alarm LAND ROVER DISCOVERY 2002 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1496 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-27

The electrically controlled seats are operated when the ignition switch is in position I or II or for a predetermined period

when the driver's door is open. If the ignition state is in crank, the seat enable relay is off. If the ignition state is off and

the driver's door open input is off, the seat enable relay is off. If the ignition state is off and the driver's door open input

is on and transit mode is on, the seat enable relay output is off.

The power supply to each seat switch pack is powered from a power seat relay located on the underside of each seat

frame. The feed from the relay is protected by a fuse located in a satellite fuse block located adjacent to the power

seat relay. The fuse block also contains two additional fuses which are used to protect the feeds to the lumbar pump

and solenoid.

With the ignition switch in position I or II or the driver's door open, the BCU provides an earth path for the coils of the

LH and RH power seat relays, energising the relays and closing the contacts. If the driver's door input signal is on for

longer than 45 seconds with the ignition switched off, the seat enable relay is switched off.

Direction indicators and hazard warning lamps

The BCU supplies reference voltages for the LH and RH indicators. When the direction indicator switch is used to

select the LH or RH indicator position, an earth path is completed which signals the BCU that a request for direction

indicator operation has been made. The BCU then communicates this request to the IDM which supplies an earth

path for the coil of the relevant relay (LH or RH indicator relay). When the relay coil is energised, the relay contacts

close and a voltage supply is provided via a resistor to the relevant direction indicators. The IDM controls the timing

of the flash operations by continually removing and restoring the earth path to the direction indicator relay coil.

The BCU checks for the following inputs for performing the logic operations associated with the direction indicator

lamps:

lIgnition state.

lRH indicators selected.

lLH indicators selected.

lHazards selected.

lInertia switch hazard request.

lOne short indicator flash request (anti-theft system arming).

lTwo short indicator flash request (superlocking).

lOne long indicator flash request (anti-theft system disarming).

lAlarm flashing indicators (anti-theft alarm triggered).

The following outputs are provided by the BCU as a result of the inputs received and the logical operations performed:

lRH indicators enable.

lLH indicators enable.

lDirection indicator left message (link to IDM).

lDirection indicator right message (link to IDM).

Direction indicator lamp failure detection

The BCU uses the following logic inputs to determine if there is a direction indicator bulb failure or if the presence of

a trailer is detected. The BCU uses the information to decide which output to enable at any particular instance:

lRight direction indicators requested.

lLeft direction indicators requested.

lRH indicators current sense.

lLH indicators current sense.

If a direction indicator bulb failure or a trailer presence is detected, the following outputs can be generated depending

on the BCU logic states:

lTrailer detected.

lBulb failure detected.

lDirection indicator short circuit.

lDirection indicator relay stuck.

Page 1497 of 1672

BODY CONTROL UNIT

86-3-28 DESCRIPTION AND OPERATION

The BCU can be configured whether or not to provide bulb failure warnings.

When the direction indicators are operating, instrument pack direction indicators flash in sequence with the exterior

direction indicators. If a failure of an indicator bulb occurs, the corresponding instrument pack indication lamp will flash

quickly to warn of the problem.

The IDM monitors the current drawn through the circuit to detect for the occurrence of a lamp failure. If an indicator

lamp fails, the IDM detects the drop in current drawn through the resistor and operates the indicator relay at a faster

speed. The fast flash is demonstrated on the instrument pack direction indicator warning lamps to bring attention to

the driver that a direction indicator bulb failure has occurred. The current sense for the related indicator lamps (RH or

LH) are checked when a direction indicator request has been made that lasts for at least 160 ms. The current level

sensed is relative to the number of working bulbs and determines the request generated by the BCU.

The output is signalled to the instrument pack using the serial communications link. If the hazard warning lamps are

operating, both sets of direction indicators are checked using the current sensing functions to check the number of

bulbs on each side of the vehicle.

If the BCU detects that a direction indicator request has not been made, but one or other of the current sense inputs

indicate that current is flowing, a 'Relay stuck' output is generated.

Hazard lamps

The BCU controls the operation of the hazard warning lamps via the IDM and dedicated relays. The hazard warning

lamps are activated under the following conditions:

lThe vehicle is locked and the security system is set (the hazard warning lamps flash three times if the

superlocking feature is used, once if not).

lThe vehicle is unlocked (the hazard warning lamps flash once for a duration of two seconds).

lThe anti-theft alarm system is triggered (the hazard warning lamps flash in phase with and for the duration of the

audible warning).

lThe hazard warning switch is pressed (the hazard warning lamps flash until the hazard warning switch is pressed

for a second time).

lThe inertia switch is triggered (the hazard warning lamps flash until the inertia switch has been reset).

The hazard warning lamp operation may differ dependent on market and customer configuration options.

The hazard warning lamps are operated from a latching pushbutton switch located on the fascia. When the switch is

pressed, both left and right indicator lamps in the instrument pack flash to show that the hazard warning lamps are

operating and all hazard warning lamps flash simultaneously. If a trailer is fitted, the ICM detects this and a trailer

symbol in the instrument pack also flashes to show correct operation of the trailer direction indicators and hazard

warning lamps.

The BCU supplies a reference voltage to the hazard warning switch. When the hazard warning switch is operated an

earth path is completed which signals the BCU that a request for hazard lamp operation has been made. The BCU

then sends a signal to the IDM via the serial data bus to communicate the request. The IDM supplies an earth path

for both direction indicator relay coils simultaneously so that the hazard warning lamps are turned on concurrently.

The IDM controls the timing of the flash operations by continually removing and restoring the earth path to both

direction indicator relay coils simultaneously.

Number of working bulbs Request generated

3 Trailer detected

2 None (bulbs okay)

1 Bulb failure detected

0 Direction indicator short circuit detected

Page 1498 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-29

Courtesy headlamps

This feature activates the headlamps for 30 seconds when the lock button on the remote transmitter is held down for

longer than 1 second. The headlamps will extinguish if the BCU receives either a lock or an unlock signal from the

remote transmitter.

The BCU checks the status of the following inputs to determine the correct qualifying conditions for requesting

courtesy headlamps:

lIgnition state.

lRemote locking request.

lRemote unlocking request.

lLazy locking request.

If the ignition is off and a lazy locking request is received, the courtesy headlamps are switched on and an internal

timer is turned on in the BCU which operates for 30 seconds. If the 30 second timer expires or a request for remote

locking or remote unlocking is received, the courtesy headlamps will be turned off.

When main beam is selected, the IDM also provides a signal to the instrument pack to switch on the main beam

warning lamp. An additional signal 'main beam indicator disable' is used to prevent the daylight running lamps

illuminating the main beam indicator when the main beam is in the daylight running lamp state and the main beam

indicator disable signal is on.

Lights on alarm

The lights on alarm in the instrument pack operates when the driver's door is open and the side lamps or headlamps

are on. The system uses inputs from the driver's door switch and the lighting switch to determine the logical conditions

that need to occur for switching on the alarm. The BCU carries out the logic operation and communicates with the

instrument pack using the serial data bus; the instrument pack will be requested to sound the alarm if the logic inputs

indicate that the driver's door is open with the lights still on.

Supply voltage is provided through the lighting switch to the IDM which acts as the signal line to indicate that the lights

are on for the logic circuits in the IDM and BCU. When the driver's door is opened, a second feed is supplied to the

BCU through the driver's door switch to indicate the condition. In this logic condition (lights on and driver's door open)

the BCU signals the instrument pack to operate the audible warning. If the lights are switched off or the driver's door

is closed the logic condition will be changed and the audible warning will be switched off.

Daylight running lamps

The BCU operates the daylight running lamps (where fitted) via the IDM. The daylight running lamps option can be

programmed in one of three states dependent on market/ customer requirements, these are:

lOption 1– no daylight running lamps.

lOption 2 – on with main beam off.

lOption 3 – on with main and dipped beam off and gearbox not in Park.

The BCU will ensure the logical conditions are satisfied for the lamps to operate under the set conditions. The BCU

checks the status of the following inputs to determine the logic action for providing an output to the daylight running

lamp relay:

lMain beam state.

lEngine running (link from instrument pack).

lDipped beam.

lGearbox state.

A voltage supply is fed to the coil of the daylight running lamp relay and the IDM. When the preconditions are satisfied

for daylight running lamp operation, the BCU sends a signal for the IDM to complete the circuit to earth to switch on

the daylight running lamps. The logical inputs are checked to ensure that the engine is running before switching the

relay to turn on the daylight running lamps. The engine running signal has to be present for at least 2 seconds before

the daylight running lamp relay can be switched on.

Page 1504 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-35

Fuel flap release

The fuel flap release solenoid only operates when the ignition switch is switched off, the anti-theft system is not

activated and the fuel flap release switch is pressed. If the BCU detects that these conditions have been satisfied, it

provides a path to earth for the fuel flap solenoid, so allowing the fuel flap to be opened.

To decide the correct conditions for providing a fuel flap enable output, the BCU checks the following input conditions:

lIgnition state.

lPerimetric alarm state.

If the battery state is not normal, the electric fuel flap enable is switched off.

Audible warnings

The BCU can request the instrument pack to generate an audible warning in response to logic conditions which have

been detected by the BCU and which need to be drawn to the driver's attention.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Seat belt warning

The BCU can be programmed to include seat belt warning using one of four options:

lOption 1 – warning on for 6 seconds.

lOption 2 – warning on for 6 seconds or until the seat belt is fastened.

lOption 3 – warning on for 6 seconds unless the seat belt is fastened.

lOption 4 – no warning.

The BCU checks the status of the following inputs:

lIgnition on.

lSeat belt fastened.

Depending on the logic conditions of the inputs, the BCU provides the following outputs:

lAudible warning No.1 requested.

lSeat belt not fastened warning on instrument pack (via datalink to the instrument pack).

When programmed for option 1 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds and a warning lamp on the instrument pack is

illuminated for the same duration.

When programmed for option 2 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds or until the seat belt fastened signal is on and a

warning lamp on the instrument pack is illuminated for the same duration.

When programmed for option 3 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds if the seat belt fastened signal is off; a warning

lamp on the instrument pack is illuminated for the same duration.

In the event of a communications link failure occurring, the audible and visual warning requests are not sent to the

instrument pack.

Page 1510 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-1

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Questa pagina è stata lasciata in bianco di proposito Diese Seite ist leer

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente This page is intentionally left blank

ALARM SYSTEM AND HORN DESCRIPTION AND OPERAT ION

Page 1511 of 1672

ALARM SYSTEM AND HORN

86-4-2 DESCRIPTION AND OPERATION

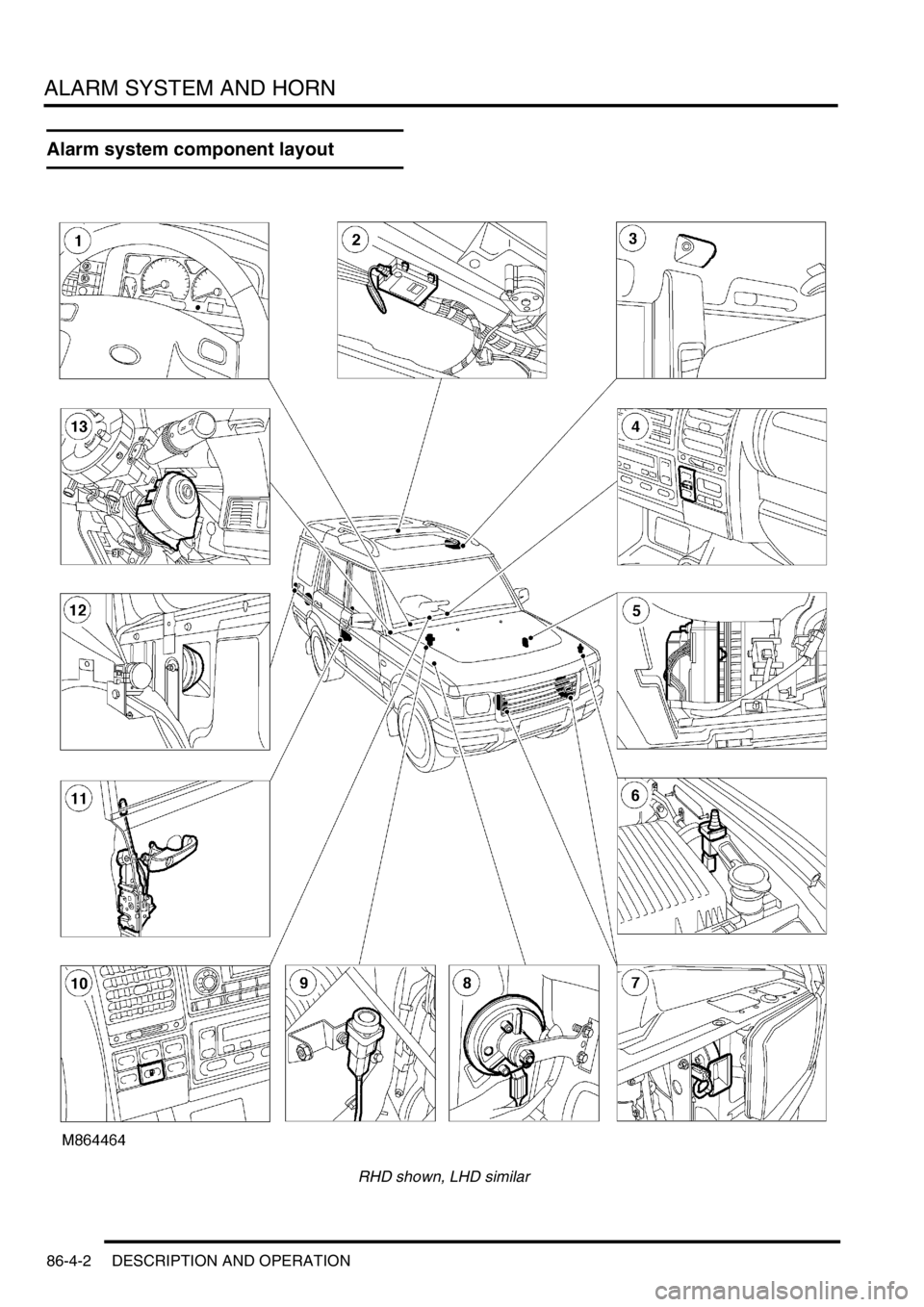

Alarm system component layout

RHD shown, LHD similar

Page 1512 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-3

1Theft deterrent LED

2Receiver

3Volumetric sensors

4Central door locking switch

5Body Control Unit (BCU)

6Bonnet activated alarm switch

7Vehicle horn

8Alarm sounder

9Fuel cut off switch

10Fuel flap release switch

11Door latch switches, drivers door key lock/

unlock switches

12Battery Backed Up Sounder (BBUS)

13Passive remobilisation exciter coil

Page 1513 of 1672

ALARM SYSTEM AND HORN

86-4-4 DESCRIPTION AND OPERATION

Alarm system block diagram

1Body Control Unit (BCU)

2Remote handset

3Receiver

4Fuel cut off switch

5Ignition switch

6Central door locking switch

7Volumetric sensors

8Bonnet activated alarm switch

9Drivers door key lock/unlock switches

10Door latch switches 11Fuel flap release switch

12Intelligent Driver Module (IDM)

13Battery Backed Up Sounder (BBUS)

14Alarm sounder

15Vehicle horns

16Direction indicators

17Door lock actuators

18Engine Control Module (ECM)

19Starter motor

Page 1514 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-5

Description

General

The anti-theft system deters the theft of the vehicle with both active and passive systems. The active systems monitor

the vehicle perimeter and, in some markets the vehicle interior, for intrusion. If the system detects intrusion, an alarm

sounds. The passive systems include a vehicle immobiliser as well as protection against intrusion through super

locking the doors. The vehicle is immobilised whenever the ignition key is removed from the ignition switch. Super

locking prevents the interior door handles from opening the doors. In addition, there are many features and functions

that enhance system operation.

It is possible to perform the various functions associated with the anti-theft system remotely. To accomplish this, the

handset generates a radio frequency when the lock button or unlock button is depressed. This signal is transmitted

to the Body Control Unit (BCU) via a receiver located in front of rear sunroof beneath the headlining. Precise alignment

of the handset to the receiver is not necessary. The approximate operating range between the handset and the

receiver is 10 metres (33 feet).

It is important to understand the configuration of the system on each particular vehicle. There are many

different combinations of features with dedicated operating modes. System configuration for each vehicle

can be determined using TestBook.

The anti-theft system is controlled centrally by the BCU, which is located below and behind the passenger glovebox.

A serial communication link communicates between the Intelligent Driver Module (IDM) located within the fusebox,

the BCU and the LED located in the instrument panel.

The state of the alarm is stored in the BCU. If the battery is disconnected while the alarm is armed, the alarm will be

triggered when the battery is reconnected.

NOTE: Disconnecting the battery while the alarm is armed triggers the alarm. Always disarm the alarm system before

disconnecting the battery.

The BCU also receives inputs from the following components:

lIgnition key in sensor.

lIgnition switch.

lFuel cut off switch.

lFuel flap release switch.

The BCU also interacts with the following components:

lStarter relay.

lVehicle horns.

lDirection indicators.

lFuel flap release actuator.

lCourtesy lamps.

Page 1515 of 1672

ALARM SYSTEM AND HORN

86-4-6 DESCRIPTION AND OPERATION

Door latch switches

The BCU uses the door latch switches to indicate if a door is open or closed. There is a door latch switch within every

door latch assembly, including the tail door latch assembly.

Input/Output

The input from the door latch switches to the BCU is either zero volts or an open circuit. Zero volts indicates the door

is open. An open circuit indicates that the door is closed. When the BCU sees an open circuit, it pulls the input high

internally.

The driver's door latch switch has a dedicated signal input to the BCU. This allows the BCU to identify the driver's

door position.

The BCU use a common signal input for the remaining door latch switches.

TestBook provides the ability to monitor the real time state of the door latch switches. Remember that the driver's

door is always in a known state. The remaining doors are combined into a single state. The BCU cannot distinguish

the state of the individual doors, other than the driver's door.