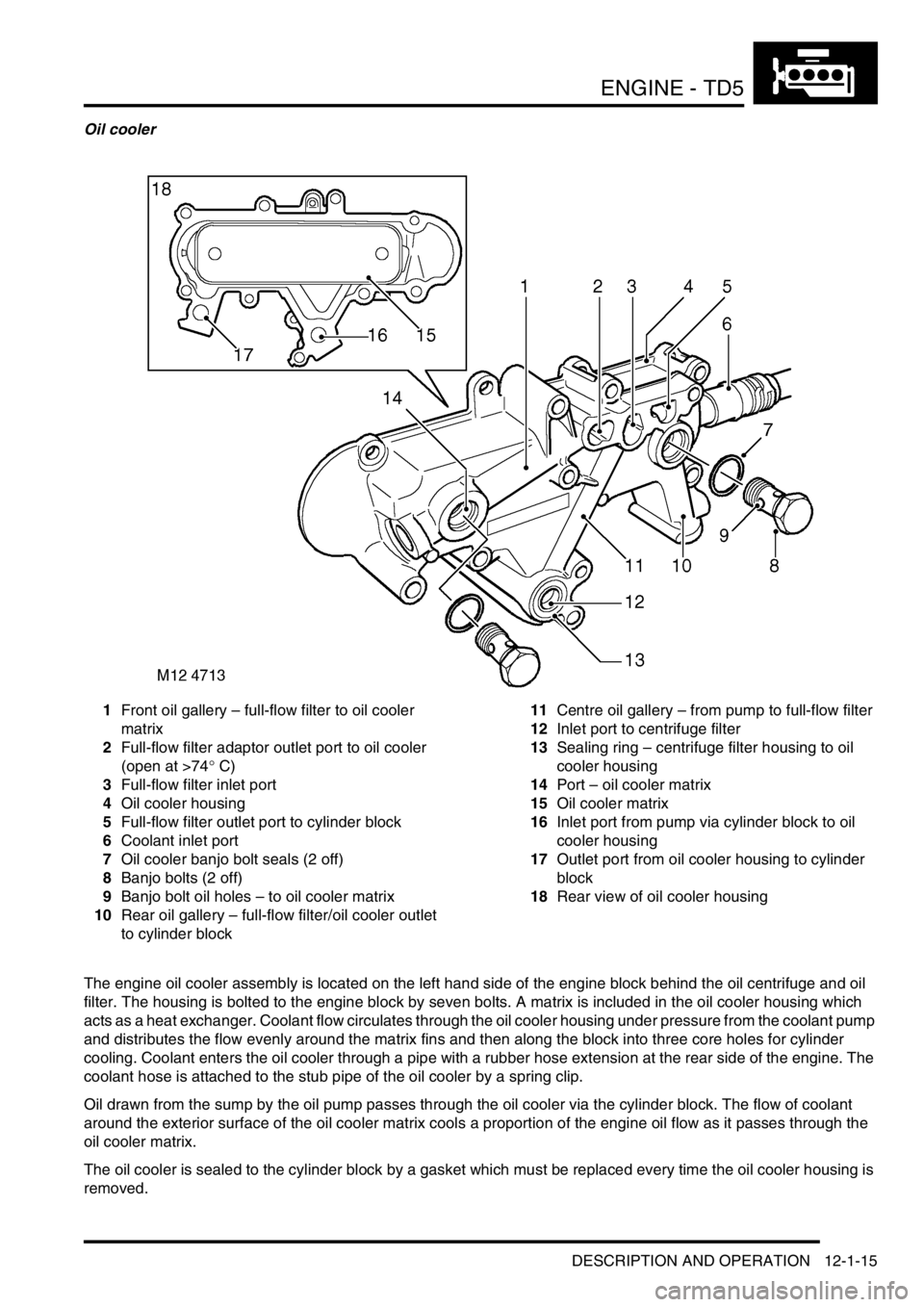

Oil cooler

1Front oil gallery – full-flow filter to oil cooler

matrix

2Full-flow filter adaptor outlet port to oil cooler

(open at >74

° C)

3Full-flow filter inlet port

4Oil cooler housing

5Full-flow filter outlet port to cylinder block

6Coolant inlet port

7Oil cooler banjo bolt seals (2 off)

8Banjo bolts (2 off)

9Banjo bolt oil holes – to oil cooler matrix

10Rear oil gallery – full-flow filter/oil cooler outlet

to cylinder block11Centre oil gallery – from pump to full-flow filter

12Inlet port to centrifuge filter

13Sealing ring – centrifuge filter housing to oil

cooler housing

14Port – oil cooler matrix

15Oil cooler matrix

16Inlet port from pump via cylinder block to oil

cooler housing

17Outlet port from oil cooler housing to cylinder

block

18Rear view of oil cooler housing

The engine oil cooler assembly is located on the left hand side of the engine block behind the oil centrifuge and oil

filter. The housing is bolted to the engine block by seven bolts. A matrix is included in the oil cooler housing which

acts as a heat exchanger. Coolant flow circulates through the oil cooler housing under pressure from the coolant pump

and distributes the flow evenly around the matrix fins and then along the block into three core holes for cylinder

cooling. Coolant enters the oil cooler through a pipe with a rubber hose extension at the rear side of the engine. The

coolant hose is attached to the stub pipe of the oil cooler by a spring clip.

Oil drawn from the sump by the oil pump passes through the oil cooler via the cylinder block. The flow of coolant

around the exterior surface of the oil cooler matrix cools a proportion of the engine oil flow as it passes through the

oil cooler matrix.

The oil cooler is sealed to the cylinder block by a gasket which must be replaced every time the oil cooler housing is

removed.

Page 155 of 1672

ENGINE - TD5

12-1-16 DESCRIPTION AND OPERATION

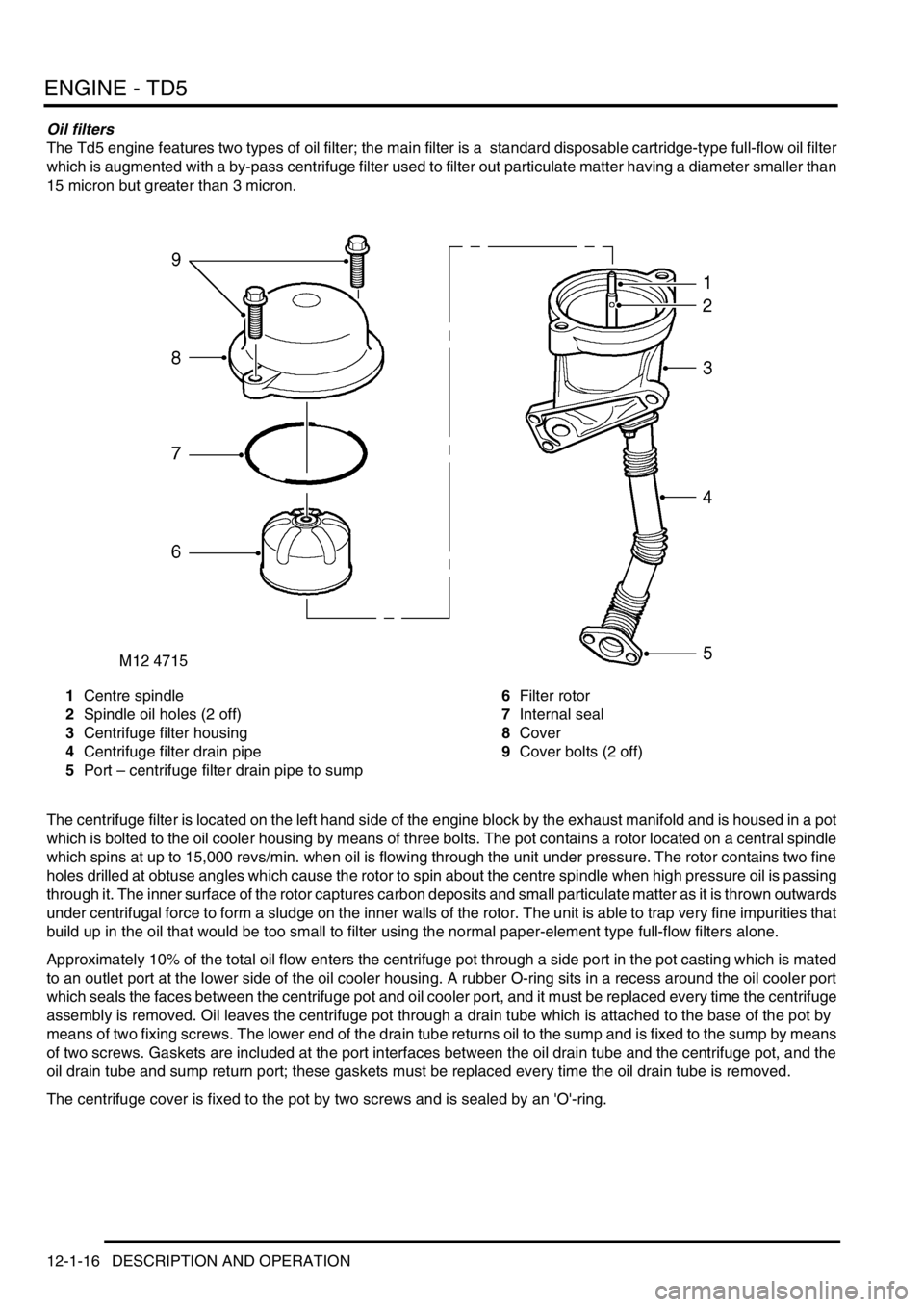

Oil filters

The Td5 engine features two types of oil filter; the main filter is a standard disposable cartridge-type full-flow oil filter

which is augmented with a by-pass centrifuge filter used to filter out particulate matter having a diameter smaller than

15 micron but greater than 3 micron.

1Centre spindle

2Spindle oil holes (2 off)

3Centrifuge filter housing

4Centrifuge filter drain pipe

5Port – centrifuge filter drain pipe to sump6Filter rotor

7Internal seal

8Cover

9Cover bolts (2 off)

The centrifuge filter is located on the left hand side of the engine block by the exhaust manifold and is housed in a pot

which is bolted to the oil cooler housing by means of three bolts. The pot contains a rotor located on a central spindle

which spins at up to 15,000 revs/min. when oil is flowing through the unit under pressure. The rotor contains two fine

holes drilled at obtuse angles which cause the rotor to spin about the centre spindle when high pressure oil is passing

through it. The inner surface of the rotor captures carbon deposits and small particulate matter as it is thrown outwards

under centrifugal force to form a sludge on the inner walls of the rotor. The unit is able to trap very fine impurities that

build up in the oil that would be too small to filter using the normal paper-element type full-flow filters alone.

Approximately 10% of the total oil flow enters the centrifuge pot through a side port in the pot casting which is mated

to an outlet port at the lower side of the oil cooler housing. A rubber O-ring sits in a recess around the oil cooler port

which seals the faces between the centrifuge pot and oil cooler port, and it must be replaced every time the centrifuge

assembly is removed. Oil leaves the centrifuge pot through a drain tube which is attached to the base of the pot by

means of two fixing screws. The lower end of the drain tube returns oil to the sump and is fixed to the sump by means

of two screws. Gaskets are included at the port interfaces between the oil drain tube and the centrifuge pot, and the

oil drain tube and sump return port; these gaskets must be replaced every time the oil drain tube is removed.

The centrifuge cover is fixed to the pot by two screws and is sealed by an 'O'-ring.

Page 156 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-17

1Full-flow filter housing

2Thermostat

3Roll-pin

4Port – feed line to turbocharger

5Outlet port from full-flow filter (> 74

° C)

6Inlet port to full-flow filter

7Outlet port from full-flow filter (< 74

° C)

The main filter is a conventional full-flow cartridge-type filter containing a paper element able to trap particles greater

than 15 micron (0.015 mm) in diameter.

The cartridge is screwed to an adaptor casting by way of a hollow brass threaded insert which connects the filter outlet

port to the adaptor casting. A sealing ring seals the union between the oil filter cartridge and the adaptor casting.

Page 157 of 1672

ENGINE - TD5

12-1-18 DESCRIPTION AND OPERATION

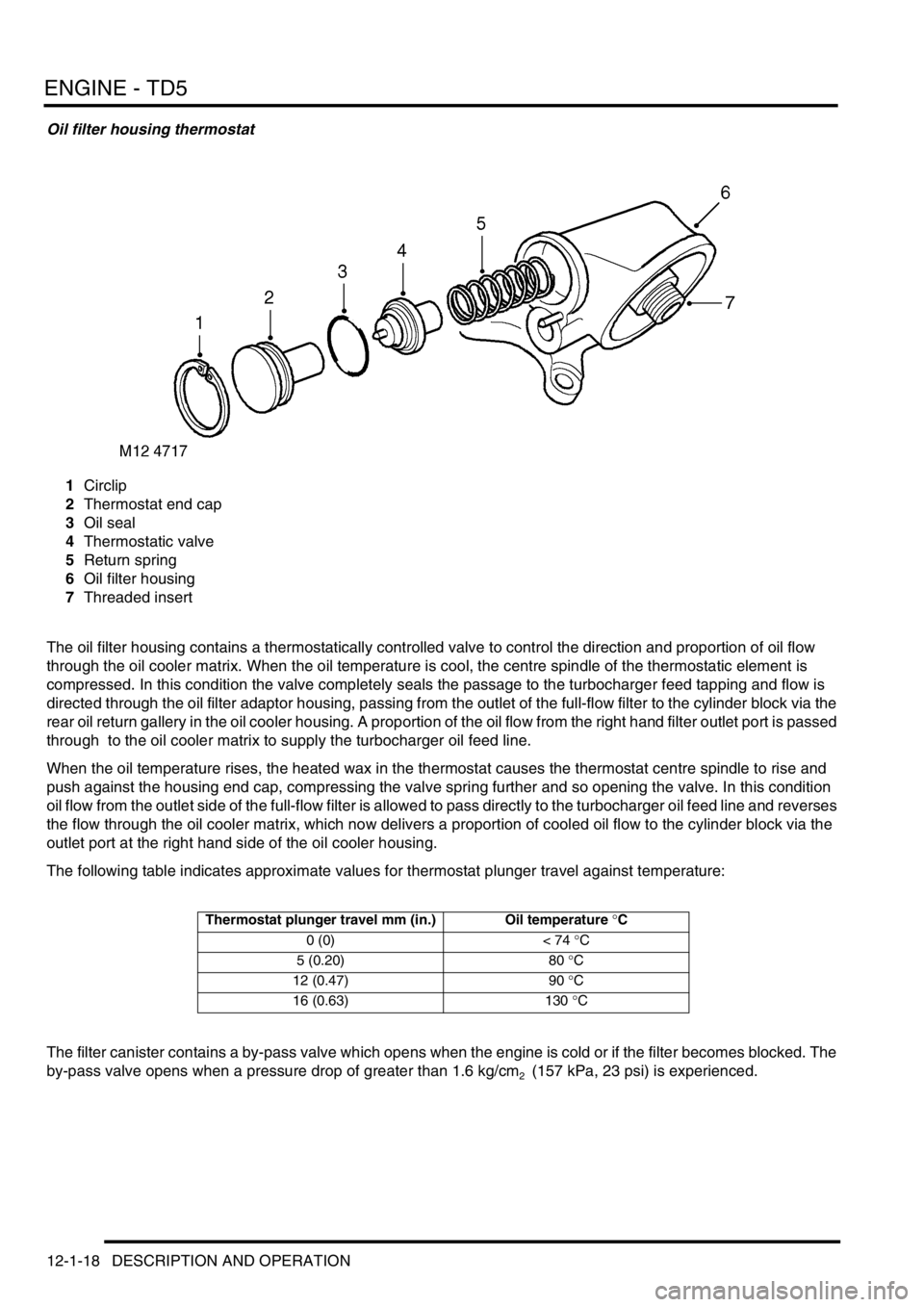

Oil filter housing thermostat

1Circlip

2Thermostat end cap

3Oil seal

4Thermostatic valve

5Return spring

6Oil filter housing

7Threaded insert

The oil filter housing contains a thermostatically controlled valve to control the direction and proportion of oil flow

through the oil cooler matrix. When the oil temperature is cool, the centre spindle of the thermostatic element is

compressed. In this condition the valve completely seals the passage to the turbocharger feed tapping and flow is

directed through the oil filter adaptor housing, passing from the outlet of the full-flow filter to the cylinder block via the

rear oil return gallery in the oil cooler housing. A proportion of the oil flow from the right hand filter outlet port is passed

through to the oil cooler matrix to supply the turbocharger oil feed line.

When the oil temperature rises, the heated wax in the thermostat causes the thermostat centre spindle to rise and

push against the housing end cap, compressing the valve spring further and so opening the valve. In this condition

oil flow from the outlet side of the full-flow filter is allowed to pass directly to the turbocharger oil feed line and reverses

the flow through the oil cooler matrix, which now delivers a proportion of cooled oil flow to the cylinder block via the

outlet port at the right hand side of the oil cooler housing.

The following table indicates approximate values for thermostat plunger travel against temperature:

The filter canister contains a by-pass valve which opens when the engine is cold or if the filter becomes blocked. The

by-pass valve opens when a pressure drop of greater than 1.6 kg/cm

2 (157 kPa, 23 psi) is experienced.

Thermostat plunger travel mm (in.) Oil temperature °C

0 (0) < 74 °C

5 (0.20) 80 °C

12 (0.47) 90 °C

16 (0.63) 130 °C

Page 158 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-19

Oil Pressure switch

The oil pressure switch is located in a port on the outlet side of the oil cooler housing. It detects when a safe operating

pressure has been reached during engine starting and initiates the illumination of a warning light in the instrument

pack if the pressure drops below a given value.

Crankshaft, sump and oil pump components

The crankshaft, sump and oil pump components are described below:

Sump

The sump is a wet-type, of aluminium construction and is sealed to the engine block by means of a rubber gasket and

twenty fixing bolts. The four bolts at the gearbox end of the sump are longer than the other sixteen bolts.

The sump gasket incorporates compression limiters (integrated metal sleeves) at the bolt holes, which are included

to prevent distortion of the gasket when the sump to cylinder block bolts are being tightened.

The oil drain plug is fitted at the bottom of the oil sump reservoir. An oil return drain pipe is also attached to the oil

sump which returns oil from the centrifugal filter.

Stiffener Plate

The stiffener plate assembly provides lower engine block rigidity and utilises dowels to align it to the bottom of the

cylinder block. A rotary oil pump is integral with the stiffener plate and an oil pick-up and strainer assembly is fitted

to the underside of the stiffener plate. The stiffener and oil pump assembly is secured to the cylinder block by 22 bolts.

Page 168 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-29

Lubrication circuit

Cylinder block flow

1Oil squirt jets (5 off)

2Main oil delivery gallery

3Inflow from oil cooler housing

4Flow to oil cooler / filters (from oil pump via

cylinder block)

5Sump

6Oil pick-up pipe

7Flow from oil pump (relief-valve in housing)

8Oil pump9Cross-drilling supply to main and crankshaft

bearings

10To cylinder head

Page 169 of 1672

ENGINE - TD5

12-1-30 DESCRIPTION AND OPERATION

Oil from the sump is drawn up through a two-piece plastic pick-up which contains a mesh to siphon any relatively large

pieces of material which could cause damage to the pump. The head of the pick-up is centrally immersed in the sump

oil and oil is delivered to the inlet side of the eccentric rotor pump through a gallery in the stiffener plate.

Pressurised oil from the pump is passed through to the cylinder block where it is delivered to the centrifuge filter and

full-flow filter via a port in the RH cylinder block which interfaces with a port in the centre gallery of the oil cooler

housing. The oil pump contains an oil pressure relief valve which opens to allow oil to be recirculated back around the

pump if the oil pressure increases to a high enough level.

10% of the oil flow from the pump is diverted through the centrifuge filter and returned to the sump via the centrifuge

filter drain tube. The remaining 90% of the oil passes through the standard full-flow filter to the main oil gallery in the

cylinder block.

Page 170 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-31

Oil cooler / Filter flow (thermostat open)

1To cylinder block main gallery (from rear of oil

cooler housing)

2Oil cooler housing

3Oil pressure switch

4Full-flow filter

5Centrifuge filter6Return to sump

7Flow from oil pump (via cylinder block)

8Oil cooler matrix

Page 171 of 1672

ENGINE - TD5

12-1-32 DESCRIPTION AND OPERATION

When the engine temperature is below 74° C, the thermostat in the full-flow filter housing is closed and a proportion

of the oil flow to the main oil gallery is diverted to the oil cooler to supply an oil feed to the turbocharger bearings. Oil

passes through the oil cooler to the front gallery in the oil cooler housing where there is a tapping to connect the feed

pipe to the turbocharger. Oil used by the turbocharger bearings is returned to the sump through an oil drain pipe which

connects to a port in the LH side of the cylinder block.

The remainder of the oil flow leaving the full-flow filter outlet is passed into the cylinder block via a port at the rear of

oil cooler rear gallery.

When the oil temperature rises above 74

° C the thermostat in the full-flow filter adaptor housing begins to open to

allow a proportion of the oil from the full-flow filter to pass through the oil cooler before it reaches the main oil gallery

in the cylinder block. In this instance, oil supply to the turbocharger bearings is fed directly from the full-flow filter

without first passing through the oil cooler. Between 74

° C and 88° C the thermostat valve plunger opens by about

9mm to allow proportionally more oil to flow through the oil cooler before being passed to the cylinder block main oil

delivery gallery. Above 88

°C the thermostat valve continues to open by about 1mm for every 10° C increase in

temperature until the valve is fully open, when all the oil flow to the cylinder block is forced to pass to the cylinder block

via the oil cooler.

An oil pressure switch is located in a port in the rear gallery of the oil cooler housing to sense the oil pressure level

before flow enters the main oil gallery in the engine block. A warning lamp in the instrument cluster is switched on if

the oil pressure is detected as being too low.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Drillings from the cylinder block main oil gallery direct oil to the crankshaft main bearings and cross drillings in the

crankshaft direct oil to the big-end bearings. An additional five drillings in the cylinder block supply oil at reduced

pressure to the oil squirt jets for piston cooling and gudgeon pin lubrication.

Oil supply from the cylinder block is then passed to the cylinder head galleries through a non-return valve which is

included as an integral item in the lower face of the cylinder head.

Page 192 of 1672

ENGINE - TD5

REPAIRS 12-1-53

Mounting - front - LH

$% 12.45.01

Remove

1.Remove centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

2.Remove 3 bolts, remove oil filter adaptor

housing and discard gasket.

3.Fit suitable lifting chains to support engine.

4.With assistance remove 2 bolts securing

engine mounting to chassis.

5.Remove 4 bolts securing engine mounting

bracket to cylinder block.

6.Remove nut securing mounting to mounting

bracket.

7.Remove mounting and mounting bracket.

8.Remove mounting shield.

Refit

1.Fit shield to mounting. 2.Fit mounting and mounting bracket.

3.Fit mounting bracket to cylinder block and

tighten – bolts securing front LH engine

mounting bracket to cylinder block to 48 Nm (35

lbf.ft).

4.With assistance, fit mounting to chassis and

tighten – bolts securing front LH engine

mounting to chassis to 85 Nm (63 lbf.ft).

5.Fit mounting to mounting bracket and tighten –

nut securing front LH mounting to mounting

bracket to 85 Nm (63 lbf.ft).

6.Remove engine support chains.

7.Clean oil filter adaptor housing and mating

face.

8.Fit oil filter adaptor housing to oil cooler

housing and tighten bolts to 25 Nm (18 lbf.ft).

9.Fit centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.