oil filter LAND ROVER DISCOVERY 2002 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 269 of 1672

ENGINE - V8

12-2-26 REPAIRS

Engine assembly

$% 12.41.01.99

Remove

1.Drain engine oil and remove oil filter.

2.Remove radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

3.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

4.Remove ignition coil assemblies.

5.Position absorbent material to catch spillage

and disconnect fuel pipe from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Release 2 hose clips and remove top hose.

7.Using a 15 mm spanner, release auxiliary drive

belt tension and remove drive belt. 8.Remove 3 bolts securing ACE pump, release

pump and tie aside.

9.Disconnect multiplug from A/C compressor.

10.Remove 4 bolts securing A/C compressor,

release compressor and tie aside.

Page 273 of 1672

ENGINE - V8

12-2-30 REPAIRS

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes. 27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 277 of 1672

ENGINE - V8

12-2-34 REPAIRS

4.Ensure ring gear is correctly seated around the

complete circumference of flywheel and allow

to cool.

5.Fit flywheel.

+ ENGINE - V8, REPAIRS, Flywheel.

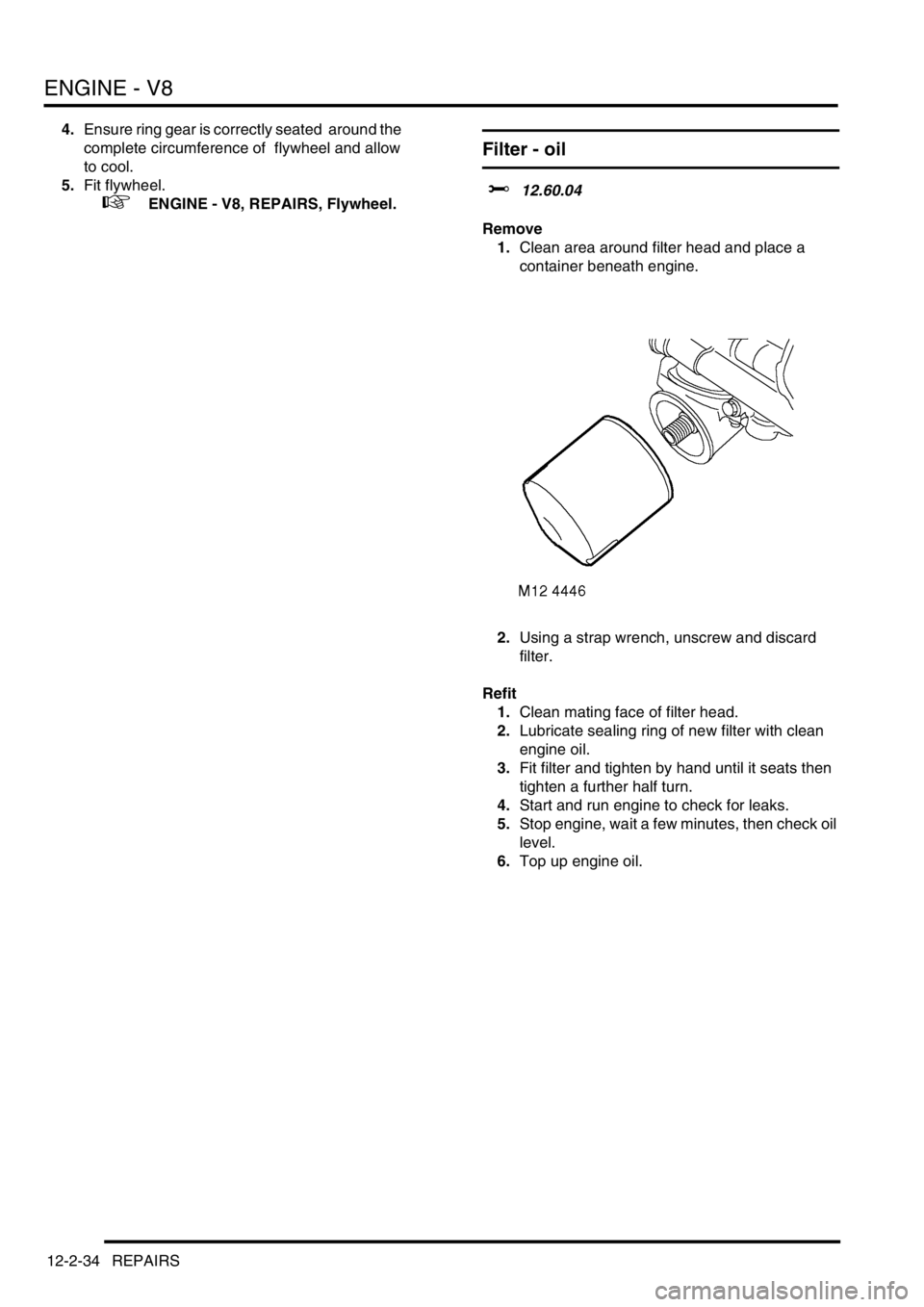

Filter - oil

$% 12.60.04

Remove

1.Clean area around filter head and place a

container beneath engine.

2.Using a strap wrench, unscrew and discard

filter.

Refit

1.Clean mating face of filter head.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit filter and tighten by hand until it seats then

tighten a further half turn.

4.Start and run engine to check for leaks.

5.Stop engine, wait a few minutes, then check oil

level.

6.Top up engine oil.

Page 278 of 1672

ENGINE - V8

REPAIRS 12-2-35

Strainer - oil pick-up

$% 12.60.20

Remove

1.Remove sump gasket.

+ ENGINE - V8, REPAIRS, Gasket -

sump.

2.Remove 2 bolts and one nut securing oil pick-

up strainer.

3.Remove oil pick-up strainer.

4.Collect spacer from stud.

5.Remove and discard 'O'ring.

Refit

1.Clean oil pick up strainer and 'O' ring recess.

2.Lubricate and fit new 'O' ring.

3.Locate spacer on stud.

4.Position oil pick-up strainer, fit bolts and tighten

to 10 Nm (8 lbf.ft). Fit nut and tighten to 22 Nm

(16 lbf.ft).

5.Fit new sump gasket.

+ ENGINE - V8, REPAIRS, Gasket -

sump.

Pump - oil

$% 12.60.26

Remove

1.Remove timing gear cover gasket.

+ ENGINE - V8, REPAIRS, Gasket -

timing gear cover.

2.Remove bolt securing CMP sensor, remove

clamp and sensor.

3.Remove 6 bolts securing coolant pump,

remove pump and discard gasket.

4.Remove oil pressure switch and discard

sealing washer.

5.Remove 4 bolts securing oil filter head, remove

filter head and discard 2 'O' rings.

6.Remove filter head adaptor.

Refit

1.Ensure filter head adaptor is clean and apply

Loctite 577 sealant to thread.

2.Fit filter head adaptor and tighten bolts to 13

Nm (9 lbf.ft).

3.Clean filter head and mating face.

4.Fit new 'O' rings to filter head and filter head

adaptor.

5.Fit filter head and tighten bolts to 8 Nm (6 lbf.ft).

6.Ensure oil pressure switch and mating face is

clean.

7.Fit new sealing washer and tighten switch to 15

Nm (11 lbf.ft).

Page 283 of 1672

ENGINE - V8

12-2-40 REPAIRS

11.Push against coupling release rings and

disconnect both hoses from oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

12.Remove screw securing oil cooler to radiator.

13.Release cooler from its location on radiator.

14.Release radiator lower mountings from

location in chassis and carefully move radiator

towards engine sufficiently only to release

engine oil cooler from radiator.

15.Remove engine oil cooler.

Refit

1.Fit engine oil cooler to radiator, engage in

location and secure with screw.

2.Fit radiator to location in chassis.

3.Ensure connections are clean, then secure

hoses to oil cooler.

4.Fit extension brackets to radiator and secure

with bolts.

5.Fit brackets with rubber mounts to extension

brackets and secure to air conditioning

condenser with screws.

6.Fit radiator upper mounting brackets and

secure to body with bolts.

7.Fit LH horn and secure with nut.

8.Fit LH and RH air deflectors to front panel and

secure with scrivets.

9.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY..

10.Fit cooling fan cowl and secure with fixings.

11.Fit battery cover and secure with fixings.

12.Top up engine oil.

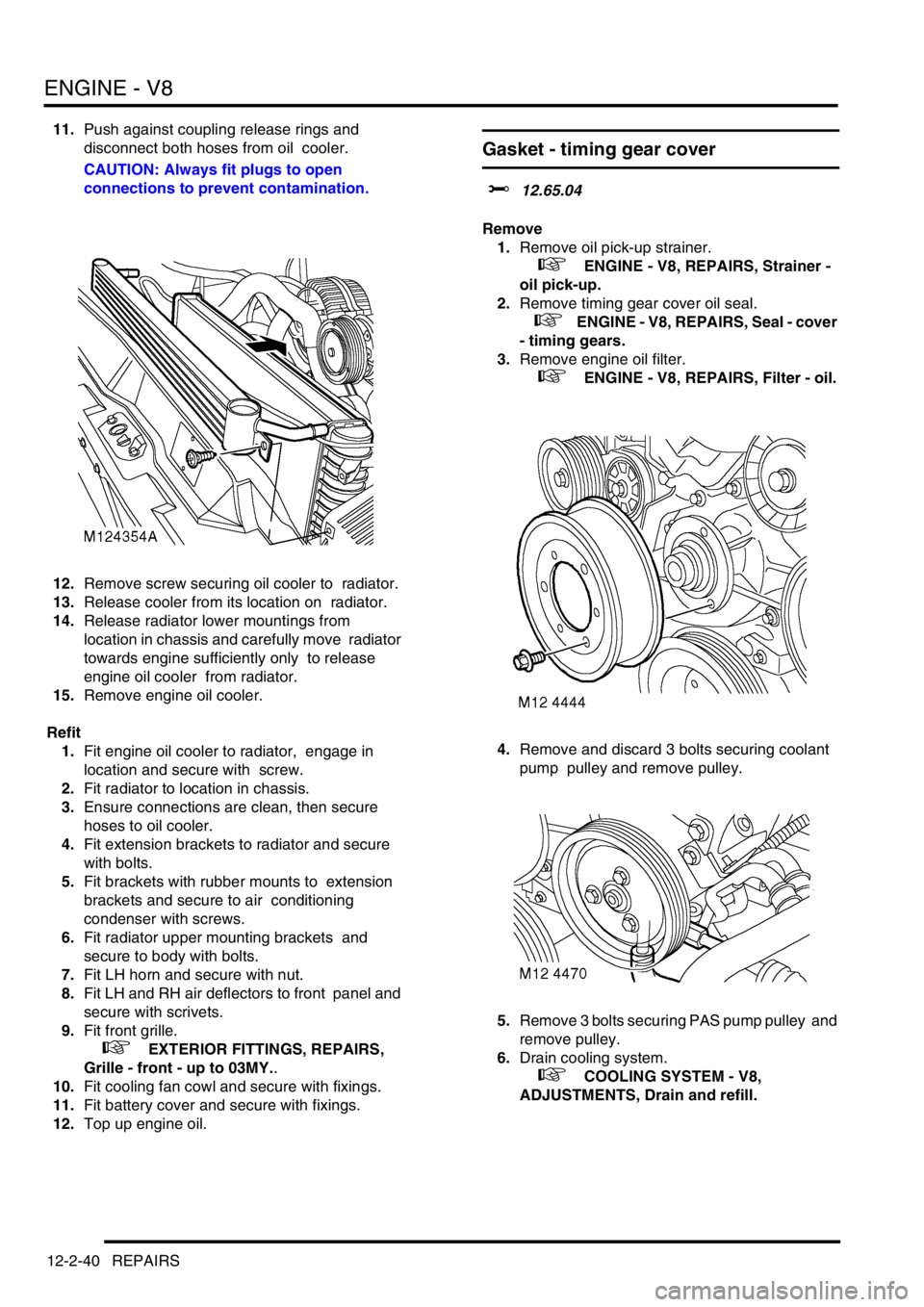

Gasket - timing gear cover

$% 12.65.04

Remove

1.Remove oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

2.Remove timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

3.Remove engine oil filter.

+ ENGINE - V8, REPAIRS, Filter - oil.

4.Remove and discard 3 bolts securing coolant

pump pulley and remove pulley.

5.Remove 3 bolts securing PAS pump pulley and

remove pulley.

6.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 285 of 1672

ENGINE - V8

12-2-42 REPAIRS

8.Ensure mating faces of PAS pump pulley and

drive flange are clean, fit pulley and tighten

bolts to 22 Nm (16 lbf.ft).

9.Remove all traces of thread locking material

from coolant pump pulley drive flange bolt

holes using an M8 tap.

10.Ensure mating faces of coolant pump pulley

and drive flange are clean, fit pulley and tighten

new Patchlok bolts to 22 Nm (16 lbf.ft).

11.Ensure mating faces of oil filter and adaptor are

clean, smear clean engine oil onto seal and fit

filter.

12.Fit timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

13.Fit oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

14.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

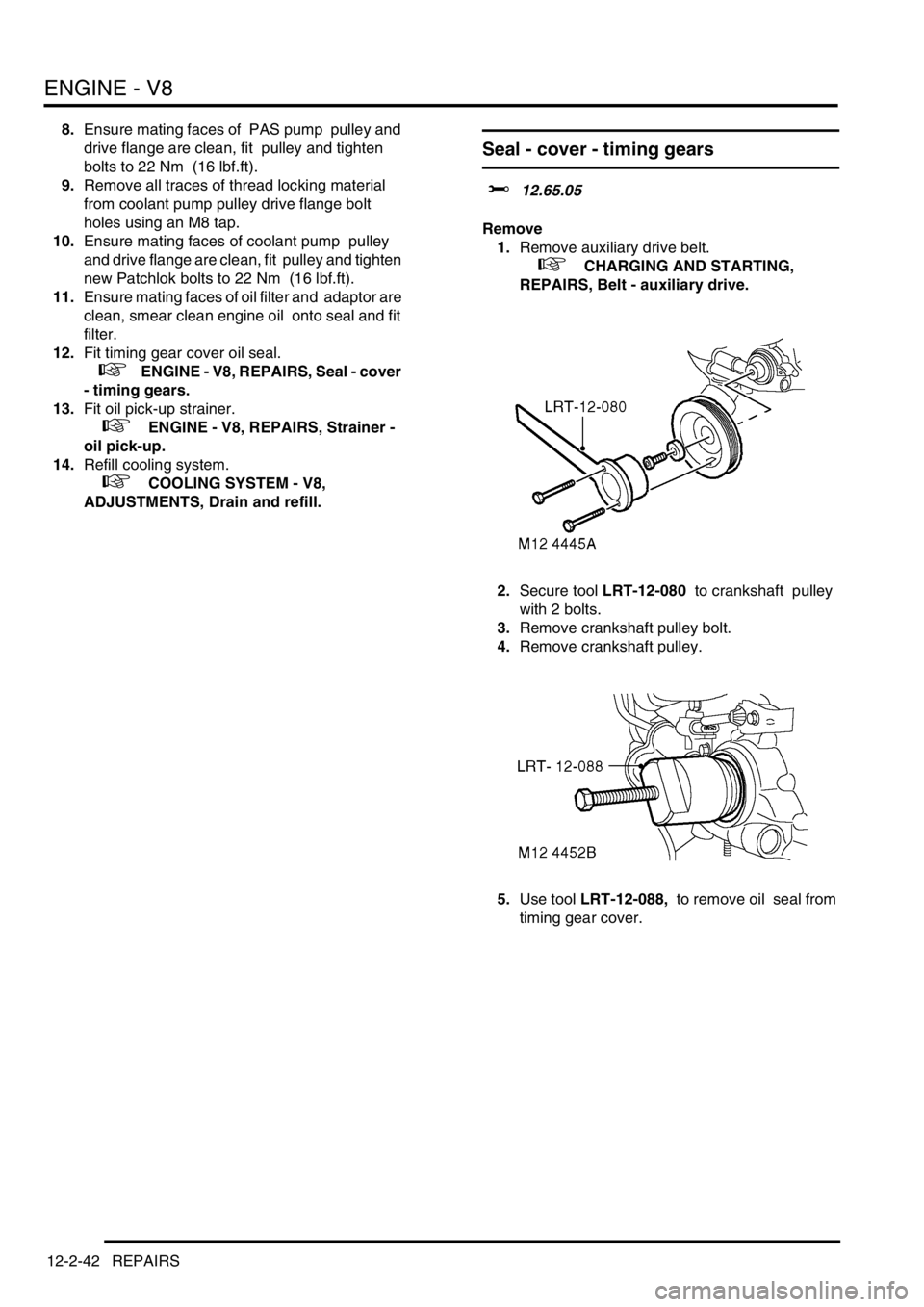

Seal - cover - timing gears

$% 12.65.05

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Secure tool LRT-12-080 to crankshaft pulley

with 2 bolts.

3.Remove crankshaft pulley bolt.

4.Remove crankshaft pulley.

5.Use tool LRT-12-088, to remove oil seal from

timing gear cover.

Page 299 of 1672

ENGINE - V8

12-2-56 OVERHAUL

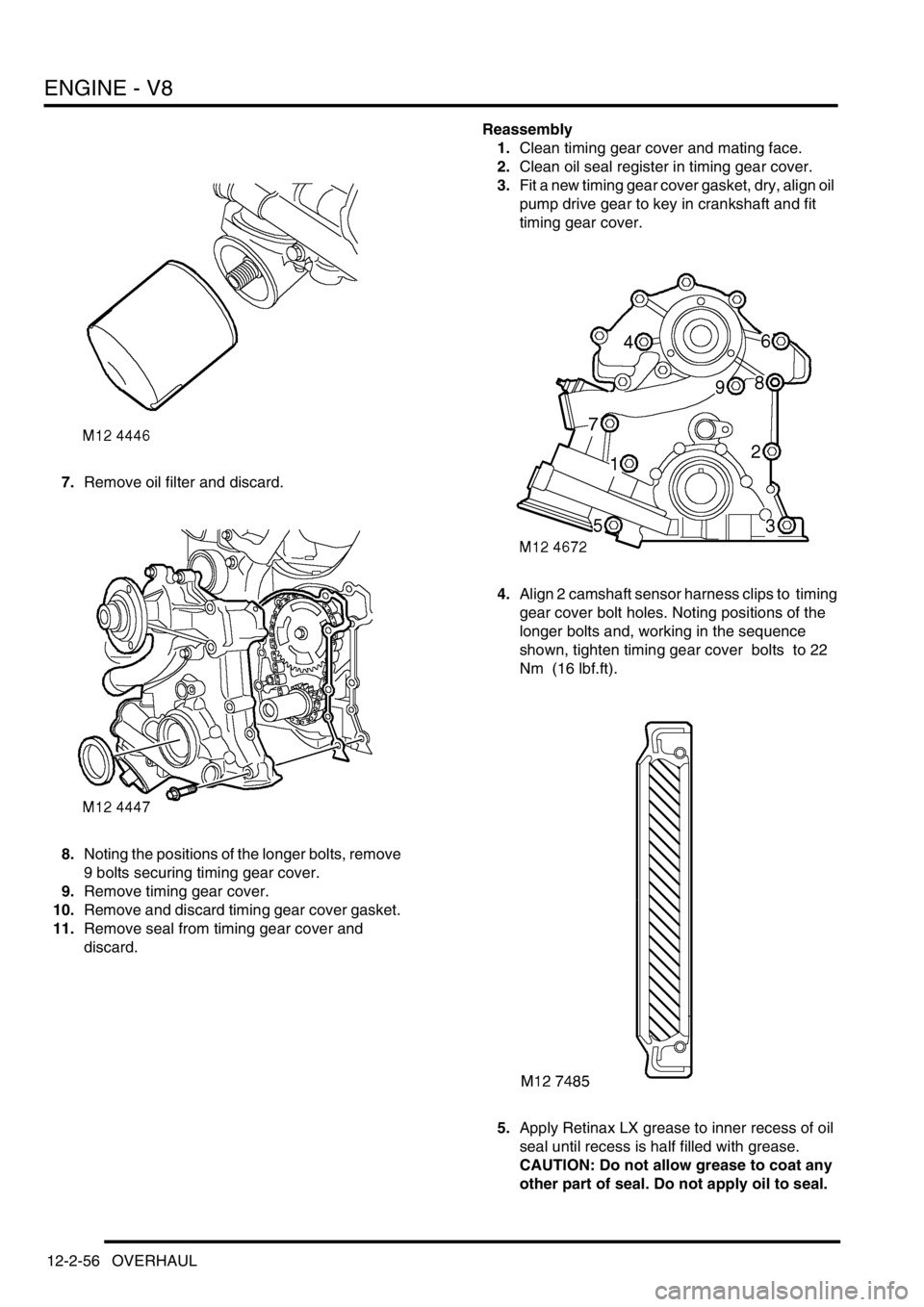

7.Remove oil filter and discard.

8.Noting the positions of the longer bolts, remove

9 bolts securing timing gear cover.

9.Remove timing gear cover.

10.Remove and discard timing gear cover gasket.

11.Remove seal from timing gear cover and

discard. Reassembly

1.Clean timing gear cover and mating face.

2.Clean oil seal register in timing gear cover.

3.Fit a new timing gear cover gasket, dry, align oil

pump drive gear to key in crankshaft and fit

timing gear cover.

4.Align 2 camshaft sensor harness clips to timing

gear cover bolt holes. Noting positions of the

longer bolts and, working in the sequence

shown, tighten timing gear cover bolts to 22

Nm (16 lbf.ft).

5.Apply Retinax LX grease to inner recess of oil

seal until recess is half filled with grease.

CAUTION: Do not allow grease to coat any

other part of seal. Do not apply oil to seal.

Page 300 of 1672

ENGINE - V8

OVERHAUL 12-2-57

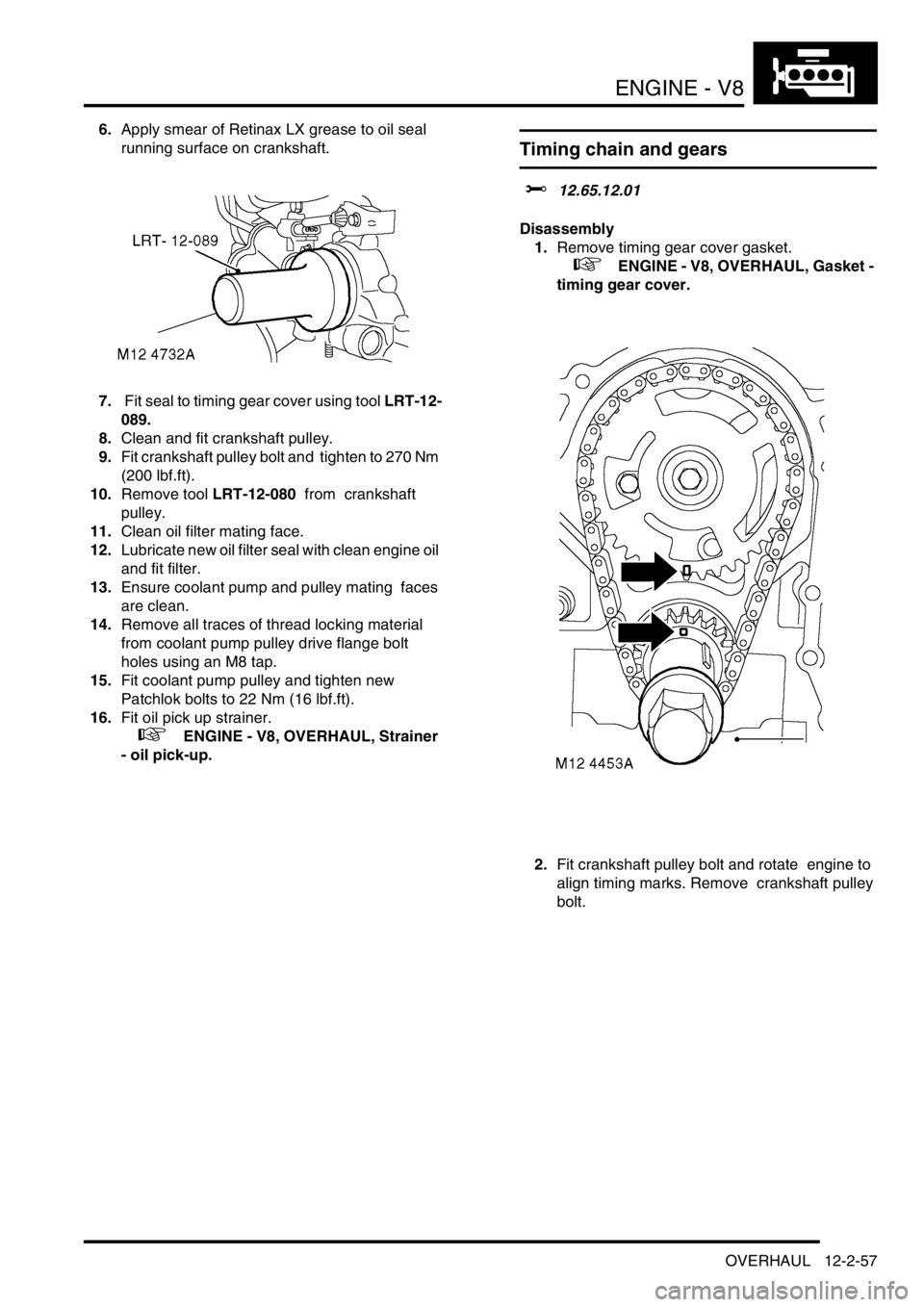

6.Apply smear of Retinax LX grease to oil seal

running surface on crankshaft.

7. Fit seal to timing gear cover using tool LRT-12-

089.

8.Clean and fit crankshaft pulley.

9.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

10.Remove tool LRT-12-080 from crankshaft

pulley.

11.Clean oil filter mating face.

12.Lubricate new oil filter seal with clean engine oil

and fit filter.

13.Ensure coolant pump and pulley mating faces

are clean.

14.Remove all traces of thread locking material

from coolant pump pulley drive flange bolt

holes using an M8 tap.

15.Fit coolant pump pulley and tighten new

Patchlok bolts to 22 Nm (16 lbf.ft).

16.Fit oil pick up strainer.

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

Timing chain and gears

$% 12.65.12.01

Disassembly

1.Remove timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

2.Fit crankshaft pulley bolt and rotate engine to

align timing marks. Remove crankshaft pulley

bolt.

Page 318 of 1672

ENGINE - V8

OVERHAUL 12-2-75

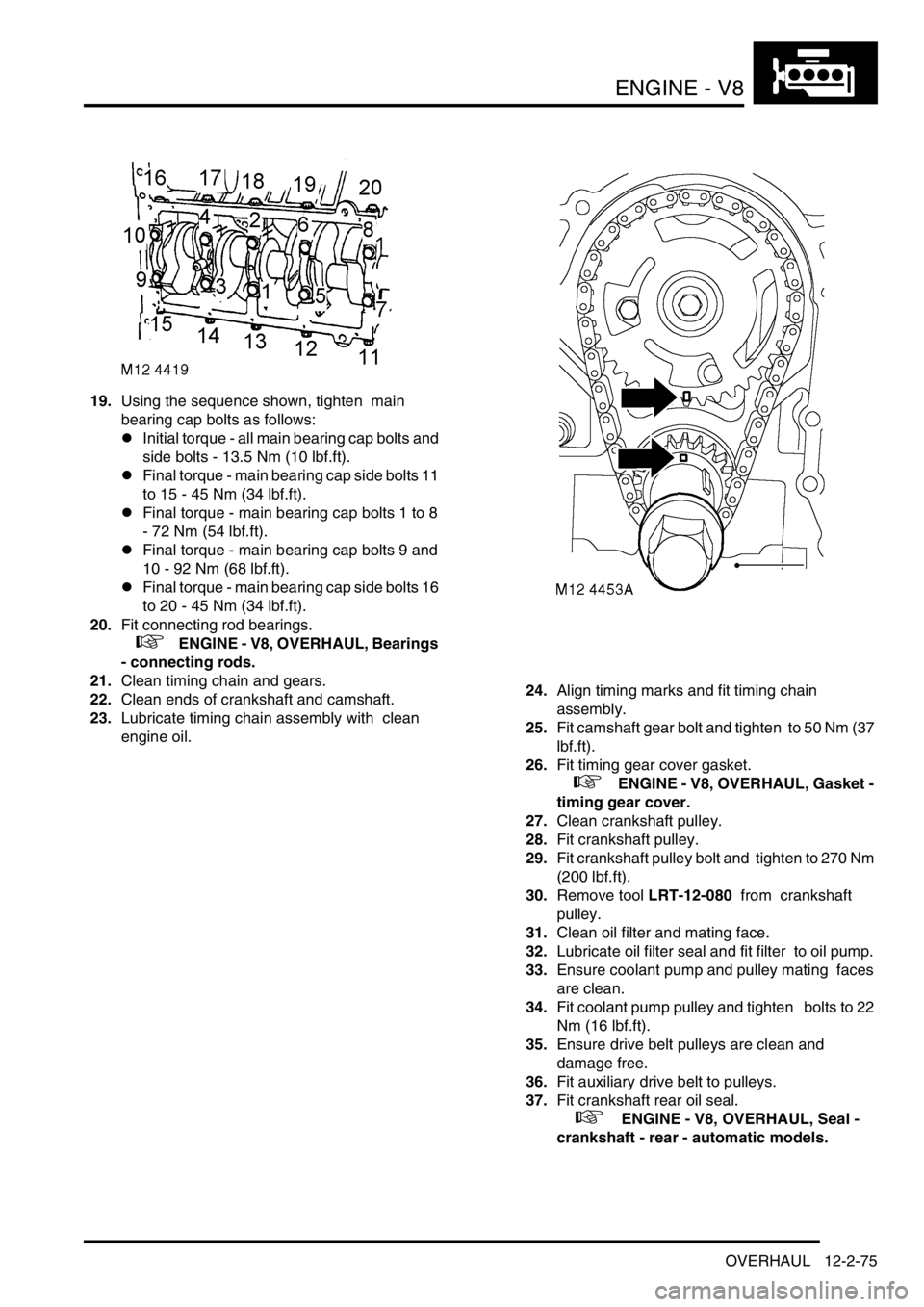

19.Using the sequence shown, tighten main

bearing cap bolts as follows:

lInitial torque - all main bearing cap bolts and

side bolts - 13.5 Nm (10 lbf.ft).

lFinal torque - main bearing cap side bolts 11

to 15 - 45 Nm (34 lbf.ft).

lFinal torque - main bearing cap bolts 1 to 8

- 72 Nm (54 lbf.ft).

lFinal torque - main bearing cap bolts 9 and

10 - 92 Nm (68 lbf.ft).

lFinal torque - main bearing cap side bolts 16

to 20 - 45 Nm (34 lbf.ft).

20.Fit connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

21.Clean timing chain and gears.

22.Clean ends of crankshaft and camshaft.

23.Lubricate timing chain assembly with clean

engine oil. 24.Align timing marks and fit timing chain

assembly.

25.Fit camshaft gear bolt and tighten to 50 Nm (37

lbf.ft).

26.Fit timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

27.Clean crankshaft pulley.

28.Fit crankshaft pulley.

29.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

30.Remove tool LRT-12-080 from crankshaft

pulley.

31.Clean oil filter and mating face.

32.Lubricate oil filter seal and fit filter to oil pump.

33.Ensure coolant pump and pulley mating faces

are clean.

34.Fit coolant pump pulley and tighten bolts to 22

Nm (16 lbf.ft).

35.Ensure drive belt pulleys are clean and

damage free.

36.Fit auxiliary drive belt to pulleys.

37.Fit crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

Page 346 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-9

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems are

fitted to Land Rover vehicles which are designed to maintain the emission levels within the legal limits pertaining for

the specified market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order so that it operates at its optimal condition. In particular, ignition

timing has an effect on the production of HC and NO

x emissions, with the harmful emissions rising as the ignition

timing is advanced.

CAUTION: In many countries it is against the law for a vehicle owner or an unauthorised dealer to modify or

tamper with emission control equipment. In some cases, the vehicle owner and/or the dealer may even be

liable for prosecution.

The engine management ECM is fundamental for controlling the emission control systems. In addition to controlling

normal operation, the system complies with On Board Diagnostic (OBD) system strategies. The system monitors and

reports on faults detected with ignition, fuelling and exhaust systems which cause an excessive increase in tailpipe

emissions. This includes component failures, engine misfire, catalyst damage, catalyst efficiency, fuel evaporative

loss and exhaust leaks.

When an emission relevant fault is determined, the fault condition is stored in the ECM memory. For NAS vehicles,

the MIL warning light on the instrument pack will be illuminated when the fault is confirmed. Confirmation of a fault

condition occurs if the fault is still found to be present during the driving cycle subsequent to the one when the fault

was first detected.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The following types of supplementary control system are used to reduce harmful emissions released into the

atmosphere from the vehicle:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust emission control – to limit the undesirable by-products of combustion.

3Fuel vapour evaporative loss control – to restrict the emission of fuel through evaporation from the fuel

system.

4Fuel leak detection system (NAS only) – there are two types of system which may be used to check the

evaporative emission system for the presence of leaks from the fuel tank to purge valve.

aVacuum leak detection test – checks for leaks down to 1 mm (0.04 in.) in diameter.

bPositive pressure leak detection test – utilises a leak detection pump to check for leaks down to 0.5 mm (0.02

in.) in diameter.

5Secondary air injection system (NAS only) – to reduce emissions experienced during cold starting.

Crankcase emission control system

The concentration of hydrocarbons in the crankcase of an engine is much greater than that in the vehicle's exhaust

system. In order to prevent the emission of these hydrocarbons into the atmosphere, crankcase emission control

systems are employed and are a standard legal requirement.

The crankcase ventilation system is an integral part of the air supply to the engine combustion chambers and it is

often overlooked when diagnosing problems associated with engine performance. A blocked ventilation pipe or filter

or excessive air leak into the inlet system through a damaged pipe or a leaking gasket can affect the air:fuel mixture,

performance and efficiency of the engine. Periodically check the ventilation hoses are not cracked and that they are

securely fitted to form airtight connections at their relevant ports.

The purpose of the crankcase ventilation system is to ensure that any noxious gas generated in the engine crankcase

is rendered harmless by complete burning of the fuel in the combustion chamber. Burning the crankcase vapours in

a controlled manner decreases the HC pollutants that could be emitted and helps to prevent the development of

sludge in the engine oil as well as increasing fuel economy.